Your cousin came to visit and offered you a favor to help fix the old car you have in your garage. The problem identified was the torque converter. If you decide to change the converter, you will need a helping hand. So, what are the torque specification of the chevy 350 torque converter?

Because your cousin knows a thing or two about cars, he will most probably tackle the complicated parts. If he suggests that the fasteners should be tightened with regular spacers, avoid it. Suppose you do not apply the right amount of torque according to the specifications.

In that case, there is a chance of future mechanical failure. In this guide, we will specifically discuss Chevy 350 converter mounting to the flexplate or flywheel and the torque specifications for that.

So, let’s begin!

Why Are Torque Specs Important?

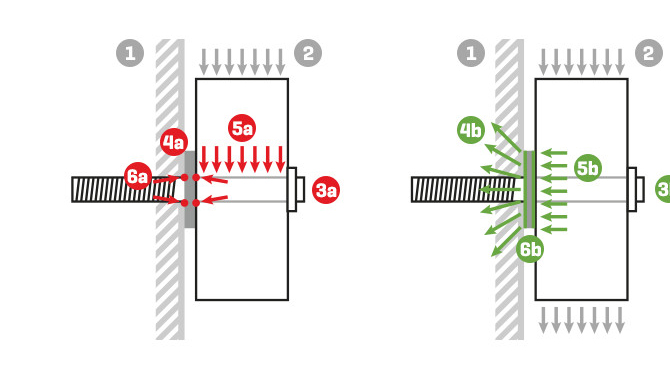

The proper amount of torque is important to ensure proper clamping between the flexplate and torque converter.

We emphasize applying the right amount of torque because the result of too much or too little torque is dire. Despite this, many professional mechanics feel confident to fasten fasteners without using a torque wrench.

However, study results say otherwise. Majority of the professionals fail to apply the appropriate amount of torque just by hand.

Either it is too much or too little. Because the fasteners are twisted into the cavity, there is a clamping force working on the joining parts. The force stretches the fastener.

Too much force will either break the nut or cut the threads if it is low grade. In case the fastener is high grade, it will damage the joint parts.

If the fastener is loose, the pressure will hinder the function of the gear and result in mechanical disaster. Thus torque specs are important for your engine and transmission health.

The Torque Specs For Chevy 350 Torque Converter

The torque specs for Chevy 350 torque’s converter are 60 to 65 ft/lbs. This torque setting is for the manual transmission. For automated transmission cars, this torque setting is 50 to 60 ft/lbs.

These specs are for rebuilding small Chevys. If you have a different type of Chevy, the specs may vary. In that case, please refer to the manual where for torque specs support.

Tools

You will need a torque wrench to apply the correct measurement of torque to the fasteners. There are different torque wrenches at various price points. These range from $40 to $140.

The socket drive sizes include ¼, ⅜, ½, ¾, also 1 inch. The smaller ones are for fragile cast housing, and larger ones twist big crank pulleys and transmission gear nuts.

To handle most major repairs, use ½ inch wrench. This is the conventional size for car repair nuts.

The fasteners that are popular for torque converters are grade 8 fasteners. You can use the Loctite thread locker at the end of the nuts to secure them in place.

You will also need an extension with the wrench. The extension will help to reach a congested space and the handling of the wrench convenient. Additionally, use a socket according to the wrench.

Specs Manual

Most shops provide the torque specs in their manuals because they are very crucial for car repair or parts replacement. The repair steps and back page tables state the fastener’s designation, location, and individual specs.

Suppose the torque specs mentioned above do not match your engine. In that case, there are standard chats available online for torque spec determination.

These charts include bolt diameter ( the rear part), thread count ( coarse or fine), dry or lubricated state. Take these readings from your purchased fasteners, then set the torque wrench according to the chart.

Measuring Units

Torque force can be measured in units of pound-feet (lb-ft), meter kilograms (m-kg), and newton meters (Nm).

The classic British measurements are exclaimed in foot-pounds. But the international units use newton meters. 1 (lb-ft )equals 14.6 Nm and 1 Nm equals 0.07 foot-pounds.

This inter-change is useful when the wrench is not calibrated with the appropriate units that are in the manual at hand.

