Soldering is a crucial skill in electronics and essential to various DIY projects. Here are give a few guides on How to solder without soldering tweezers. Soldering is a relatively easy process; it requires the right tools and techniques to do the job correctly.

One of the essential tools required in soldering is a pair of tweezers, which helps hold the components in place during the process. However, what happens when you don’t have a soldering tweezers? How do you solder effectively without it? Luckily, you don’t have to worry, as there are alternative methods to solder without soldering tweezers. Discuss how to solder without tweezers, highlighting the required techniques and tools.

What Are Soldering Tweezers?

Soldering tweezers, also known as soldering forceps or clamps, are helpful for anyone who works with electronics or small metal components. These tweezers are designed to hold small objects in place while soldering. Allowing for precision and accuracy in your work. They are typically make of heat-resistant materials such as copper or steel and come in various shapes and sizes to fit different types of projects. Soldering tweezers hold small components steady while solderings, such as wires, resistors, and capacitors.

Hey are handy when working with small electronic devices; a steady hand is essential. The tweezers hold components in place while you apply heat to the solder, ensuring the solder bonds correctly. One of the benefits of soldering tweezers is that they allow you to work with smaller components than you might be able to with your fingers alone.

What Tools I Need To Solder Without Soldering Tweezers

- Soldering Iron: This is the primary tool you’ll need for soldering. It is used to heat the solder and the components you want to join.

- Solder: Choose a solder appropriate for your application, such as lead-free or rosin-core solder.

- Soldering Stand: This tool holds the soldering iron when unused, preventing accidental burns or surface damage.

- Helping Hands: A tool with adjustable clips or alligator clamps that holds your workpiece in place, leaving your hands free to solder.

- Heat-resistant Work Surface: Protect your work area with a soldering mat or heat-resistant pad to prevent heat or solder splatter damage.

- Flux: Flux helps clean the surfaces to be soldered and promotes good solder flow by reducing oxidation.

- Desoldering Braid/Wick: A copper braid that absorbs molten solder, allowing you to remove it from a joint.

- Wire Cutters: Used to cut and strip wires before soldering, ensuring clean connections.

- Needle Nose Pliers: These are handy for bending and holding wires or components during soldering.

How To Solder Without Soldering Tweezers: Step By Step

Soldering is a process that joins two pieces of metal by melting a filler metal between them. Here are a few steps to help you solder without soldering tweezers. Not everyone has access to soldering tweezers, which can make the process a bit more challenging. Fortunately, alternative methods use to solder without soldering tweezers. How to solder without soldering tweezers Here is a step-by-step guide on it.

1. Prepare Your Work Area

Before starting any soldering project, it is crucial to prepare your work area. Clear any clutter on your workspace and ensure you have enough room to work comfortably. Having a stable and flat surface is essential, and it’s best to work in a well-ventilated area.

Once you have ensured that your work area is safe and ready, the next step is to gather your materials. If you don’t have soldering tweezers, don’t fret. You can still solder without soldering tweezers.

One alternative is to use regular tweezers for small parts, but it’s best to use a soldering iron with a fine tip to make precise and controlled soldering. A helping hand or a third-hand tool can also be helpful in holding the parts you’re soldering. Avoid touching the soldering iron tip with your bare hands, as it can cause severe burns.

2. Gather Your Materials

When it comes to electronics DIY projects, gathering your materials before starting is essential. Whether building a robot or repairing a circuit board, having all the necessary components within reach can make the process smoother. One tool that’s often needed in electronics projects is a soldering iron. However, if you don’t have a soldering iron, don’t worry! There are other ways to solder without one. For instance, you can use a conductive adhesive or a soldering paste.

Another option is to use solder without soldering tweezers. This technique involves heating the wire, applying flux, and touching it to the surface you want to solder. Then, you can use tweezers to hold the wire in place while it cools. This method may not be as precise as a soldering iron, but it can be helpful in a pinch.

3. Prepare The Components

When preparing electronic components for assembly, it is essential to have the right tools at hand. One such tool that is highly useful is the soldering tweezers. These tweezers make it possible to hold small components firmly in place as you work on them without risking dropping or damaging them. Unlike traditional soldering methods that require a soldering iron, soldering tweezers allow you to solder without needing this equipment.

