Soldering is a process of joining two metals by melting a filler metal onto the joint. Here are a few steps on How to solder without soldering fume extractor. While soldering is an essential technique in various industries, it poses a risk of exposure to harmful fumes that may cause health hazards.

Therefore, a soldering fume extractor is a vital equipment that helps reduce the risk of inhaling these harmful fumes. However, not everyone has access to or can afford a soldering fume extractor. In such cases, learning how to solder without a fume extractor is essential to stay safe.

This blog post will provide you with tips and tricks on how to solder without a fume extractor. We will discuss the risks of inhaling soldering fumes and the importance of safety measures. We will also explore alternative ways to minimize the risks of exposure to harmful fumes by using simple tools and techniques. Our step-by-step guide will walk you through the process of soldering safely without a fume extractor.

What Is Soldering Fume

Soldering is a common process use in electronics and electrical work. It involves joining two metal components together using a filler metal called solder. However, this process can produce a dangerous byproduct known as soldering fumes.

Soldering fumes contain a mixture of harmful chemicals such as lead, cadmium, and zinc that can pose a serious risk to the health of those working in the vicinity. Exposure to these fumes can cause various health problems, including respiratory issues, nervous system damage, and even cancer.

Therefore, taking precautions to minimize exposure to soldering fumes is crucial. Using a soldering fume extractor is one way to reduce the risk of exposure to these harmful fumes. These extractors capture and filter the fumes before workers inhale them. In addition, proper ventilation and the use of personal protective equipment such as respirators and gloves can also help to minimize exposure to soldering fumes.

What I Need To Solder Without A Soldering Fume Extractor

Soldering is a common technique use in electronics to join components together. However, without proper safety measures, it can also be hazardous to your health. One of the main concerns when soldering is the release of fumes that could be harmful if inhaled.

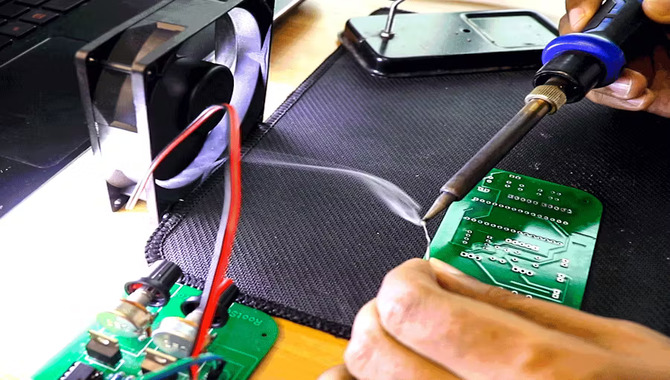

While a soldering fume extractor is highly recommend. There are ways to solder without one. Firstly, it is essential to work in a well-ventilated area. Keep windows and doors open to allow fresh air to circulate.

Secondly, use a fan or a fume absorber to direct the fumes away from your face. You can also position yourself at an angle to the fumes. Wear a mask or respirator to prevent inhaling any harmful particles. Another tip is to use a low-temperature soldering iron to minimize the amount of fumes released. Keeping the workspace clean and free from any clutter or debris that could interfere with the soldering process is also essential.

How To Solder Without Soldering Fume Extractor: Step By Step

Soldering is a popular technique to join two or more metal pieces together. How to solder without soldering fume extractor We are giving you some techniques step by step. The soldering process generates fumes that can harm human health.

To avoid this, several methods exist to solder without a soldering fume extractor. The first step is to ensure that the workspace is well-ventilate. This is achieve by opening windows or using a fan to blow the fumes away. The next step is to use a low-temperature soldering iron.

This will help to reduce the amount of fumes generated during the soldering process. Another option is to use a water-soluble flux, which can be easily cleaned up with water, instead of using a more toxic flux.

When soldering, avoiding inhaling the fumes by holding your breath or wearing a mask is also important. Finally, cleaning up any excess flux or solder using a damp cloth or sponge after soldering is important.

