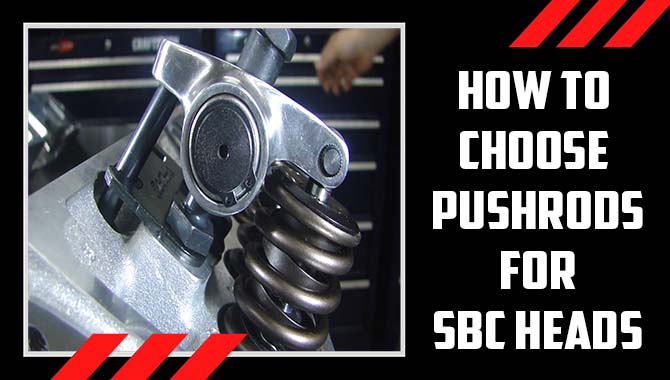

Pushrods are critical in delivering power from the camshaft to the valve train and, ultimately, to the wheels. So it is essential to know How to choose pushrods for SBC Heads.

With so many different types of pushrods available on the market, it can be challenging to know which ones best fit your SBC heads. That’s why we’ve compiled this comprehensive guide to help you easily navigate the pushrod selection process. In this guide, we’ll cover everything you need to know about pushrods for SBC heads, including their function, materials, length, and diameter.

We’ll also discuss the importance of proper pushrod geometry and explain how to measure pushrod length accurately. Additionally, we’ll examine the different types of pushrods available, such as solid, tubular, and hydraulic pushrods, and their advantages and disadvantages.

Understanding The Importance Of How To Choose Pushrods For SBC Heads

How to choose pushrods or SBC Heads is essential to understand their importance. Pushrods play a crucial role in transferring the camshaft’s motion to the rocker arms, which then open and close the valves. Therefore, selecting the right pushrods can significantly impact an engine’s performance, reliability, and longevity.

One of the critical factors to consider when choosing pushrods is the material and construction. Steel pushrods are ideal for high-performance applications as they are strong, stiff, and have high resistance to bending and deflection.

However, Chromoly or hardened pushrods are more than enough for street applications. Another factor to consider is the length and diameter of the pushrod, as both directly affect valve timing.

Therefore, choosing the right length and diameter ensures optimal valve lift and duration. Lastly, it is crucial to consider the pushrod’s weight, as it can affect the valve train’s stability and overall performance.

Types Of Pushrods

Pushrods are an important component of the internal combustion engine. They are used to transfer motion from the camshaft to the rocker arms, which operate the valves. Several types of pushrods are available on the market today, each with unique advantages and disadvantages.

- One of the most common types of pushrods is the solid pushrod. This type of pushrod is made from a single piece of steel or other high-strength material and is designed to be very durable. Solid pushrods are often used in high-performance engines that require maximum reliability and strength.

- Another popular type of pushrod is the tubular pushrod. This type of pushrod is made from a hollow tube that is stronger and lighter than a solid pushrod. Tubular pushrods are often used in high-performance engines where maximum power and efficiency are required.

Finally, there is the adjustable pushrod. This type of pushrod allows the user to adjust the length of the pushrod.

Materials Used To Make Pushrods

Pushrods are crucial components of an internal combustion engine as they transfer the upward and downward movement of the camshaft to the rocker arms, which then open and close the engine valves. The materials used to make pushrods must be strong enough to withstand the constant stress and pressure of engine operation while also being lightweight.

- One of the most commonly used materials for pushrods is chrome-moly steel, known for its high strength-to-weight ratio and excellent durability. It is a popular choice for high-performance and racing engines as it can withstand the extreme conditions of high RPMs and high valve spring pressures.

- Another material used for pushrods is titanium, which is even lighter and stronger than chrome-moly steel. However, titanium pushrods are more expensive to manufacture and may not be necessary for all engine types. Some pushrods are also made from aluminium, which is lightweight but not as strong as steel or titanium.

Measuring Pushrod Length

Measuring pushrod length is a crucial step in engine building. It is important to ensure that the pushrods are the correct length to achieve proper valve train geometry. Improper pushrod length can result in excessive wear on the valve train components, including the camshaft, lifters, and rocker arms.

Measuring pushrod length is a simple process that involves using a pushrod length checker tool. This tool allows you to measure the distance between the rocker arm and the lifter at the base circle of the camshaft.

Once you have determined the correct pushrod length, you can use adjustable pushrods to achieve the desired length. It is important to note that pushrod length can vary depending on the type of engine, camshaft, and other components used.

Therefore, it is essential to consult the manufacturer’s specifications or a trusted engine builder to determine the correct pushrod length for your specific application. In summary, measuring pushrod length is a critical step in engine building that ensures proper.

Choosing The Right Diameter Of Pushrod

When building an engine, it is crucial to choose the right diameter of the pushrod. Pushrods are an essential part of the valve train system, and they are responsible for transferring the motion from the camshaft to the lifters, rockers, and, ultimately, the valves.

The diameter of the pushrod is important because it determines the amount of strength and rigidity that the pushrod has. If the diameter is too small, the pushrod may have too much flex, which can lead to valve float, poor performance, and even engine failure. On the other hand, if the diameter is too large, the pushrod may be too stiff, which can lead to excessive wear and tear on the valve train components.

To choose the right diameter of the pushrod, you must consider the application, the engine’s horsepower, and torque output, and the valve train components being used. You can consult with an engine builder or a professional to determine the right diameter for your engine. It is essential to understand.

