Soldering is a crucial process in the manufacture of electronics, and the quality of the soldering job depends largely on the type of soldering iron used.

In particular, the soldering iron tip and the soldering iron heater are two key components of a soldering iron that can make a big difference in the quality of a soldering job. In this article, we will discuss the differences between a soldering iron tip and a soldering iron heater, and how each affects the soldering process.

We will also discuss the advantages and disadvantages of each component, and how to choose the right one for the job. In the end, the reader will be equipped to make an informed decision when it comes to choosing the best soldering iron tip and soldering iron heater for their needs. So, if you want to know more about the differences between soldering iron tips and soldering iron heaters, read on to find out!

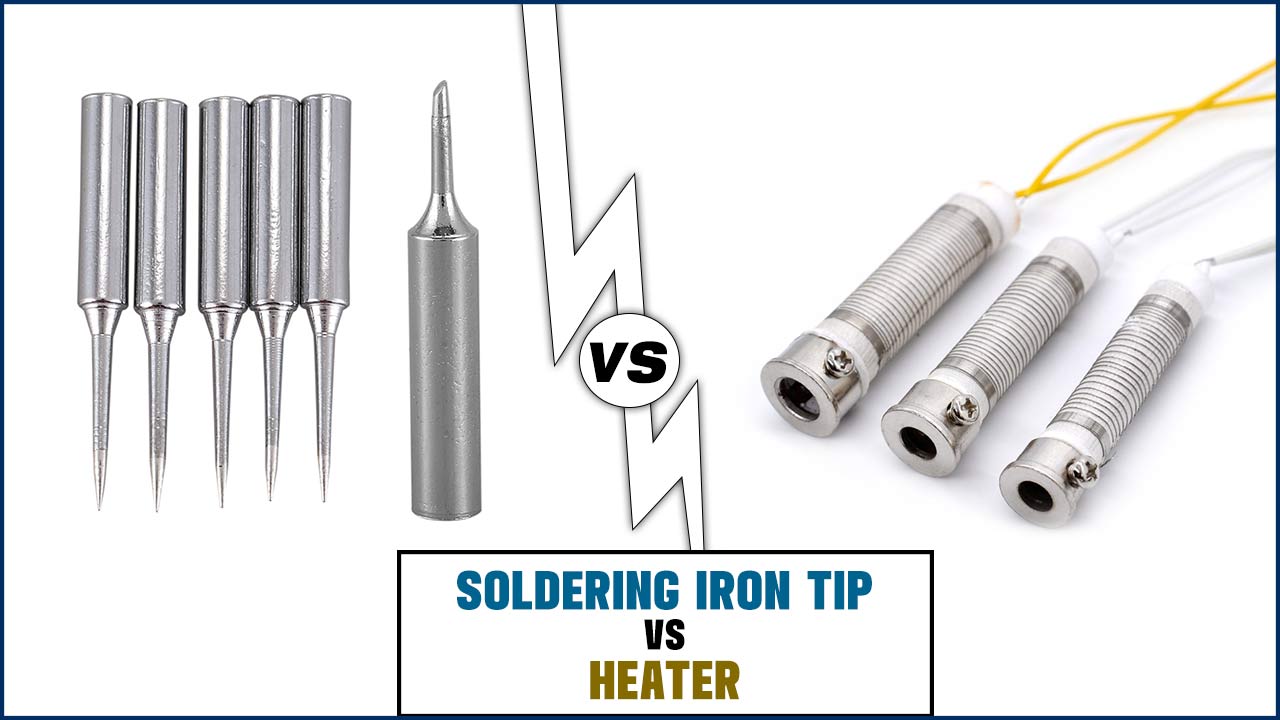

Comparing Soldering Iron Tip & Heater

Soldering is a process of joining two metals together by melting a filler material, usually a lead-based alloy. A soldering iron is a tool used for this purpose. It has two main components: the tip and the heater. The tip is the part that comes into contact with the metals, and the heater is the part that heats up the tip.

