Soldering is becoming a simple job to handle by people, and many don’t look for electricians, plumbers anymore because they know soldering. So, why solder won’t stick to iron?

Although they know to solder, they still make mistakes because of lacking some knowledge. A common problem they face is when soldering, and the solder does not stick to the iron.

It keeps falling and forming globules. Many among them don’t understand the issue, and without having a solution, they stop the work. Did you too face this problem?

You have come to read the right article because here we will discuss this issue and give you the solution. Hence, let’s not waste any more of your valuable time and jump right on to the topic as well as other important facts.

Why The Solder Won’t Stick To Iron?

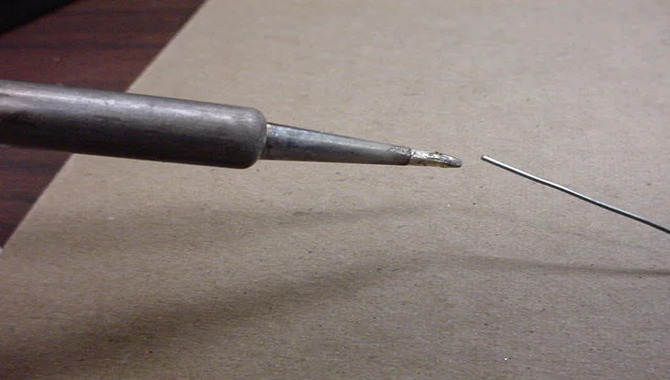

The chief reason why the solder is not sticking to iron is the oxidized tip. Yes, when the soldering iron tip is badly oxidized, it fails to give the proper service.

So, the immediate solution to this issue is replacing the tip and using a new one, and to prevent this, you must learn how to protect the soldering tips.

If you try to fix it with a tip-tinner’s help, know that it won’t help a bit because that will never work again for being oxidized too much.

You have known why you should also know about ways that your soldering iron tip can get damaged or oxidized. Next, let’s check this part because you can prevent it when you know how the problem may create.

How The Soldering Iron Tip Gets Ruined

There is not one way or two to ruin the iron tip of a soldering but more. We discussed them all one by one. Let’s take a look at them below;

- If you do not tin the iron tip and let the solder touch it this way

- If you let the iron tip get to the highest heat without solder wetted onto its tip

- If you leave it for one or more hours, even for a whole day

- If you don’t give it gradual cooling, rather wipe off the solder tip with a wet sponge instead

- If you turn back on the station, dip the iron tip in a wet shopping sponge for several hours straight it will get ruined

If you keep these in your mind and avoid these mistakes, you can prevent your soldering tip from getting damaged soon.

Although there are some special tips to take care of your solder tips, let’s not miss them either.

How To Take Care Of Your Soldering Iron Tips

Using Solders With High Quality

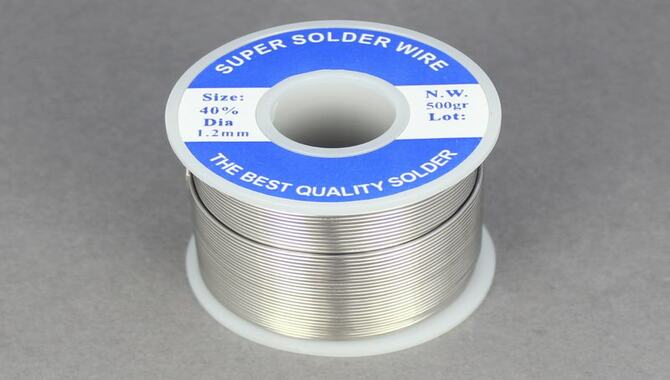

We think among all the preventive measures, the best is to get a high-quality solder. The reason is usually low-quality solder mostly contains impurities.

These contaminants will later build upon soldering iron tips and get themselves in the heat transferring way. That makes the soldering job much difficult. Buy your solder from reputable brands if you want to have a quality full solder tip.

Another way you can be sure if the solder you are going to buy is good or not. Tell the shopper to test it in front of you and see if the solder is melting the metal readily at the proper temperature.

It should do it nicely. These aren’t the end, and you can also check the appearance of metal and understand if it is of high quality or not.

For example, if the leaded solder looks matte, it means the product is of low quality, but if the solder shine, it means the product is of high quality.

Keep Up The Optimal Temperature

Try to keep up the solder tip temperature close to optimal and consistent. This way, you can increase their lifespan. In general, when you use the soldering iron often, the temperature of its tip will eventually decrease.

Many solderers make a common mistake that is turning up the heat more than the necessary temperature to stop this from happening. However, doing this rather reduces the lifespan of tips and may open up to suboptimal results.

Use soldering station irons because they have sensors that can regulate the temperature while not damaging the tip.

Keep Your Solder Iron Tip Clean

If you want every piece of equipment to perform well, you must keep them clean. You can clean the solder iron tip before using it, during working, or after using it.

You can understand when your tip is cleaned perfectly, and it’s when the tips look shiny and bright. If you want to clean it before using get alcohol and a piece of clean cloth, then with their help, remove contaminants from the solder.

To clean the tip, you need either stainless steel wool or good brass. When you are done cleaning, wet the iron tip using fresh solder to get oxidized later.

Tin The Tip

Before and after every soldering session, you must tin the solder tips. As well as the joints, two or three in between the soldering. Keep the tips tinned all the time no matter if it’s going to be your first use or 20th time to use.

Tinning a tip means covering it with the thin solder layer. This way, you can easily prevent the oxidation issue by creating a layer between air and your solder tip.

Reactivate The Tips

When a tip gets too much oxidized, it becomes dark, and in such cases, you will not be able to tin the tip. Using a tip activator will solve this problem. It will re-wet or reactivate tips.

Dip your til into the activator substance paste to reactivate it and keep moving it around until the shine comes back to the tip.

When it’s almost clean, take it away from the activator substance paste and then again, using brass or steel wool, clean it again.

Change The Soldering Iron Tip Often

It is the correct way of making your soldering iron tips live longer. No matter what metal you use, it will face erosion; hence you cannot use a metal forever.

Better to replace the metal on time. Just like if you replace the old iron tip with new ones, the solder will work for years.

Conclusion

Soldering does not stick to iron is a common scenario. No need to get worried all of a sudden if you face this situation.

Now that you know why it happens and what you should do and what not, we ensure you have a long-living solder. We hope you will properly take care of the solder iron tip and prevent the problem we discussed.

Before we close, take a piece of good advice; keep your budget higher when buying a solder so that you get a high-quality product. I hope now you know about solder won’t stick to iron.