How to solder without soldering wick is the most important. Soldering is a crucial skill for any electronics enthusiast or professional. It allows for the joining of two pieces of metal through. The application of heat and a filler material called solder.

However, traditional soldering methods often require. Use a soldering wick to remove excess solder and ensure a clean joint. While soldering wick is an effective tool, it can also be messy and time-consuming to use.

Fortunately, there are alternative methods for soldering that do not require the use of soldering wick. This blog post will explore how to solder without soldering wick and achieve clean, professional-looking joints. We’ll cover the tools and materials needed and provide step-by-step instructions for the process.

Whether you’re new to soldering or a seasoned pro. This guide will provide valuable insights and techniques for improving your soldering skills. By the end of this post, you’ll discover how to achieve high-quality, reliable soldering joints without the need for solder.

What Is The Soldering Wick?

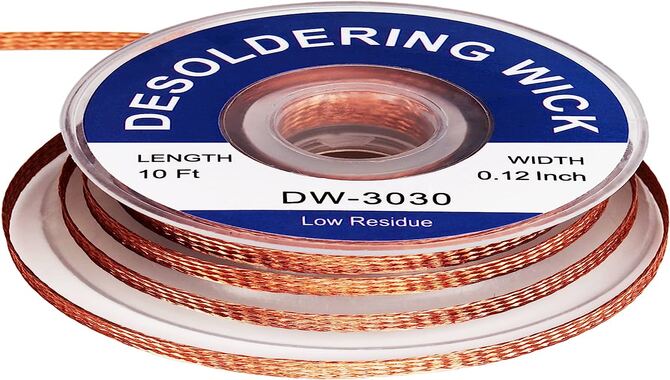

A soldering wick is a useful tool in the electronics industry. Used for removing excess solder from circuit boards and components. It is a braided copper wire coat in flux place over the solder joint and heated with a soldering iron. As the solder melts, the wick absorbs it, leaving a clean, smooth surface behind.

The wick, also known as desoldering braid, comes in different sizes and thicknesses depending on the application. Apart from desoldering, the wick also helps repair damaged circuits by removing the solder bridges that cause short circuits.

It is an essential tool for any technician or hobbyist who works with electronics and requires precision and accuracy in their work. When using the soldering wick. It is important to ensure the braid is in contact with the solder. Joint and that the iron is heat to the appropriate temperature. The flux coating on the wick helps to prevent oxidation and ensure a clean solder joint.

What Do I Need To Solder?

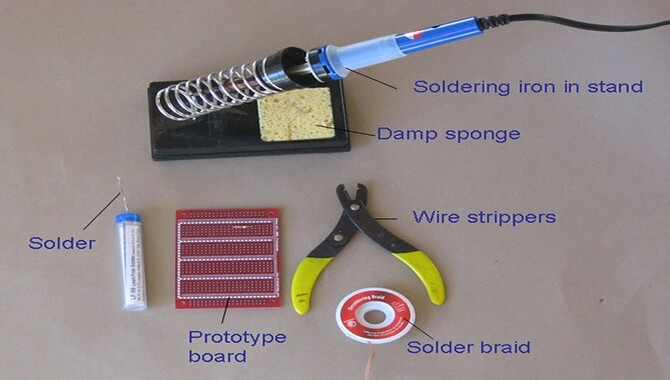

Soldering is a process of joining two metal components by melting a filler metal and then cooling it to create a strong bond. You need certain tools and equipment to get start to perform this task. Firstly, you need a soldering iron or gun to generate enough heat to melt the solder.

You also need a soldering station or mat to work on to avoid damaging any surfaces. Additionally, you need a soldering wire that matches the metal you are working with. Apart from these basic requirements, the type of project you are working on will determine what else you need to solder.

For example, if you are soldering two wires together, you will need heat shrink tubing to protect the connection from damage and to insulate it from moisture. If you are soldering electronic components, you will need a third-hand tool to hold the parts in place while you work. In summary, the things you need to solder will depend on the project you are working on.

How To Solder Without Soldering Wick: Step By Step

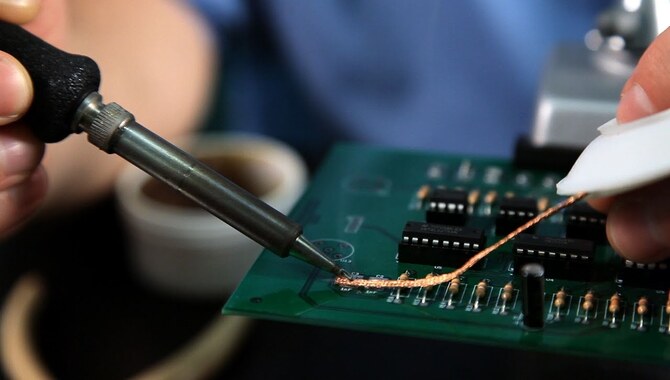

Soldering is a common technique to join metals together, but what if you don’t have a soldering wick? Don’t worry; we give you how to solder without soldering wick: step by step. You can still solder without it. First, clean the surfaces to be join with a wire brush or sandpaper. Then, apply flux to the surfaces to help the solder flow. Next, heat the surfaces with a soldering iron until the flux bubbles.

