Using diagonal cutters is an effective way to cut through tough materials such as metal, plastic, and wood. Diagonal cutters are a type of hand tool used for cutting wires and other materials.

They are generally made of steel and have two cutting edges, one of which is angled. They are used for a variety of tasks, including cutting through tough materials, stripping insulation from wires, and cutting bolts. In this article, we will discuss the various techniques for using diagonal cutters to cut through tough materials.

We will also discuss the advantages and disadvantages of using these tools, as well as safety tips for using them. So, if you’re looking for an efficient and effective way to cut through tough materials, read on to learn more about how to cut through tough materials with diagonal cutters.

Mastering The Art Of Diagonal Cutters

Before we get started on the main article on how to cut through tough materials with diagonal cutters, let’s take a moment to understand the basics. Diagonal cutters are a type of hand-held pliers used for cutting wires, nails, and other small objects. They are designed to cut through materials that are too tough for regular scissors or other cutting tools. They are also used for gripping and bending wires. With the right technique, these tools can be used to cut through even the toughest materials. In this article, we’ll explore the best ways to use diagonal cutters to cut through tough materials.

Select Proper Cutters

When selecting a pair of diagonal cutters for tough materials, it is important to consider the type of material that will be cut. Different materials require cutters designed for that type of material. For example, hardened metals require a pair of cutters with a higher hardness rating than those used to cut soft metals. The cutting edges of the cutters should be sharp and clean, free of chips, burrs, and other deformities.

Additionally, the cutting edges should be aligned properly so they meet evenly when the cutters are closed. The handles of the cutters should also be comfortable and fit the user’s hand properly. If the handles are too small, they can cause fatigue and may even cause the user to lose grip, resulting in injury.

Lastly, the cutters should be of the correct size and shape for the job. If the cutters are too small, they will not be able to cut through the material; likewise, if they are too large, they can cause excess strain on the user.

Types Of Cutters

Cutting through tough materials can be a tricky task. To make it easier, it is important to use the right tool for the job. Diagonal cutters are a type of pliers designed to cut through materials such as wire, nails, and bolts. They have long, pointed tips and angled cutting edges, which allow them to get into tight spaces and make precise cuts.

Diagonal cutters come in a variety of sizes, so you can find the right tool for your project. They also have serrated jaws, which are designed to grip materials and prevent slipping. For extra precision, look for a pair with adjustable joint tension, which allows you to customize the cutting action to your needs.

Size And Cutting Edge

The size and cutting edge of diagonal cutters is an important factor to consider when attempting to cut through tough materials. A larger cutter with a thicker cutting edge will provide a greater amount of leverage and power, making it easier to make a clean cut. On the other hand, a small cutter with a thin cutting edge may have difficulty cutting through dense materials and may require more effort to make a clean cut. I

t is important to select the right size and cutting edge for the job at hand. If the material is too thick for the cutter, it will be difficult to make a clean cut. Similarly, if the material is too thin, the cutter may not have the necessary power to cut through the material.

Material And Handle

When cutting through tough material, it is important to have the right tool for the job. Diagonal cutters are the perfect tool for this task. These cutters have a sharp blade with angled cutting edges that can easily cut through materials like wire, plastic, and metal. The handles on diagonal cutters are designed to provide a comfortable grip and are usually made of a material such as steel, aluminum, or plastic.

The material of the handle also helps to reduce fatigue when the tool is in use for long periods of time. Additionally, the handles are usually textured to provide better grip and control. Diagonal cutters come in a variety of sizes and shapes to fit the needs of the user and the materials being cut.

Safety

Safety is paramount when using diagonal cutters to cut through tough materials. It is important to wear protective gear such as goggles, gloves and appropriate clothing. Make sure the work area is free from distractions and that there is nothing that could cause a distraction, such as a pet or child. It is also important to secure the material being cut, as it could cause injury should it slip or move.

For best results, use the diagonal cutters on a flat, stable surface. Additionally, make sure to keep your hands and fingers clear from the cutting blades to avoid injury. Finally, be sure to inspect the blades before and after use to make sure they are not damaged. By following these safety measures, you can ensure a safe and successful experience when cutting through tough materials with diagonal cutters.

Prepare Materials

Before attempting to cut through any tough material using diagonal cutters, it is important to ensure that you have all the necessary materials and tools. Start by gathering the material you need to cut, such as steel, cast iron, or aluminum. You should also have diagonal cutters, which are designed to cut through these materials with ease. Additionally, you should have safety glasses, work gloves, and a reliable workspace with plenty of lighting.

Lastly, you’ll want to have a ruler or measuring tape to ensure that you are cutting the material to the correct length. With all the necessary materials and tools in place, you are now ready to begin cutting through tough materials with diagonal cutters.

Choose Materials

When using diagonal cutters to cut through tough materials, it is important to choose the right material for the job. Different materials require different cutting tools and techniques. Steel is a popular choice for many cutting tasks, as it is strong and durable. For cutting through thicker materials such as aluminum or brass, it is best to use high-carbon steel cutters, as they can handle the increased pressure.