When it comes to soldering, using a fume extractor is generally recommended to protect yourself from potentially harmful fumes. However, if you don’t have access to a soldering fume extractor, there are still steps you can take to minimize your exposure to fumes. Here is a step-by-step guide on how to solder without a soldering fume extractor:

1. Choose a well-ventilated area: When soldering, make sure you are in a room with good airflow. Open windows or use fans to help circulate the air and carry away any fumes.

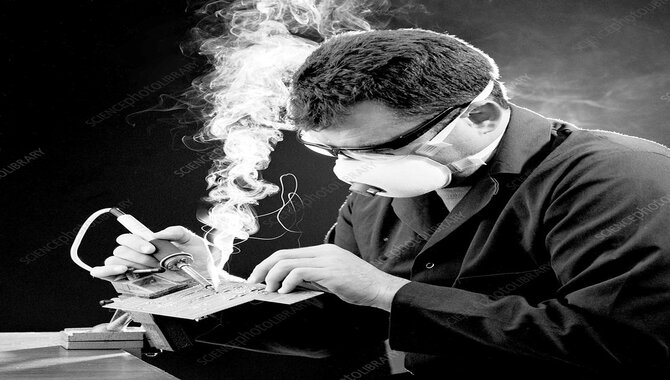

2. Wear appropriate protective gear: It’s important to protect yourself when soldering without a fume extractor. Wear safety glasses to shield your eyes from any splattering solder and consider wearing a mask or respirator to filter out some of the fumes.

3. Use lead-free solder: Lead-free solder produces fewer toxic fumes compared to lead-based solder. Opt for lead-free options whenever possible to reduce your exposure.

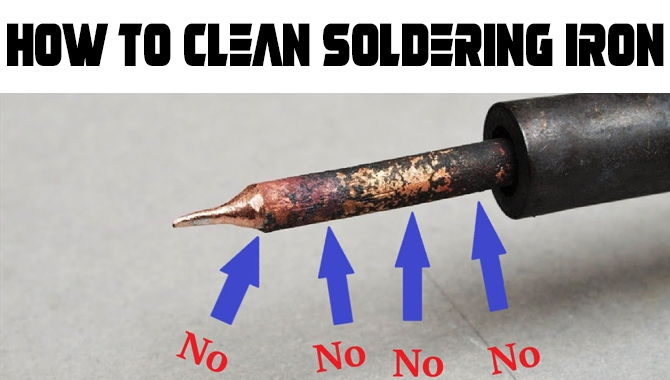

4. Keep your work area clean: Clean up any excess flux and residue as you work. This can help minimize the amount of smoke and fumes produced during the soldering process.

5. Take breaks: If you’re doing an extended soldering session, take regular breaks to get some fresh air and allow any lingering fumes to dissipate.

While using a soldering fume extractor is ideal, following these steps can help mitigate some of the risks associated with soldering without one. Remember, safety should always be a priority when working with any potentially hazardous materials or processes.

What Is The Best Soldering Fume Extractor?

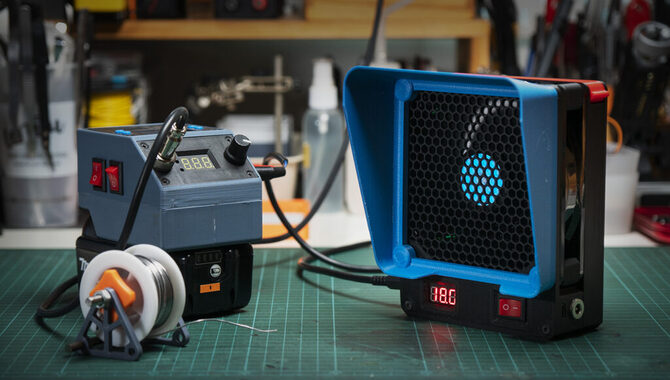

Soldering is common in many industries, but it comes with health risks due to its toxic fumes. Using a soldering fume extractor is necessary to protect yourself from these hazardous fumes. But what is the best soldering fume extractor?

