Engine building is a complex and intricate process that requires attention to detail and precision. Every step matters, from selecting the right components to carefully assembling them.

One crucial step in this process is torquing the cylinder heads on your Small Block Chevy (SBC) engine. Properly torquing the heads ensures that the head gasket seals correctly and prevents any leaks or issues down the road.

However, following the correct torque sequence and specifications is important to avoid damaging your engine. In the post, we’ll provide step-by-step instructions on how to torque SBC heads properly.

We’ll cover the tools you need, the proper torque sequence, and the torque specifications for different head gaskets. We’ll also provide tips on how to avoid common mistakes and ensure that your engine is running smoothly. Whether you’re a seasoned engine builder or just starting, mastering the art of torquing heads is essential.

What Is An SBC Head?

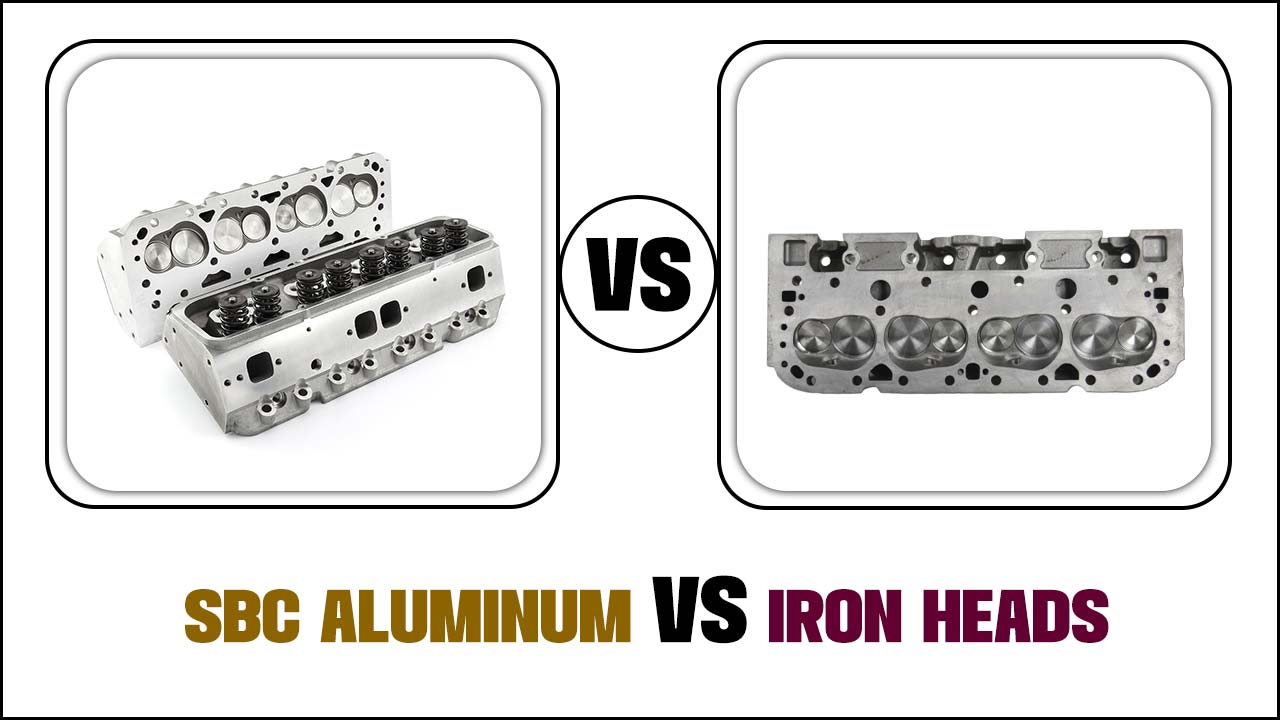

SBC heads refer to small-block Chevy heads, which are cylinder heads designed for small-block engines produced by Chevrolet. These heads are a crucial component of the engine as they control the flow of air and fuel into the combustion chamber.

SBC heads can come in various configurations and materials, some designed for stock engines and others for high-performance racing applications. Upgrading the cylinder heads can increase power and improve engine efficiency.

Understanding Torque And Its Importance In SBC Heads

Torque is a crucial engine-building aspect and plays a significant role in Small Block Chevy (SBC) heads. Torque measures the force required to rotate an object around an axis. In engine building, the bolt torque spec determines the amount of force used to secure the cylinder head to the engine block.