Once the flux is bubbling, touch the solder to the joint and hold it until it melts and flows into the joint. Be sure to use the right amount of solder, as too little will result in a weak joint and too much will cause a messy joint. After the solder has cooled, inspect the joint for defects or cracks. If you notice any. Reheat the joint and add more solder until it’s fill. With these steps, you can successfully solder without a soldering wick.

When it comes to soldering, using a soldering wick is a common method for removing excess solder. However, there may be times when you don’t have a soldering wick on hand or prefer not to use one. In such cases, there are alternative methods you can try to achieve the same result. Here is a step-by-step guide on how to solder without a soldering wick:

1. Prepare your materials: Gather all the necessary tools and materials for soldering, such as a soldering iron, solder, flux, and a wet sponge or cloth for cleaning the iron.

2. Clean the solder joint: Before attempting to remove excess solder, make sure the area is clean and free of any debris or oxidation. Use a wire brush or sandpaper to gently clean the surface if needed.

3. Apply flux: Apply a small amount of flux to the solder joint. Flux helps to improve the flow of solder and enhance the bond between the components.

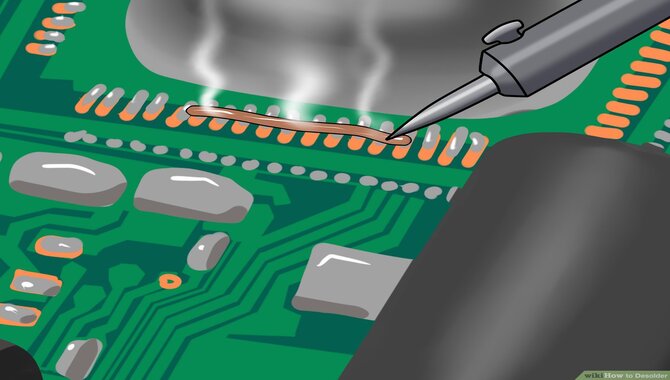

4. Heat up the joint: Turn on your soldering iron and allow it to heat up to the appropriate temperature for your solder. Place the tip of the iron on the joint and heat it evenly.

5. Melt the excess solder: Once the joint is heated, touch your solder to the joint and let it melt. Be careful not to apply too much solder as this can create additional problems.

6. Remove excess solder: While the melted solder is still in its liquid state, quickly remove it using an alternative method. This can include using copper wire, desoldering braid, or even another piece of clean copper foil.

7. Clean and inspect: After removing excess solder, clean the area with a wet sponge or cloth to remove any remaining residue.

What Should You Not Do When Soldering

Soldering is a crucial process in electronic manufacturing and repair. It involves joining two pieces of metal by melting a filler metal and applying it to the joint. However, there are certain things that you should never do when soldering.

Firstly, you should never apply too much heat to the joint as it can damage the components or cause the solder to flow excessively. This can result in a dry joint or a short circuit. Secondly, you should avoid touching the joint immediately after soldering as it can be hot and cause burns.

Waiting for the joint to cool down before testing or handling it is important. Thirdly, using dirty or corroded materials can affect the quality of the joint. Therefore, clean the surfaces to be solder and using fresh solder and flux is essential.

Additionally, you should never blow on the joint to cool it down, as it can disturb the solder and cause a bad joint. Finally, avoid breathing in the fumes produced by soldering, as they can

Desolder Without Wick, Flux Or Sucker?

Desoldering without wick, flux, or a sucker can seem like a challenging task, but it is possible with the right technique. One way to desolder without a wick is to use a hot air gun or soldering iron to melt the solder and then quickly remove the component.

Another method involves using a desoldering pump, which creates a vacuum to suck the molten solder out of the joint. However, if you don’t have a desoldering pump, you can still desolder by heating up the joint and using a small screwdriver or pliers to wiggle the component out of the molten solder.

Flux is often use to improve solder flow and remove oxides from the joint. However, if you don’t have any flux, you can still desolder by using a small amount of solder to create a new joint with the old one. This fresh solder will help to melt the old solder, making it easier to remove the component.

Do You Remove Solder From A PCB?

When it comes to repairing or modifying a printed circuit board (PCB), one of the most common challenges is removing solder. Whether you need to replace a component, add a new connection, or correct a faulty joint, removing solder is a critical step in the process. But the question is, how do you remove solder from a PCB? Well, the answer depends on the specific situation and the tools you have available.

