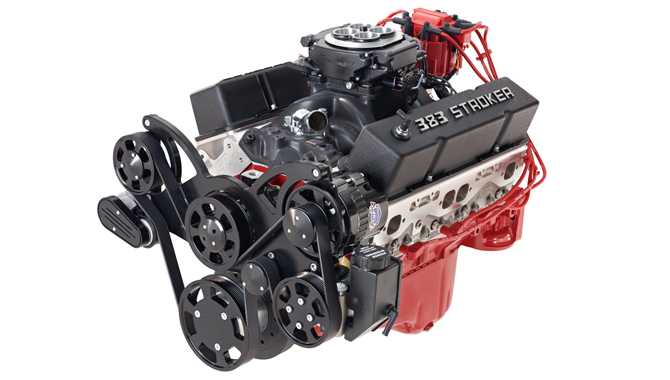

Looking for a stroker that can increase the torque in your vehicle like a monster? Then here is the perfect deal. Installing a stroker engine is a way of increasing a vehicle’s torque or horsepower.

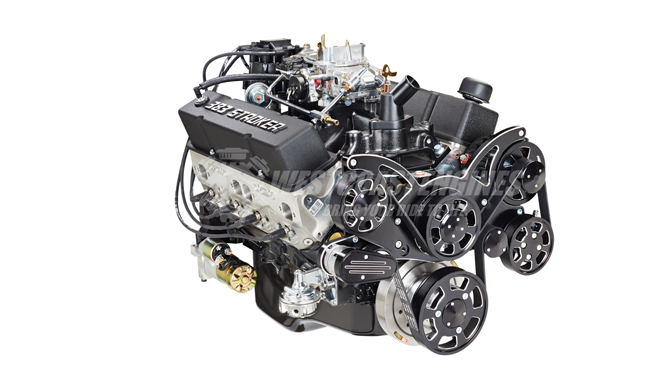

383 stroker is a popular one. Many have a lot of questions regarding it, and they look for answers to us. That’s why we choose this topic to discuss in this article.

Now, 383 strokers have so many things to be understood by us. Let’s get into detail and understand the stroker engine. So, what is a 383 stroker torque monster?

The more you get details of a product, the more it becomes easy to decide on purchasing it. So, spare some minutes to get all your queries appropriately answered.

Displacement Calculation

The bore of a 383 stroker engine is 4.03 inches, and its stroke is 3.75 inches. The formula to calculate the cubic inches of 383 is: 4.030 bores is multiplied by the 4.030 bores.

When the result is multiplied by 3.75 strokes, multiply it with 0.7854 another time, multiplying the answer by 382.668 (multiplying by eight cylinders). The answer in total is rounded up to the 383 inches displacement figure.

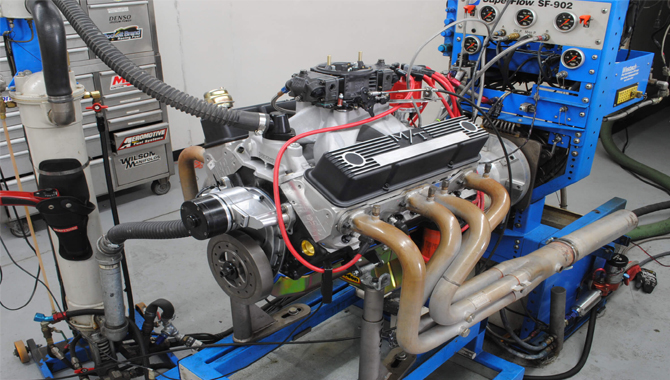

Required Machine Work

The 383 stroker has a base that is a 350 engine. You need the small block 400 crankshafts to machine it and fit the small 350 engine block.

You must have to bore 0.030 the engine block over the original size of it, or else creating proper clearance and displacement will not be easily possible.

If your small block 400 crankshaft stroke is longer, it will need better clearance to prevent rods and cylinder’s severe wear.

