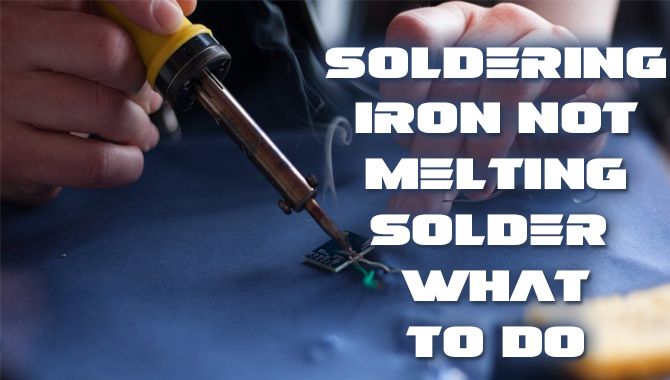

Admit it or not, soldering iron is more like a savior these days. You can join stained glass, metal and even do some heavy electronic soldering work using this small tool. This small handy tool has many beneficial factors that you can’t deny.

But there may arise some issues as well. One of the most common problems that soldering iron shows is not melting solder. So, in this guide, our talk is about the solution of soldering iron not melting solder.

A malfunction soldering iron can mostly cause this problem/, but there might be other reasons as well. So we will share the reasons and the ways you can solve those.

So without any further delay, let’s get into the details and know about the solutions elaborately. Later on, we will also let you know about clarifications on soldering iron not soldering issues on circuit boards, and other related problems.

Soldering Iron Not Melting Solder – Solutions Explained

As we all know, soldering iron is used to warm up the solder by using electricity. The heat that the soldering iron contains while melting the solder can easily burn your skin within a moment.

It is so hot that while heating up, you may notice some hot smoke around the iron. As the solder has a shallow melting point, it should melt without any complications.

But if it doesn’t melt, then what you can try is:

Check The Main Switch

You might have forgotten to turn the switch on. Check if the power indicator is turned on or not. You have to check the main switch of the power source too to ensure the proper power supply in the soldering iron.

Check The Workability

Malfunctioning iron can create the issue. So firstly, check if the iron is working correctly.

You can use paper and test if the tip of the iron is hot enough or not. Be careful not to touch it by hand as it can easily burn your skin dangerously.

If the iron is not working, then check if the power cord is plugged or not. Sometimes we forget to plug the power cord, and therefore the iron fails to work. Also, check if you have turned on the switches to turn the iron on.

Follow Up The Power Indicator

By this time, if your power cord is plugged, now it’s time to check if the power indicator is on or not.

If you don’t have a power indicator on the iron, then you can try the first suggestion again, which was using paper to test if the iron is heating up or not.

But if you have a power indicator and the light is off, then check if you have plugged the cord and turned the switch or not. If it still doesn’t work, you need to change the power indicator, as this one might be damaged.

Avoid Using Thick Solder

It is proven that thicker solder uses a lot of heat and is difficult to heat up easily. They also take a lot of time to heat up and melt.

In this case, you can avoid using thick solder. Also, if you like using thick ones, make sure the power supply is faster than the regular time.

Cleaning Up Helps

Try cleaning the tip by using a soft sponge. Do not touch the tip with your bare hands. Sometimes using a sponge to clean the tip helps a lot if there is dirt stuck in the iron tip. After cleaning, check the iron with a little bit of fresh and clean solder.

Give The Iron Some Time

Wait for a bit to make the iron transfer the heat. As every product varies in designs, your solder iron may take a little more time to transfer the heat in the tip and heating itself up compared to the regular ones.

In this case, it is better to wait for a little bit longer. If the iron still does not heat up, then you might have a damaged soldering iron.

Then, you need to check the source of power first and then try purchasing a new soldering iron.

Add More Solder

Try adding a bit more solder to the solder mixture. Usually, a new layer of solder in the old mixture may help you to melt the solder. You don’t have to use it a lot. Just a small amount of new and fresh solder will do the job.

Do Not Let It Sit Idle

Use the soldering iron regularly. If you don’t use the iron often and store it up in the corner of the house, then the soldering iron might get damaged and become unusable.

The temperature of the room also matters. If the temperature is too cold or too hot, then it can damage the product and make it unusable in the future.

Oxidized Tip

Letting your soldering iron idle for a long time can cause the oxidation issue. Especially if you do not maintain the optimum temperature of the place where you keep it, so do not keep it heated up for more than 15 minutes.

Do not use the iron in high temperatures like 340 – 380°C. Also, clean the iron tip properly using wet clothes after every usage.

Check For Damaged Signs

Your soldering iron might be damaged if it fails to heat up. If so, you need to replace it as soon as possible. To check if it’s working or not, try using a paper on the tip to know if it’s heating up or not.