Choosing The Right Length Of Pushrod

There are a few factors that need to be considered. The length of the pushrod is crucial in maintaining proper valve train geometry. If the pushrod is too short, it can cause the rocker arm to bind on the valve stem, resulting in engine damage. On the other hand, if the pushrod is too long, it can lead to excessive wear and tear on the valve tip and rocker’s arm.

To choose the right length of the pushrod, start by measuring the distance between the rocker arm and the centre of the lifter. This will give you a baseline measurement to work with. Next, take into account the thickness of the cylinder head gasket, the deck height of the block, and the camshaft profile.

All of these factors can affect the final pushrod length needed for your engine. It’s also important to note that different engine configurations may require different pushrod lengths.

What Makes Pushrods Important

Pushrods are a vital component in the operation of many types of engines, including those found in cars, trucks, and motorcycles. These slender metal rods transmit the motion of the camshaft to the valves, allowing them to open and close at the correct times.

This is critical for the engine to operate properly, as the valves allow air and fuel into the combustion chamber and expel exhaust gases after ignition. Pushrods’ ability to withstand high forces and temperatures without bending or breaking is important.

They must also be precisely engineered to match the specifications of the engine’s camshaft and valve train, ensuring that the timing of the valve movements is accurate.

This is especially important in high-performance engines, where even small deviations can significantly impact power and efficiency. Pushrods may seem small and simple, but they play a crucial role in the operation of internal combustion engines. Without them, engines would not be able to generate power.

Factors To Consider When Choosing Pushrods For SBC Heads

First and foremost, it’s crucial to select pushrods that are the right length for your engine. This will ensure that the valve train operates correctly and that there is no unnecessary stress on the components.

In addition to length, it’s also important to consider the diameter and wall thickness of the pushrods. Thicker and stronger pushrods will be able to handle higher loads and will be more durable in the long run.

Another important factor to consider is the material of the pushrods. Titanium pushrods, for example, are incredibly strong and lightweight, making them an excellent choice for high-performance engines.

However, they can also be quite expensive, so weighing the benefits against the cost is important. Finally, it’s important to consider the brand and reputation of the Pushrod manufacturer. Choosing a trusted and reputable brand will ensure that you are getting quality.

Installing And Maintaining Pushrods

Pushrods are critical components in the operation of internal combustion engines. They help to transfer the motion from the camshaft to the valves, controlling the flow of fuel and air into the engine and the exhaust gases out.

Installing and maintaining pushrods is an essential task to ensure the engine’s proper functioning. Pushrods must install correctly to ensure they are in the right position and aligned with the rocker’s arms.

One should first check the length of the pushrods and compare them with the manufacturer’s specifications. If they are not the right length, they must replace. The pushrods should lubricate before installation to prevent wear and tear. In addition to installation, maintaining the pushrods is also essential.

It is recommended to inspect the pushrods regularly to check for any signs of wear or damage. If there are any signs of damage, it should be replaced immediately. Proper maintenance of the pushrods can help to extend their lifespan and prevent costly repairs down.

Troubleshooting Common Pushrod Problems

Pushrods are an essential component of an engine’s valve train system, responsible for transmitting the motion of the camshaft to the rocker’s arm. However, like any other mechanical component, they are prone to wear and tear, leading to a variety of problems that can hamper engine performance and reliability.

One of the most common issues with pushrods is bending, which can cause by excessive valve spring pressure, improper camshaft or rocker arm geometry, or inadequate lubrication.

This can result in a loss of power, misfiring, or even engine failure if left unchecked. Another issue is wear, which can cause the pushrod to become elongated or develop flat spots, causing the valve to remain open or closed for extended periods.

This can lead to poor fuel economy, reduced power, and increased emissions. To troubleshoot common pushrod problems, it is important to inspect them regularly for signs of wear, bending, or damage.

Conclusion

Choosing the right pushrods for your SBC heads is a critical aspect of engine building that should not overlook. Knowing How to choose pushrods for SBC Heads is a crucial task that requires attention to detail and precision.

As we have seen, factors such as engine type, camshaft design, valve train geometry, and rocker arm ratio all play a significant role in determining the correct pushrod length and diameter. Moreover, the pushrods’ quality is also important, as any failure in this component can lead to catastrophic engine damage.

By applying the principles and guidelines outlined in this comprehensive guide, you can make an informed and confident decision when selecting the ideal pushrods for your SBC heads, ensuring optimal engine performance and reliability.

FAQ

1.What Part Of The Engine Does The Pushrod Go In?

Ans: The pushrod is part of the valve train and goes between the camshaft and the rocker’s arm to activate the opening and closing of the engine’s valves.

2.What Factors Should Be Considered When Selecting Pushrods For SBC Heads?

Ans: The engine’s intended use (street, track, or racing) will affect the pushrod choice.

3.What Type Of Pushrod Is Best For SBC Heads?

Ans: The type of pushrod that is best for SBC (Small Block Chevy) heads depends on the specific application and setup.

4.How Do You Ensure Proper Fit And Alignment Of Pushrods In SBC Heads?

Ans: Measure the length of the pushrods required for the engine build. Install the lifters and rocker arms in the head.

5.What Color Are Pushrods?

Ans: Pushrods can come in various colors depending on the manufacturer, but they are usually silver or black.

![SBC Main Cap Torque Sequence [Effective Ways]](https://accuratepicker.com/wp-content/uploads/2022/03/SBC-Main-Cap-Torque-Tester.jpg)