Finding the right extractor can be challenging because it depends on the type of soldering work you do. If you work in a small space like a garage or a workshop, you can consider the Hakko FA400-04. This extractor has a compact design, quiet operation, and can be mounted on a bench.

If you work in a larger space and need a more powerful extractor, the Weller WSA350 is a good option. It has a three-stage filtration system, a powerful fan, and a high-quality activated carbon filter that can last up to six months. Another good option is the Aoyue 486 Benchtop Solder Smoke Absorber, which has a large filter area and a

Do Fume Extractors Work For Soldering?

When it comes to soldering, safety is always a top priority. Many soldering processes involve using flux and other chemicals that produce fumes, which can be harmful if inhaled. This is where fume extractors come in. But do fume extractors really work for soldering? The answer is yes. Fume extractors are designed to capture and remove harmful fumes and particles generated during the soldering process, making the air in your workspace cleaner and safer to breathe.

They work by drawing the fumes and particles away from the soldering area and filtering them through a series of filters before releasing the clean air back into the environment. However, it’s important to note that not all fume extractors are created equal.

The effectiveness of a fume extractor depends on its design, airflow rate, and the type of filter used. For the best results, it’s recommended to use a fume extractor specifically designed for soldering applications.

Why Your Need A Soldering Fume Extractor

If you love to tinker with electronics or are a professional in the field, you know how important it is to have a good soldering fume extractor. Soldering is a process that involves melting a metal alloy to join two pieces of metal together, and this process releases harmful fumes that can be hazardous to your health. Inhaling these fumes can cause headaches, dizziness, and in some cases, long-term respiratory problems.

That’s why having a soldering fume extractor in your workshop is crucial. A soldering fume extractor is a device that captures the fumes released during the soldering process and filters them out, making the air in your workshop safer to breathe. It’s essential for anyone who wants to protect themselves from the harmful effects of soldering fumes.

Tips On How To Solder Safely

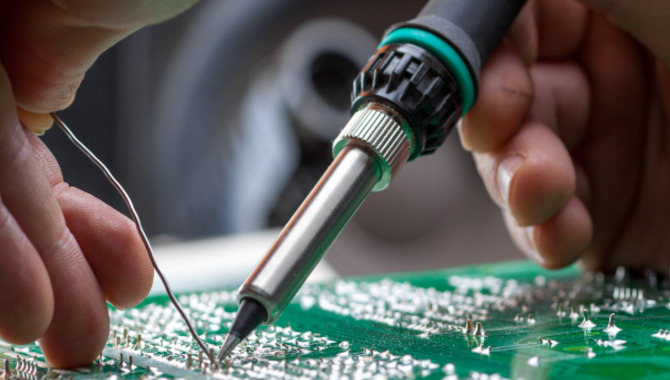

Soldering is a common task in electrical and electronic work that involves joining two or more pieces of metal or wires by melting and flowing a filler metal into the joint. However, soldering can be hazardous if not done safely. Therefore, the following two tips on how to solder safely are essential.

Why Use A Soldering Iron

Soldering is essential for anyone who wants to work with electronics or metalworking. A soldering iron is a tool that can be used for various tasks, from repairing broken wires to creating intricate designs in metalwork. So, why use a soldering iron?

Firstly, a soldering iron provides a strong, permanent bond between two pieces of metal, which is important for creating durable electrical connections. This is especially important when working with delicate components that require a steady, reliable flow of electricity. Secondly, a soldering iron allows for precision work that cannot be achieved with other tools.