This is because they come with built-in heating elements that melt the solder, thus eliminating the need for a separate soldering iron. This makes the process more efficient and reduces the risk of burns and other injuries associated with traditional soldering methods.

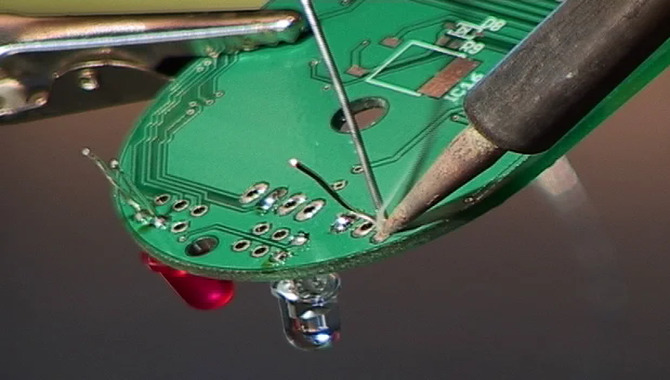

4. Set Up The Soldering Iron

Setting up the soldering iron is an essential aspect of any electronics project. You can create a reliable and long-lasting connection between your electronic components with the right tools and techniques. However, many people struggle with soldering, especially when they don’t have the right equipment. For instance, soldering without soldering tweezers can be challenging because it requires a steady hand and a lot of patience. But, with some practice and tips, you can solder without soldering tweezers like a pro.

You must have a few things on hand to set up a soldering iron. First, you must have a soldering iron, the main tool used for soldering. You also need a soldering stand that will hold your soldering iron when not used. Additionally, you need to have soldering wire, which is the material that melts and flows onto your components to create a connection.

5. Secure The Workpiece

Securing the workpiece to prevent movement during the process is essential when it comes to soldering. This can be done using clamps or other holding tools to keep the piece in place. Another way to ensure stability is to use soldering tweezers, which allow precise control and manipulation of the workpiece. These tweezers are especially useful for intricate work and delicate materials.

But what if you don’t have access to soldering equipment? Believe it or not, you can still solder without soldering tweezers. One method is to use a third-hand tool, which holds the workpiece in place while leaving your hands free to apply the solder. Another option is to use a weighted base to anchor the workpiece and keep it steady. This is a useful technique for larger pieces or when using unconventional materials.

6. Apply Flux

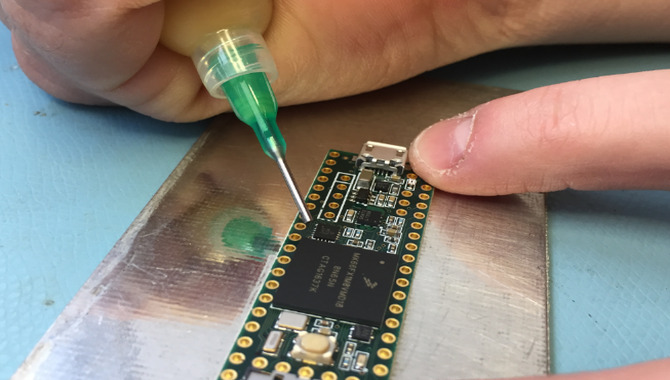

When working with delicate electronic components, having the right tools for the job is important. One such tool is flux, which can help solder without the need for traditional soldering tweezers. Flux is a type of liquid applied to the surface of the joined materials.

It helps to clean the surface and remove any oxidation or other impurities that may interfere with the soldering process. Once the flux has been applied, the solder can be melted and applied to the joint, creating a strong, permanent bond.

This method is beneficial for soldering small components, as it removes the need for tweezers which can be difficult to use in tight spaces. Additionally, flux can help prevent overheating and damage to the components being soldered by reducing the heat needed to create a strong bond.

7. Heat The Soldering Iron

When it comes to soldering, the first step is always to heat the soldering iron. This is a crucial step in ensuring that the solder will melt and bond properly with the joined components. However, you may wonder how to complete the task if you don’t have soldering tweezers. The good news is that it is still possible without these tools. One option is to use a small piece of wire to hold the component in place while applying the solder.

Alternatively, you can hold the component steady with your fingers, carefully avoiding touching the hot solder or iron. While this method is not as precise as tweezers, it can still be effective if you have a steady hand and plenty of patience. Ultimately, the key to successful soldering is to take time, work carefully, and ensure that all components are properly secured and connected.