The proper torque specification ensures that the head gasket seals the combustion chamber correctly and prevents oil and coolant leaks. Failure to apply the correct torque can cause engine damage, so it’s essential to understand and apply the correct torque specifications.

How To Torque SBC Heads – A Comprehensive Guide

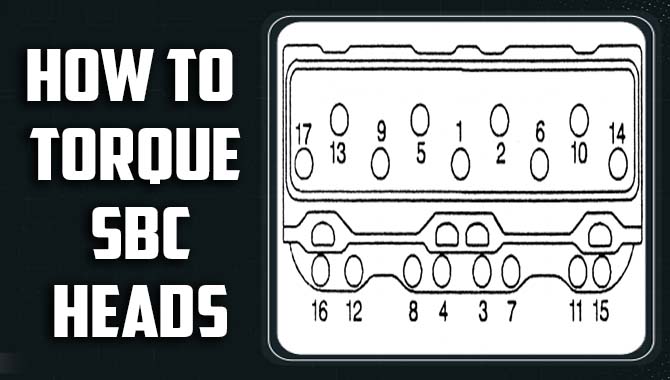

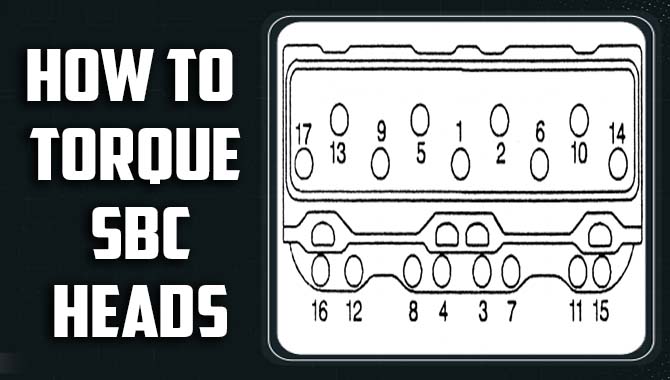

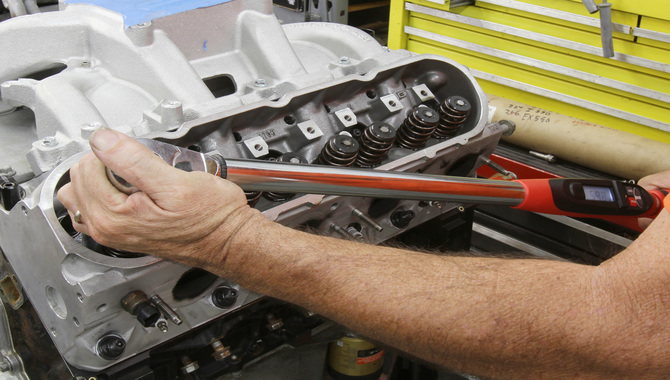

When torquing Small Block Chevy (SBC) heads, following a specific sequence and torque specification is important to ensure proper tightening and avoid damaging the engine. The first step is to clean the head bolts and bolt holes thoroughly.

Then, using a torque wrench, tighten the bolts in three stages, following a specific pattern. The first stage involves torquing all bolts to 25 ft-lbs, the second stage involves torquing them to 50 ft-lbs, and the final stage involves torquing them to the specified torque for your specific engine and head type.

It is important to follow the manufacturer’s recommended torque specification and pattern, as these can vary depending on the year and model of your SBC. Here are some tips on how to torque SBC heads:

1. Torque Specifications

When installing head bolts on your engine, it’s crucial to use the correct torque specifications to ensure proper fit and avoid potential engine damage. To start, look up the recommended torque specifications for your specific engine to ensure accuracy.

Once you have found the specifications, choose the correct torque specifications for your type of head bolts. Using a torque wrench, tighten the bolts to the specified values accurately. Be aware of any variations in torque specifications for different engine models or years.

Lastly, always follow the manufacturer’s recommended torque specifications to maintain the integrity of your engine.

2. Choosing The Right Tools For Torquing SBC Heads

Choosing the right tools is essential for a successful job. The first tool you’ll need is a torque wrench. Calibrate it and check if it has a range suitable for your specific application. Next, you’ll need a torque angle gauge, which measures the rotation of the bolt as it’s tightened.