The small tip of a soldering iron can be used to create intricate designs, repair small components, or even create custom jewellery. Finally, using a soldering iron is a cost-effective solution for repairing or modifying electronics. Rather than replacing an entire circuit board or device, a soldering iron can be used to repair or replace individual components, saving time and money

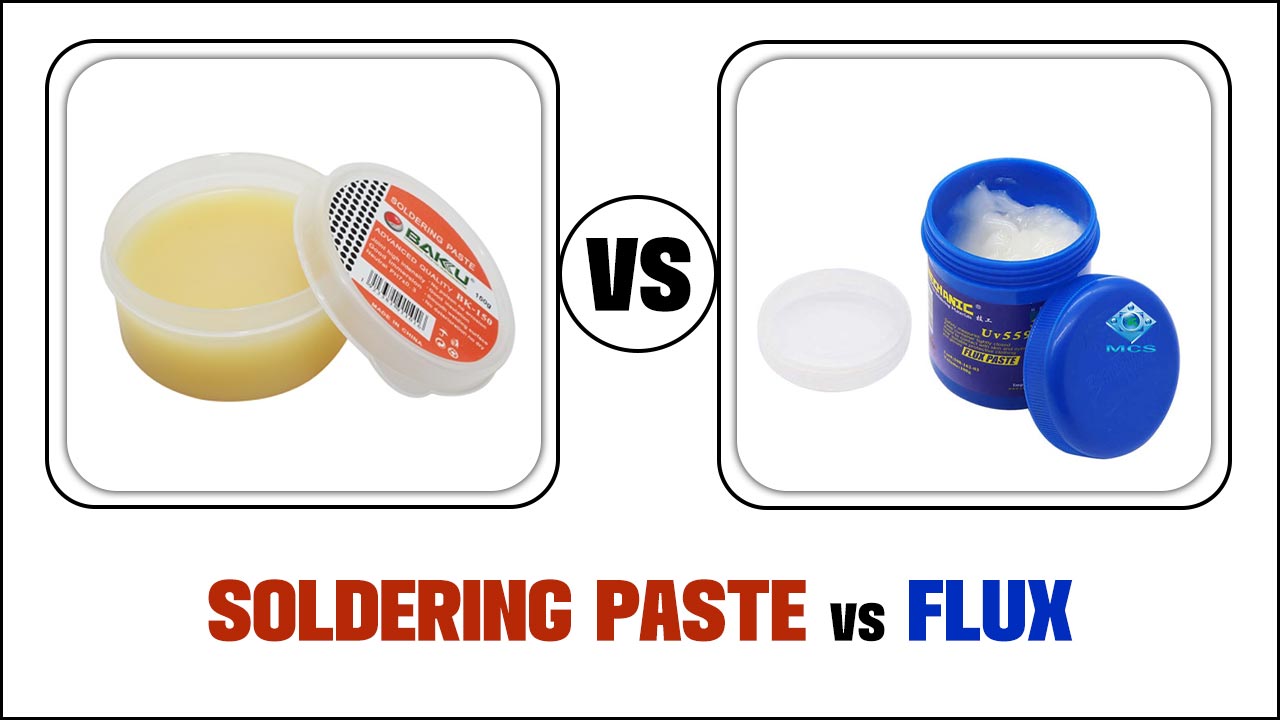

Dealing With Solder, Flux, And Cleaners

Dealing with solder can be tricky, especially when it comes to ensuring a strong and reliable joint. One key element in achieving a successful solder joint is using flux. Flux helps clean the metal’s surface, removing any oxides or impurities that may hinder the solder from bonding properly.

It also helps to prevent oxidation during the soldering process, which can lead to a weak joint. However, cleaning the joint after soldering is important to remove any excess flux residue properly. This is where cleaners come into play.

There are various types of cleaners available, including solvent-based and water-based options. Solvent-based cleaners effectively remove stubborn flux residue but should be used cautiously as they can be flammable and emit harmful fumes.

Water-based cleaners are a safer option but may require more time and effort to clean the joint properly. Ultimately, the key to successfully dealing with solder, flux, and cleaners is to follow proper safety protocols.

What Type Of Liquid Solder Works Best For Electrical Soldering

When it comes to electrical soldering, choosing the right type of liquid solder is crucial to ensure a strong and reliable bond. Several options are available in the market, including lead-based, lead-free, and silver-based liquid solder.

Each type has its own set of advantages and disadvantages, and selecting the best one depends on various factors, such as the type of metal being soldered, the required strength of the bond, and the application environment.

Lead-based liquid solder is the traditional choice for most electrical soldering applications. It is easy to work with and provides a strong bond, but it has been associated with health concerns due to the presence of lead.

