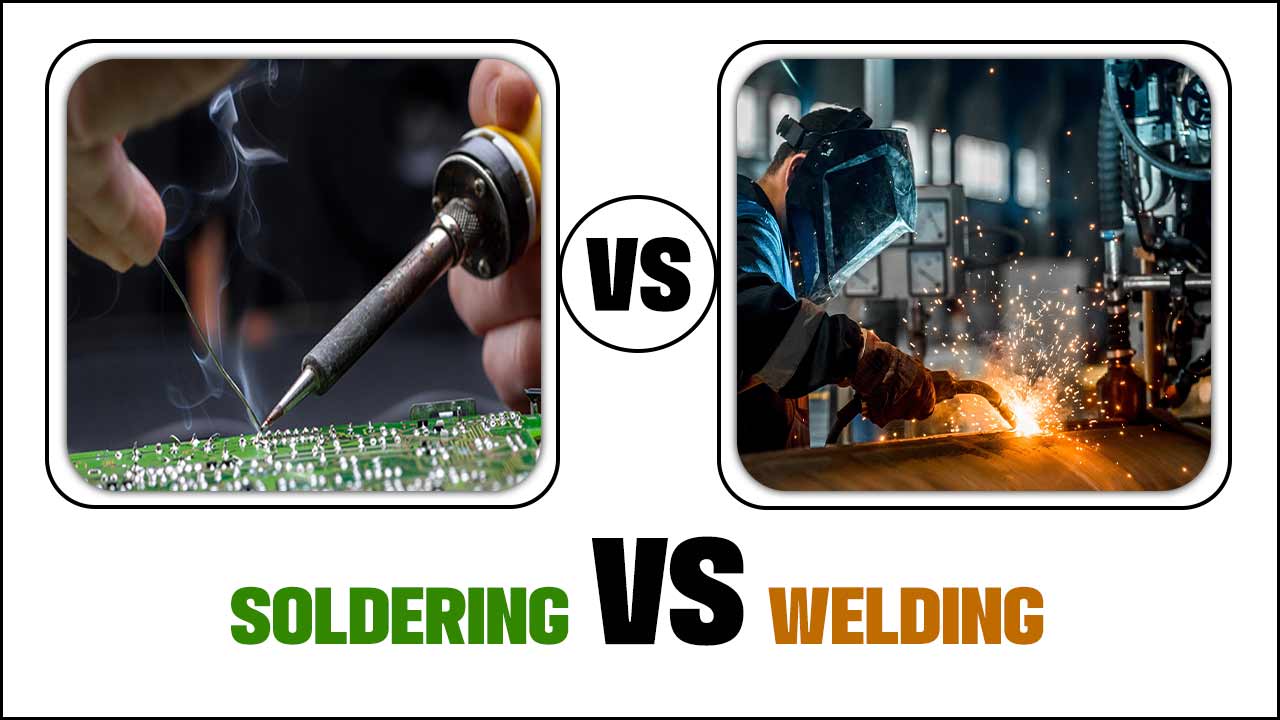

Soldering and welding are two popular processes used in metalworking and manufacturing. Both processes involve joining two or more pieces of metal together, but they differ in the way the metals are joined and the materials used.

Soldering uses a low-temperature, low-melting-point alloy, while welding uses heat and pressure to form a strong bond. The type of process used depends on the application and the materials being joined.

This article will explore the differences between soldering and welding, their uses, and the advantages and disadvantages of each. It will also provide an overview of how to choose the right process for a given application. Get ready to explore the world of soldering and welding and learn how to make the best choice for your project.

Soldering Vs. Welding: What’S The Difference?

Soldering and welding are two popular methods used to join metals. Soldering involves melting a filler metal over the joint to create a strong bond, while welding involves melting the two metals together to form a single piece. Both processes have their advantages and disadvantages, depending on the application.

Soldering is typically used for small, delicate projects, while welding is used for larger, more complex projects. Soldering is also much easier to learn and requires less equipment, making it a more cost-effective option for many projects.

However, welding is much stronger and more durable than soldering, making it a better choice for more demanding applications. When deciding between soldering and welding, it is important to consider the size and complexity of the project, as well as the desired strength of the joint. Soldering and welding are two processes used to join metal co

Definition

mponents. Soldering involves melting a low-melting-point metal alloy, such as a tin-lead alloy, to form a joint between two metal components.

The metal alloy is heated to the melting point and then adheres to the two components being joined. Welding, on the other hand, is a process in which two pieces of metal are melted and then joined together by a filler material, such as an alloy of nickel and chromium.

