As technology advances, we cannot overstate the importance of working with electronics. Soldering is one of the most fundamental techniques for working with electronics, as it allows us to make electrical connections in various devices.

However, soldering can be challenging, and not having the right tools can make it even more difficult. One of the most important tools for soldering is a magnifying glass, as it helps to provide a clearer view of the soldering area. Not everyone may have access to a magnifying glass or may not find it comfortable to use one. This is where techniques for soldering without a magnifying glass come in handy.

We will explore different techniques for How to Solder without soldering magnifying glass. We will discuss the importance of good lighting. Choosing suitable soldering iron, and using various tools that can help increase visibility. We will also provide tips on holding and positioning the soldering iron.

Now We Describe: How To Solder Without Soldering Magnifying Glass

People use soldering, a technique involving a molten metal alloy called solder, to combine two metal pieces. However, not everyone has access to a soldering magnifying glass, which makes the process easier and more precise. Fortunately, there are other ways to solder without one. Follow the step-by-step guide below on How to Solder without a Soldering magnifying glass:

Types Of Soldering Irons

Several soldering irons are available, each with specific features and applications. Here are some common types:

- Standard Soldering Iron: This is the most basic type of soldering iron, consisting of a heated metal tip and a handle. People commonly use it for general soldering tasks.

- Temperature-Controlled Soldering Iron: These soldering irons allow you to adjust and set the temperature of the tip according to the specific requirements of your soldering job.

- Cordless Soldering Iron: As the name suggests, these soldering irons are not tethered to a power cord. Rechargeable batteries power them, offering greater mobility and convenience.

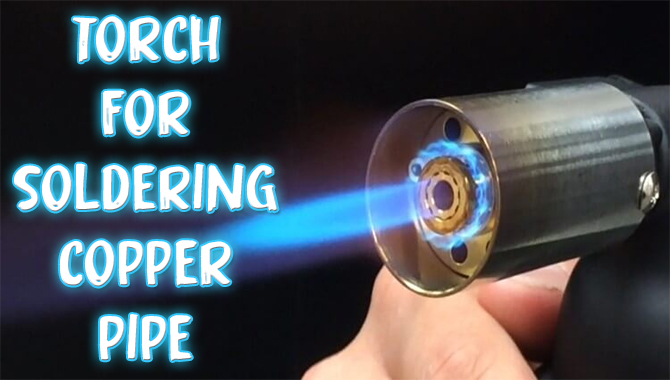

- Butane-Powered Soldering Iron: These soldering irons use butane gas to heat the tip. You can use them when electricity is unavailable because they are portable.

- Soldering Station: A soldering station comprises a power unit and a detachable soldering iron. The power unit provides temperature control and additional features such as temperature readouts, programmable settings, and safety features.

- Hot Air Soldering Station: This type of soldering iron is equipped with a hot air gun or nozzle. It is used for soldering surface-mount components, removing or reworking electronic components, and heat-shrink tubing applications.

- Desoldering Station: A desoldering station combines a soldering iron and a vacuum pump or suction device. It is specifically designed for removing soldered components or excess solder.

- Micro Soldering Iron: Micro soldering irons are small, lightweight, and have fine tips. They are used for intricate soldering work, such as small electronic components, jewelry, or circuit board repairs requiring precision and accuracy.

These are some of the common types of soldering irons available. The choice of soldering iron depends on the specific soldering task, skill level, and personal preferences.

Types Of Soldering Wires

Several soldering wires are available, each with different compositions and properties. The most common types include:

- Lead-Tin (Pb-Sn) Solder: This is one of the traditional solder types, consisting of a mixture of lead and tin. It has good soldering properties, such as low melting points and excellent wetting characteristics.

- Lead-Free Solder: Lead-free solder wires have become a safer alternative to lead-based solder wires. These solder wires typically contain a combination of tin, silver, and copper (Sn-Ag-Cu) or other elements like bismuth or antimony.

- Rosin-Core Solder: This type of solder wire contains a rosin (flux) core in the center. The rosin core provides flux during soldering, which helps clean the surfaces being soldered and enhances the wetting action.

- Acid-Core Solder: Acid-core solder wires are specifically designed for plumbing applications, such as soldering copper pipes. The core of this solder wire contains a flux with an acidic nature, which helps remove oxides and contaminants from the metal surfaces during soldering.

- Solid-Core Solder: Solid-core solder wires do not have a flux core. They are often used when a separate flux is applied to the soldering joint before soldering.

- Silver Solder: Silver solder wires contain a high percentage of silver and other metals, such as copper and zinc. They are known for their superior strength and conductivity compared to other solder types.

These are some of the most commonly used soldering wires available on the market. The selection of the solder wire depends on the specific application, soldering technique, and any regulatory restrictions in your region.

