The debate between SBC Aluminum Heads and SBC Iron Heads has been going on for years, with no clear winner. Both offer advantages and disadvantages, and ultimately, the choice between the two depends on the individual’s needs and preferences.

In this article, we will explore the differences between SBC Aluminum Heads and SBC Iron Heads, and provide an in-depth analysis of the pros and cons of each. From performance to cost, we’ll provide a comprehensive overview to help you make the best decision for your engine. So, if you’re looking to upgrade your engine, read on to find out which type of SBC head is right for you.

Comparing Sbc Aluminum & Iron Heads

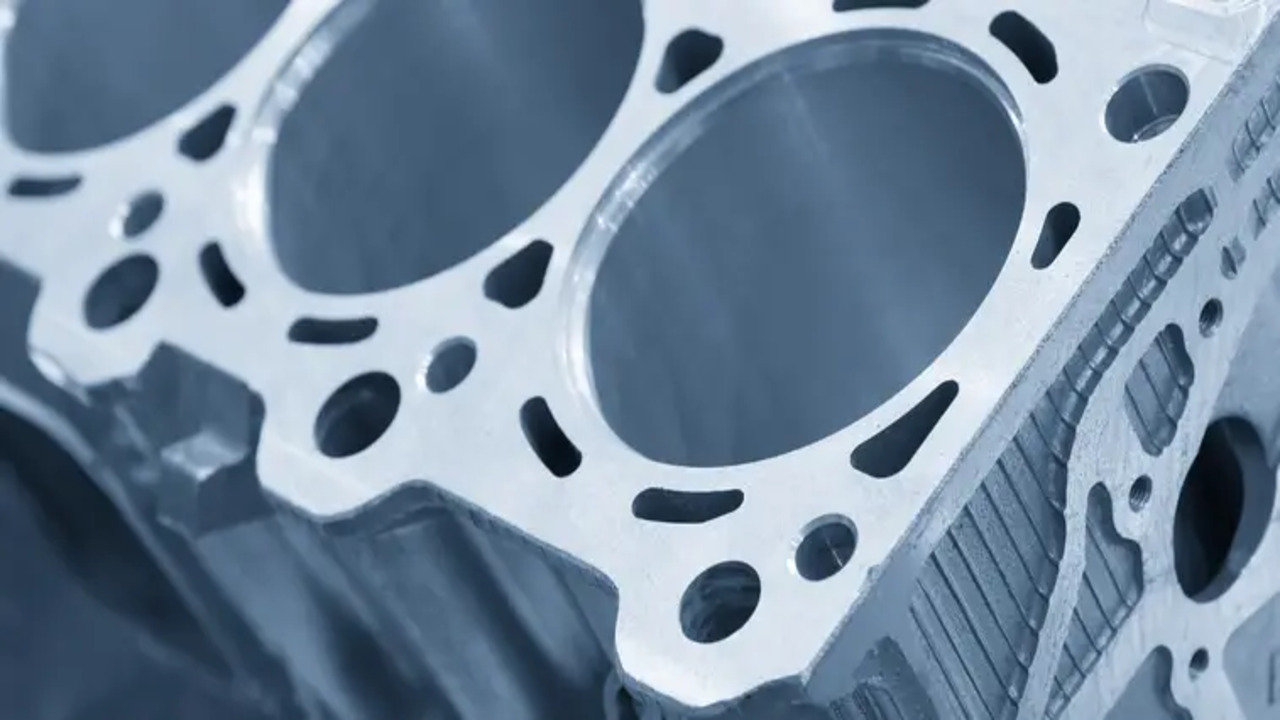

When it comes to choosing the right cylinder head for a Small Block Chevy (SBC) engine, there are two main options – aluminum heads and iron heads. Both have their advantages and disadvantages, and it’s important to understand the differences between them in order to make the best decision for your project.

In this article, we’ll explore the pros and cons of SBC aluminum heads vs. SBC iron heads, and provide some helpful tips on which option is best for your needs.

Advantages Of Aluminum Heads

Aluminum heads are a great upgrade for your small block Chevy engine. They offer several advantages over iron heads, such as improved airflow, lighter weight, and better heat management. Aluminum heads are able to flow more air at lower engine speeds, resulting in better performance and more power.

The lightweight design also reduces strain on the rest of the engine, allowing for better overall performance. The improved heat management of aluminum heads also helps to reduce engine temperatures, extending the life of the engine. Additionally, aluminum heads are more corrosion-resistant than iron heads, which can help protect your engine against the harsh elements.