The filler material is heated to the melting point and then adheres to the two components. The result of both processes is a strong bond between the two components. Soldering is usually used for lighter components and for electrical connections.

It is a relatively easy process to perform and is more affordable than welding. Welding, on the other hand, is a more permanent and stronger connection and is used for heavier, thicker components. It is more complex than soldering and requires more skill and specialized tools.

Soldering

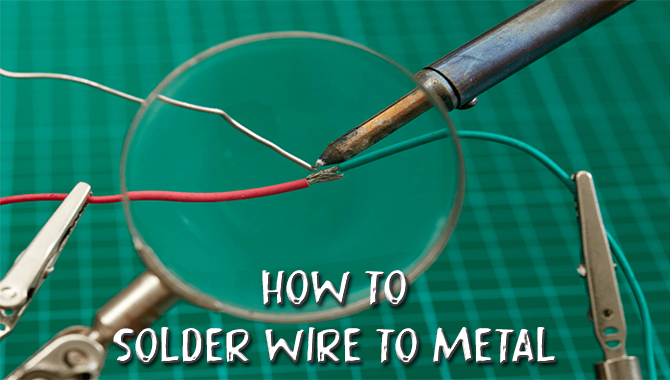

Soldering is a process in which two or more metal items are joined together by melting and flowing a filler metal into the joint. It is a relatively simple and low-cost process, and is commonly used in electronics assembly, as well as to make jewelry and other metal art.

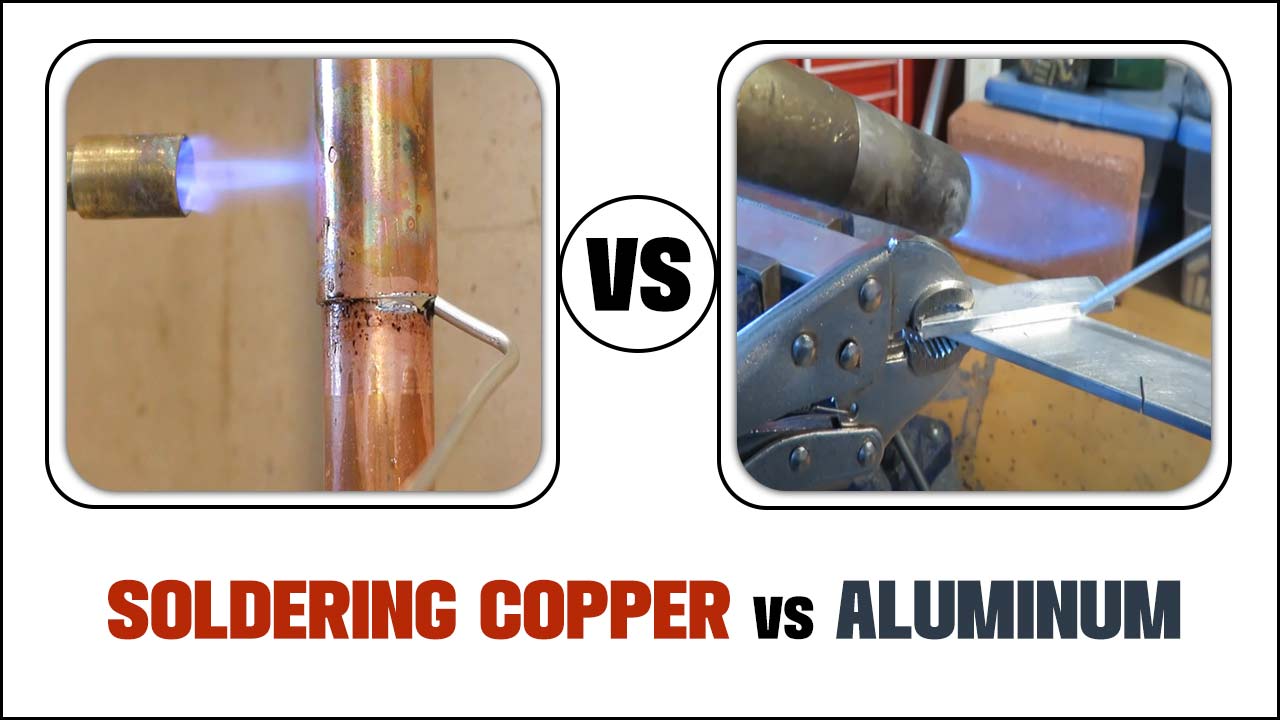

Because soldering does not involve melting the base metals, it can be used to join items made of different materials, such as aluminum and copper. Additionally, soldering is often preferred over welding in applications where strength or durability is not a major concern. Soldering is also used in plumbing and automotive applications, and is often used to repair or modify existing metal items.