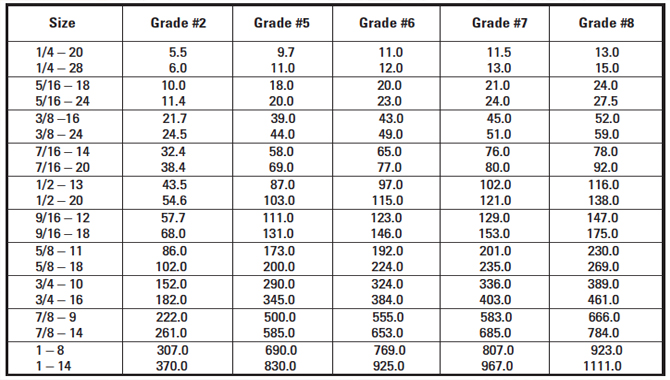

Torque Specifications

The main caps torque of the two-bolt main engine is 70 foot-pounds. You should set the torque wrench for four-bolt main torque to 70 foot-pounds.

The top cap bolts placed inside and the bolts placed outside should be 65 foot-pounds. Then torque the connecting rods with the 3/8 bolts to 45 foot-pounds—torque to 35 foot-pounds the connecting rods with 11/32 bolts.

Torque the cylinder head bolts to 65 foot-pounds. The oil pump bolt should be torqued to 65 foot-pounds and torque 12 foot-pounds the oil pan.

You should torque the timing cover to 6-foot pounds and the intake manifold to 30-foot pounds.

The exhaust manifold bolts need to be torqued to 25 foot-pounds. Lastly, torque both the harmonic damper and flywheel bolts to 60 foot-pounds.

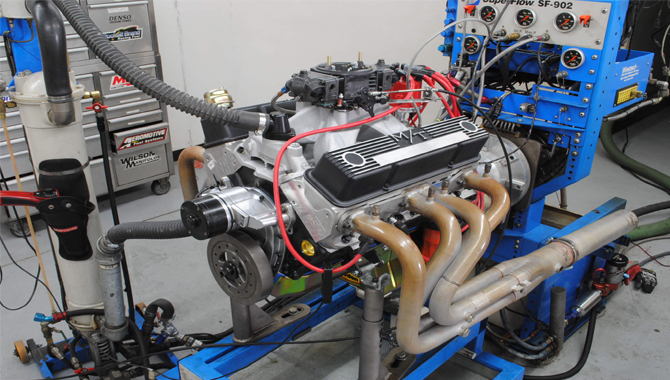

Performance Range Of 383 Stroker

It’s reported that the 383 stroker horsepower has varied but seems to produce torque at a significant amount.

The torque of the GM HT383 Base Performance engine is 45 foot-pounds at an rpm of 4000, and the exciting fact is it can boast over 400 foot-pounds of torque while the rpm is at 2,500. The GM ZZ383 Performance engine has a torque of 449 foot-pounds and 425 horsepower.

Many other 383 engines have been reported by the users 420 foot-pounds of torque and 330 horsepower. It is a torque monster, isn’t it? To obtain 395 horsepower, you need to torque 410 foot-pounds.

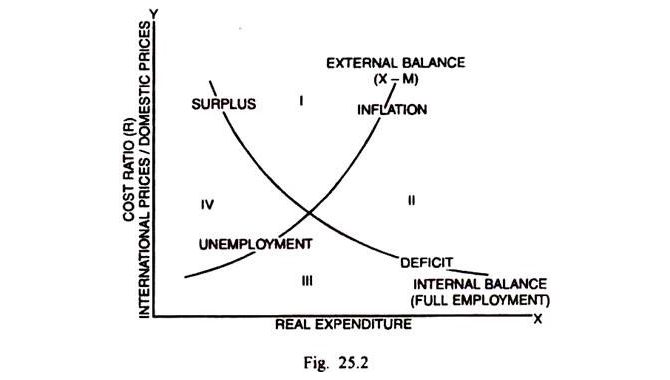

Internal And External Balance

In the ’60s, the chevy engineers drew a design of 400ci small-block, which means they tried to counterweight the crankshaft so that you can offset the longer stroke adequately.