For instance, if you need to remove a small amount of solder from a pin or a pad, you can use a desoldering pump or a solder wick. These tools allow you to heat and absorb the solder with a vacuum pump or braided wire.

On the other hand, if you need to remove a large amount of solder from a through-hole or a surface-mount component, you may need to use a soldering iron with a specially designed tip, a hot air rework station, or a solder pot.

Do You Remove Solder From An Electrical Connection?

Removing solder from an electrical connection is a common task that is usually required when replacing a component or repairing a damaged circuit board. The process of removing solder can be done using different techniques, including desoldering wick, desoldering pump, or solder sucker.

Desoldering wick is a braided copper wire that is used to absorb molten solder and remove it from the connection. A desoldering pump, also known as a solder sucker, uses a vacuum to suck up the molten solder and remove it from the connection.

To remove solder from an electrical connection, you will need to heat it until it melts and then use one of the above techniques to remove it. Using the right technique and tools is important to avoid damaging the connection or the surrounding components. It’s also important to use caution when handling hot solder and to wear protective gear, such as gloves and safety glasses, to prevent injuries.

3 Step How To Solder Without Soldering Wick

Soldering can be daunting for beginners, but it doesn’t have to be. With the right technique, you can learn how to solder without using a soldering wick in five easy steps. Firstly, Use a Soldering Iron to Desolder To do this, first heat up the soldering iron and apply it to the solder joint holding the component in place.

The solder will melt, allowing you to remove the component from the circuit board. It’s important to be careful not to overheat the board or surrounding components, as this can cause damage. Once the component is removed, you can clean up the area with a desoldering braid or pump, which will absorb any excess solder.

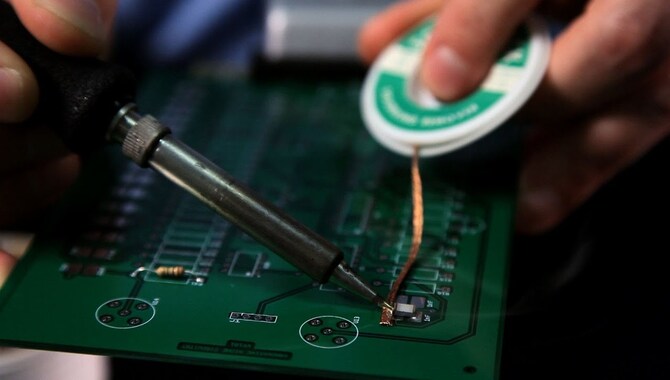

Use Desoldering BraidTo use desoldering braid, simply heat the solder joint with a soldering iron until it melts, then place the braid over the joint and press it down with the iron. Use a Desoldering Pump

such tool is a desoldering pump, which is a tool designed to suck up molten solder from a circuit board. This tool is also known as a solder sucker or a solder vacuum, and it can be used for various tasks such as removing components, repairing small electronic devices, or modifying existing circuits.

Conclusion

How to solder without soldering wick is an effective technique that can save time and resources. While using a wick is a commonly accepted method, it is not always necessary. You can successfully solder without using a wick by following the steps outlined in this post.

Always take the necessary safety precautions and practice the technique on scraps before applying it to your project. You can become proficient in this technique and expand your soldering skills with patience and practice.

FAQs

1.Can You Use A Soldering Iron To Remove Excess Solder Without A Soldering Wick?

Ans: Yes, it is possible to use a soldering iron to remove excess solder without a soldering wick.

2.What Are Some Alternative Methods For Removing Excess Solder Without Using A Soldering Wick?

Ans: A solder sucker is a tool that sucks up excess solder using a vacuum. Hot tweezers are a type of tool that heats up and can be used to remove excess solder by gripping and pulling it away from the joint.

3.Is It Possible To Solder Without Using A Soldering Wick, And If So, What Steps Are Involved?

Ans: Yes, it is possible to solder without using a soldering wick. Here are the steps involved. Clean the area to be soldered with a wire brush or sandpaper to remove any dirt, rust, or oxidation. Apply flux to the area to be soldered. Flux helps the solder to flow and bond to the metal.

4.Can You Achieve The Same Level Of Precision And Accuracy When Soldering Without Using A Soldering Wick?

Ans: It is possible to achieve certain precision and accuracy when soldering without a soldering wick, but it may be more difficult and time-consuming.

5.Are There Any Risks Or Downsides To Soldering Without Using A Soldering Wick, And How Can You Mitigate Them?

Ans: Yes, soldering has several risks or downsides without using a soldering wick. Applying too much heat to the joint is easy without a soldering wick, which can damage the components or the PCB. Removing excess solder or cleaning the joint properly is difficult without a soldering wick, resulting in poor quality or unreliable joints.

![How To Tin A Soldering Iron? [Step-By-Step]](https://accuratepicker.com/wp-content/themes/Extra/images/post-format-thumb-text.svg)