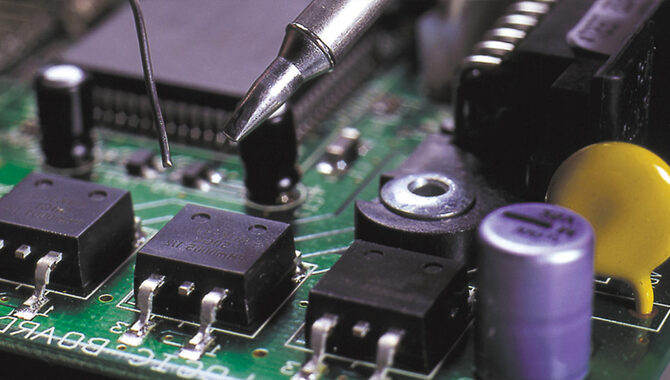

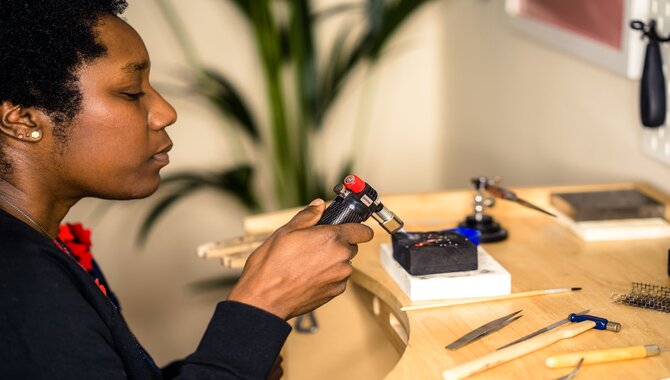

Soldering is common in the electronics industry, as it allows for electrical components’ secure and permanent connection. However, one of the soldering challenges is maintaining a clean tip, which can become contaminated with residue from previous soldering jobs or oxidation.

This can make it challenging to achieve a robust and reliable solder connection. But fear not; there are several how to solder without soldering tip clean. We will explore some tips and tricks for soldering without a clean end to help you achieve the perfect connection every time.

We will discuss the importance of selecting the proper soldering technique using flux. And other tools and techniques that can help you solder without a clean tip. Whether you are a seasoned pro or just starting. Our tips and tricks will help you achieve a clean and secure solder connection, even when your tip is not perfectly clean.

How To Solder Without Soldering Tip Clean – Comprehensive Guide

How to solder without soldering tip clean can be challenging, but it’s not impossible. Here’s a comprehensive guide on how to solder without a clean soldering tip, along with some important “do’s” and “don’ts” to keep in mind:

- Prepare your materials: Gather all the necessary materials for soldering, including the soldering iron, solder wire, and flux. And the components you need to solder.

- Clean the tip as best as possible: Even if your soldering tip is not perfectly clean, remove any excess solder or debris by gently wiping it on a damp sponge or using a brass tip cleaner. This will help improve the heat transfer and solder flow.

- Apply flux: Flux is crucial in soldering as it helps clean the surface, promote solder flow, and prevent oxidation. Apply a small amount of flux to the joint or the component you are soldering to enhance the connection.

- Pre-tin the soldering iron: To improve heat transfer and solder flow, “pre-tinning” the soldering iron tip can be helpful. This involves melting a small amount of solder onto the tip, ensuring it coats the entire surface evenly. It creates a protective layer and helps with heat conduction.

- Heat the joint: Place the soldering iron tip onto the joint you want to solder. Hold it there for a few seconds to allow the heat to transfer to the joint and the surrounding area.

- Apply solder: Once the joint is heated, gently touch the solder wire to the joint, not the soldering iron tip, directly. The heat from the joint will melt the solder, allowing it to flow into the joint. Ensure that the solder wets the joint properly, forming a strong bond.

Proper Maintenance And Storage Of Your Soldering Iron

Properly maintaining and storing your soldering iron ensures its longevity and effectiveness. To begin with, it is essential to clean the tip of your soldering iron regularly. This can do using a damp sponge or specialized tip cleaner.

Additionally, it is recommended to use high-quality solder to prevent the buildup of residue on the tip, which can affect its ability to transfer heat. When not in use, it is best to turn off the soldering iron and allow it to cool down before storing it in a safe and dry location.

It is also important to remember to replace the tip when worn or damaged, as this can affect the quality of the solder joint. When storing your soldering iron, keeping it away from moisture and dust is essential, which can cause corrosion and damage to the heating element. A protective case or storage box can help prevent accidental damage or exposure to the details.

Using Flux To Compensate For A Dirty Tip

When it comes to welding, a clean and well-maintained welding tip is crucial for achieving high-quality welds. However, even with the best practices, a welding tip can become dirty and compromise the welding process. One solution to compensate for dirty information is by using flux.

Flux is a chemical compound that helps to clean and protect the weld area by removing impurities and preventing oxidation. Applying flux to the weld area can help compensate for a dirty tip and improve the quality of the weld.

