Soldering is a crucial skill for any electronics enthusiast. From creating homemade circuits to repairing broken devices, it’s an essential technique every DIY enthusiast should know. But what if you can’t access How to Solder without soldering vice? Don’t worry; you can still learn how to solder without one. This guide will explore the best techniques and tools to solder without a vice.

While a soldering vice is undoubtedly helpful, it’s not always accessible, especially for beginners. Fortunately, there are other ways to hold your workpieces in place during soldering, such as using your hands, a clamp, or a helping hand.

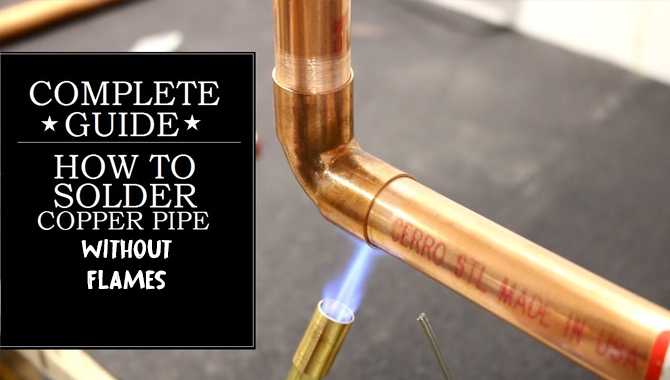

We’ll also cover the different soldering methods, such as iron soldering, torch soldering, and even how to make a soldering paste at home. Additionally, we’ll dive into the types of soldering joints and how to create them without a vice.

How To Solder Without Soldering Vice – Comprehensive Guide

How to solder without soldering vice can be challenging, but you can achieve good results with the right techniques and precautions. Here’s an ultimate guide on how to solder without a soldering vice and what not to do:

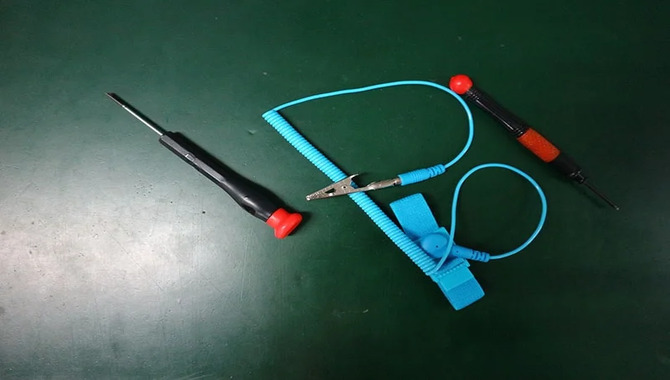

Tools And Materials Needed:

- Soldering iron

- Solder

- Desoldering pump or solder wick

- Heat-resistant surface (e.g., ceramic tile or a silicone mat)

- Helping hands tool or third-hand tool (optional, but helpful)

- Safety goggles or glasses

- Heat-resistant gloves (optional but recommended)

How To Solder Without Soldering Vice Steps

- Safety First: Wear safety goggles or glasses to protect your eyes from potential solder splatters or flying debris. If you’re working with high heat, consider using heat-resistant gloves to protect your hands.

- Prepare Your Workstation: Set up a heat-resistant surface to work on, such as a ceramic tile or a silicone mat. Ensure the surface is stable and won’t easily slide or tip over.

