The use of specialized pliers in specific industries is a critical component of success in many trades. With the right tool, tasks can be completed faster and with greater precision.

Exploring the different types of pliers available and the industries that benefit from their use is essential for any professional looking to maximize their efficiency.

This article will discuss the various types of specialized pliers available, the industries in which they are used, and how to select the best option for a given job. With the right knowledge and the right tools, any professional can reach their full potential. Read on to learn more about the fascinating world of specialized pliers.

Exploring Specialized Pliers For Industries

Before we explore specialized pliers for specific industries, it’s important to understand the basics. Pliers are hand tools that are used to hold, grip, and bend objects. They are typically made of metal and feature two handles and two opposing jaws.

Depending on the type of plier, the jaws can be serrated, flat, or angled. While pliers are commonly used in a variety of industries, there are certain types of pliers that are designed for specific purposes. In this article, we will be exploring specialized pliers for specific industries and how they can be used to make work easier and more efficient.

Electrical Pliers

Electrical pliers are one of the most versatile and widely used tools in the electrical industry. Primarily, these pliers are used for cutting, stripping, crimping, and twisting wires. They are also capable of cutting metal objects, such as screws and bolts, as well as fastening objects together.

The handles of electrical pliers are usually made of a rubberized material, which provides a secure grip and protection against electric shocks. The blades of electrical pliers are typically made of hardened steel and designed to provide the user with maximum precision and accuracy.

Electrical pliers come in a wide variety of sizes and styles, making them suitable for a range of applications. They are commonly used in the manufacture and installation of electrical components, as well as in the repair and maintenance of electrical systems. Electrical pliers are an invaluable tool for any professional or amateur electrician.

Types

There are many types of specialized pliers available for specific industries. One type is the end cutting pliers, which are used in the automotive industry. They are designed to cut through metal, plastic, and other materials. Another type is the needle nose pliers, which are designed for precision work.

These pliers have a long, narrow tip that allows you to reach into hard-to-reach areas. They are often used in the electronics and jewelry industries. Lastly, bent nose pliers are usually used in the electronics industry as they have the capacity to bend wires. All of these types of pliers have a specific use and can help make certain tasks much easier.

Advantages

When it comes to industrial applications, specialized pliers can provide a range of advantages. For one, they can help make the job of an industrial worker easier and more efficient. For instance, pliers designed specifically for a certain type of material, such as copper or steel, can make it much simpler to work with that material.

They also usually come with features that make them more suitable for the task at hand, such as increased leverage or a curved jaw for increased gripping power. Additionally, they can often be customized to fit the user’s needs, allowing for a more personalized fit in the workplace. Specialized pliers are also often more durable and reliable than standard pliers, making them a worthwhile investment.

Disadvantages

Specialized pliers can be expensive to purchase and maintain, as they are often not available for purchase in bulk. Additionally, some specialized pliers may require specialized training to use properly, which can be time-consuming and costly. Furthermore, specialized pliers may not be suitable for all types of jobs, as they may not be able to accommodate the variety of tasks needed in certain industries.

Not all pliers are designed to perform the same tasks, so it is important to research the type of pliers needed for a job before purchasing. Finally, specialized pliers may be difficult to find in certain areas, making it necessary to purchase them online or from a specialty store.

Uses

Pliers are a versatile tool, and can be used for many different tasks. Specialized pliers are designed to help with specific jobs in various industries. Electricians may use needle nose pliers for working with electrical wiring. Automotive technicians may use oil filter pliers for removing and replacing oil filters.

Jewelers may use flat nose pliers to help with delicate work on jewelry. Plumbers may use tongue and groove pliers to help with pipe fittings. Industrial mechanics may use cutting pliers to help with larger projects.

Specialized pliers are invaluable for helping to make jobs easier and get the work done more efficiently, no matter what the industry.

Automotive Pliers

Automotive pliers are a specialized type of pliers designed to meet the needs of the automotive industry. They are usually made from high-grade steel, and feature long handles for extra leverage when tackling tough jobs. The curved jaws of automotive pliers are designed to fit snugly around nuts, bolts, and other automotive components for a secure grip.

Many automotive pliers feature a spring-loaded design, allowing them to be used for repetitive tasks with ease. The short jaws of automotive pliers make them ideal for reaching into tight spaces and removing parts from cramped engine compartments. They’re also great for cutting off wires and other small components.

Automotive pliers are a must-have tool for any DIY mechanic or professional automotive technician. They come in a variety of sizes and shapes, allowing users to tackle a wide range of automotive projects. Whether you’re replacing brake pads, removing spark plugs, or fixing wiring, having the right automotive pliers can make the job much easier.