For softer materials, such as wood, plastic, or rubber, standard steel cutters will work fine. It is also important to consider the shape of the material when choosing the right cutting tool. If the material is circular, a pair of round-nose cutters is ideal, while flat materials will require flat-nose cutters. Additionally, for more intricate cuts, such as those required for intricate wire work, precision cutters are recommended.

Mark Cutting Line

Marking is an essential step when using diagonal cutters to cut through tough materials. Before you begin to cut, use a marker to clearly outline the line you are going to cut. This will ensure that the cut is precise and exact. Make sure the mark is visible and clear so that you can follow it with the cutting tool. If the material is thick, use a ruler to measure the outline to make sure the edges are even.

This will help you avoid any mistakes when cutting. Additionally, mark the material with an “X” where you want to make the cut. This will help you identify the exact spot to begin slicing. Take your time and make sure the outline is even before you start cutting. Doing this will save you time and effort in the long run.

Secure Materials

When it comes to cutting through tough materials with diagonal cutters, it is essential to secure the materials before starting. This can be done by clamping or using a vise to hold the materials in place. It is also important to ensure that the cutting surface is free of debris and any sharp edges are safely covered.

When cutting, it is important to take care to not put too much pressure on the blades, as this may cause them to become dull or even break. Also, it is important to use a lubricant such as oil or wax to reduce the friction between the material and the blades. Finally, when finished with the cutting, it is important to clean off any excess debris or lubricant from the blades. Taking these precautions will help ensure that the cut is both successful and precise.

Wear Safety Gear

When working with tough materials like metal, it is important to wear safety gear. This includes gloves, safety glasses, and protective clothing. Additionally, it is important to ensure that the work area is well-ventilated so that any dangerous fumes created by the metal are not inhaled. Be sure to use a sharp pair of diagonal cutters for the job. Dull cutters can increase the chances of injury and take longer to make the cut. It is also important to use a cutting board and wear thick gloves to protect the hands. Make sure the cutters are not too tight or too loose; the handles should fit comfortably in the hand. Finally, always cut away from yourself and be aware of what is around you.

Execute Cut

To execute a cut with diagonal cutters, it is important to take the time to properly set up and prepare. Firstly, securely fasten the material in place so that it doesn’t move when cutting. Secondly, select the correct size of diagonal cutters for the job, as using the wrong size can easily damage the material or the cutters. Thirdly, ensure the cutting blade is sharp and in good condition. Finally, make sure you use a steady, controlled motion while cutting to ensure a clean and accurate cut. If you take the time to properly set up and prepare, you will be able to easily cut through tough materials with diagonal cutters.

Position Cutters

Positioning your diagonal cutters correctly is key to making a successful cut. It’s important to ensure the cutting edge of the tool is aligned perpendicular to the material you’re cutting. To achieve this, you need to hold the tool firmly with your index finger on the top of the handle and your thumb on the side of the handle.

You should also make sure the cutters are firmly gripping the material. Once in position, squeeze the handles of the cutters together to make your cut. Adjust the tension of the handles as needed to ensure that your cut is clean and precise. With practice, you’ll be able to make clean cuts through even the toughest materials.

Apply Pressure

When using diagonal cutters, it is important to apply the right amount of pressure. Too little pressure will not cut through the material, while too much pressure can cause the cutters to slip and cause injury. For best results, hold the cutters firmly and apply a steady pressure while cutting.

Make sure to keep your fingers away from the line of the cut. Additionally, you may need to use a hammer to apply additional pressure to the cutters. This will help the cutters to penetrate the material more easily. Once the material is cut, release the pressure and allow the cutters to move freely. With practice, you will be able to determine the right amount of pressure to use for each material.

Move Cutters

Diagonal cutters, also known as move cutters, are a type of pliers used to cut through tough materials, such as wires and nails. Using diagonal cutters correctly can be tricky, but with the right technique you can quickly cut through materials with ease. Start by ensuring the cutting blades are sharp and in good condition. Then, adjust the handles of the cutters so that when the blades meet they form an angle.

When cutting, always ensure the blades are in a straight line and apply pressure evenly across the blades. This helps to prevent the blades from getting jammed. To make a clean cut, carefully guide the edges of the blades along the material, keeping the blades closed until they reach the end. Make sure to leave the blades in a closed position when finished to prevent any accidental cuts. With practice, you can quickly and easily cut through tough materials using diagonal cutters.

Cut In Multiple Passes

When cutting through tough materials like steel, it is best to cut in multiple passes. This will help to prevent the cutters from jamming and also reduce the risk of the material fracturing. To do this, set the cutters to the desired size and make one pass, then slightly reduce the size of the cutters and make a second pass. After each pass, check that the material has been cut evenly and accurately.

If you need to make a third pass then repeat the process, gradually reducing the size of the cutters. For the last pass, use the smallest size cutters to ensure the cleanest cut.

Conclusion

Diagonal cutters are a versatile tool that can be used to cut through tough materials such as metal, plastic, and wood. To use them, align the blades of the cutters with the material and gently squeeze the handles together. Make sure to apply even pressure and keep the blades aligned with the material to ensure a clean, straight cut. With a little practice, you’ll be able to cut through tough materials with ease.