The tip and the heater are both essential components of a soldering iron and they must be properly maintained in order to ensure the quality of the soldered joint. In this article, we will discuss the differences between a soldering iron tip and a soldering iron heater and how they affect the quality of the soldered joint.

Comparison

When looking at the differences between a soldering iron tip and a soldering iron heater, it’s important to consider the purpose of each component. A soldering iron tip is a metal point that is heated and used to melt and join metals together. It is the part of the soldering iron that actually comes into contact with the metal being worked on.

In contrast, a soldering iron heater is a device that provides heat to the soldering iron tip. It is usually an electric coil that is powered by electricity and is responsible for heating the soldering iron tip.

The heater is often the most expensive part of the soldering iron, as it requires more energy and is typically more complex than the tip. Both the tip and the heater are essential components of a soldering iron and must work together for successful soldering.

Tip

When soldering, it is important to understand the difference between a soldering iron tip and a soldering iron heater. The tip is the business end of the soldering iron and is responsible for the actual soldering of the two components. It is usually made of a thin piece of metal such as copper or brass and has a metal tip, usually of a pointed shape, that is heated by the soldering iron heater.

The heater is a separate element from the tip and is responsible for heating up the tip to the desired temperature. The tip is then used to transfer heat to the two components to be soldered together. The temperature of the tip must be regulated for optimal soldering. If the temperature is too high, it could cause damage to the components.

If the temperature is too low, it could prevent the components from being soldered properly. The tip and heater must be regularly cleaned and maintained for optimal soldering results.

Heater

When it comes to soldering iron tips and heaters, it is important to understand the difference between the two. A soldering iron tip is the part that comes into direct contact with the metal being soldered, while the soldering iron heater is the component that generates the heat. The heater is typically located inside the handle of the soldering iron and is responsible for heating the metal tip.

While the soldering iron tip is the part that is responsible for the actual soldering process, the heater is the component that needs to be maintained and replaced periodically to ensure that the soldering iron tip is kept hot enough to do its job. Therefore, it is important to keep an eye on the condition of your soldering iron heater, as it will directly affect the performance of your soldering iron tip.

Purpose

Soldering irons are essential tools for any electronics repair or assembly job. The two main components of a soldering iron are the tip and the heater. The purpose of the tip is to conduct heat to the soldering joint, while the purpose of the heater is to generate the heat.

The tip is usually made of copper, while the heater is usually an electric heating element. The tip can be replaced when it becomes worn or corroded, while the heater is not typically replaceable.

The tip is also the part that comes into contact with the soldering joint, so it must be kept clean and in good condition. The heater is also responsible for maintaining a consistent temperature, so it needs to be monitored as well.

Components

Soldering iron tips and heaters are the two main components of a soldering iron. The tip, also known as the soleplate, is the part of the iron that comes in contact with the material being soldered. It is usually made of a copper alloy and is shaped to fit the application.

The heater is the part of the iron that produces heat and is usually contained in the handle of the iron. It is typically made of a high-temperature alloy and is designed to keep the tip of the iron at the desired temperature. The heater is usually powered by an AC power source, although some models may be powered by a battery. Both components must be of high quality in order to ensure the safety and reliability of the soldering iron.

Safety

When it comes to safety, using the right tool for the job is essential. Soldering irons come in a variety of shapes and sizes, and each type has its own unique safety considerations.

When considering which type of iron to use, it is important to understand the differences between soldering iron tips and soldering iron heaters. Soldering iron tips are the portion of the iron that makes contact with the workpiece and applies heat to the solder.

Soldering iron heaters are the part of the iron that heats the tip. Soldering iron tips are often made of copper or brass and are designed to conduct heat from the heater to the workpiece. They come in a variety of shapes and sizes to fit the job.

It is important to use the correct size and shape of tip for the job to avoid damaging the workpiece or the tip. It is also important to make sure the tip is properly mounted to the heater to prevent it from coming loose. Soldering iron heaters are typically made of stainless steel and contain a heating element. They are designed to provide a steady source of heat to the tip and may be adjustable to control the temperature.