Types

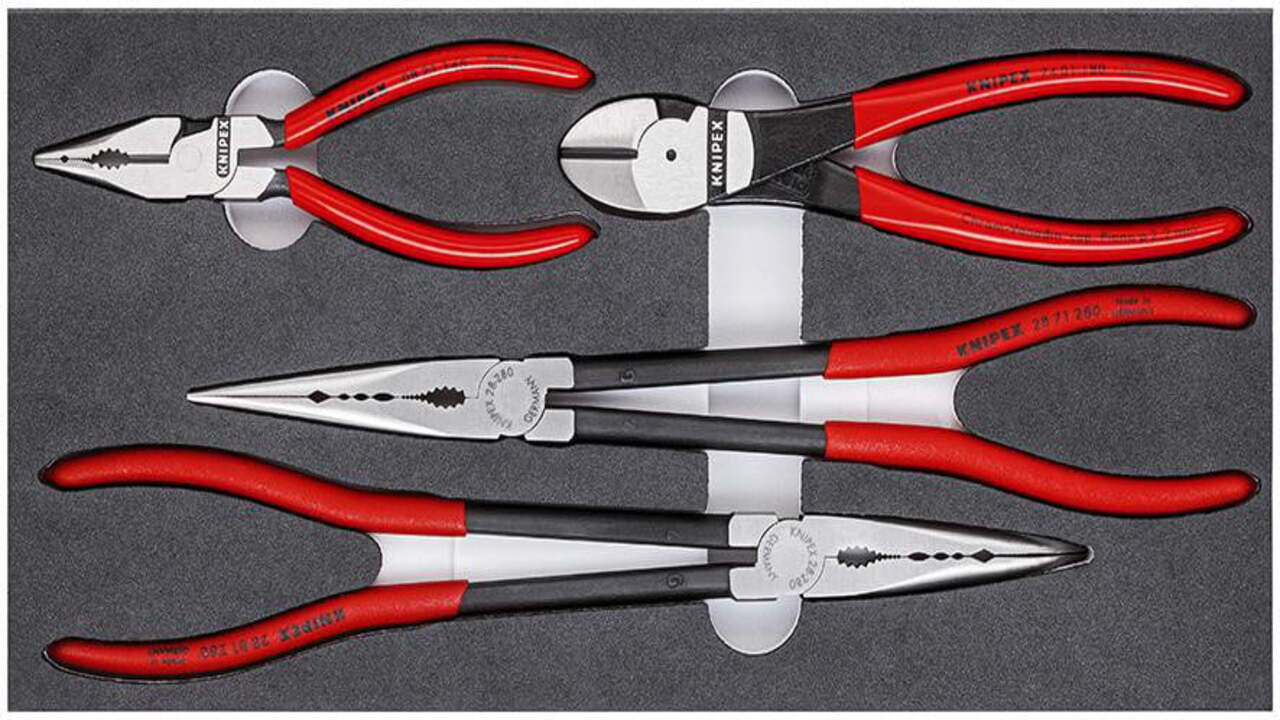

There are a variety of specialized pliers that are designed for use in specific industries. Pliers are tools that are used to grip and hold objects, and they come in a variety of shapes and sizes. Some of the more common types of pliers are diagonal cutters, needle nose pliers, and combination pliers.

Diagonal cutters are used to cut wire and other objects while needle nose pliers are used to access small areas. Combination pliers are used for a variety of tasks such as gripping, cutting, and bending.

Some industries, such as automotive and engineering, require specialized pliers for specific tasks such as crimping, snipping, and stripping. These pliers come in a variety of shapes and sizes in order to perform these specific tasks efficiently and effectively.

Advantages

Specialized pliers have many advantages when used in specific industries. They can be designed to meet the exact needs of the job, providing a solution that is tailored to the task. These pliers can also be more durable than standard ones, allowing them to last longer and perform better in harsh industrial environments.

Additionally, they can be produced in a variety of sizes, making them more suitable for specialized tasks. Furthermore, specialized pliers can provide greater precision, making them ideal for accurate and delicate work. Finally, they can also be fitted with special features, such as ergonomic handles, to provide a more comfortable user experience.

Disadvantages

When it comes to specialized pliers, there are some drawbacks to consider. Firstly, they can be expensive, especially when you need a specific model or type for a particular application. Secondly, these pliers may not be readily available in many areas, as they are generally designed for a specific industry and can be difficult to find. Thirdly, the specialized pliers may require additional skill and knowledge to use correctly, which means that workers may need to receive additional training.

Finally, using specialized pliers also increases the chance of injuries, as workers must use them with caution to avoid damaging the material or their hands.

Uses

Specialized pliers are used in a wide variety of industries. From automotive repair shops to industrial manufacturing, pliers can help complete jobs quickly and accurately. Pliers also come in handy for electricians who are wiring homes and offices, where they are used for cutting, stripping and crimping wire. In machine shops, pliers are used for a variety of tasks, including bending, cutting and shaping metal components.

Pliers are also used in the medical field, where they are used to hold and cut tissue. Specialized pliers can be used in many ways in the construction industry, from cutting and bending metal bars to squeezing and cutting nails and other fasteners. Pliers are an essential tool in any industry that requires precision and accuracy.

Electronics Pliers

Electronics pliers are a specialized tool used by professionals in the electronics industry. They are designed specifically for the electronic components of various electronic equipment. They are made from stainless steel or aluminum and have specially designed jaws to grip tight onto small components.