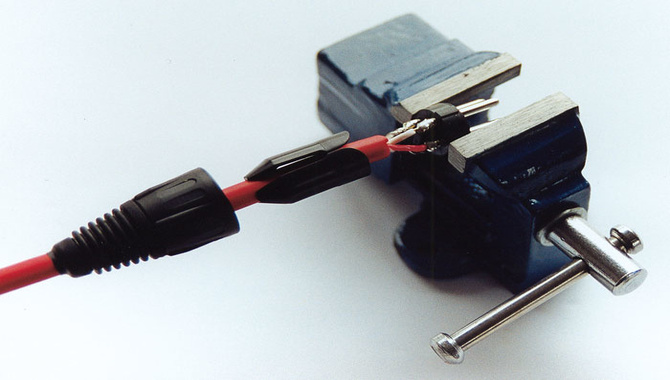

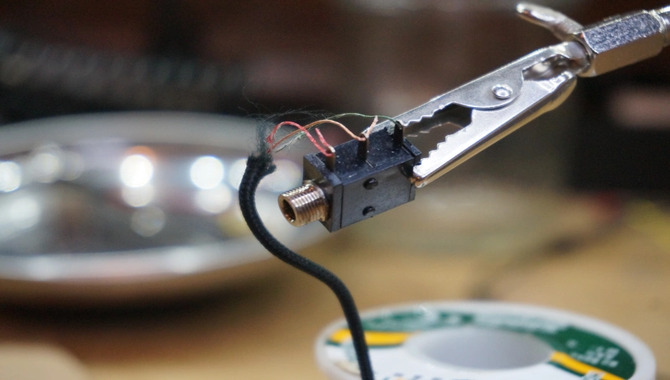

- Stabilize the Components: If you don’t have a soldering vice, use a helping hand or third-hand tool to hold the components in place. These tools typically consist of adjustable clamps that steady your workpieces while you solder.

- Clean the Components: Before soldering, make sure the surfaces you’ll be soldering are clean and free of any dirt, oxidation, or contaminants. Use isopropyl alcohol or a specialized flux remover to clean the area.

- Apply Flux: Apply a small amount of flux to the joint you’ll be soldering. Flux helps clean the surface and improves the flow of solder.

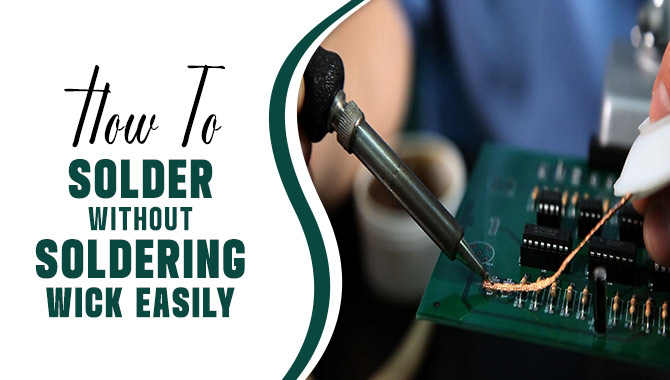

- Heat the Joint: Hold the soldering iron in one hand and position it close to the joint you want to solder. With your other hand, touch the solder to the joint while heating it. The heat from the soldering iron will melt the solder, allowing it to flow into the joint.

- Soldering Technique: Once the joint is heated, touch the solder wire to the joint, not the soldering iron tip. Allow the solder to melt and flow into the joint by capillary action. Apply just enough solder to create a strong and reliable connection.

- Remove the Soldering Iron: Once you’ve added enough solder, remove the solder wire and then remove the soldering iron. Be careful not to disturb the joint until the solder has solidified.

- Inspect the Joint: Once it has cooled down, visually inspect it for irregularities. It should have a smooth, shiny appearance and form a strong bond between the components.

Introduction To Soldering Without Soldering Vice

Soldering is a technique that has been used for centuries to join metal parts together. It is a process that involves melting a metal alloy, called solder, and using it to connect two metal surfaces. However, not everyone has access to a soldering vice or the skills to use one, which is why there are alternative soldering methods requiring less equipment and experience.

One such method is known as soldering without a soldering vice. This technique involves using a heat source, such as a lighter or torch, to melt the solder and apply it to the metal parts that need to be joined.

It requires a steady hand and patience, but it can be done successfully with practice. When soldering without a vice, it is important to keep safety in mind and use protective gear, such as gloves and goggles, to avoid burns and eye damage. Choosing the right type of solder for the job is also essential, as different metals require different types of solder.

Preparing Your Workspace For Soldering

Soldering is a delicate and precise process that requires a clean and organized workspace. Before starting any soldering project, it is essential to prepare your workspace to ensure safety and prevent any accidents. The first step is to clear the area of any unnecessary clutter, ensuring enough space to move around freely.

You should also ensure the workspace is well-lit, as this will help you see small details and make precise movements. Next, you should gather all the necessary tools and materials, such as a soldering iron, solder, flux, and a soldering stand.

Keeping these items within easy reach is essential to avoid unnecessary movements that can cause accidents. Additionally, wearing proper protective gear, such as safety glasses, is crucial to protect your eyes from any hot soldering material. Finally, ensure proper ventilation in the workspace to prevent inhaling toxic fumes released during the soldering process.

