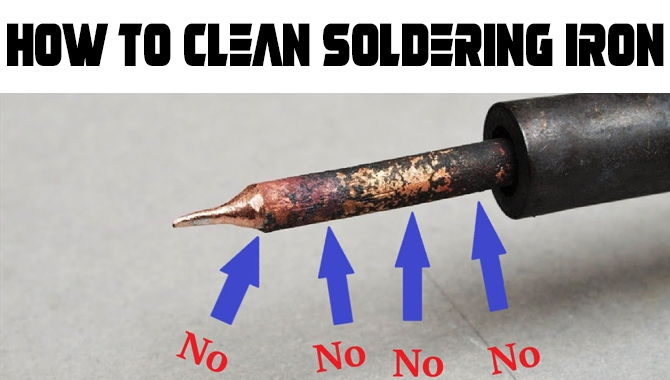

While soldering, many problems can arise, especially because of the tip of the soldering iron. There is a prior chance of the tip getting rust when it is not maintained correctly.

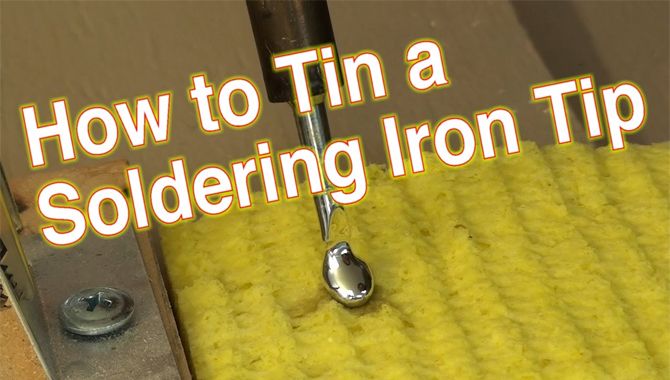

Then what to do? How to prevent these problems? Well, tinning the soldering iron is the only solution. When we say tinning soldering iron, it actually means “tinning the tip.” Well, tinning the tip is a priority as it can solve more than half of the problems. So, how to tin a soldering iron?

Soldering is the process of connecting electrical wires or connectors by using Solder. And for soldering, soldering iron is needed. Soldering iron gives proper heat to melt the Solder.

After soldering, one should take care of the soldering iron. Otherwise, it will not work. Especially if it’s rusted, it’s useless. There is more to know before learning the tinning process. Here we are giving you a short glimpse of what you must know.

Let’s take a look!

Soldering Iron

Soldering iron provides heat to melt the Solder on the joints. its provides high heat. That’s why, when soldering, one should be very careful. Otherwise, the heat can burn the skin.

It can heat up to 700c. You can even use a soldering station. It has a better benefit as the heat is adjustable. Though sometimes, it is not able to provide sufficient heat. So, check the heat when working.

If you are working on a big project, a soldering station is a must.

Soldering Tips

It means the tip of the soldering iron. Also, it is the most important part of soldering iron, and it transfers heat to Solder. By melting the Solder, it connects the joints.

The tip is made up of copper with an iron layer on top. That’s why it gets oxidized easily.

There are varieties of soldering tips available in the market, and the varieties depend on the shape. But the most commonly used tips are conical tips and chisel tips.

The tips are changeable yet not cheap.

Why Tinning?

Suppose you are preparing for soldering. Getting out the soldering iron from the box.

But, the soldering iron is not working. Actually, the tip is oxidized. Should you change the tip? Even though you do, you might regret not using the soldering iron at least once.

If you leave the soldering iron carelessly after using it, it will again get rusted. Do you want to use it for one time?

Such a waste, right?

When the tip oxidizes, it reduces the transfer of heat. As a result, the Solder will not melt. And the whole soldering process will go in vain.