It is important to make sure the heater is properly connected to the power source to avoid over-heating and damaging the tip. Additionally, it is important to use a properly rated heater for the job to ensure the tip does not become too hot.

When working with soldering irons, it is important to understand the differences between soldering iron tips and soldering iron heaters. Using the right tool for the job is essential for safety and to ensure the best results. Be sure to follow the manufacturer’s instructions to ensure the tool is used correctly and safely.

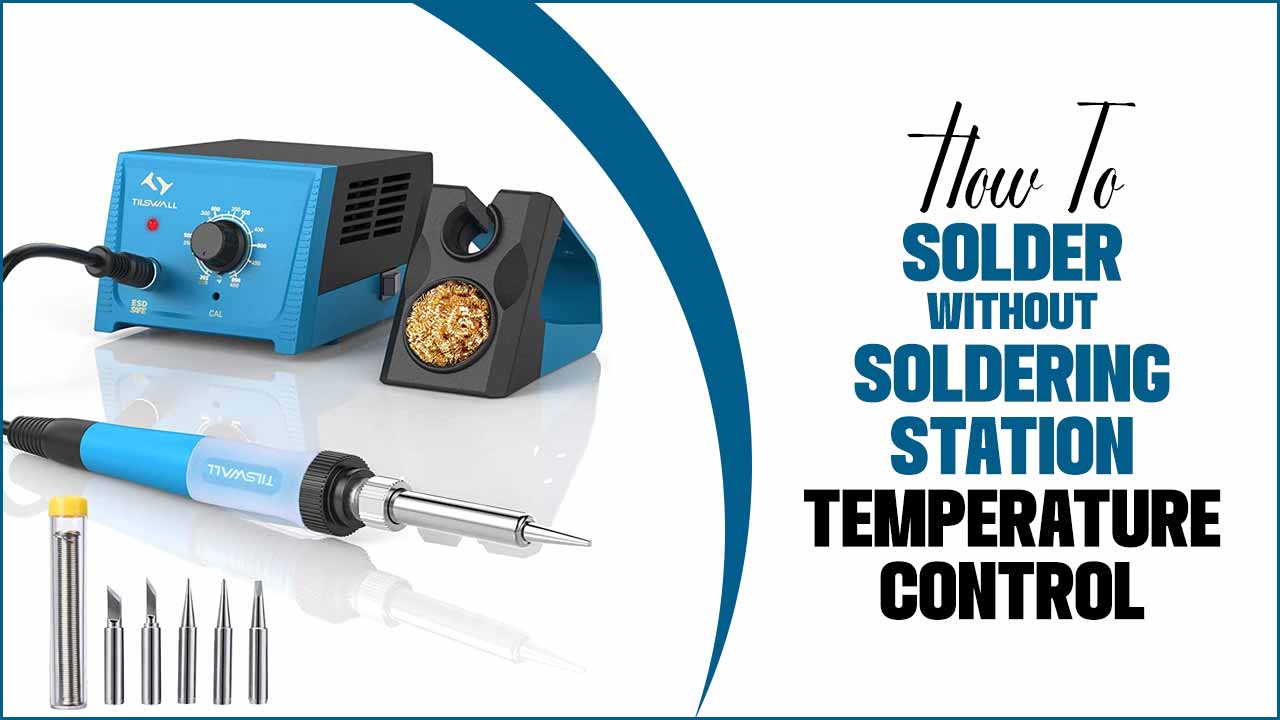

Temperature

When it comes to soldering, temperature is a critical factor. The tip of the soldering iron is the part that needs to be heated up to the right temperature in order to melt the solder and make a secure connection. The tip is usually made of copper and has a coating to protect it from oxidation.

The temperature of the tip is usually controlled by the soldering iron heater, which is a heating element that is usually located inside the handle of the soldering iron. The heater is usually controlled by a knob on the outside of the handle, allowing you to adjust the temperature of the tip.

The hotter the temperature of the tip, the quicker the solder will melt and create a secure connection. However, it is important to not go too hot, as this can cause damage to the components you are soldering.

