Air compressors are vital for many industries, including construction, automotive, manufacturing, and more. Air compressors are essential for efficiently completing tasks, from powering pneumatic tools to inflating tires.

However, air compressors are susceptible to common issues that hinder their performance like any other machinery. As a professional, you must equip yourself with the knowledge and skills to troubleshoot these problems quickly and effectively.

In the post, we will discuss how to troubleshoot common air compressor issues. From low pressure to overheating, we’ll provide step-by-step instructions on how to diagnose and fix these problems. We’ll also cover preventative maintenance tips to help extend the life of your air compressor and avoid future issues. This post will provide valuable insights and practical solutions to keep your air compressor running smoothly.

Type Of Air Compressor

- Reciprocating air compressors: also known as piston compressors, these devices use a reciprocating motion of a piston within a cylinder to compress air.

- Rotary screw air Compressors: compressors utilize interlocking helical screws to compress air, providing continuous duty cycles and high efficiency.

- Rotary vane air compressors: characterized by a rotor with blades sliding in and out of slots within a cylindrical chamber; these compressors create compression chambers to trap and compress air.

- Centrifugal air compressors: these compressors employ centrifugal force to accelerate and compress air, featuring a high-speed impeller that draws in air and rapidly spins it.

- Scroll air compressors: equipped with two spiral-shaped scrolls, one fixed and one orbiting, these compressors compress air by gradually decreasing the volume of trapped air pockets.

Tips For How To Troubleshoot Common Air Compressor Issues

Common air compressor issues include low pressure, leaks, excessive noise, and failure to start. To troubleshoot these issues, check for clogs or obstructions in the air filter, inspect the hoses and connections for leaks, and ensure proper oil levels and belt tension. Also, check the electrical connections and pressure switch for proper function. Here are some steps on how to troubleshoot common air compressor issues.

1. The Compressor Fails To Start

If an air compressor fails to start, a few possible causes exist. It could be due to an electrical problem, such as a blown fuse or faulty wiring. A mechanical issue, like a seized motor or broken belts, could also cause it. A lack of proper maintenance could also contribute to the problem.

2. The Compressor Fails To Stop

When an air compressor fails to stop, it can be due to various issues. One common cause is a malfunctioning pressure switch that fails to detect the desired pressure level and keeps the compressor running continuously. Other potential causes include leaks in the system, a faulty unloader valve, or a malfunctioning motor control switch. Diagnosing and addressing the underlying issue is important to prevent further damage to the compressor.

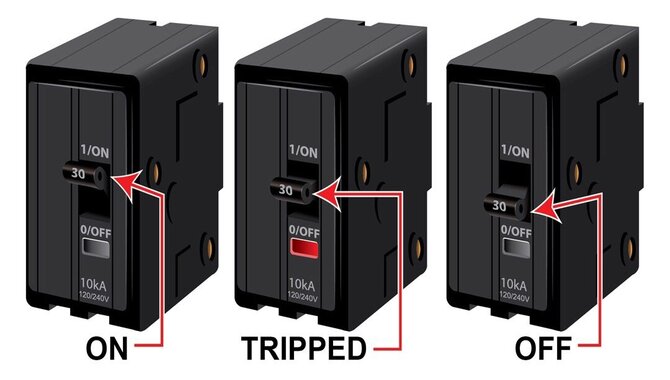

3. Compressor Overloads And Trips Breaker

Air compressor overloads occur when there is excessive current flowing through the motor. This can occur due to low voltage, low oil levels, or clogged air filters. When the overload occurs, the compressor will trip the breaker to prevent damage to the motor. Regular maintenance and proper usage can help prevent overloads and breaker trips.

4. The Compressor Runs But Doesn’t Build Pressure

If your air compressor is running but not building pressure, there could be a number of causes. It could be an issue with the valves, the air filter, or the pressure switch, among other things. Diagnosing and fixing the problem promptly is essential to avoid further damage to the compressor.

5. Air Leaks

Air leaks in an air compressor can cause a drop in pressure, reducing its efficiency and performance. They can also lead to overheating and damage to the compressor’s components. Common causes of leaks include loose connections, damaged hoses, and faulty valves.

Regular inspection and maintenance can prevent leaks and ensure the proper functioning of the compressor. If you detect leaks, you should promptly repair them to avoid further damage and ensure optimal performance.

6. Pressure And Flow Problems

Pressure and flow problems in air compressors can arise due to various reasons. One of the common reasons is a clogged air filter, which can restrict airflow and cause a drop in pressure. Another reason could be a leak in the compressor system, which can cause a drop in pressure and a decrease in flow.

Sometimes, the pressure switch or the pressure relief valve may malfunction, causing pressure problems. Low oil levels or a malfunctioning pump can also result in poor performance. It is essential to regularly maintain the compressor and address any issues promptly to avoid pressure and flow problems.

7. Uncharacteristic Noise And Vibrations

Uncharacteristic noise and vibrations in an air compressor can indicate various issues within the system. Some common causes include loose or damaged belts, worn bearings, faulty motor mounts, or issues with the compressor’s valves or pistons.

It’s essential to address these problems promptly to prevent further damage to the compressor and ensure its efficiency. Regular maintenance and inspections can help prevent these issues from occurring in the first place.