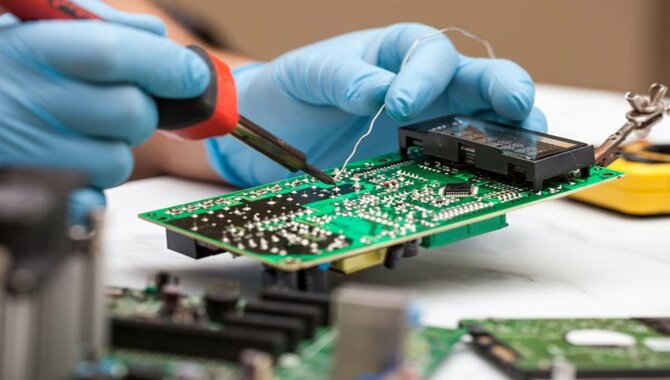

Why Is My Soldering The Iron Not Melting Solder On Circuit Board?

Solder is something that gets melted very easily because of its low melting point. However, it becomes a big problem when the solder refuses to do so.

If your soldering iron refuses to melt the solder on the circuit board, then you can try out the suggestions written below:

- Make sure that a layer does not suppress the heat in the board made of copper. It is seen in many cases that the copper layer suppresses the heat fully in the board and thus prevents the soldering iron from melting the solder on the board.

- Use the melted mixture of fresh solder or flux to create a bridge between the iron. This helps a lot in melting the solder on the circuit board.

- Try using a soldering iron which is of high power, instead of the ones that use electricity. As the speed matters more than the temperature, in this case, the soldering irons that are high in power slay the job of melting solder in the circuit board.

- You can check out the preheating technique on the circuit board in this regard. It would be best if you would use a preheating system in this case. But if you can’t afford a preheating system, you can also try using hot air guns to preheat the circuit board.

- All you have to do is to preheat the circuit board. The tools that you are using, in this case, do not matter, actually, as long as the board is getting preheated by enough heat.

- If the board seems to have an extra coating covering the surface, then try wiping it off with the help of applying the mixture of melted solder or flux in the tip of the soldering iron.

- You need to change your soldering iron tip if the tip is too small or too weak. You can use the chisel tip in your soldering iron for better service. The bigger and stronger the tip is, the better service you will get in melting solder on the circuit board.

- Try cleaning the tip of the soldering iron with a soft sponge. If the tip is jammed or stuck with another object, it might not melt the solder properly.

Is There A Way To Solder Without A Soldering Iron?

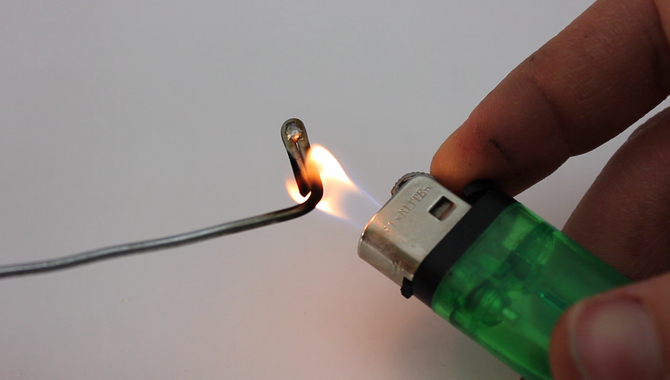

During an emergency, when you can’t get a soldering iron, you can use the simple tools around you with the help of some simple tips.

The simple tools around you, like screwdrivers or steel wires, are enough to do emergency soldering.

All you have to do is just heat them and start soldering right away before it gets cold. If the tool gets cold, you have to warm it up again, which is very irritating.

This is why soldering irons are of fewer complications. It will only take 30 minutes to get the tool heated up properly.

Make sure the tools and power source are safe to use, and be careful not to touch the hot ingredient as it can easily burn your skin within a second.

This technique is kind of old, but it works just fine during an emergency. It might not be able to melt solder perfectly, but this technique can cover up multiple spots at a time.

If you only need to solder two wires together, you don’t even need any soldering tool for this. But for something a little bit more complicated, you may use a heated-up screwdriver or anything else during an emergency.

Frequently Asked Questions (FAQs)

1.Can I Melt The Solder With A Lighter?

Ans: Yes, you can, if the temperature created by the lighter is enough to reach the melting point of the solder.

In this case, Bhutan lighters are highly recommended by many people. You can also use candles, burners, etc., as an alternative to a lighter.

2.Can I Use Superglue Instead Of Solder?

Ans: No, there is certainly no alternative to solder. If you use superglue instead of solder, then you will damage the port for sure. It is because superglue does not contain that much strength that solder does.

3.Can I Use Hot Glue Instead Of Solder?

Ans: No, you can’t use hot glue as an alternative to solder. Hot glues can’t get hot as much as solder does. Also, the warmth in the glue gun is not in the tip but in the middle. This is why hot glue cannot be used as an alternative to solder.

Final Thoughts

Although the soldering iron is so hot that it can easily melt the solder, which is of shallow melting point, in some cases, it refuses to do so.

For a suggestion, we must say that you should check the power supplies first. Because most of the time, this silliest issue makes us a fool afterward.

But if the power supply and indicator notify everything as alright, you can follow the given solutions one by one to check which one works in the best way.

Do not attempt to put any soldering iron on your hand because it will cause a serious burn, so be careful while dealing with this. Even after everything properly, if your iron fails to work, you need to replace it. I hope now you know about soldering iron not melting solder.