Are you planning on upgrading or repairing your engine? We give you How to Install SBC Head. One of the most important components to consider is the cylinder head.

The cylinder head is responsible for housing the valves and spark plugs that ignite the fuel and air mixture, making it a critical part of the combustion process. If you’re a DIY mechanic, installing a new or rebuilt cylinder head can be challenging but rewarding.

This blog post focuses on installing a Small Block Chevy (SBC) cylinder head. The SBC is a popular engine among car enthusiasts due to its affordability, availability, and versatility.

Installing a new SBC cylinder head can improve engine performance, increase horsepower, and enhance overall efficiency. However, it’s important to note that the installation process requires careful attention to detail and precision.

In this blog post, we’ll walk you through the steps of installing a new SBC cylinder head, from removing the old head to the final torquing of the bolts. We’ll cover the tools you’ll need

Choosing The Right Size And Shape

As a designer or architect, one of the most important decisions you’ll make in the planning stages of a project is choosing the right size and shape. The size and shape of a building or space can significantly impact its functionality, aesthetic appeal, and overall success.

From residential homes to commercial buildings, there are many factors to consider when determining the appropriate size and shape for your project. In this blog post, we’ll discuss the key considerations to consider when making this crucial decision. The first factor to consider is the purpose of the building or space.

Are you designing a home for a family of four or an office for a team 50? The size and shape will be very different depending on the answer. You’ll also need to consider the available space and how it will be used.

For example, a narrow lot may require a different shape than a wide lot. The location of the building or space can also impact the size and shape, as local building codes and regulations may limit

Understanding The Basics Of Cylinder Heads

Cylinder heads are a vital component of a combustion engine and play a crucial role in the efficient functioning of the engine. While many people may know the importance of cylinder heads, understanding these components’ intricacies can help maintain and repair engines better.

In this blog post, we will dive deep into the basics of cylinder heads, examining their function, construction, and maintenance. We will cover the different types of cylinder heads, their materials, and the importance of proper installation and maintenance.

Additionally, we will explore the common issues that can arise with cylinder heads and how to diagnose and repair them.

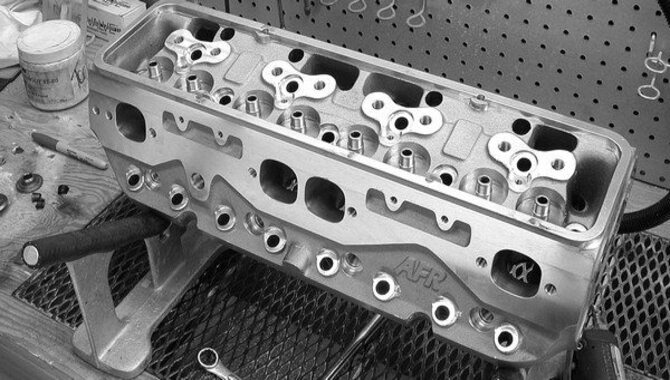

Types Of SBC Heads: OEM Vs. Performance

When it comes to small block Chevy (SBC) engines, there are two types of cylinder heads: OEM and performance. OEM heads are the heads that come standard on a factory-built SBC engine from General Motors. These heads are designed to meet certain specifications for durability, emissions, and fuel economy.

On the other hand, performance heads are designed and built to increase the power output of an SBC engine. They are typically lighter, have larger valves, and have better flow characteristics than OEM heads. Performance heads come in various designs, each with its own benefits and drawbacks.

Some popular options include aluminum heads, which are lighter and dissipate heat better than cast iron heads, and angle plug heads, which allow for better spark plug placement and increased horsepower.

Ported heads are another option, which involves modifying the intake and exhaust ports for better flow. While performance heads can significantly increase the power output of an SBC engine, they may not be the best option for everyone.