Lightweight

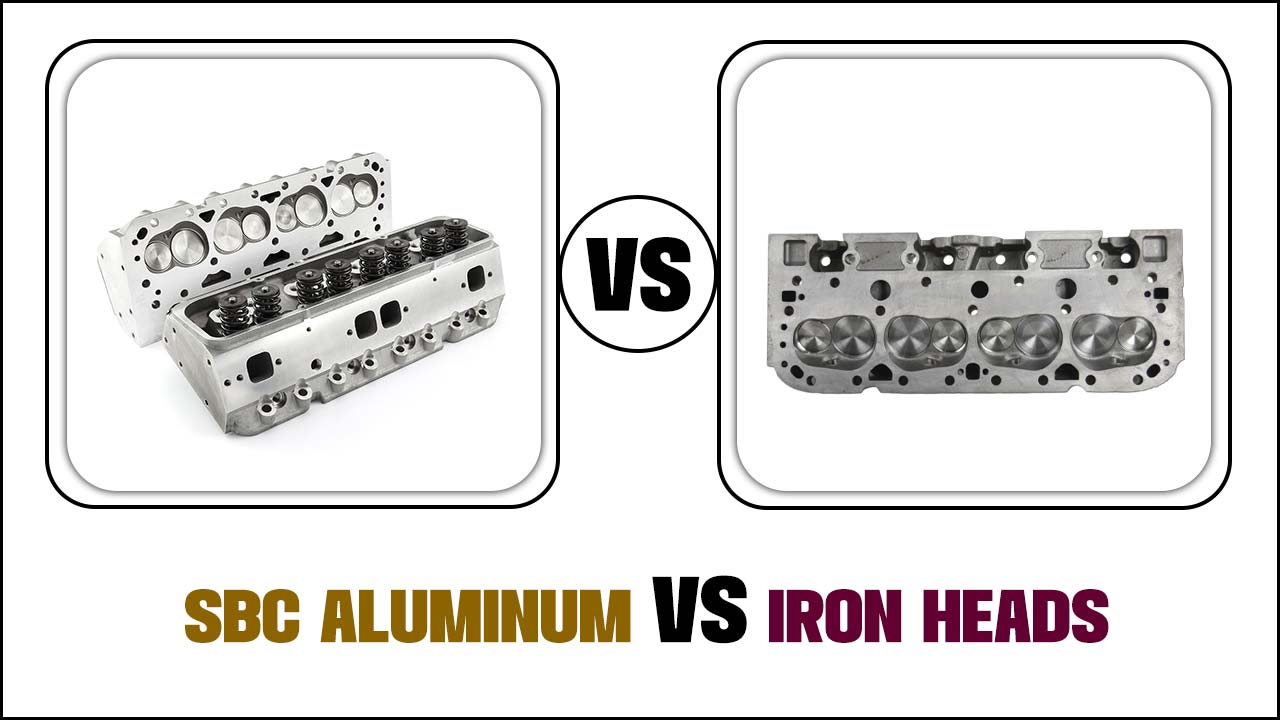

When considering SBC Aluminum Heads vs. SBC Iron Heads, the main difference lies in their weight. Aluminum heads are much lighter than their iron counterparts, weighing in at around 35-40 pounds, as opposed to iron heads which can weigh up to 55 pounds.

This makes aluminum heads a great choice for race cars and other vehicles that need to be as light as possible. The lightweight design can also help reduce wear and tear on the engine, as well as reduce fuel costs.

Additionally, aluminum heads are more durable, with a longer lifespan, so they can be used for longer periods of time without needing to be replaced. Finally, aluminum heads are also generally more affordable than iron heads, making them a great choice for those on a budget.

Better Heat Transfer

When it comes to heat transfer, aluminum heads are superior to iron heads. Aluminum is a better conductor of heat than iron, so it will more efficiently transfer heat away from the combustion chamber and out of the engine. This is especially important in high-performance engines that generate more heat.

Aluminum heads can also be machined more precisely than iron heads, which allows for better air flow and increased performance. Additionally, aluminum heads are lighter than iron heads, which helps reduce overall engine weight and improves performance.

Improved Flow

Aluminum heads are known for their improved flow when compared to iron heads. This improved flow is due to their lightweight construction, more open and larger intake ports, and smaller and more efficient combustion chambers. Aluminum heads also feature improved cooling, which helps to reduce the operating temperature of the engine.

The improved flow of the aluminum heads helps to provide more power and torque for a given displacement. Additionally, the improved flow also helps to reduce emissions and improve fuel efficiency. The improved flow of the aluminum heads helps to create an engine that is more efficient and powerful than an iron head engine.

Higher Compression

SBC Aluminum Heads offer higher compression ratios than SBC Iron Heads due to the differences in material. Aluminum is naturally more compressible than iron, allowing more air and fuel to be compressed into the combustion chamber.

This results in higher cylinder pressure and a more efficient engine. Additionally, aluminum heads are far lighter than iron heads, making them a great choice for race engines.

They also dissipate heat much faster than iron heads, helping to reduce engine temperatures. However, aluminum heads are more expensive and require more maintenance than iron heads. If you’re looking for a higher compression ratio, the performance benefits of aluminum heads may outweigh the cost and maintenance.

Disadvantages Of Aluminum Heads

Aluminum heads for small-block Chevys have some disadvantages when compared to iron heads. For one, they are more expensive than iron heads, and this cost can add up when you consider the additional costs of aftermarket parts and labor. Aluminum heads are also more fragile than iron heads, and the possibility of damage during installation or use is higher.

They also tend to require more frequent maintenance and tuning than iron heads, and the performance gains they offer can be hard to quantify. Finally, aluminum heads are often more difficult to find than iron heads, and it may be harder to find the right aftermarket parts to fit them.

