The melting point is a specific temperature that helps to perform soldering. Do you know what specific melting point or temperature is required to do that?

Well, there are a lot of variations. Most people lack this knowledge, and that’s why we are here to help you by giving you the right information. The melting point varies dramatically, and different matters have different melting points. So, what is the lead free solder melting point?

To bring a smooth finish and make the work go fine, we should know each of the matter’s melting points that we want to solder.

In this guide, our only topic is not the melting point of lead-free solder but many more. Hence, keep reading the article and see every little piece of the necessary information we are about to share.

What Is Melting Point?

The temperature at which a substance melts and changes its state. For example, becoming liquid from solid is called the melting point of that specific substance.

Depending upon the pressure, melting points are measured. Every substance increases their temperature until they reach the melting point.

Then the solid matter will start to turn itself into liquid, and at that phase, the temperature remains the same. Every substance varies by melting point.

Lead Free Solder Melting Point

Now that you understand the melting point, it is the right time to let you know the melting point of lead-free solder.

The general melting point of a lead-free solder lies within 217°C/427°F, which is a higher temperature than the lead-based solder.

You need to know that to increase your knowledge is, the lead-based solder melting point is 183°C/361°F.

That’s why you can solder the electronic components and PCB materials at a higher temperature without being worried about causing an accident. If you want to know the exact melting point of lead-free solder, it is 425 °F.

The Importance Of Knowing Melting Point

Knowing melting points helps you a lot in working like a professional. Soldering is all about heat, and whether you solder a metal, copper, lead-based, or lead-free option, you need to apply heat.

You should have the information on melting point because you might over melt or melt a little without knowing it of a substance. Soldering is a typical job that requires a lot of useful knowledge.

You should know the timing, the quantity, melting points, and more.

If you read and memorize the common material melting points, you should be able to solder them using the right timing and to apply the right amount of heat while understanding the state of that certain substance.

Lead-Based Or Lead-Free – Which Should You Choose

Well, for doing welding work, it’s better to choose the lead-based soldiers, and the reasons for choosing it are many.

The first reason is working with a leaded solder is easier than the lead-free solder because leaded solders require low temperature. The quality issues regarding the joints are less of the lead-based soldiers.

People use lead-free soldiers only when they are not allowed to use the leaded solders or plan to sell any goods made of lead-free solders outside the country (European countries).

You may have heard that leaded solders pose more risk for health, but that’s not true at all. Rather it is lead-free soldiers that can cause more risk to your health.

Lead’s vapor pressure is so low that a little number of molecules come out in the air when soldering. Besides, the only danger you can consider for your health is inhaling the vaporized flux.

This vaporized flux is more intense when soldering a lead-free solder because the required temperature is higher enough than the leaded ones. Therefore, it’s good to work on lead-based solders.

Soldering Procedure For Lead-Free Solder

You are here in this article which means you want to solder lead-free solders, but wait! Do you know the process?

If you are still gaining knowledge, then stay with us and learn from us the whole procedure of soldering a lead-free solder. The process includes steps below;

First Step

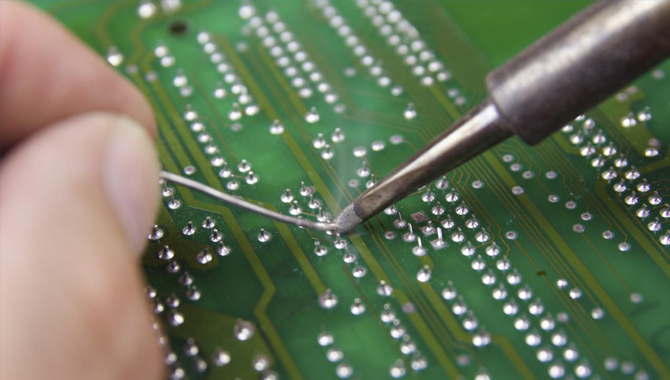

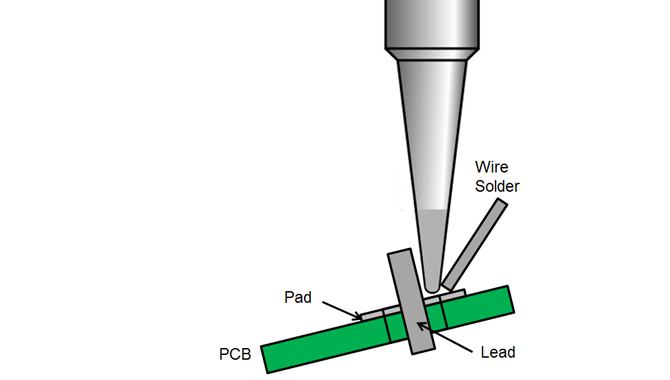

In between the pen and pad, there are connection sides. Place the iron tip on any side of the connection and keep it there for a few seconds.

Now, place the lead-free solder on the other side. It will cover the joint by melting and flowing.

Second Step

The lead-free solder will take around seven seconds to melt.

Be sure you are making the lead-free joint as quickly as possible, or else working longer time may cause overheating the components, PCB damaging, and lifting pads.

If the connection needs more heat, use an iron of a larger tip or higher wattage.

Third Step

After removing the solder, pull out the soldering iron immediately. Let the joint get cool within some time and be undistributed.

Fourth Step

Do not retouch the lead-free connections because they tend to have a rough finish and dull appearance.

If you retouch it anyway, it will weaken the joints because of the intermetallic growth between the copper land and the component.

Is Soldering Lead-Free Solder Possible At Home

Some think it’s a hassle to solder by themselves, especially when it comes to soldering a lead-free solder because it needs more temperature than lead and releases more vapor, which can harm you if inhaled anyhow.

But to be honest, this is not a big deal. You just need little precautions and work carefully using tools that safeguard you, and then follow the steps we mentioned above. You can easily do lead-free soldering at your home.

The chief thing you need is confidence. After having the first-time experience, you will not hesitate a little to do soldering again.

Conclusion

Now that you know both the melting point of lead-free solder and how you can solder it, we hope you will successfully do the job.

Whether this will be your first soldering work or you have gained experience before, do not hurry while soldering. Even the pros make mistakes sometimes. Keep in mind the melting point and be slow, steady while soldering.

Before we close, take advice from us; check all your tools to see if they are working properly or not because soldering is such a work that needs to keep going smoothly from start to finish. I hope now you know about what is the lead free solder melting point.