Suppose there are other units that do not comply with the repair procedures, keep a conversion table handy. Most vehicles have foot-pound torque specs expressed in their manuals.

Location Of The Torque Converter

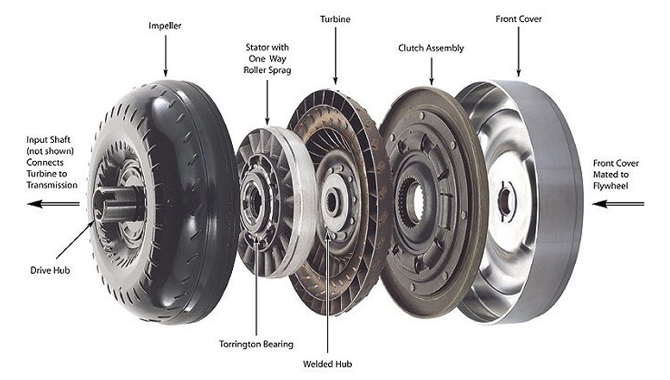

The torque converter is located just before the transmission input shaft. This shaft connects the turbine to the transmission. The torque converter has an impeller, a turbine, and a stator.

The entire converter is situated inside the bell housing. The transmission is connected to the engine block via flexplate or flywheel. It is connected to the crankshaft.

All these parts have to be aligned. Firstly, set the torque converter in the bell housing with a rotating and jerking motion.

The converter should rotate freely without any tightness. Then bring together the adjoining segments. The flexplate or flywheel will come face to face with the torque converter.

Mating The Engine Block With The Transmission

After placing the parts together, align both holes from the flexplate and torque converter. Once the holes are paired, thread the fasteners into the holes.

The first one should not be tightened immediately. Loosely put them in place. Then turn the crankshaft.

Turn it to the opposite point of the prior threaded hole. Thread the nut in it. In a crisscross manner, thread the fasteners in the flexplate or flywheel.

If there are six holes, you have to go back and forth to join both parts. If there are three holes, you only need one rotation. For Chevy 350, the flex plate consists of six mounting holes.

Torque Wrench Setting

To set the wrench at a specific torque, determine the specification for the nuts. Then twist the end; this will make it loose.

To adjust the setting, rotate the handle and bring it towards 60. If the number is absent, just bring it towards a number that is close to 65.

The zero on the handle should match the mark on the chosen number. Let us suppose this number is 60. Now you can add 5 to that number.

Just rotate the handle five marks further to make 65 or adjust it as you like. Also, if you go towards the opposite side, the specs go down. Now tighten the end. This will prevent any movement from the right setting.

Tightening The Fasteners

You have to use the torque wrench to tighten the nuts. Attach it with the extension and socket. Then put the socket onto the fastener’s head. Twist it with force. You may pull on the lever or push.

You have to use the torque wrench to tighten the nuts. Attach it with the extension and socket. Then put the socket onto the fastener’s head. Twist it with force. You may pull on the lever or push.

Do it a few times, and the torque wrench will make a clicking sound. If you are using the electrical wrench, it will turn on its indicator. Then you know that it is time to stop.

Although the wrench can be tightened further, you have to halt. Then in a crisscross manner, repeat this step. Now all the fasteners are in place, and they will fully function due to the right torque application.

Tips:

- The flexplate will have one hole that has a narrow hole. It is the starting hole. If you mount this hole first, the flex plate will not sway much when threading other nuts.

- The torque wrench has a spring component. Bringing the dial down to its lowest setting is essential for the instrument.

- Constant pressure on the spring will cause friction to create a mechanical error. This ignorance will cause inaccuracy in further usage. Thus, store it in the lowest setting.

Conclusion

Furthermore, there are many information chats in different books and the Internet. They might seem different from each other. So it is very hard to decide what specifications are acceptable. The priority will land on the manufacturer’s manual.

The manual provided will have all the specifications regarding mounting parts. If the specs differ from your car, the engineers that designed it had calculated them for this model. So it is best for you to follow the manual for the Chevy 350 torque converter.

![5 Best Stock SBC Heads [Reviews With Buying Guide]](https://accuratepicker.com/wp-content/uploads/2022/03/Best-Stock-SBC-Heads-150x150-1.jpg)