These pliers are also designed with an adjustable jaw, so that the user can easily adjust the size of the opening to fit their needs. They are also designed with ergonomic handles for comfortable gripping.

Electronics pliers are also designed to handle delicate components and can be used for precision work, making them ideal for intricate soldering projects. They are also a great tool for stripping wires and other components. With the right tools, electronics pliers can help professionals complete their tasks with ease and precision.

Types

Specialized pliers come in a variety of shapes and sizes, each designed for a specific industry application. From electrician’s side cutting pliers to long nose pliers used for intricate work in jewelry making, each type of plier comes with its own unique set of features. Constructed of hardened steel, electrician’s side cutting pliers are designed to cut cables and wires with ease.

Long nose pliers are typically constructed of tempered steel and feature an extended reach for delicate tasks such as removing small components and forming loops. Lineman’s pliers are designed to crimp and strip cables and wires, while slip-joint pliers are ideal for gripping, cutting, and turning.

Groove-joint pliers are designed to adjust and turn nuts and bolts, while needle nose pliers are designed for precision work such as gripping small items.

Advantages

Specialized pliers are a great choice for many industries, as they offer a range of advantages. Firstly, they are specifically designed for the job at hand, meaning the user can work with confidence that the tool is up to the task.

Additionally, the pliers are often more ergonomic and comfortable to use, reducing the risk of injury. Furthermore, specialized pliers can often be used in ways that standard pliers cannot, allowing for more specific jobs to be completed.

Finally, as they are designed for a specific job, they are often more efficient and can complete the job faster than with standard pliers. In summary, specialized pliers are an excellent choice for a variety of industries and can provide many advantages over standard pliers.

Disadvantages

Using specialized pliers for specific industries can be beneficial in many ways, but there are some disadvantages associated with them. Firstly, they can be expensive compared to other tools, making them difficult to purchase for those with limited funds. Secondly, they may be difficult to find, as they are only available in select stores.

Finally, they may require special care and maintenance, which can be time consuming and expensive. Additionally, specialized pliers may not be suitable for all tasks, meaning that other tools may be needed in addition to them. For these reasons, it is important to consider the pros and cons of specialized pliers before committing to them.

Uses

Pliers are essential tools used across a variety of industries, from construction to automotive. They come in different shapes and sizes, and each type has its own specific use. Specialized pliers are designed for more specialized tasks, and can be used in a variety of industries.

For example, lineman’s pliers are ideal for electricians in need of a tool to cut, strip, and twist wires, while needle nose pliers are useful in a variety of tasks, from jewelry making to automotive work.

Other specialized pliers include long nose pliers, which can reach into tight spaces, and combination pliers, which are perfect for gripping and cutting. These tools can be invaluable in different industries, and are often essential for getting the job done.

Conclusion

This article explored specialized pliers used in various industries. It discussed how pliers are used in different industries, the types of pliers available, and the advantages of using specialized pliers. It concluded that specialized pliers can provide greater precision and accuracy, making them a valuable tool for any industry.

It also highlighted the importance of selecting the right type of plier for the job, as different types of pliers can be better suited for different industries.

FAQ’s

1.What Industries Commonly Use Specialized Pliers?

Ans: Industries that commonly use specialized pliers include automotive, construction, electrical, plumbing, and HVAC. These specialized pliers are designed for specific tasks, such as cutting, gripping, crimping, and holding. They are often made of steel, chrome, or nickel-plated steel for durability and corrosion resistance. Additionally, they are often ergonomically designed to provide comfort and ease of use.

2.What Features Should Be Considered When Selecting Specialized Pliers For A Specific Industry?

Ans: When selecting specialized pliers for a specific industry, features such as the pliers’ design, construction, strength, material, handle size, and weight should be taken into consideration. It’s also important to check that the pliers meet the industry’s standards and are compatible with other tools and equipment.

Additionally, the pliers should be comfortable to use and easy to maintain. Finally, make sure the pliers are cost-effective and fit within your budget.

3.What Are The Safety Precautions To Be Aware Of When Using Specialized Pliers?

Ans: When using specialized pliers, it is important to wear protective gloves and safety goggles. Always check the pliers for any defects or damage before use. Make sure the pliers are securely held and the handles are firmly gripped. Finally, use the pliers only for the purpose for which they are intended.

4.What Are The Benefits Of Using Specialized Pliers In An Industrial Setting?

Ans: The use of specialized pliers in an industrial setting offers many benefits. These pliers are designed to handle specific tasks, allowing for more precise and efficient production. Additionally, specialized pliers can be used to complete difficult tasks that regular pliers are not designed to do. The use of specialized pliers also helps to reduce the risk of injury due to their ergonomic design.

5.Are There Any Specialized Pliers That Are Designed For Multiple Industries?

Ans: Yes, there are specialized pliers designed for multiple industries. For example, diagonal cutting pliers are used in the electronics, automotive, and aerospace industries. Long nose pliers are used in the jewelry, plumbing, and carpentry industries. Locking pliers are used in the automotive, plumbing, and electrical industries. Finally, needle nose pliers are used in the jewelry, automotive, and plumbing industries.