Expensive

When it comes to SBC aluminum heads versus SBC iron heads, the former is generally more expensive. This is mainly due to the cost of the material used and the extra machining required for the aluminum. The aluminum heads require special inserts to be installed, which adds to the cost of the part.

Additionally, machining and other labor costs associated with the aluminum heads are higher than for the iron heads. As a result, the cost of SBC aluminum heads typically runs much higher than the cost of the SBC iron heads.

Easily Damaged

When it comes to durability, aluminum heads are much more easily damaged than iron heads. Aluminum is generally softer than iron, which makes it more prone to cracking and warping with the high temperatures and pressures that come with engine operation. Iron, on the other hand, is much more durable and able to withstand greater temperatures and pressures.

It is also much more resistant to corrosion and rusting. While aluminum heads require more frequent maintenance to prevent corrosion, iron heads are much less likely to need additional maintenance. Additionally, aluminum heads can be more difficult to repair if they are damaged due to their softer nature. Iron heads, however, are much easier to repair and can be welded and machined much more easily.

Require Special Gaskets

When it comes to SBC aluminum heads versus SBC iron heads, one major difference is that aluminum heads require special gaskets. These gaskets are designed to provide an improved seal between the head and the block, reducing the risk of oil or coolant leaks.

Additionally, the gaskets help reduce heat transfer from the cylinder head to the cylinder block. This is important because aluminum dissipates heat more quickly than iron, and having too much heat in the block can lead to premature engine failure.

Finally, special gaskets are needed to help ensure a proper fit between the head and the block. Without the proper gasket, the head may not fit correctly, leading to other issues. In conclusion, when using SBC aluminum heads, special gaskets are needed to ensure a correct fit, reduce the risk of leaks, and reduce heat transfer.

Specialized Machining

For many performance auto enthusiasts, the choice of SBC aluminum heads versus SBC iron heads can make a significant difference in the performance of their engine. Specialized machining is a key factor in the decision-making process. Aluminum heads are much lighter than iron heads, allowing for better engine performance and fuel economy.

Additionally, aluminum heads can be machined to a much finer tolerance, allowing for improved combustion efficiency and increased horsepower. On the other hand, iron heads are much stronger and more durable than aluminum heads and can withstand higher operating temperatures.

Iron heads also provide better heat dissipation which can help reduce the risk of engine damage due to overheating. Ultimately, the choice between SBC aluminum heads and SBC iron heads comes down to the application and individual preference.

Depending on the application, one head may be preferable over the other. Specialized machining is essential to ensure the best performance and the longevity of both aluminum and iron heads.

Conclusion

SBC aluminum heads are often chosen for their lightweight and increased airflow compared to SBC iron heads. Aluminum heads can provide more power, but they are also more expensive and require more maintenance.

Iron heads are more affordable and require less maintenance, but they are heavier and provide less airflow. Ultimately, the decision between SBC aluminum heads and SBC iron heads comes down to personal preference and the desired performance outcome.

FAQ’s

1.Are Iron Or Aluminum Heads Better?

Ans: It depends on the application. Aluminum heads are usually lighter and have a higher thermal conductivity than iron heads, so they are often preferable for racing engines. Iron heads are typically more durable and better able to withstand extreme temperatures, so they are often preferred in heavy-duty applications. Ultimately, the best choice depends on the specific engine and its intended use.

2.What Are The Advantages Of A Cast Iron Cylinder Head?

Ans: The advantages of a cast iron cylinder head include its durability, heat retention, and strength. It is also resistant to cracking and wear and tear, meaning it will last for a long time. Additionally, it is relatively easy and inexpensive to manufacture compared to other materials. Finally, it can be machined with precision to allow for a greater degree of customization.

3.Which Material Is Used For Cylinder Head?

Ans: The material used for cylinder heads varies depending on the application. Generally, aluminum is used for lightweight and cost-effective solutions, while cast iron is used for heavier-duty applications that require more strength. For higher-performance applications, materials such as titanium and stainless steel alloy are sometimes used. Specialty materials such as ceramics and nickel-iron alloys may also be used in very specific applications.

4.Are Iron Heads Better Than Aluminum Heads?

Ans: The answer to this question depends on the application. Generally, iron heads are heavier than aluminum heads, making them better for durability and strength. However, aluminum heads provide better heat dissipation, making them an ideal choice for high performance engines. Ultimately, the best choice will depend on the intended use and desired outcomes.

5.What Is The Best Material For Cylinder Heads?

Ans: The best material for cylinder heads depends on the specific application and budget. Aluminum alloy is the most common material and is lightweight, strong, and relatively inexpensive. Cast iron is heavier but more durable and can withstand higher temperatures. For high performance applications, exotic materials such as titanium and beryllium copper may be used.

6.How Much Does A Sbc Weight With Aluminum Heads?

Ans: The weight of a small block chevy engine with aluminum heads will depend on the specific model and size of the engine. Generally speaking, a 350 cubic inch engine with aluminum heads will weigh about 500lbs. However, the weight can vary depending on the components and accessories that come with the engine. Additionally, the weight can be affected by the type of oil pan and intake manifold that is used.