Welding

Welding is a technique used to join two pieces of metal together by melting the materials and using a filler material. It is different from soldering, which joins metals together using a lower temperature and a non-metallic filler material.

Welding is often used for industrial and commercial applications, as it is a stronger and more permanent joint than soldering. Welding utilizes high temperatures and pressure to create a strong bond and is commonly used for metal fabrication, automotive manufacturing, pipeline construction, and many other industries.

Additionally, welding can be done in a variety of ways and techniques, such as arc welding, gas welding, and tungsten inert gas welding. Welding is also used in many hobbies, such as jewelry making, gunsmithing, and automotive repair.

Process

Process is an important factor to consider when determining which technique to use for a metalworking project. Soldering is a relatively simple process that involves melting a lead-based alloy, known as solder, between two metal pieces.

The solder bonds the two pieces together when it cools. Welding, on the other hand, is a more complex and advanced process that involves the application of heat and pressure to join two pieces of metal together.

It requires specialized tools and a great degree of skill to ensure a tight, durable connection. Both soldering and welding are very different processes but are both capable of joining two pieces of metal together. Depending on the project, either one can be the best choice.

Soldering

Soldering is a method of joining two pieces of metal or other materials by melting a filler metal. The filler metal has a lower melting point than the metals being joined, and when melted, it forms a strong bond. Unlike welding, soldering does not require extreme heat or pressure, and it can be performed with relatively simple equipment.

Soldering is a great option for low-temperature and low-pressure applications, such as electronic components. It is also often used in jewelry making and plumbing. The biggest advantage of soldering is that it requires less skill and effort than welding, making it ideal for quick repairs or projects that require multiple joints.

Welding

Welding is a process that binds two pieces of metal together by melting and fusing them. It is a permanent join that results in a strong bond between the two pieces. The most popular type of welding is arc welding, which uses an electrical arc to create heat between two pieces of metal.

It is also possible to use gas welding, which uses a flame to melt the metal, and oxy-acetylene welding, which uses a combination of oxygen and acetylene gas. All these methods are used to join metal components together.

Welding is a skill that requires a great deal of practice and experience. It is important for welders to understand the properties of the metals they are working with, and to follow safety protocols to prevent injury and damage to the weld.

Benefits

Soldering and welding both have distinct advantages and disadvantages. When it comes to the benefits of soldering vs. welding, there are a few key differences to consider. Soldering is the preferred choice for smaller, more delicate projects as it puts less strain on the materials involved.

It is also less expensive and can be done with basic tools. Because it doesn’t require as much heat, it is also safer to use than welding. Welding, on the other hand, is more suitable for larger projects and offers greater strength and durability.

It also has a greater range of potential uses, such as creating permanent bonds between two metals. Welding also requires more specialized tools, skills, and safety precautions, making it more expensive than soldering. Ultimately, the choice between soldering and welding will depend on the project at hand.

Soldering

Soldering is a form of welding that is used to join two metal surfaces. The process involves melting a metal alloy, usually lead, tin or a combination of both, and applying it to the surface to be joined. The alloy then cools and creates a strong, permanent bond.

Soldering is often used in electrical and electronic applications, such as joining wires together. It is also used to attach components to circuit boards, as well as to seal joints in metal piping. Soldering is quicker and simpler than traditional welding, and it does not require any additional equipment. It is also less expensive than welding, making it an attractive option for many applications.

Welding

Welding is a fabrication process that permanently joins two metal pieces together. It uses extreme heat to create a strong bond between the two pieces. Heat is generated by an electric arc, or sometimes a gas flame, and the metal pieces are fused together.

The strength of the bond created by welding depends on the type of welding process used and the metal being joined. Common materials used in welding include steel, aluminum, brass, and stainless steel. Welding is used in a variety of industries including automotive, construction, and manufacturing.

Drawbacks

Soldering and welding are two processes used for joining materials together. Both have their advantages and drawbacks, and it is important to understand the differences in order to choose the best process for a given application. One of the main drawbacks of soldering is that it is not as strong as welding.