Techniques For Soldering Without Soldering Vice

Soldering is essential for anyone who wants to work with electronic components. However, not everyone can access a soldering vice; some may even prefer not to use one. Fortunately, there are several techniques for soldering without a soldering vice.

One popular method is to use a helping hand tool, a device that holds the component in place while you work on it. Another technique is to use a clamp or a pair of pliers to hold the component in place. This can be a bit more precarious, but with a little practice, it can be just as effective as a soldering vice.

Another option is to use a heat gun instead of a soldering iron. This method requires more skill and precision, but it can be a great way to make small, precise solder joints without a vice. Ultimately, the best technique for soldering without a soldering vice will depend on your preferences and the specific project you are working on.

Choosing The Right Soldering Iron For The Job

When it comes to soldering, choosing the right soldering iron is crucial for getting the job done effectively and efficiently. Many different types of soldering irons are available, each with its advantages and disadvantages. The first thing to consider when choosing a soldering iron is the type of work you will be doing.

A low-wattage iron with a fine tip may be the best choice if you work on small electronic components. On the other hand, if you work on larger components or thicker wires, a higher-wattage iron may be necessary to achieve the desired results.

Another important factor to consider is the type of soldering you will be doing. If you will be doing a lot of precision work, a temperature-controlled iron may be the best choice, as it allows for more precise temperature adjustments. Additionally, if you are doing a lot of soldering, it may be worth investing in a soldering station, which allows you to switch easily.

Tips And Tricks For Successful Soldering Without Soldering Vice

Soldering is a common process used in electronics, but not everyone has access to a soldering vice. However, some tips and tricks can help you achieve successful soldering without one.

- always ensure that your workspace is clean and organized. This will help you avoid any mishaps or accidents during the soldering process.

- use a helping hand tool to hold your components in place while you solder. This will help keep the components stable and reduce the risk of damaging them.

- use a small amount of soldering flux to help the solder flow smoothly. This will also help prevent any cold joints or poor connections.

- use a high-quality soldering iron with a fine tip. This will give you more precision and control when soldering small components.

- be patient and take your time. Rushing the process can lead to mistakes and poor connections. With these tips and tricks, you can achieve successful soldering without the need for a solder

Conclusion

How to solder without soldering vice can be challenging but not impossible. You can achieve a successful and professional soldering job with the right tools, techniques, and patience. Always prioritize safety by wearing protective gear and working in a well-ventilated area. Practice makes perfect, so don’t be discouraged by initial failures. Keep practicing, and you will soon be able to solder like a pro without a soldering vice.

FAQs

1.Are There Any Safety Precautions When Soldering Without A Vice?

Ans: Yes, there are several safety precautions to take when soldering without a vice:

- Wear safety goggles to protect your eyes from flying debris and hot solder.

- Use heat-resistant gloves to protect your hands from the soldering iron’s heat.

- Use a non-slip surface to hold the object you are soldering in place, such as a rubber mat or a clamp

2.Can You Achieve The Same Level Of Precision And Accuracy When Soldering Without A Vice?

Ans: It is possible to achieve similar precision and accuracy when soldering without a vice, but it may be more challenging. A vice helps stabilize the workpiece and keep it in place while soldering, making it easier to apply the solder precisely where needed. Without a vice, one may use other methods to hold the workpiece in place, such as tape, clamps, or hand, which can be more complex and less precise.

3.What Projects Or Materials Best Suit Soldering Without A Vice?

Ans: Projects or small materials easily held in place with tweezers or third-hand tools are best suited for soldering without a vice. Examples include jewelry making, electronic components, and small repairs on metal objects.

- Can Non-Soldering Methods Be Used On All Types Of Metal, Or Are Certain Materials Better Suited For Soldering?

Ans: Non-soldering methods can be used on most types of metal, but certain materials may be better suited for soldering. Generally, metals with lower melting points, such as copper, brass, and silver, are ideal for soldering. In comparison, metals with higher melting points, like steel and aluminum, may require alternative methods like welding or brazing.

- What Are Some Common Mistakes To Avoid When Using Non-Soldering Methods To Join Metal Parts?

Ans: Not cleaning the metal surfaces properly before joining: Any dirt, grease, or oxide layers on the metal surfaces can prevent a strong bond from forming.