Soldering is an essential technique in electronics and metalworking. Whether working on a DIY project or repairing an electronic device, soldering is a skill you must master. A soldering sponge is a standard tool used to clean the soldering iron tip during the soldering process, but what happens when you don’t have a sponge at hand?

That’s where this step-by-step guide comes in handy. Using simple tools and techniques, we will teach you how to solder without a soldering sponge. We’ll walk you through the process, from preparing your soldering iron to cleaning your tip using alternative methods.

We’ll also discuss tips and tricks to help you get the best results when soldering without a sponge. So, whether you’re a beginner or an experienced soldering enthusiast, this guide is for you.

How To Solder Without Soldering Sponge – Comprehensive Guide

Soldering without a sponge can be challenging, but it’s not impossible. Here’s a comprehensive guide on how to solder without a soldering sponge, along with some dos and don’ts to keep in mind:

1. Prepare Your Workstation

- Ensure you have a stable work surface.

- Place a non-flammable material like ceramic tile or a heat-resistant silicone mat to protect your work surface from heat damage.

- Keep a damp sponge or a wet cloth nearby to clean the soldering iron tip as an alternative to a soldering sponge.

2. Clean The Soldering Iron Tip

- Before starting, make sure the soldering iron tip is clean and tinned. Tinning refers to applying a thin layer of solder to the tip.

- Heat the soldering iron and wipe it on a damp sponge or wet cloth to remove any dirt or old solder.

3. Use Flux

- Flux is a substance used to promote solder flow and improve the wetting action. Apply flux to the joint you want to solder.

- For this purpose, you can use flux paste, flux pen, or flux core solder.

4. Tin The Wire Ends

- Apply a small amount of solder to the exposed wire ends separately. This process is called tinning.

- Tinning helps improve the soldering process by providing a better electrical connection and preventing oxidation.

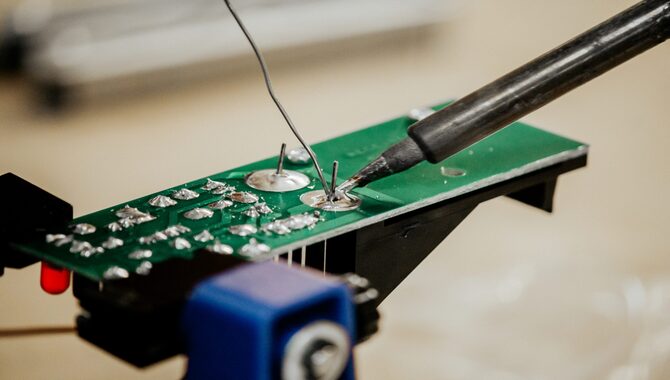

5. Heat The Joint And Apply Solder

- Hold the soldering iron tip against the joint where the two tinned wire ends meet.

- Allow the joint to heat up for a few seconds until it reaches the right temperature for soldering.

- Touch the solder wire to the joint and let it flow onto the joint, ensuring good contact with the wires.

Alternative Methods Of Cleaning The Soldering Iron

Soldering irons are an essential tool for electronic and electrical work. They are used to join components together, and a clean tip is necessary for efficient and effective soldering. Traditional methods of cleaning the soldering iron involve using a damp sponge or brass wire cleaner. However, these methods can be time-consuming and may not always be practical. As a result, alternative forms of cleaning the soldering iron have emerged in recent years.

One of the most popular alternative methods is a soldering iron tip cleaner. These cleaners are made of a brass wire mesh and are designed to remove excess solder and other contaminants from the tip of the soldering iron.

Another alternative method is the use of a tip tinner. Tip tinner is a paste-like substance applied to the soldering iron’s tip. It works by cleaning and re-tinning the end, making it easier to work with.

Using Brass Wool

Bringing brass wool can be a safe and effective method when cleaning delicate or expensive surfaces. People use brass wool to clean, polish, and remove dirt or grime from various surfaces because it is non-abrasive. Its soft and flexible texture makes it ideal for delicate items such as jewellery, silverware, or fine china. Additionally, brass wool is an excellent alternative to the more abrasive steel wool, which can cause damage to surfaces if misused.

To use brass wool, wet the surface to clean and gently rub the brass wool over the area. The soft fibres will provide a light scrubbing action, removing dirt or grime without causing any damage. Use a mild detergent or cleaning solution with the brass wool for tougher stains. Another benefit of using brass wool is that it can reuse multiple times.

Using Steel Wool

Using steel wool is a great way to achieve a variety of DIY projects. Steel wool is made from thin strands of steel wire, which can use for cleaning, sanding, polishing, and even starting fires. One of the most popular uses for steel wool is cleaning various household items such as pots, pans, and grills. Its abrasive texture lets it easily remove tough stains and grime, leaving surfaces sparkling clean.

Steel wool can also sand and polish woodwork, metal surfaces, and car exteriors. Its fine texture smooths out rough edges and leaves a polished finish. In addition, steel wool can use for artistic purposes, such as creating texture on paintings or sculptures. Steel wool can also start fires for those who enjoy camping or hiking. A fire can start quickly and easily by creating small bundles of steel wool and igniting them with a lighter.

