People use soldering to combine two metal parts by melting a filler metal or solder between them. So it is essential to know how to Solder without Solder paste. However, soldering without solder paste can be challenging. But it’s possible to achieve this with the right tools and techniques.

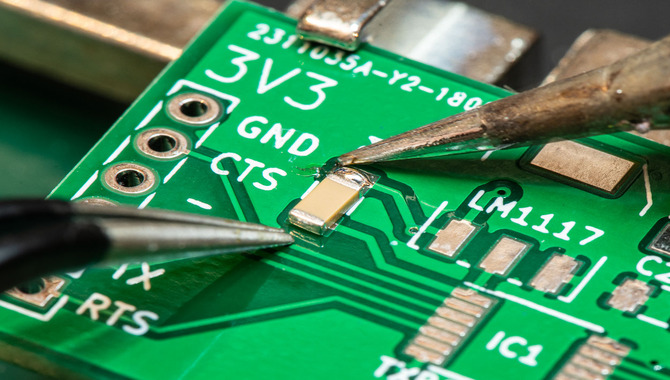

Firstly, you need a soldering iron with a pointed tip and a flux pen to clean the surfaces and improve the solder flow. Begin by heating the metal parts with the soldering iron and touching the solder to the areas where you want to join them.

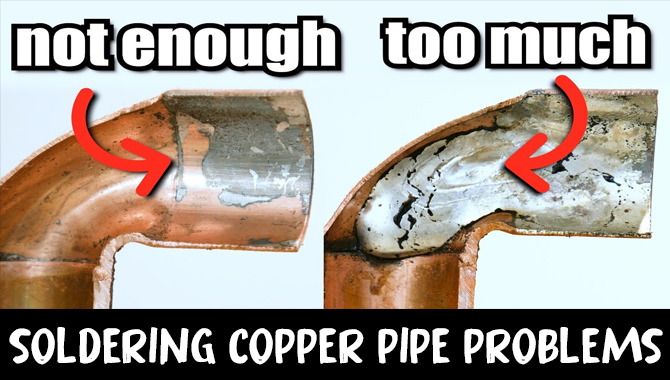

Hold the soldering iron in place until the solder melts and flows into the joint. Then, remove the soldering iron and allow the metal to cool down. It is important to note that using too much heat can damage the components, so using the right amount of heat and solder is essential. Also, cleaning and preparing the surfaces before soldering is crucial, as this ensures good adhesion and reduces the risk of corrosion.

Types Of Soldering Techniques

Through-Hole Soldering: Through-hole soldering is a widely used technique for soldering components with leads that pass through holes in a circuit board. The leads are inserted into the holes, and solder is applied to the opposite side of the board, creating a connection.

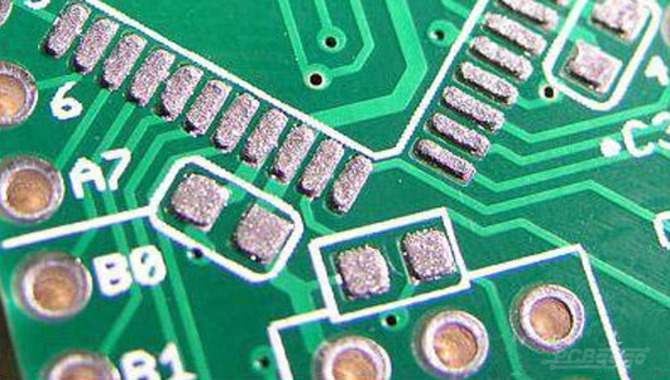

Surface Mount Soldering: Surface mount soldering (SMT) is a technique used to solder surface mount components directly onto the surface of a circuit board. SMT components do not have leads but instead have small metal contacts or pads that make contact with the board’s surface. Solder paste is applied to the board’s pads, and the components are placed onto the paste. The assembly is then heated to melt the solder and create the connection.

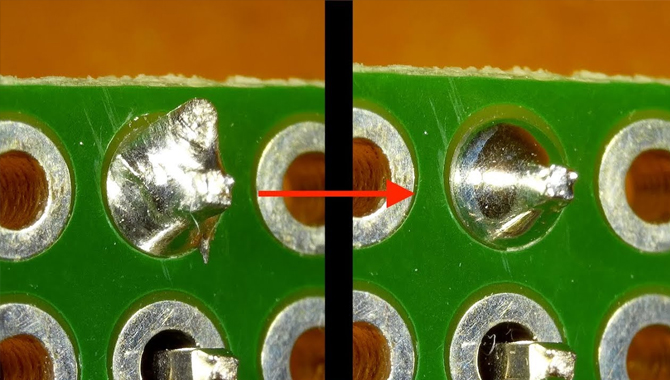

Desoldering: Desoldering is the process of removing solder from an existing joint or connection. Desoldering techniques include using a desoldering pump or desoldering braid/wick to heat the joint and remove the molten solder, allowing the component or wire to be removed.