Ventilation

Ventilation is an important factor to consider when deciding between a soldering iron tip and a soldering iron heater. Soldering iron tips are connected to the soldering iron by a cord, which allows for proper ventilation of the work area. This helps to reduce the risk of fumes and gases from the solder that could potentially cause serious harm.

Soldering iron heaters, on the other hand, are portable and require no cords. However, they may not provide the same level of ventilation as soldering iron tips, as they cannot be placed away from the work area.

For this reason, it is important to ensure that the area is well ventilated when using a soldering iron heater. Additionally, it is important to be aware of the source of heat when using a soldering iron heater, as it can become very hot and cause burns if not used properly.

Hazards

Soldering irons present a number of hazards that should not be overlooked. Firstly, there is the danger of electric shock, as the iron is plugged into an electrical socket. Additionally, the tip of the iron may reach temperatures of around 450°C, making it hot enough to cause burns.

Furthermore, the melting solder itself can produce toxic fumes if not properly ventilated. It is important to take the necessary precautions when using a soldering iron, such as wearing protective clothing and using a fume extractor.

Additionally, it is important to ensure that children and animals are kept away from the soldering area. By following these safety measures, the risks associated with using a soldering iron can be minimized.

Maintenance

Maintenance of both the soldering iron tip and heater is relatively simple. A damp sponge should be used to clean off any oxidation or residue from the tip after each use. The tip should be regularly checked for wear and tear and replaced when necessary.

The heater should be cleaned regularly to prevent dust and debris from clogging the heating elements. If the heater is not working properly, it should be taken apart and checked for any broken parts, then reassembled and tested.

If any parts need to be replaced, they should be replaced with genuine parts from the manufacturer. Finally, the soldering iron should be stored in a safe place when not in use to prevent damage or injury.

Conclusion

Soldering iron tips and heaters are both essential components of a soldering iron. The tip is the part that makes contact with the workpiece and transfers heat to the joint. The heater is the component that heats up the tip.

The tip needs to be changed regularly as it wears out over time, while the heater can last for several years. The correct tip must be chosen for the job, and the heater must be set to the correct temperature to ensure a successful soldering job.

FAQ’s

1.What Is The Difference Between A Soldering Iron Tip And A Soldering Iron Heater?

Ans: A soldering iron tip is the metal piece at the end of a soldering iron that is heated up and used to melt and fuse metal pieces together. A soldering iron heater is the component inside a soldering iron that heats up the soldering iron tip to the desired temperature.

The soldering iron tip and the soldering iron heater are two separate parts of a soldering iron that work together to create strong, secure bonds between two metal pieces.

2.Is A Soldering Iron Tip Replaceable?

Ans: Yes, soldering iron tips can be replaced. They are usually made of copper and wear down over time. Soldering iron tips can be purchased at most electronics supply stores or online. They are relatively inexpensive and easy to replace.

3.What Type Of Soldering Iron Tip Is Best For Circuit Board Work?

Ans: The best type of soldering iron tip for circuit board work is a conical tip. This tip is small and sharp, allowing for precise soldering of small components. It is also not too wide, which helps to avoid overheating and damaging components. An adjustable temperature soldering iron is also helpful for circuit board work, so that the temperature can be adjusted for different components.

4.What Is The Temperature Range Of A Soldering Iron Heater?

Ans: The temperature range of a soldering iron heater is typically between 200-450 degrees Celsius (392-842 F). Depending on the wattage, the temperature may be adjustable. For delicate work, a soldering iron with a lower wattage should be used. The tip should also be kept clean to ensure proper heat transfer.

5.Is A Soldering Iron Heater Necessary For A Soldering Iron To Work?

Ans: Yes, a soldering iron heater is necessary for a soldering iron to work. The heater is responsible for generating the heat that melts the solder, which allows the parts to be connected. This heat is generated by electricity which is regulated by the heater. Without a heater, the soldering iron will not be able to generate the necessary heat.

![9 Best Torch For Soldering Copper Pipe [Reviews With Buying Guide]](https://accuratepicker.com/wp-content/uploads/2022/03/Best-Torch-For-Soldering-Copper-Pipe.jpg)