The heat used in soldering is much lower than welding, so the bond created is weaker and less durable. Additionally, soldering is limited to joining two metal surfaces which fit together, whereas welding can be used to join dissimilar materials. Finally, soldering is not suitable for joining thicker metals, as the heat cannot penetrate deep enough to create a strong bond.

Soldering

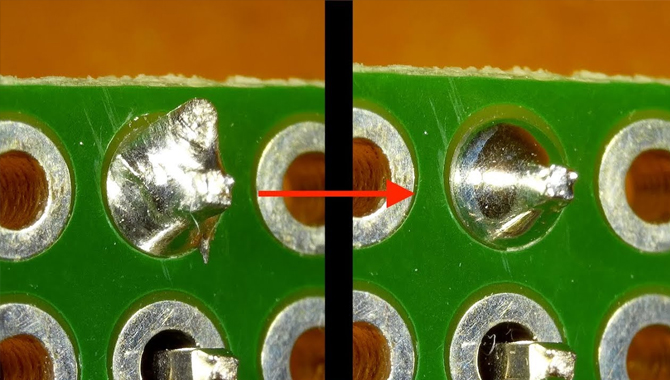

Soldering is a metalworking process that joins two pieces of metal together by heating them to a point that they form a strong bond. It involves the use of a soldering iron and a solder paste made of a mixture of flux and metal. The flux helps to clean and prepare the surfaces of the two pieces of metal for the soldering process.

When heated, the paste melts and, when it cools, it forms a strong bond between the two pieces of metal. Soldering is often used to repair damaged electronics or to attach electrical components to a circuit board. It is also commonly used to create jewelry and other decorative pieces.

Soldering requires less heat than welding, making it a preferred method when working with delicate materials. Additionally, soldering does not require any specialized equipment, making it a cost-effective option for small jobs.

Welding

Welding is a process that uses heat or pressure to join two or more metal pieces together. It is a more permanent form of joining than soldering, and it is used for larger components and for heavier loads. Welding is typically done with a gas flame or an electrical arc, which uses an electric current to generate the heat.

This process is used in many industries, including automotive, aerospace, and construction. Welding is a skilled trade and requires specialized training to be done safely and effectively. It is important to follow safety protocols to ensure a quality weld and to protect yourself and those around you from potential hazards.

Conclusion

Soldering and welding are two popular methods of joining metal components. Soldering involves melting a low-melting point alloy to form a joint between two pieces of metal, while welding involves melting and fusing two pieces of metal together.

Soldering is typically used for smaller projects, such as electronics, while welding is used for larger projects, such as automotive and construction. Both processes require the use of specialized tools and safety equipment.

FAQ’s

1.What Are The Differences Between Soldering And Welding?

Ans: Soldering and welding are two common methods of joining metal pieces. Soldering is a relatively low temperature process that joins metals using a filler material that melts at a lower temperature than the base metals.

Welding is a process that uses high heat to melt and join the base metals together. Welding is stronger than soldering, which is why it is often used for structural applications. Additionally, welding does not require a filler material, while soldering does.

2.What Are The Benefits Of Using Soldering Over Welding?

Ans: Soldering has a few benefits over welding. It is much easier and faster to do than welding, and there is no need for special tools and equipment. Soldering also causes less damage to the surrounding material than welding, which can be important for delicate materials or components. Additionally, soldering is a great choice for small repairs and jobs, as it produces a strong bond without the need for high temperatures.

3.What Are The Temperature Requirements For Soldering And Welding?

Ans: Soldering typically requires temperatures between 400 – 500°C (750 – 930°F). Welding requires temperatures that are generally much higher, often ranging from 500 – 600°C (930 – 1,100°F). However, depending on the type of welding, temperatures could range from 200 – 700°C (390 – 1,290°F). Finally, for brazing the temperature requirements range from 450 – 480°C (840 – 896°F).

4.What Materials Are Suitable For Soldering And Welding?

Ans: Soldering and welding are two different processes that use different materials. Soldering uses materials such as lead, tin, copper, silver, aluminum, and nickel alloys. Welding uses materials such as steel, stainless steel, aluminum, brass, and bronze. Both processes require specialized equipment and knowledge to be done safely and correctly.

5.What Tools Are Required For Soldering And Welding?

Ans: Soldering and welding both require a heat source, such as a torch or electric soldering iron, and a filler material such as solder or welding rod. For soldering, flux is also needed to ensure a secure bond. For welding, a protective mask and gloves are required to protect the welder from sparks. In either case, a good work surface and an understanding of safety protocols are also important.