Flux can also help improve the weld puddle’s flow, making it easier to control and manipulate. It is important to remember that not all fluxes are created equal, and choosing the right type of flux for the job is essential. Some fluxes are designed for specific materials, such as aluminium or stainless steel, while others are more versatile and can use on various materials.

Preparing Your Workspace For Soldering

Preparing your workspace for soldering is an essential step in ensuring the success of your project and your safety. First, you should clear the area of any clutter or unnecessary items that may pose a hazard. Next, ensure that the workspace is well-lit and that there is adequate ventilation to prevent the inhalation of any harmful fumes.

It is also essential to have a fire extinguisher in case of accidents. Once you have cleared the space and ensured proper ventilation, you should gather all the necessary tools and materials, such as a soldering iron, solder, flux, and wire cutters.

Everything within reach will help you work more efficiently and avoid unnecessary movements. Additionally, you should protect your work surface with a heat-resistant mat or board to prevent any damage or burns. Finally, ensure that you clearly understand the soldering process and any safety precautions that must be taken before you begin.

Proper Soldering Techniques And Best Practices

Proper soldering techniques and best practices are essential for ensuring a successful and reliable bond between two metal surfaces. One of the most important aspects of appropriate soldering is preparing the surfaces to be joined.

The metal must be clean and free of oils, grease, or other contaminants. This can achieve using a solvent, such as isopropyl alcohol, and a clean rag. Once the surfaces are clean, applying an appropriate amount of flux to the joint is essential.

Flux is a chemical that helps to remove oxides from the metal and promote adhesion between the solder and the metal. Next, using the correct type of solder for the job is essential. Different solders have different melting points and compositions, so choosing the right one for the specific application is essential. When soldering, it is important to use the right amount of heat.

Tips And Tricks For Soldering Without A Clean Tip

Soldering is a delicate process that requires precision and a clean environment. However, having a perfectly clean tip when soldering is not always possible. When this happens, you can use several tips and tricks to ensure a successful soldering job. Firstly, try using a damp sponge to clean the end before starting the career.

This will remove any debris or oxidation accumulated on the surface. Another helpful tip is to use a flux pen to help the solder flow better. This will reduce the time the information has to stay in contact with the material, reducing the chances of the information getting dirty.

Additionally, you can apply a small amount of solder to the tip before starting the job. The solder will help to absorb any impurities on the end, making it cleaner and more effective. It is also essential to keep a steady hand and avoid excessive pressure on the tip, as it can cause it to wear out faster.

Best Practices For Soldering With A Dirty Tip

Soldering with a dirty tip can be frustrating and time-consuming, but you can follow some best practices to make the process easier and more efficient. First and foremost, keeping your soldering iron tip clean and well-maintained is essential. This means regularly cleaning it with a damp sponge or using a tip cleaner to remove any excess solder or debris.

Additionally, you may want to consider using a soldering iron with a temperature control feature, as this can help prevent the tip from getting too hot and accumulating excess debris. Another helpful piece of information is to use a flux pen to prepare the area you’ll be soldering, which can help the solder flow more smoothly and evenly. Finally, taking your time and patience when soldering with a dirty tip is important. Rushing the process can lead to mistakes, making achieving a clean and precise result even harder.

Conclusion

How to solder without soldering tip clean can be a frustrating experience. However, implementing the tips and tricks we’ve discussed can improve your soldering techniques and achieve better results. Remember to use the proper flux, keep your information tinned, and clean it regularly. Also, consider investing in a quality soldering iron and using the proper technique. With these practices in mind, you can elevate your soldering skills and create more reliable and durable electronic devices.

FAQs

1.Can Using A Dirty Soldering Tip Affect The Quality Of The Solder Joint? If So, How?

Ans: Yes, using a dirty soldering tip can affect the quality of the solder joint. Contaminated information can cause poor heat transfer, leading to insufficient melting of the solder and inadequate wetting of the joint, resulting in a weak and unreliable connection.

- Do You Take Any Precautions When Soldering Without A Clean Tip To Prevent Damage To The Components Or Circuit Board?

Ans: As an AI language model, I do not personally engage in soldering. However, cleaning the tip of the soldering iron before use is generally recommended to prevent damage to components or circuit boards.

- Are There Any Soldering Projects That Are More Forgiving When Using A Slightly Dirty Tip, Or Should You Always Strive For A Clean Tip Regardless Of The Project?

Ans: While it’s always best to strive for a clean tip when soldering, some projects may be more forgiving when using a slightly dirty tip. For example, if you’re soldering larger components or joints. There may be enough heat transfer, even with a slightly dirty tip, to achieve a good bond.

4.What Alternative Methods Can You Use To Clean Your Soldering Tip If You Don’t Have A Traditional Tip Cleaner?

Ans: Damp sponge or cloth: Dip a damp sponge or cloth in water and wipe the tip of the soldering iron across it. This will remove any excess solder and debris from the tip.

5.Are There Any Particular Types Of Soldering Projects Or Materials That Are More Forgiving If Your Tip Is Not Perfectly Clean?

Ans: Certain soldering projects and materials may be more forgiving if your tip is not perfectly clean. For example, larger components or solder joints may allow for some imperfections in the soldering process.