Do I Need A Magnifying Glass For Soldering?

Here are a few reasons why using a magnifying glass can be helpful during soldering:

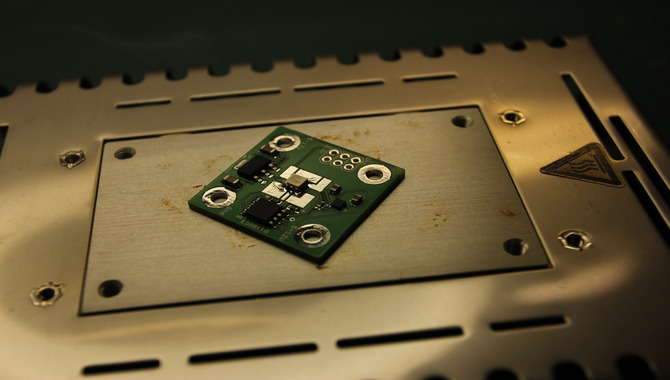

- Enhanced visibility: The magnifying glass provides a closer view of the components, solder joints, and PCB (Printed Circuit Board). It allows you to see finer details and inspect your work more effectively.

- Improved accuracy: Soldering requires precision, and a magnifying glass can assist you in making accurate connections. It helps you correctly align components, position the soldering iron tip, and ensure proper solder flow.

- Reduction of eye strain: Soldering often involves focusing on small details. Using a magnifying glass reduces eye strain by enlarging the objects you’re working with, making it easier to see and reducing fatigue.

- Fine-tuning: A magnifying glass can be precious if you work with intricate soldering tasks or small components like surface-mount devices (SMDs). It enables you to work with greater precision and make adjustments more easily.

While a magnifying glass can be helpful, it’s not an absolute requirement for soldering. Some soldering irons have built-in magnifying lenses or LED lights to aid visibility.

Ultimately, whether or not you choose to use a magnifying glass for soldering depends on your personal preference, the complexity of the work, and the level of precision you aim to achieve.

Soldering Techniques Without A Magnifying Glass

Soldering is an essential skill in electronics, but it can be challenging, especially when you don’t have the right tools. One of the most common issues is not having a magnifying glass to see the small details of the components and the solder joints.

However, there are some techniques you can use to solder without a magnifying glass. One of the first things you can do is to use a third-hand tool to hold the components in place. These tools have adjustable arms with alligator clips to hold the pieces while you solder them. This will free up your hands and give you a better view of the solder joint.

Another technique is to use a head-mounted magnifier. This type of magnifier has a small lens that attaches to a headband, leaving your hands free to work. They are comfortable to wear and provide a clear view of the soldering area. Additionally, you can use a bright light source to illuminate the work area. This will help you see.

Choosing The Right Workspace And Lighting

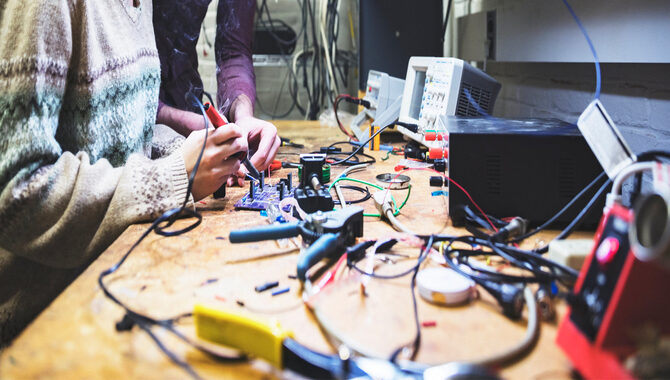

Choosing the right workspace and lighting is crucial for creating an environment that promotes productivity, focus, and well-being. Here are some considerations to keep in mind when setting up your workspace:

- Location: Find a dedicated space in your home or office that is quiet and free from distractions. Ideally, choose a room with natural light and good ventilation.

- Desk and Chair: Invest in a comfortable desk and chair that properly supports your posture. The desk should be spacious enough to accommodate your work essentials, such as a computer, notepads, and other necessary items.

- Lighting: Natural light is best for a workspace as it helps reduce eye strain and improves mood. Position your desk near a window if possible. If natural light is limited, incorporate ambient and task lighting.

- Color Scheme: Choose a color scheme that promotes a calm, focused environment. Opt for neutral or pastel colors on the walls and furniture, creating a soothing atmosphere.

- Organization: Keep your workspace tidy and organized to minimize distractions and enhance productivity. Use storage solutions like shelves, drawers, or file cabinets to arrange your supplies and documents neatly.

- Ergonomics: Ensure your workspace is ergonomically designed to support your physical well-being. Adjust your chair height so that your feet rest flat on the floor and your knees are at a 90-degree angle.