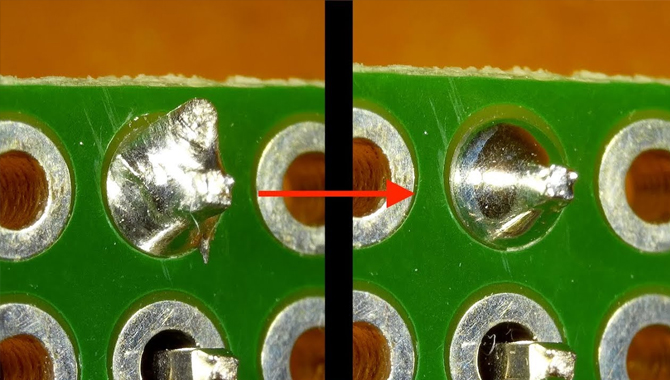

That’s why tinning is necessary. Here, the tip is covered with a layer of Solder, making heat conductivity easier. Also, prevent the tip from getting rust.

As now you know why tinning is necessary, you may want to know the process. Let’s quench your curiosity.

How To Tin A Soldering Iron?

As tinning is necessary, why not doing it fast? After tinning, you will get better benefits. If tinning doesn’t work, change the tip.

Tinning is an easy process. You just need to put a layer of Solder in proper steps. For doing this, you may need:

- Solder

- Sandpaper

- Sponge.

After getting all these, you should proceed. Here’s the procedure:

- The first thing you have to do is cleaning the tip.

- If it’s a new soldering iron, you can wipe the tip with Sponge. You can wipe it with water, but we will not recommend it. Instead, use cleaner.

- Then, heat the soldering iron nearly at 39 c. After heating it, apply a thin layer of the Solder on the tip. Do not touch it with bare hands.

- Wait till the Solder melts. That’s how you can tin your new soldering iron. It will make your soldering iron long-lasting.

- Same goes for the old soldering iron but in a different way.

Old soldering iron may have flux stick to it. You have to clean it before tinning, and the easiest way is to dab it on a wet sponge. Use a cleaner for that.

The main motive is to remove old flux or Solder. You can also remove oxidized parts. Rub Sandpaper on the tip to sharpen it. Sharp till it gives you a shiny look. Then heat the tip and apply the Solder.

Dry it properly. You can also use resin. For that, use resin-layered cardboard. And move the tip (after applying Solder) on that unless it gives a shiny finish.

Lastly, clean it again. Most likely, wipe the tip.

Now you have done tinning the soldering iron. It will not just last longer and will also increase conductivity.

Sharpening the tip may go wrong sometimes. It can damage the tip too. So, do it carefully.

After tinning the soldering iron, you will see half of your soldering problems are gone. The Solder will melt easily; heat will conduct properly.

And the process will go smoothly.

FAQ’s

1.Is It Necessary To Tin A New Soldering Iron?

Ans: Of course, it is necessary as tinning will increase heat conductivity. Not just that, it will prevent rusting.

There is a high chance of the tip getting oxidized. It also happens to the new soldering iron. So, it’s always better to tin it.

2.Should I use Rosin?

Ans: If you want to, you can. But some tips may get damaged as well. Those tips don’t go along with rosin.

Instead, use flux containing Solder. It will give better prevention and easy to use.

3.Can I Use Several Layers of Solder for Tinning?

Ans: Do not. Tinning means applying a thin layer of Solder on the top of the tip. You are not supposed to use several layers.

A thin layer increases conductivity while several layers will reduce it. So, do not try it. It will not give better protection.

4.Will it Work if I Tin the Tip for only Once?’

Ans: Actually, you need to re-tin it after using it. After using soldering iron, some solder and flux may still stick on the tip. Removal of the extra Solder and flux is necessary as these can also cause rusting. I hope now you know how to tin a soldering iron.

So, clean it and tin it.

Final Remarks

Oxidation is the major problem of soldering iron. Though it is bound to happen, you should tin the Solder. Otherwise, it will not last long at all.

Even if it gets oxidized, one can sharpen it to remove that part. So, don’t worry about that. Remember, all the tips are not the same. Some may oxidize faster. So, tinning is important.

Finally, do not put away soldering iron after working. Dry it and clean it. Also, re-tin it. Now quickly tin your soldering iron to get the best result.