FAQ’s

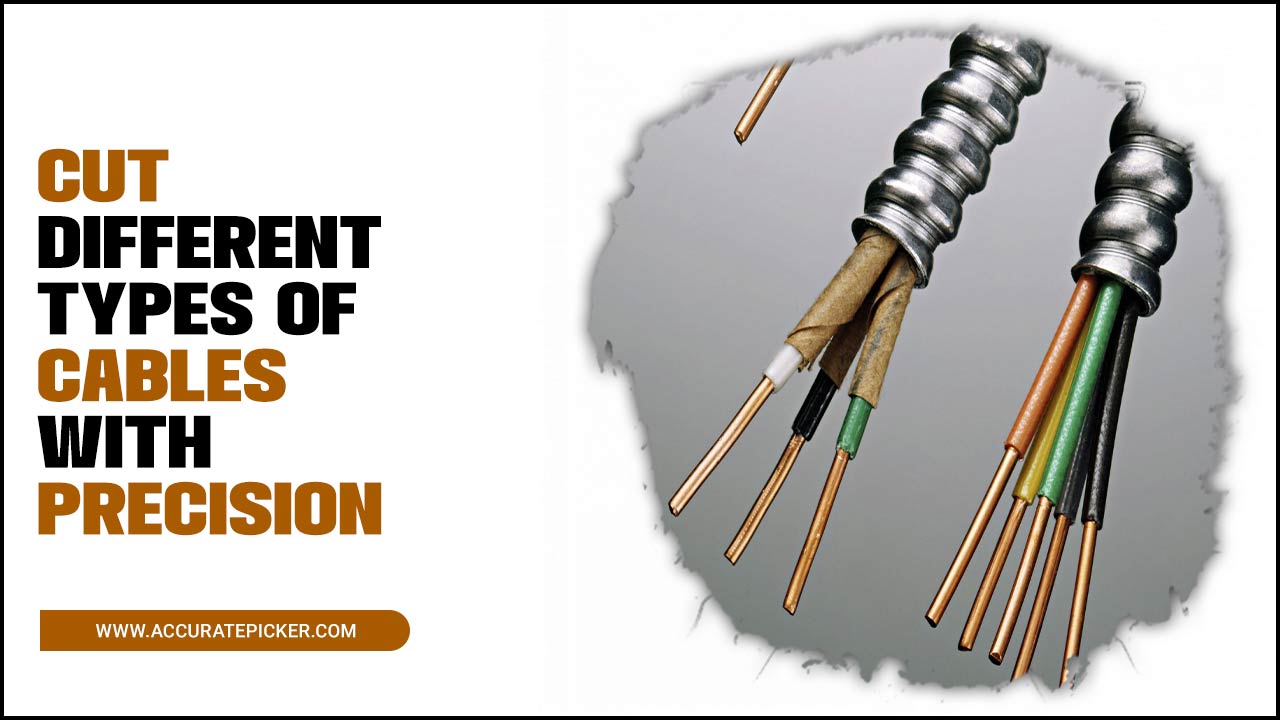

1.What Kind Of Materials Can Be Cut With Diagonal Cutters?

Ans:Diagonal cutters are a type of plier used to cut wire and other small items. They are generally used to cut softer materials such as copper wire, vinyl, rubber, or plastic. They can also be used to cut through cables, but they should not be used for materials such as steel or hard metals. Diagonal cutters are an essential tool for electricians, mechanics, and other professionals who work with wire and other materials.

2.What Is The Best Way To Set Up The Workpiece For Cutting With Diagonal Cutters?

Ans:The best way to set up the workpiece for cutting with diagonal cutters is to secure it in a vise or clamp. Make sure the workpiece is secure and will not move during the cutting process. Position the workpiece so the cutters can reach the area you want to cut. Ensure the area you are cutting is well lit so you can clearly see what you are doing.

3.What Safety Precautions Should Be Taken When Using Diagonal Cutters?

Ans:When using diagonal cutters, it is important to wear safety goggles or glasses to protect eyes from flying debris or metal splinters. It is also important to wear gloves to protect hands from cuts and scrapes. The diagonal cutters should be regularly inspected for signs of wear or damage and replaced as needed. Finally, it is important to maintain a firm grip on the handles and use slow, steady movements when cutting.

4.How Can The Cutting Pressure Be Adjusted When Using Diagonal Cutters?

Ans:The cutting pressure can be adjusted by varying the force applied to the handles of the diagonal cutters. In addition, the distance between the handles can be adjusted to increase or decrease the cutting pressure. The cutting pressure can also be adjusted by changing the size of the cutting edge of the diagonal cutters. Finally, the cutting pressure can be adjusted by changing the angle of the cutters in relation to the material being cut.

5.What Is The Best Way To Sharpen And Maintain Diagonal Cutters?

Ans: The best way to sharpen and maintain diagonal cutters is to use a file to create a sharp edge. Make sure to sharpen both sides of the blades evenly. After sharpening, lubricate the blades with a light oil. Finally, store the diagonal cutters in a protective pouch or container to ensure they stay sharp and long-lasting.