Soldering is a crucial skill for any DIY enthusiast or electronic hobbyist. It involves joining two pieces of metal using a heated soldering iron and a small amount of metal alloy called solder. However, one of the biggest challenges beginners face is keeping the pieces steady while soldering.

This is where third-hand tools come in handy, holding the components in place while the soldering occurs. However, not everyone has access to or can afford these tools. In this ultimate guide on How to solder without soldering third hand, we will explore alternative methods and tools that can use to make soldering a breeze.

We will provide step-by-step instructions on making simple and affordable DIY tools and tips and tricks for proper soldering techniques. We will also discuss common mistakes to avoid and safety precautions to take when soldering.

How To Solder Without Soldering Third Hand – Comprehensive Guide

Soldering without a third hand can be challenging, but it’s possible with the right techniques. Here’s a comprehensive guide on how to solder without a third hand, along with some important “dos and don’ts” to keep in mind:

Dos:

- Prepare your workspace: Make sure you have a clean, well-lit area. Keep your soldering iron, solder, and other tools within reach.

- Secure the components: Use non-conductive tools like masking tape or rubber bands to hold your components in place while you solder. Position them in such a way that they don’t move during the soldering process.

- Use heat sinks: For sensitive components that are heat-sensitive or easily damaged, you can use heat sinks. These metal clips or clamps absorb heat and protect the component from excessive heat transfer.

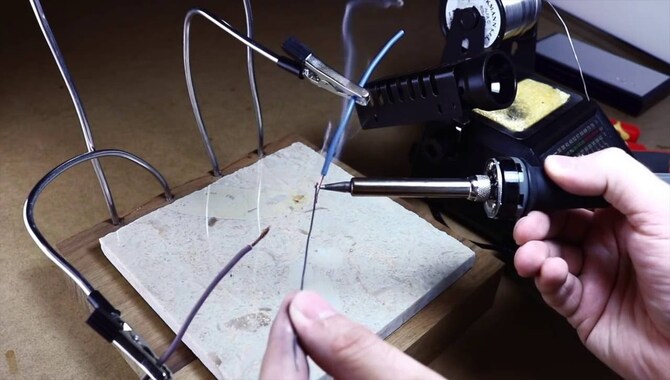

- Tinning your wires: Before soldering, it’s a good practice to tin the wires by applying a thin coat of solder to them individually. This will make the soldering process easier and more efficient.

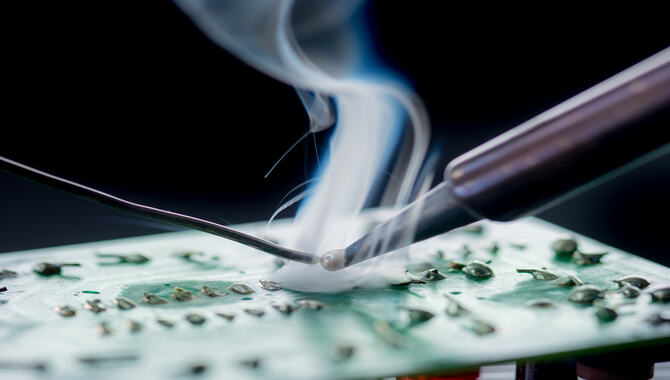

- Practice good soldering techniques: Ensure you’re using the correct temperature setting on your soldering iron and applying the soldering iron tip to the joint for sufficient time to achieve a good solder connection. Properly heat the joint and apply solder to the heated joint, not directly to the soldering iron.

Tools And Materials Needed For Soldering

Soldering is a process that involves joining two pieces of metal by melting a metal alloy, called solder, into the gaps between them. Having the right tools and materials is important to successfully perform this task. The essential tool for soldering is the soldering iron, which is used to heat the solder and melt it onto the metal.

Various types of soldering irons are available in the market, ranging from basic to advanced, and you should choose one that fits your needs. Another important tool is the soldering stand, which holds the iron safely when not in use. In addition to these tools, you will need a soldering mat or a surface to work on and a pair of pliers or tweezers to hold the metal pieces together while you solder them.