How To Install SBC Head – Step By Step

If you’re looking to install an SBC head on your engine, it’s important to take the process step by step to ensure a successful outcome. We give you How to install the SBC head step by step. The first step is to remove the old head from your engine, including all bolts and gaskets.

Next, you’ll want to thoroughly clean the engine block surface to ensure proper sealing of the new head. Once the surface is clean, it’s time to apply a layer of sealant to the engine block surface, using a gasket or sealant as necessary. With the sealant in place, it’s time to carefully position the new SBC head onto the engine block, lining up any bolt holes or other connections.

Next, you’ll want to carefully torque down all bolts, tightening them in a specific sequence to ensure even pressure and a secure fit. It’s important to follow the manufacturer’s instructions for torque settings, as these will vary depending on the specific head and engine.

Common Mistakes To Avoid When Choosing SBC Heads

When it comes to upgrading your Small Block Chevy engine, choosing the right cylinder heads is crucial. However, there are a few common mistakes that many people make when selecting SBC heads. The first mistake is not considering the engine’s camshaft and overall performance goals.

Different camshafts require different types of heads to achieve the desired performance. Secondly, not matching the heads to the engine’s compression ratio can lead to poor performance and even engine damage. It’s important to choose heads with the correct combustion chamber size to match the engine’s compression ratio.

Another common mistake is not paying attention to the valve size and its compatibility with the engine’s bore size. Mismatched valve and bore sizes can lead to poor airflow and reduced performance. Lastly, some people overlook the importance of head material and quality.

Choosing heads from inferior materials can lead to poor durability and potential engine failure. You can achieve maximum performance by avoiding these common mistakes and carefully selecting the right SBC heads for your engine.

Installation And Tuning Tips

When it comes to installing and tuning software or hardware, there are a few tips that can help ensure a smooth and successful process. Firstly, it’s important to carefully read the installation instructions and follow them step by step.

Skipping a step or installing components incorrectly can cause issues down the line. Additionally, it’s a good idea to check for any updates or patches that may be available before starting the installation. This can ensure that the software or hardware is up-to-date and free of known issues.

Another important tip is to allocate enough time for the installation and tuning process. Rushing through the process can lead to mistakes and oversights, which can cause problems later on. It’s also a good idea to have a plan in place for troubleshooting any issues that may arise, such as having a support team or resources available.

How To Install Small Block Chevy Heads

Installing small block Chevy heads on your engine can be daunting, but with the right tools and knowledge, it can be done with ease. The first step is to ensure that the engine block is clean and free of any debris. Once that is done, place the head gasket onto the block and make sure it is aligned correctly.

It is important to torque the head bolts in the right sequence and to the proper specifications. This will prevent leaks and ensure the heads are securely fastened to the block.

When installing the heads, it is essential to make sure that the pushrods are in their correct locations. The rocker arms should be tightened to the correct torque specifications as well. After the heads have been installed, check the valve clearance to ensure that everything is functioning correctly.

Head Bolt Torque Specifications

Regarding engine assembly, one crucial aspect that cannot be overlooked is the head bolt torque specifications. These specifications provide the exact amount of torque that should be applied to the head bolts to ensure that the cylinder head is securely fastened to the engine block.

Failure to adhere to these specifications could lead to several issues, including blown head gaskets, oil leaks, and engine failure. The torque specifications may vary depending on the engine’s make and model and the cylinder head and head gasket materials used.

It is crucial to use a torque wrench when tightening head bolts to ensure that the recommended torque specifications are met accurately. Over-tightening the bolts could cause them to stretch or even break, while under-tightening them could result in insufficient clamping force, leading to leaks and other issues.

Therefore, it is vital to take the time to research and follow the manufacturer’s specifications and, if necessary, invest in a good quality torque wrench to ensure that the engine is assembled.

Cylinder Head Bolt Torque Specifications

Regarding engine assembly, one of the most important aspects to consider is the cylinder head bolt torque specifications. These specifications provide the guidelines for tightening the bolts that hold the cylinder head in place and ensure proper engine compression and combustion.