- Personalization: Add personal touches to your workspace that inspire and motivate you. Decorate with plants, artwork, or items that reflect your interests and personality.

Everyone has unique preferences and needs, so experiment with different setups and arrangements to find what works best for you.

What Are The 3 Things We Need Without A Soldering Magnifying Glass?

A magnifying glass can be a helpful tool for ensuring precision and accuracy. However, there are times when a magnifying glass is unavailable or necessary. We can use three things in place of a soldering magnifying glass:

- We can use a bright light source to illuminate the area we are working on. This can be a desk lamp or a flashlight on our mobile device. A bright light can help us see small details and adjust as needed.

- We can use a pair of tweezers to hold small components in place. This can provide better control and stability than manipulating elements with our fingers alone.

- We can use a steady hand and patience to ensure accuracy. Taking the time and being deliberate in our movements can help us achieve the desired results without a magnifying glass.

While a magnifying glass can be helpful, it is not always necessary for successful soldering.

1.Tips For Soldering Small Components

Soldering small components can be challenging but can be done effectively with the right techniques and tools. First and foremost, having a well-ventilated workspace and using appropriate safety gear such as safety glasses and gloves is important.

Selecting the right soldering iron is crucial. A fine-tipped soldering iron with adjustable temperature control is ideal for working with small components. A High-quality solder and flux are also important to ensure a strong and reliable bond.

Before starting the soldering process, it is useful to clean the components with isopropyl alcohol to remove any dirt or debris. Using a steady hand and applying just enough heat and solder to create a solid joint is important.

Using a magnifying glass or microscope is also helpful to ensure precision. In addition, it is important to avoid overheating the components as this can cause damage or even melt them.

2.Troubleshooting Common Soldering Problems

Soldering is a fundamental skill that every electronic enthusiast should master. However, even experienced solderers encounter problems during their work. Troubleshooting common soldering problems can be frustrating, but it is essential to learning.

One of the most common issues is cold solder joints. This happens when the solder doesn’t bond with the component or the PCB, resulting in a weak connection. You must reheat the joint and add more solder to solve this issue. Another common problem is overheating components.

This can happen when the soldering iron is too hot, or you leave the iron on the component for too long. The solution is to use a lower-temperature iron and use the right technique to minimize heat transfer.

Another issue is solder bridging, which connects two or more solder points, resulting in a short circuit. To solve this problem, you can use a solder wick or a desoldering pump to remove the excess solder.

3.Safety Precautions To Follow When Soldering Without A Magnifying Glass

Soldering is a popular technique that involves joining two metal surfaces by melting a metal alloy and filling the gap between them. However, soldering without a magnifying glass can be challenging, especially since it requires more attention to detail. Therefore, it is essential to follow some safety precautions to ensure that the soldering process is successful and safe.

- Wearing protective gear such as gloves, eye protection, and a respirator is crucial to prevent inhalation of fumes.

- Ensure that the soldering iron is unplugged when not in use to prevent accidental burns or fires.

- Work in a well-ventilated area or use a fume extractor to minimize the risks of inhaling fumes.

- Ensure the workspace is clean and organized to prevent the soldering iron from accidentally touching combustible materials.

- Lastly, ensure the soldering iron is properly grounded to prevent electrical shocks. Following these safety precautions can help to prevent accidents.

Conclusion

Knowing How to Solder without a soldering magnifying glass is a crucial task that requires attention to detail and precision. Soldering without a magnifying glass is possible and achievable with the right technique and tools. It may seem daunting at first, but with practice and patience, you can master the skill of soldering without a magnifying glass.

Remember to use a good soldering iron, flux, and the correct soldering technique. Following the tips and tricks outlined in this post, you can confidently solder small components without needing a magnifying glass. With time and practice, you will become a pro at soldering small components with precision and accuracy.

FAQs

1.Does Magnifying Glass Increase Heat?

No, a magnifying glass does not increase the heat on its own. If the sun’s rays are focused through a magnifying glass onto a specific area, it can cause an increase in temperature and potentially start a fire.

2.How Important Is Proper Lighting When Soldering Without A Magnifying Glass?

Ans: Proper lighting is very important when soldering without a magnifying glass, as it allows the solder to clearly see the soldered components’ details clearly and ensures that the solder is applied correctly.

3.Are There Any Risks Or Potential Issues To Know When Attempting To Solder Without A Magnifying Glass?

Ans: Yes, there are several potential issues and risks when attempting to solder without a magnifying glass:

- Eye strain.

- Inaccurate soldering.

- Safety risks.

4.What Type Of Solder Connects Electronic Components In A Computer?

Ans: The type of solder used to connect electronic components in a computer is lead-based solder. There are also lead-free solder options available.

5.What Type Of Metal Is Most Likely To Erode?

Ans: The type of metal that is most likely to erode is iron.