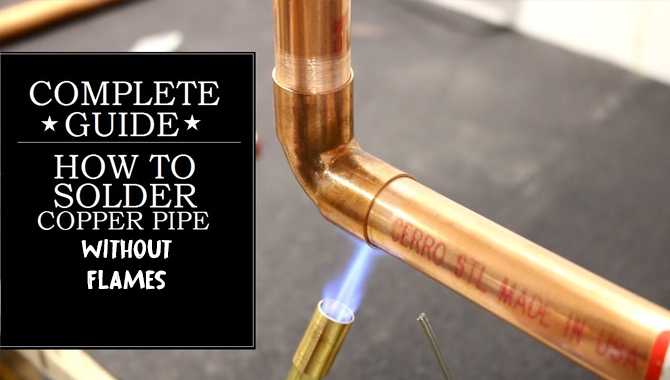

We solder copper pipes to build something strong. Usually, using technical supports, the pipes are joined to each other by flames. However, it’s kind of a risky task for people who are not professionals because of the flame.

But how to solder copper pipe without flames? Do you want to know that You or anyone else who wants to solder pipes without using flames should know the other risk-free way of welding pipes.

Soldering the copper pipes but not using flames is also known as solderless copper bonding, gluing copper, soldering copper, or cold welding.

In this guide, we are going to answer all your queries regarding the topic. Hence let’s check the process as well as other essential facts about it!

Types Of Solder

Solder is divided into three types.

- lead-free solder

- 50% lead/50% tin

- 95% tin-antimony/5% lead

Soldiers containing 5% lead should be used to solder a water tube. But use the lead-free solder if you can manage. The 50% lead solder is employed to make copper drain lines.

It can melt at a lower temperature and can bridge larger gaps with cooling. It will be useful whenever you work with copper pipes and fittings that have large diameters.

How Hard Is It To Solder A Copper Pipe?

There are two favorite ways to solder a copper pipe, one is by using flames, and the other is by using adhesive. To be honest, both of you should give almost the same effort.

Still, if you want to know hard which way to choose? If you are afraid of flames and never have worked using flames, then soldering copper pipes with flames will be a challenging task for you because one must understand the flame’s temperature and how to control it.

But if you try the without flame copper bonding, you will need to work using glue, and everyone understands how the glue works.

Therefore, if you want to choose one way from these two, thinking which one will be easier, it is a soldering pipe without flames.

The Advantages And Disadvantages Of Soldering Copper Pipe Without Flames

Advantage

- You don’t have to take the risk of working with a fire.

- The work seems easier

- It takes a few seconds to finish the work

- No chance of setting fire in your home accidentally

- It Doesn’t cost you much money

Disadvantage

- Not much Helpful for soldering water pipes

- The adhesive doesn’t last as much as the soldered pipes using flames

- It Doesn’t make the bonding between copper pipe and fittings as strong as the flames can

Tools You Need To Solder Copper Pipe Without Flame

It would be best if you had some tools which are necessary for soldering pipes. Keep in mind to manage all the following tools before you start the soldering process;

1. Deburring Tool

Inside the pipe and fittings there, you may find some uneven or jagged metal pieces. Deburring Tool will help you to remove them. An alternative metal file will also do the work.

2. Wire Brush

This brush is created using wires and is small enough to clean the fittings’ inner parts.

3. Pipe Cutter

It’s a must to have a tool for cutting the pipes in suitable shapes.

4. Emery Tape

It is also famous for emery cloth or plumber’s tape. That works like cloth sandpaper because of its abrasive kind surface. You need this to smooth the rough edges on copper pipes.

5. Pipe Fittings

It’s vital to choose the right copper fittings that will rightly and tightly fit your pipe. Make sure to fit them before you jump to the soldering procedure.

6. Adhesive

Remember we are not going to use the flame. Hence we need to think of something alternative. A powerful adhesive can do this job second best.

Purchase a superpower adhesive that will keep your pipe and fittings connected for a long time.

5 Steps On How To Solder Copper Pipe Without Flames?

We understand that some of you want to solder the copper pipes trouble-free, meaning no use of flames and soldiers at all.

There is a way, and it’s called solderless copper bonding. But to follow this method, the pipes and fittings you want to use should have very adjacent tolerances.

One important thing, without Super Power solderless copper bonding solution and rigid pipe, we cannot guarantee the successful soldering pipe without flames.

Follow the steps mentioned below if you fulfill the conditions and want to solder copper pipe without flames;

- First Step

Get polishing P60 grit cloth and cleanse pipe, fittings to make trench.

- Second Step

Now, shake the Super Power solderless copper bonding solution bottle and apply its liquid to the tube’s outer part and fittings’ inner part, not too much or too little.

- Third Step

Put the copper pipe inside of the fitting. Rotate it at 360 degrees so that the glue is distributed equally into the fitting.

- Fourth Step

Flush the remaining gluey from the tube and fitting.

- Final Step

Keep it away for 5 minutes because it will first take 60 seconds to dry and 5 minutes to cure a structural bond.

The Usefulness Of Soldering Without Flame

Soldering Copper pipe without flame or cold copper bonding has a lot of usefulness. Some pipes become truly difficult to solder because they don’t fit in the correct position or had slid drip before.

In such situations soldering with flames is not a wise choice to use. Also, without flame, soldering works best for those who are scared a little of soldering.

How To Fix A Leaked Copper Pipe Without Soldering?

Often accidentally, a leak occurs in the copper pipe. You might want to fix it, and therefore you should know how to fix the leak. You can either use copper or a PEX pipe.

Another thing you should have is shark bite couplings. At the first turn, the main water line is off. Secondly, remove the section where the leak is by using a pipe cutter.

When you have removed the previous pipe, attach shark bite couplings to both ends of the waterline. To measure and mark the depth of shark bite couplings sitting on a pipe, use the tool shark bite depth.

Deburr the new and existing pipe endings and smooth the ends using emery cloth. Suppose you have successfully ready each of the ends and measured them, then cut the new pipe. Now insert this pipe tightly into the shark bite fitting. You have done it great.

Solving the plumbing problems yourself is not that hard a task indeed, but many depend on professionals.

But if you visit the hardware store by your will and see the materials you need to solve this problem, you will think that you can repair the pinhole on your own.

Conclusion

Hopefully, now after seeing the easy process, you can do the work yourself. If this will be the first experience for you to work on pipes, gather some confidence, and don’t think you can’t.

Check the list of things you must-have for the procedure before you start working. Buy each Tool mentioned for giving your work the perfect finish.

Now it’s time for us to close, but before going, we have one little tip for you; get the most potent adhesive by researching and purchasing that because the success behind this work depends on how powerful the glue is. I hope now you know about how to solder copper pipe without flames.

![Top 8 Best Solder For Copper Pipe [Reviews With Buying Guide]](https://accuratepicker.com/wp-content/uploads/2022/03/Best-Solder-For-Copper-Pipe.jpg)