On the other hand, lead-free liquid solder is becoming increasingly popular as a safer alternative to lead-based solder. It is also environmentally friendly and has a lower melting point, making it ideal for delicate electronic components. Silver-based liquid solder, as the name suggests, contains a higher percentage of silver than other types of solder.

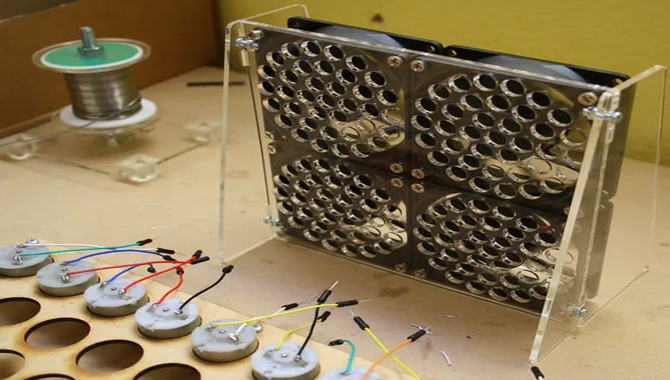

How To Make A Solder Fume Extractor

If you enjoy tinkering with electronics, you’re probably familiar with the unpleasant smell of solder fumes. Inhaling these fumes can be hazardous to your health, which is why it’s important to have a solder fume extractor in your workshop. A solder fume extractor filters harmful particles and gases released during the soldering process.

You’ll need a few things if you’re wondering how to make a solder fume extractor. First, you’ll need a DC fan, a HEPA filter, a power supply, and PVC piping. You’ll also need a soldering iron and basic tools to assemble the extractor. The first step is to assemble the fan and filter housing using the PVC piping. Next, you’ll need to attach the fan to the housing and connect it to the power supply.

Conclusion:

How to solder without soldering fume extractor we already give you. Soldering without a fume extractor is a potential health hazard and can damage your equipment or lead to poor-quality workmanship. However, by following best practices such as working in a well-ventilated area, using a fan to blow fumes away from your face, wearing a respirator, and choosing flux with low fumes, you can ensure safer and more effective soldering.

Prioritizing your health and safety while maintaining high work standards is important. By implementing these tips, you can continue selling without a fume extractor while minimizing risk and maximizing results.

FAQs

1.What Are Some Alternative Methods For Soldering Without A Fume Extractor?

Ans: Some alternative methods for soldering without a fume extractor include working in a well-ventilated area, using a fan to blow away fumes, wearing a respirator mask, soldering in short intervals with breaks in between, and using low-odour or lead-free solder.

2.Should I Take Any Safety Precautions When Soldering Without A Fume Extractor?

Ans: Taking some safety precautions when soldering without a fume extractor is recommended. Work in a well-ventilated area with an open window or a fan blowing air out of the room. Wear a respirator mask or a dust mask to prevent inhaling the fumes.

3.Can I Use A Makeshift Fume Extractor, Such As A Fan Or Vacuum, Instead Of Purchasing One?

Ans: Using a makeshift fume extractor is not recommended as it may not effectively remove hazardous fumes and could potentially be a safety hazard. Using a properly designed and calibrated fume extractor is important to ensure proper ventilation and protection against harmful fumes.

4.How Can I Ensure I Am Not Inhaling Harmful Fumes While Soldering Without A Fume Extractor?

Ans: Work in a well-ventilated area: Open windows and doors to allow fresh air to circulate and carry away fumes. Use a fan: Position a fan to blow fumes away from your face and towards an open window or door.

5.Are There Any Types Of Solder Or Flux That Are Safer To Use Without A Fume Extractor?

Ans: There are no types of solder or flux that are completely safe to use without a fume extractor. However, some types of solder and flux may produce fewer fumes and be less hazardous than others.

![How To Tin A Soldering Iron? [Step-By-Step]](https://accuratepicker.com/wp-content/themes/Extra/images/post-format-thumb-text.svg)