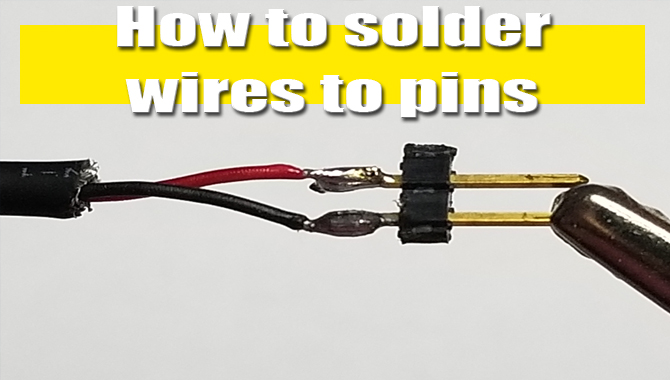

8. Apply Solder

Applying solder without soldering tweezers can be a tricky task. With some practice and patience, it is possible to achieve a solid solder joint. To apply solder, clean the surfaces of the components you want to join.

Use fine-grit sandpaper or a wire brush to remove any oxidation or debris from the metal. Then, place the two components together in their desired position and hold them steady with pliers or clamps. Next, heat the joint with a soldering iron until the metal is hot enough to melt the solder.

Take a small amount of solder and touch it to the joint. The heat will cause the solder to flow into the joint, creating a strong bond. Be careful not to use too much solder, as this can cause the joint to become brittle and fail over time. With practice, you can apply solder without soldering tweezers and create professional-quality solder joints.

bligatory Safety Warning

Before undertaking any soldering project, it is essential to remember that certain safety precautions must be taken. Following these safety warnings is obligatory to prevent accidents or injuries. One of the most important things to remember is to use the proper tools and equipment.

Tweezers are essential for any soldering project, as they allow for precise placement and manipulation of small components. However, if you find yourself without soldering tweezers, it is still possible to complete your project safely.

In this case, it is essential to exercise caution and use alternative tools, such as needle-nose pliers or a small screwdriver, to handle the components. It is essential to avoid touching the components with your bare hands, as the oils and moisture from your skin can damage sensitive electronic parts. Additionally, working in a well-ventilated area and wearing appropriate safety gear, such as gloves and safety glasses, is crucial.

Conclusion

How to solder without soldering tweezers it’s we already give you. Soldering without tweezers may seem daunting, but it is a skill that can be learned and mastered with practice. You can achieve precise and clean soldering results using alternative tools and techniques, such as a heat sink or a third-hand tool. Remember always to prioritize safety and to work in a well-ventilated area. With these tips and tricks, you can confidently tackle soldering projects even without soldering tweezers.

FAQs

1.What Are Some Alternative Tools That Can Be Used For Soldering If I Don’t Have Tweezers?

Ans: Some alternative tools that can be used for soldering if tweezers are not available include needle-nose pliers, hemostats, alligator clips, or a helping hand tool with clips.

2.Can I Use Regular Pliers Or Wire Cutters Instead Of Soldering Tweezers?

Ans: No, regular pliers or wire cutters cannot be used instead of soldering tweezers. Soldering tweezers are specifically designed with a fine, pointed tip that allows for precise handling of small components during the soldering process.

3.How Can I Ensure My Soldering Joints Are Neat And Secure Without Tweezers?

Ans: Use a soldering stand to hold the components steady while soldering. Utilize A helping hand tool with alligator clips to hold the components in place. Use a soldering iron with a fine tip to ensure precision and accuracy.

4.Are There Any Specific Techniques Or Tips For Soldering Without Tweezers That I Should Know?

Ans: Yes, there are several techniques and tips for soldering without tweezers.

- Use a third-hand tool or a helping hand tool to hold the components in place while you solder

- Use a small piece of double-sided tape or adhesive putty to hold the components in place.

5.Can I Still Achieve A Professional-Looking Soldering Job Without Using Tweezers, Or Is It Necessary To Invest In This Tool?

Ans: It is possible to achieve a professional-looking soldering job without tweezers, but tweezers can make it easier and more precise. Investing in a good pair of tweezers is recommended if you frequently do soldering work.