To properly melt the solder, you will also need a flux, a chemical that helps the solder flow onto the metal.

Safety Precautions To Follow When Soldering

Soldering is a process that involves joining two pieces of metal by melting a metal alloy, called solder, into the gaps between them. Having the right tools and materials is important to successfully perform this task. The essential tool for soldering is the soldering iron, which is used to heat the solder and melt it onto the metal.

Various types of soldering irons are available in the market, ranging from basic to advanced, and you should choose one that fits your needs. Another important tool is the soldering stand, which holds the iron safely when not in use.

In addition to these tools, you will also need a soldering mat or a surface to work on and a pair of pliers or tweezers to hold the metal pieces in place while you solder them together. To properly melt the solder, you will also need a flux, a chemical that helps the solder flow onto the metal.

Preparing The Work Area For Soldering

Preparing the work area for soldering is crucial to achieving successful and efficient soldering. First and foremost, it is important to ensure the area is well-ventilated to prevent any harmful fumes from accumulating. A fume extraction system or a well-placed fan can use to achieve proper ventilation.

Additionally, it is important to have a clean and organized work area. This includes removing any unnecessary clutter, such as papers or tools that are not being used, and ensuring that all necessary tools and materials are easily accessible. A clean and organized work area helps prevent accidents and promotes efficiency during soldering.

Furthermore, it is important to have a suitable work surface for soldering. Ideally, this should be a heat-resistant surface, such as a ceramic tile or a silicone mat. This will prevent heat damage to the surrounding area and provide a stable surface for the soldering process.

Techniques For Holding Components In Place Without A Third Hand

Regarding electronics projects, one of the biggest challenges can be holding components in place while you solder them together. You could use a third-hand tool to steady everything, but sometimes that’s not practical. You can use a few techniques to hold components in place without a third hand.

One popular method is using double-sided tape to stick the component onto your work surface. This can work well for small components like surface mount resistors or capacitors. Another option is to use a small piece of blu-tack or sticky tack to hold the component in place.

This is especially useful for larger components like ICs or connectors. You can also try using small clamps or clips to hold the component in place, though this can be tricky if you don’t have a lot of space to work with.

Tips For Soldering Without A Third Hand

Soldering is a crucial skill for anyone working on electronics or DIY projects. However, it can be challenging to do without a third hand. Luckily, several tips can help make the process easier.

- choose the right soldering iron. A high-quality iron with a temperature control feature will make the process more efficient and precise.

- use a helping hand tool. This tool has a clamp and a magnifying glass to help you hold the soldering iron and wire in place.

- use a weighted base to hold the circuit board. This will keep it steady and prevent it from moving while soldering.

- use heat shrink tubing to protect your connections. It will protect the connections and make them look more professional. Finally, make use of a bench vice to hold the circuit board.

This will allow you to use both hands for soldering without any distractions.

Troubleshooting Common Soldering Problems

Soldering is a fundamental skill that many electronics enthusiasts and professionals must master. However, even experienced solderers encounter problems from time to time. Troubleshooting common soldering problems requires a good understanding of the process and the equipment involved.

One of the most common issues is forming cold solder joints, which are weak and prone to breaking. This problem can solve by ensuring that the soldering iron is hot enough and that the solder flows smoothly onto the joint.

Another problem is the appearance of solder bridges, which happen when a thin solder line connects two adjacent joints. This problem can solve using a solder wick to remove the excess solder between the joints. Additionally, soldering iron tips can get dirty or oxidized, leading to poor heat transfer and difficulty in soldering. This issue can solve by cleaning the tip with a damp sponge or using a tip cleaner.

How To Clean And Maintain Your Soldering Equipment

When it comes to soldering equipment, proper cleaning and maintenance are crucial for its longevity and proper function. One of the first steps in cleaning your soldering iron is to unplug it and let it cool down completely.