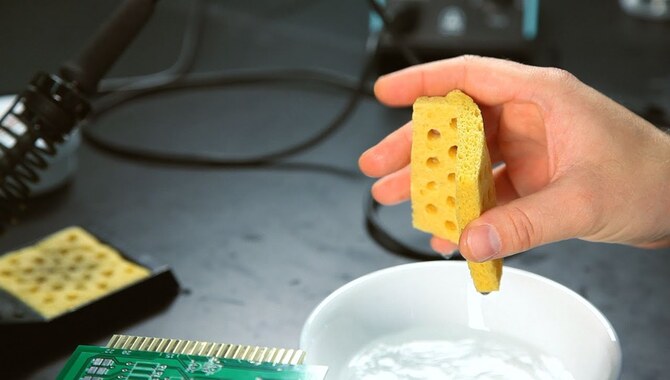

Using A Damp Sponge

Using a damp sponge is one of the best ways to clean surfaces in your home. Whether you’re wiping down countertops, cleaning up spills, or scrubbing away grime, a damp sponge can be a versatile tool to have on hand.

The dampness of the sponge allows it to pick up dirt and debris easily while providing enough moisture to help break down any stubborn stains. A damp sponge is less likely to scratch surfaces than a dry cloth or abrasive cleaner.

To get the most out of your damp sponge. Start by wetting the sponge and wringing out any excess water. You want the sponge to be moist but not dripping wet. Then, use gentle circular motions to clean the surface, careful not to apply too much pressure. If you’re dealing with tough stains, you may need to apply more pressure but test a small area first to avoid damaging the surface.

Using Flux-Cored Solder]

Using a damp sponge is one of the best ways to clean surfaces in your home. Whether you’re wiping down countertops, cleaning up spills, or scrubbing away grime, a damp sponge can be a versatile tool to have on hand.

The dampness of the sponge allows it to pick up dirt and debris easily while providing enough moisture to help break down any stubborn stains. A damp sponge is less likely to scratch surfaces than a dry cloth or abrasive cleaner.

To get the most out of your damp sponge. Start by wetting the sponge and wringing out any excess water. You want the sponge to be moist but not dripping wet. Then, use gentle circular motions to clean the surface, careful not to apply too much pressure. If you’re dealing with tough stains, you may need to apply more pressure but test a small area first to avoid damaging the surface.

Using Soldering Flux

Using soldering flux is an essential step in the process of soldering. Soldering flux is a chemical agent that helps to clean and prepare the surface of the metal for soldering. It also helps to prevent oxidation during the soldering process, ensuring a robust and reliable bond.

The flux is applied to the joint before the solder is used, and it works to remove any impurities or contaminants that may be present on the surface of the metal. This is important because any impurities can lead to a weak bond or even a complete failure of the solder joint.

Many different soldering flux types are available, each designed for specific applications. For example, some fluxes are designed with certain metals, such as copper or brass, while others are designed with electronic components.

Tips For Successful Soldering Without A Sponge

Soldering is a crucial process in electronics and metalworking. It involves melting metal alloys to join two or more pieces of metal. While many soldering stations come with a sponge to clean the iron tip, it’s possible to solder without one. Here are some suggestions for successful soldering without a sponge.

- use a brass wire brush to clean the end of the soldering iron. This removes any oxidation or debris that may accumulate on the information.

- wipe the iron’s tip with a damp cloth or paper towel. This will help to keep the tip clean and cool.

- use a flux pen or liquid flux to help the solder flow. Change helps to remove oxidation and other impurities that can interfere with the soldering process.

- use a soldering iron stand to hold the iron when it’s unused. This will prevent the tip from contacting any surfaces that could damage it.

Conclusion

while a soldering sponge is a standard tool for cleaning soldering tips, it is not the only available option. Following the step-by-step guide outlined in this post, you can effectively solder without a soldering sponge and still achieve professional results.

Whether in a pinch without a sponge or prefer an alternative method, this technique can be helpful for any DIY project or electronic repair. With practice and patience, you can become proficient in soldering without a sponge and expand your skill set as a DIY enthusiast or professional technician.

FAQs

- Can A Damp Cloth Or Paper Towel Clean A Soldering Iron Tip?

Ans: A damp cloth or paper towel can clean a soldering iron tip. The dampness helps to remove any built-up residues or soldering flux on the information. Using a clean damp cloth or paper towel is essential to avoid introducing contaminants that may affect the soldering process.

2.Are There Any Risks Or Downsides To Soldering Without A Sponge?

Ans: Yes, soldering without a sponge has several risks and downsides.

Firstly, soldering without a sponge can cause the tip of the soldering iron to become dirty and contaminated with old solder, which can affect the quality of the solder joint and make it difficult to control the flow of solder.

- What Are Some Tips For Beginners Who Want To Try Soldering Without A Soldering Sponge?

Ans: Use a damp cloth: Instead of a soldering sponge, use a wet cloth to clean the tip of your iron. This will help remove any excess solder or debris from the end.

4.Can You Provide A Step-By-Step Guide On Adequately Cleaning A Soldering Iron Tip Without A Sponge?

Ans: Use a damp cloth or paper towel to clean the soldering iron tip between uses. This will help remove any excess solder or debris.

- Are Any Soldering Projects Better Suited For Using A Sponge Versus Not Using One?

Ans: Yes, there are specific soldering projects that are better suited for using a sponge while soldering. For example, when soldering printed circuit boards (PCBs), frequently cleaning the soldering iron tip is essential to remove any excess solder or debris. Using a damp sponge to wipe the information can help keep it clean and prevent any damage to the PCB.

![10 Best Torch For Plumbing [Reviews With Buying Guide]](https://accuratepicker.com/wp-content/uploads/2022/03/Best-torch-for-plumbing.jpg)