Guess what? For moving the crank counterweights away from the crank centerline, there was no room in the crankshaft. The reason was the weight, and it was hitting the block. That’s why the designers build on the weight at the flex plate.

The crankshaft harmonic balancer end was making an exceptionally balanced engine. 400 is the one and only Gen I small-block requiring offset balance weights on the crank on both ends.

It means most graded 383 rotator collections make use of an externally balanced crank.

That will require a flex plate and a 400-style offset weight balancer. Although the externally balanced engines were doing great for decades, sadly, heavy external weights became a problem and used to put a twist in the crank at the higher engine speed.

Many 383 cranks started to offer internally balanced to keep the weights down. It requires heavy metal or Mallory, and you should add them to the crank throws.

To counterbalance the usually added weight to the flexplate and balancer. Though the process is much expensive, the internal balance provides durability advantages.

You will find many crank manufacturers who proffer internal balance options for 383 stroker collections, either as complete or separate rotator collections.

The Amount Of Power A 383 Stroker Torque Monster Can Provide

The job of a stroker is to increase the torque and power. So, it’s a must that you should gain knowledge about the amount of a stroker can provide for your car engine.

Such combos can make around 465 horsepower and almost 500 lb-ft, but the rpm is less. And some offer you 502 lb-ft at 4,700 rpm, 500-plus horsepower from 5,700-6,200 rpm.

Even you will find one that can knock down 500 LB-FT and 500 horsepower. There are fewer and more. It varies upon the company you are going to purchase the machine’s capability.

But anyway, the point is it’s an excellent stroker, and the power, speed it can offer is vast enough that you can call it a monster. It can be a perfect choice for your racing car to experience a tremendous yet relaxing speed while driving.

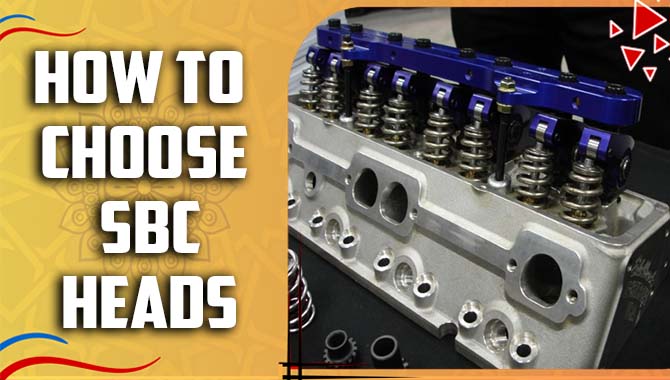

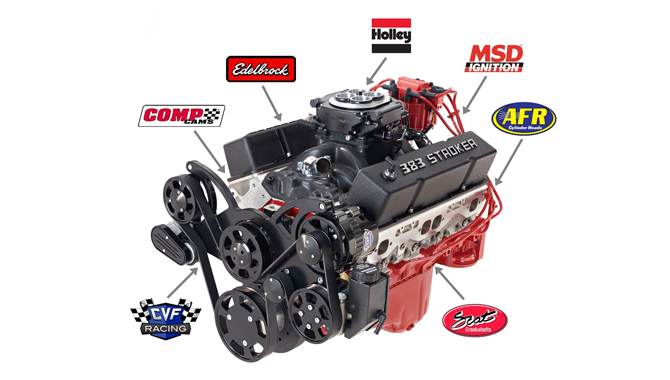

The Required Size Heads For A 383 Stroker

If you have confusion thinking about what size heads you should use for the 383 strokers you have or are going to buy, then don’t worry. We are here with excellent suggestions for you.