Next, wipe the iron tip with a damp sponge or cloth to remove any excess solder or debris. Be careful not to use anything abrasive that could damage the tip. Use a brass or copper wire sponge to gently scrub the tip for tougher residue.

In addition to cleaning the tip, keeping the rest of the soldering equipment clean is important. Use a soft cloth to wipe down the handle and cord, removing any dust or debris that may have accumulated. If any rust or corrosion is present, use a rust remover to clean it off. To maintain your soldering equipment, replace worn-out parts, such as the tip or heating element, as soon as possible.

Advanced Soldering Techniques

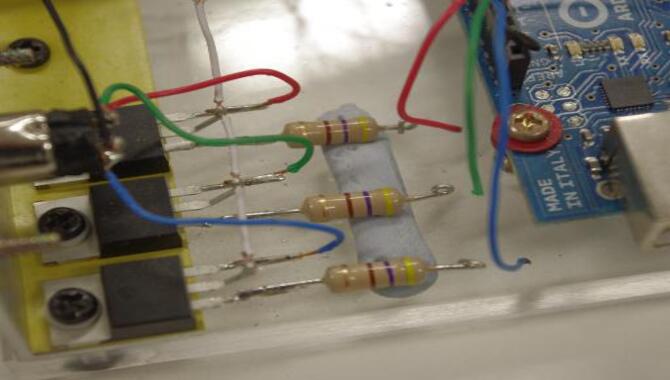

Advanced soldering techniques are crucial for those who want to take their skills to the next level. These techniques create more complex and intricate solder joints that require precision and expertise. One of the most common advanced soldering techniques is surface mount soldering, which involves soldering components directly onto the surface of a printed circuit board (PCB). This method requires specialized tools, such as a reflow oven and a soldering iron with a fine tip.

Another technique is through-hole soldering, which involves passing components through holes in the PCB and then soldering them on the other side. This technique requires a steady hand and a good understanding of properly heating the joint and applying the solder.

In addition, advanced soldering techniques such as wave and selective soldering are used in mass-production environments to quickly and efficiently solder large quantities of components to a PCB.

Conclusion

How to solder without soldering third-hand may seem challenging initially, but it can become second nature with practice and the right techniques. Following the steps outlined in this guide and implementing our tips, you can improve your soldering skills and confidently take on new projects. Remember to work safely, use protective gear, and never rush. You can become a skilled solderer without expensive equipment with patience and determination.

FAQs

1.Are There Any Specific Techniques Or Tips You Should Follow When Soldering Without A Third Hand?

Ans: Yes, there are several techniques and tips you can follow when soldering without a third hand:

- Use a vice or clamp to hold the workpiece in place.

- Place the workpiece on a stable surface or use a non-slip mat to prevent it from moving.

- Use a weighted object like a paperweight to hold the workpiece in place.

2.What Are Some Common Mistakes To Avoid When Attempting To Solder Without A Third Hand?

Ans: Using your fingers to hold components in place while soldering can lead to burns and accidental movement of the component, resulting in a poor solder joint.

3.What Alternative Tools Or Techniques To A Third Hand When Soldering?

Ans: Some alternative tools or techniques to a third hand when soldering include using a vice, a helping hand with a magnifying glass, magnetic holders, clips, or a jig to hold the parts in place.

4.What Projects Are Best Suited For Soldering Without A Third Hand?

Ans: Projects that involve soldering small components or wires that can be held in place with tweezers or clamps are best suited for soldering without a third hand. For example, soldering a simple circuit on a breadboard or attaching wires to a connector can be done without a third hand.

5.Are There Any Safety Precautions To Remember When Soldering Without A Third Hand?

Ans: Yes, there are several safety precautions to keep in mind when soldering without a third hand:

- Use safety glasses to protect your eyes from hot solder and flying debris.

- Work in a well-ventilated area to avoid inhaling toxic fumes.

- Keep flammable materials away from the soldering area.