This is important because torque alone doesn’t ensure proper clamping force. You’ll also need a good quality gasket and lubricant to ensure proper sealing and reduce friction. Lastly, follow the manufacturer’s specifications for torque and sequence to avoid damaging the engine.

3. Preparation

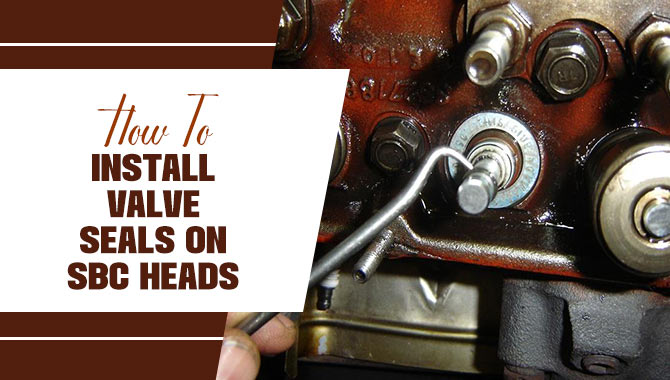

It’s important to gather all the necessary tools and equipment to assemble an engine properly. Once you have everything you need, the first step is to thoroughly clean the cylinder head and block surfaces to ensure a tight seal. Before installing the head bolts, inspect them for any damage or wear that could affect their performance.

Applying engine oil to the threads and washer faces of the bolts will help them turn smoothly and prevent seizing. Finally, install the head gaskets onto the block to complete the assembly process. Properly following these steps will ensure a well-built and reliable engine.

4. Tightening Sequence

When tightening the bolts on your engine, it’s important to follow the correct sequence to ensure an even distribution of pressure. Hand-tighten all bolts correctly before beginning to torque them down in increments.

Repeat the torque sequence until all bolts reach the final torque value, as specified in your engine’s manual. After this, double-check the torque on all bolts to ensure they are properly tightened. Following this process can prevent uneven pressure distribution and potential damage to your engine.

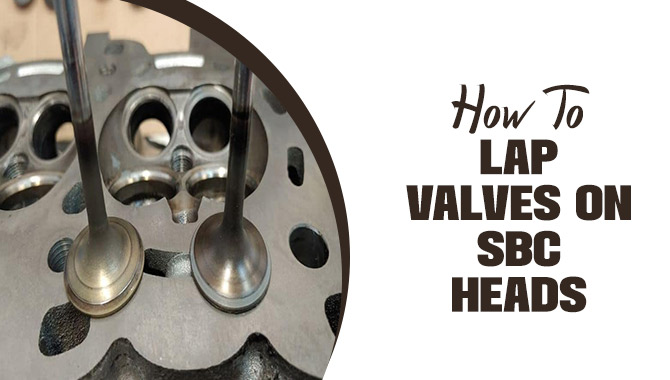

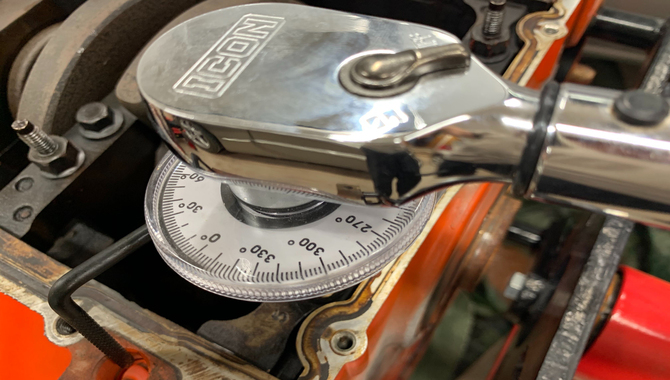

5. Torque Angle Method

The torque angle method is a precise way to tighten head bolts. To use this method, you need to determine the correct degree of rotation for each bolt. This can be done by consulting the manufacturer’s specifications.

Once you have this information, you can use a torque angle gauge to measure the degree of rotation accurately. Next, tighten the bolts to the specified torque, then rotate them the correct number of degrees.

Finally, double-check the torque and angle on all bolts to ensure they are within the specified range. This method ensures you properly tighten the head bolts and helps prevent future engine problems.