Soldering Iron Techniques: The soldering iron is the primary tool used for soldering. It consists of a heated metal tip that melts the solder, allowing it to flow and create a connection. Soldering irons come in different types and power ratings, ranging from simple pencil irons to more advanced temperature-controlled irons.

Wave Soldering: Wave soldering is an automated technique used for soldering through-hole components on a large scale. The circuit board is passed over a wave of molten solder, which selectively solders the component leads to the board. This technique is commonly employed in electronics manufacturing.

Reflow Soldering: Reflow soldering is a technique often used in surface mount technology (SMT).It involves applying solder paste to the board’s pads, placing the components onto the paste, and then heating the assembly in a reflow oven. The controlled temperature profile in the oven melts the solder paste, creating reliable solder joints.

Through-Hole Soldering: Through-hole soldering is a traditional technique used to solder components with leads (wires) that pass through holes in a printed circuit board (PCB).The leads are inserted into the holes, and solder is applied to the opposite side of the board, forming a mechanical and electrical connection.

Surface Mount Soldering: Surface mount soldering (SMT) is a technique used to solder surface mount components directly onto the surface of a PCB. Surface mount components do not have leads but instead have small metal contacts or pads that make contact with the PCB’s surface. SMT involves applying solder paste to the PCB’s pads, placing the components onto the paste, and then heating the assembly to melt the solder and create the connection.

Desoldering: Desoldering is the process of removing solder from an existing joint or connection. Desoldering techniques include using a desoldering pump or solder wick to heat the joint and remove the molten solder, allowing the component or wire to be removed.

Wave Soldering: Wave soldering is an automated soldering technique used for the large-scale production of PCBs. The PCB is passed over a wave of molten solder, which selectively solders the components’ leads to the PCB. This technique is often used for through-hole components and provides efficient and consistent soldering.

Reflow Soldering: Reflow soldering is a technique commonly used in surface mount technology (SMT).It involves applying solder paste to the PCB’s pads, placing the components onto the paste, and then heating the assembly in a reflow oven. The oven’s controlled temperature profile melts the solder paste, creating reliable solder joints.

Basic Tools And Materials For Soldering

- Soldering Iron

- Solder

- Flux

- Soldering Stand

- Soldering Tip Cleaner

- Soldering Sponge

- Helping Hands

- Wire Cutters

- Tweezers

- Safety Equipment

- Ventilation

A Step-By-Step Guideline On How To Solder Without Solder Paste

Soldering is a process of joining two metal components by melting a metal alloy and allowing it to flow into the joint. People commonly use solder paste in the process of soldering. However, it is possible to solder without solder paste. Here is a step-by-step guideline on how to solder without solder paste.

- Ensure that you have all the necessary tools for soldering, such as a soldering iron, soldering wire, flux, and a cleaning agent.

- Use a cleaning agent to clean the metal components to be joined and remove any dirt or debris.

- Apply the flux to the metal components to be joined. The flux promotes the solder’s flow and helps prevent oxidation of the metal.

- Heat the soldering iron until it reaches the required temperature.

- Place the soldering wire onto the metal components and gently heat it with the soldering iron until it melts and flows into the joint.

Understanding Soldering Flux

People use soldering to combine two pieces of metal in electronics and metalworking. However, to achieve a strong and durable bond, it is necessary to use a soldering flux. You apply chemical compound flux to the joint before applying the solder. The design cleans the surface of the metal and prevents oxidation, which can weaken the bond. Understanding the properties and function of flux is crucial to achieving a successful soldering job.

Flux works by removing oxides from the surface of the metal being soldered. When the solder is applied, it then creates a strong bond without any contaminants. Various types of flux are available, including water-soluble, no-clean, and rosin-based. It is important to choose the right type of flux for the job and follow the manufacturer’s instructions carefully.

Preparing The Surfaces To Be Soldered

Preparing the surfaces to be soldered is one of the most important steps when soldering. Ensuring that the soldering iron tip and the surfaces being soldered are clean and free of contaminants is involved in this. You can achieve this by using a soldering iron tip cleaner to remove any built-up debris or oxidation on the tip and by using a wire brush or sandpaper to clean the soldered surfaces.

Ensuring proper alignment and holding surfaces in place during the soldering process is important to prevent weak or faulty joints. Choosing the right type of solder and flux for the job is also important, as different materials and applications may require different soldering materials. Properly preparing the surfaces to be soldered is essential for ensuring a strong and reliable connection and can help prevent damage or failure of the finished product overall.