If our suggestion seems okay, we would say go for a 195 to 210 cc volume intake port if it’s street strip 383 to experience solid and high performance.

But if your choice is something that is out of the box and at the same time the best, you should check the CNC ported heads because they can provide the power you are demanding.

Is 400 Better Or 383?

It’s a common query people have, especially when a person knows about both the strokers. It’s simple to understand, and we are here to explain it.

The 383 has a lot of low-end torque. Do you know what it means? It means your vehicle will respond very well, and your drive is going to be very relaxing.

Moreover, the rpm range of 383 is better than the 400. About the 400 strokers, it is perfect as an engine of trucks. If it is done correctly, it can work as a fantastic car engine.

The common overheating issue of the two engines was for the GM used to use a small radiator. Overall for cars, the 383 stroker engine is better, and it was made especially for the car.

How Much Speed Of The 383 Stroker?

People who love to drive their car at an incredible speed, you should get excited! Because 383 strokers can satisfy your hunger for speed.

Let’s try to understand how the speed is increased by 383. The stroke makes the primary rod centerline diameter increase. Both the piston and rod have to go in a diameter that is larger and is placed in the exact engine rpm.

For this, the piston speed increases. It results in pulling more air by the stroker at a lower engine rpm. A 383 stroker has the exact piston speed at rpm of 2500, while the rpm of a 350 is at 3100.

So, as you can see, we can say without any doubt that 383 stroker is a monster as a speed provider too. You will never regret having this engine set inside of your car.

Best Transmission For A 383 Stroker?

To understand what transmission could be best for your 383 strokers, you have to understand your car’s current fuel or spark setup.

If you could easily add the computing power to change gears in a 4L80ea, even the gnarly 383 strokers will face difficulty killing an 80e.

You can find such guys making 700+ rear wheel horsepower on 80e’s installed with nothing else but only a shift kit.

Now, if you are not interested in the electronic shift, go for TH400. You can build 700 or 60e for handling a 383. To make your 383 reliable, you need to build a 700 or 60e.

The TH400 or 80e are going to be cheaper even if you manage a transmission controller. It will be better if you get the 2500 or 3500 in the wrecker. Then yank the transmission, add a shift kit, and you are ready to get going.

Conclusion

Now that you have got to know all the essential information regarding the 383 strokers, we believe that you have understood how cool the 383 stroker engine is for a car to have.

As we said, you will have zero regression after purchasing and using one. If you already have a 350 stroker, you can turn it to 383, and the performance will be almost the same. I hope now you know the 383 stroker torque monster.

FAQs

1. How Much Does It Cost To Turn A 350 Into a 383 Stroker?

Ans: If you are planning on rebuilding the engine and turning the 350 into a 383 stroker, you should focus on horsepower.

If you want your engine to handle around 400 to 450 horsepower, you need to put a 383 together, which will probably cost you 1500-1600 dollars. It would be a short block.

Though there is a possibility to build it while costing around 1200 dollars, you will get everything within the budget for 350 and 400 except for the new rings, bearings, and pistons.

2. How Do You Tell if a 350 is a 383 Stroker?

Ans: The result of a 350 stroked is a 383 stroker. That is why the 383 block still looks like the 350 blocks, having the same numbers.

But there is only one way to understand more efficiently: check out the engine’s bottom end. If you see it is ground for clearance and its crank has markings, know that it’s a 383 stroker updated from 350 strokers.

3. How Do You Tell if it’s a 383 Stroker?

Ans: If you see the engine is balanced internally, you can’t be sure and tell that it’s a 383 stroker by looking at it. But if the engine is balanced externally, you can check the counterweight upon the flexplate and tell it’s a 383 stroker.

![383 Stroker Torque Monster [Easy Steps & Tips]](https://accuratepicker.com/wp-content/uploads/2022/03/383-Stroker-Torque-Monster.jpg)