6. Retorqueing

Retorquing after the initial installation is crucial to prevent any loose bolts and ensure the proper seating of the head gasket. It is important to wait until the engine has cooled completely before retorquing to avoid inaccuracies caused by thermal expansion.

We recommend maintaining consistency with the same torque sequence and specifications as the initial installation. You should retorque all bolts to the specified torque value, including those not initially tightened.

We also recommend retorquing after the first few heat cycles to ensure the proper seating of the head gasket. Overall, retorquing is a simple yet important step in engine maintenance.

7. Using A Criss-Cross Pattern To Tighten The Bolts

When tightening bolts, using a criss-cross pattern is recommended. This involves tightening the bolts in a sequence that crosses over each other rather than tightening them in a circular pattern.

This method helps evenly distribute the pressure and torque on the bolts, which can prevent warping or damage to the bolted object. It’s important to follow the recommended torque specifications for the specific bolts used and avoid over-tightening, which can also cause damage.

How To Use Torque SBC Heads For Maximum Performance

To use Torque SBC (Small Block Chevy) heads for maximum performance, choosing the right cylinder head is important based on the engine’s intended use. The Torque SBC head offers several benefits, including increased airflow and better combustion efficiency.

When selecting a Torque SBC head, consider the compression ratio, camshaft profile, and intake manifold design. It is also important to properly match the head to the rest of the engine components for optimal performance. With proper installation and tuning, the Torque SBC head can help maximize power and torque output from your engine.

Re-Torquing SBC Heads After The Engine Has Been Run

After running an engine with newly installed Small Block Chevy (SBC) heads, it is important to re-torque them. This is because the heat generated during engine operation can cause the head bolts to loosen. Re-torquing involves tightening the bolts in a specific sequence to ensure proper clamping force.

The recommended torque specifications can vary depending on the head and engine combination, so it is important to consult the manufacturer’s guidelines. Generally, experts recommend re-torquing SBC heads after the first 20-25 hours of operation and periodically thereafter. This helps to ensure a reliable and long-lasting engine.

Avoiding Over-Torquing And Damaging The Cylinder Heads

Over-torquing can cause significant damage to cylinder heads, so it’s important to follow the manufacturer’s recommended torque specifications. You can find this information in the owner’s manual or service manual. It’s also important to use the correct torque wrench and socket size to ensure accurate torque readings.

When tightening the cylinder head bolts, it’s recommended to use a criss-cross pattern to distribute the torque evenly. Over-torquing can cause cylinder head warpage, gasket failure, or even cause the bolts to break. By following the recommended torque specifications and proper tightening procedure, you can avoid costly damage to your engine.

Conclusion

Torquing SBC heads is a critical process that requires careful attention to detail and adherence to proper techniques. Torquing cylinder heads is essential to engine assembly, requiring precision and attention to detail. Following the proper steps and using the correct tools and techniques is critical to ensure the engine runs smoothly and efficiently.

Whether you are a professional mechanic or an amateur enthusiast, mastering the art of torquing SBC heads will allow you to achieve optimal performance and reliability from your engine. Learn how to torque SBC heads with practice and experience, become proficient at this skill and take pride in keeping your engine running at peak performance.

FAQ’s:

1.What Does “SBC” Stand For In The Context Of Engine Heads?

Ans: In the context of engine heads, “SBC” stands for Small Block Chevy. The term refers to a family of V8 engines produced by Chevrolet that features a compact design and relatively smaller displacement than their larger counterparts.

2.Why Is Torquing The Cylinder Head Important?

Ans: Properly torquing the cylinder head ensures that the head is securely fastened to the engine block, essential for a tight seal and proper engine function.

3.What Is The Torque Specification For SBC Heads?

Ans: The torque specification for SBC heads can vary depending on the specific engine and head type. It is important to consult the manufacturer’s specifications or a trusted mechanic for the correct torque specification.

4.What Tools Are Needed To Torque SBC Heads?

Ans: To torque SBC heads, you will need a torque wrench, a socket set, and a torque angle gauge.

5.How Do You Prepare The Engine For Torquing The Cylinder Head?

Ans: Before torquing the cylinder head, it is important to clean the head and block mating surfaces and threads of the head bolts. You should also apply a thin layer of engine oil to the threads and washer of each head bolt.