Techniques For Applying Solder

To electronic repair or soldering projects, it’s important to understand the different techniques for applying solder. The most common technique used is the drag method. Draw the solder across the joint to be soldered while holding the soldering iron at a 45-degree angle. This method allows the solder to flow evenly into the joint, creating a strong bond. Another technique is the dip method. You dip the soldering iron tip into the solder and then apply it to the joint.

This method is useful for small components and tight spaces. The touch method involves touching the soldering iron tip to the joint and then applying the solder. This technique requires a steady hand and practice to avoid touching other components. Lastly, the wave method is used for surface mount components, where a wave of molten solder is passed over the components to create a strong bond.

Safety Precautions For Soldering

People in the electronics and metalworking industries widely use soldering to join two pieces of metal or electronic components. Safety precautions are essential when working with hot soldering tools and chemicals. First and foremost, it is crucial to wear protective gear such as safety glasses, gloves, and a heat-resistant apron to prevent burns and exposure to toxic fumes.

Additionally, make sure to work in a well-ventilated area to avoid inhaling harmful gases. Experts always recommend keeping a fire extinguisher nearby when using soldering irons to prevent fires caused by improper use or left unattended. When not in use, turn off the soldering iron and place it on a designated stand to prevent accidental burns or tips touching flammable objects. Lastly, you should keep a first aid kit nearby in case of any injuries and be aware of the risks associated with lead-based solder and other hazardous chemicals.

Advanced Soldering Techniques Without Solder Paste

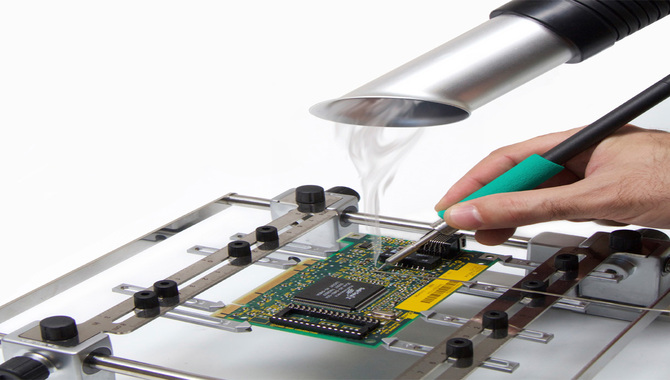

Advanced soldering techniques without solder paste can be challenging for even seasoned engineers. However, with the right tools and knowledge. It is possible to achieve high-quality solder joints without needing messy solder paste. One technique that has gained popularity in recent years is the use of a soldering iron and flux. To make the solder joint, apply flux to the area and use a soldering iron to heat the area and melt the solder wire onto the joint using this method.

Another technique is using a hot air soldering station. Which works by directing a stream of hot air onto the solder joint. Melting the solder wire and forming a strong bond. This technique requires more skill and precision than the traditional soldering iron and flux method but can produce excellent results. With these advanced soldering techniques. It is possible to achieve high-quality joints and connections without the need for messy solder paste.

Conclusion

Knowing how to Solder without solder paste is a crucial task that requires attention to detail and precision. It is possible to solder without solder paste, and one can also do it with great precision and attention to detail. Using alternative methods such as flux pens, pre-tinning, and hot air rework stations, one can achieve high-quality results just as good as those achieved with solder paste. While solder paste may be the preferred method for some. It’s always good to have alternate methods in your arsenal as a professional. With these tips and techniques, you can confidently approach your next soldering project without the need for solder paste.

FAQs

1.Can You Use Regular Rosin-Core Solder Wire Without Solder Paste?

Ans: Yes, rosin-core solder wire contains flux inside, so you can use it without requiring additional flux.

2.What Are Some Tips For Soldering Without Solder Paste?

Ans: You should ensure that your soldering iron is at the correct temperature, clean the joint surfaces properly, use the right amount of solder, and heat the joint evenly.

3.How Do You Ensure Good Solder Flow Without Solder Paste?

Ans: Apply heat to the joint with the soldering iron first, and then touch the solder wire to the heated joint. The heat will cause the solder to melt and flow onto the joint.

4.Are There Any Alternative Methods To Soldering Without Solder Paste?

Ans: Yes, you can explore other soldering techniques like using soldering preforms, soldering irons with built-in flux, or using soldering flux in paste or gel form to aid the soldering process.

5.Can I Solder Without Using Solder Paste?

Ans: Yes, soldering without solder paste is possible by using solid-core solder wire.