The torque specifications vary depending on the make and model of the engine, as well as the type of cylinder head and bolts being used. It is crucial to follow these specifications precisely to avoid damaging the engine or causing it to fail.

It is important to consult the manufacturer’s guidelines or a trusted mechanic to determine the correct cylinder head bolt torque specifications for a particular engine. In general.

The specifications include information on the amount of torque to apply to each bolt and the sequence in which the bolts should be tightened. Following the correct sequence is important to ensure even pressure distribution and prevent warping or cracking of the cylinder head.

The Importance Of Choosing The Right SBC Heads

When it comes to building a high-performance small-block Chevy engine, selecting the right cylinder heads is essential. The cylinder heads are one of the most critical components of an engine, as they are responsible for controlling the airflow into and out of the engine.

Choosing the right SBC heads can mean the difference between an engine that performs to its full potential and one that falls short. The right cylinder heads can improve power, torque, and overall engine performance. Your selection should be based on several factors, including the engine’s intended use, budget constraints, and the desired power output.

Numerous options are available, from stock replacement heads to performance heads with advanced features such as larger valves, better airflow, and improved combustion chambers. It’s important to do your research and choose a set of heads that are compatible with your engine’s camshaft, intake manifold, and exhaust system.

Conclusion:

How to Install SBC Heads is a crucial process that requires careful attention to detail and a thorough understanding of the engine’s components. This comprehensive guideline has provided step-by-step instructions on installing SBC heads, including the necessary tools, torque specifications, and safety precautions.

It is important to follow these guidelines closely to ensure the proper operation and longevity of the engine. By adhering to these guidelines and taking the necessary precautions, one can successfully install SBC heads and achieve optimal performance from their engine.

FAQ:

1.What Tools Are Necessary For Installing SBC Heads?

Ans: Some necessary tools for installing SBC (Small Block Chevy) heads include a torque wrench, a head gasket scraper, a socket set, a torque angle gauge, a valve spring compressor, a set of feeler gauges, and a dial indicator.

2.What Are The Steps For Removing Old SBC Heads And Installing New Ones?

Ans: Drain the coolant from the engine and remove the radiator hoses. Remove the carburetor, intake manifold, and exhaust manifolds or headers. Delete the rocker arms, pushrods, and lifters. Remove the head bolts and lift off the old heads. Clean the engine block surface and inspect for any cracks or damage.

3.How Do You Properly Torque The Head Bolts On SBC Heads?

Ans: Clean the threads and bolt holes thoroughly with a suitable cleaning solution. Lubricate the threads and washers with engine oil. Tighten all bolts to 25 ft-lbs. Fix all bolts to 50 ft-lbs. Fix all bolts to 70 ft-lbs

4.What Are Some Common Mistakes To Avoid When Installing SBC Heads?

Ans: Clean the threads and bolt holes thoroughly with a suitable cleaning solution. Lubricate the threads and washers with engine oil. Tighten all bolts to 25 ft-lbs. Fix all bolts to 50 ft-lbs. Tighten all bolts to 70 ft-lbs. Tighten all bolts to the final torque of 80-85 ft-lbs in the sequence provided by the manufacturer.

5.How Do I Properly Break In My SBC Heads After Installation?

Ans: Fill the oil filter with engine oil and install a new oil filter. Check the oil level and ensure that it is at the proper level. Prime the engine oil system by using an engine oil priming tool to circulate oil through the engine before starting it. Start the engine and let it idle for 20-30 minutes.

![5 Best Flowing 23 Degree SBC Head [Reviews With Buying Guide]](https://accuratepicker.com/wp-content/uploads/2022/03/Best-Flowing-23-Degree-SBC-Head.jpg)

![How To Choose Patriot SBC Heads? [The Definitive Guide]](https://accuratepicker.com/wp-content/uploads/2022/03/Patriot-SBC-heads.jpg)