8. The Air Compressor Leaks The Oil

The air compressor can leak oil due to a variety of reasons. One of the most common causes is a faulty oil seal or gasket. In addition, over-filling the oil can cause excessive pressure and lead to leaks. Other causes may include worn piston rings, damaged valves, or a cracked oil pan.

It is important to identify the root cause of the oil leak and address it promptly to prevent further damage to the air compressor. Regular maintenance and inspection can help prevent oil leaks from occurring in the first place.

9. Extremely Hot Emissions

The presence of extremely hot emissions in an air compressor can indicate a problem with the unit. This could occur due to various issues, such as a malfunctioning valve, a clogged air filter, or a faulty thermostat. It is important to address the issue promptly to prevent further damage to the compressor and ensure safe operation.

A professional technician should be consulted to diagnose and repair the problem. Regular maintenance and inspection can also help prevent these types of issues from occurring in the first place.

10. Electrical Motor And Power Problems

Electrical motor and power problems can significantly affect the performance of an air compressor. If the motor is not functioning properly, the compressor may not be able to generate the necessary pressure to operate effectively.

Various issues, such as worn-out bearings, faulty wiring, or a malfunctioning capacitor, can cause this. Power problems such as voltage fluctuations or surges can also impact the compressor’s performance. Regular maintenance and monitoring can help identify and prevent these issues from occurring.

11. Air Filter Clogs

When the air filter in an air compressor becomes clogged, it can cause a number of issues. The compressor may struggle to generate the necessary pressure, leading to decreased performance and longer run times.

In addition, the compressor may overheat, which can cause damage to the unit and potentially create a safety hazard. To avoid these problems, it’s essential to regularly check and clean or replace the air filter as needed. This will help ensure that the compressor operates efficiently and safely.

12. The Compressor Tank Rusts Or Corrodes

The compressor tank in an air compressor may rust or corrode over time. This can be caused by moisture buildup inside the tank, leading to rust formation. Corrosion can also occur if the tank is exposed to harsh environmental conditions.

It is essential to regularly inspect and maintain the tank to prevent rust and corrosion, as they can weaken the tank and increase the risk of a catastrophic failure. If rust or corrosion occurs, replacing the tank is recommended to ensure the air compressor’s safe and reliable operation.

Parts And Repair Needed

Regarding air compressors, various parts may need repair or replacement over time. Some common parts that may require attention include the pump, motor, pressure switch, regulator, and valves. It is essential to regularly inspect and maintain these components to ensure optimal performance and prevent breakdowns.

In addition, if any of these parts fail, it is important to promptly address the issue to minimize downtime and potential damage to the compressor. Overall, staying on top of maintenance and repairs can help extend the lifespan of your air compressor and keep it running smoothly.

When Troubleshooting Doesn’t Work, Contact A Professional

If troubleshooting methods fail to fix an issue with your air compressor, it may be time to contact a professional. Trying to fix the problem yourself could lead to further damage or even injury. A professional will have the expertise and tools to diagnose and repair issues safely and efficiently. Don’t hesitate to seek help if you’re unsure how to proceed with your air compressor.

Conclusion

Knowing how to troubleshoot common air compressor issues is essential for maintaining the functionality and efficiency of the equipment. Understanding the problems that can arise with an air compressor allows individuals to identify and address issues promptly, minimizing downtime and maximizing productivity.

Troubleshooting common air compressor issues involves diagnosing problems such as air leaks, low pressure, abnormal noises, and inadequate airflow. By being familiar with these potential issues and their underlying causes, individuals can take the necessary steps to resolve them, whether it involves replacing worn-out parts, adjusting settings, or conducting routine maintenance.

The importance of troubleshooting common air compressor issues lies in preventing costly repairs, ensuring safe operation, and prolonging the lifespan of the equipment. Specificity in troubleshooting allows for targeted solutions tailored to each unique problem, leading to efficient and effective resolution.

By mastering the art of troubleshooting air compressor issues, individuals can confidently overcome challenges, maintain optimal performance, and maximize their investment.

FAQ’s:

1.Why Is My Air Compressor Producing Oil In The Air Output?

Ans: Check if the oil level is too high or if the oil separator is clogged. Also, inspect the piston rings for wear.

2.Why Is My Air Compressor Producing Moisture In The Air Output?

Ans: Check whether the drain valve is clogged or the air filter is dirty. Also, make sure the compressor is properly lubricated.

3.Why Is My Air Compressor Vibrating Excessively?

Ans: Check whether the compressor is properly levelled or the mounting bolts are loose. Also, inspect the motor and the pulleys.

4.Why Is My Air Compressor Producing A Burning Smell?

Ans: Check if the motor is overheating or if the belt is slipping. Also, inspect the wiring and the electrical connections.

5.Why Is My Air Compressor Tripping The Circuit Breaker?

Ans: Check if the power source is overloaded or if the compressor is drawing too much current. Also, inspect the wiring and the electrical connections.

![7 Best 110V Air Compressor 2022 [Reviews With Buying Guide]](https://accuratepicker.com/wp-content/uploads/2023/05/Best-110V-Air-Compressor.jpg)