What’s the biggest mistake we do with the diagonal cutter, you want to know? We either threw it away or buy a new one if the existing one doesn’t have enough sharpness.

You may know or know not, but you can sharpen the existing diagonal cutter at your home with some simple tools. This way, you can save the money you plan to spend on buying a new diagonal cutter.

Now, how are you supposed to sharpen the diagonal cutter? The process is neither too long nor too short. It can’t be described within few lines. So, how to sharpen diagonal cutters?

Hence it would be best if you went through our diagonal cutter sharpening guideline. Here we will discuss the sharpening and other useful facts. Now it’s time to jump onto the queries!

How To Sharpen Diagonal Cutters?

Here’s a complete procedure of sharpening a diagonal cutter –

First Step – Get A Hand File

One hand file is enough with fine grain. The grain will sharpen diagonal cutter blades. Please do not use a coarse file because it can remove too much blade material with little precision, hence will cause damage to the small blade.

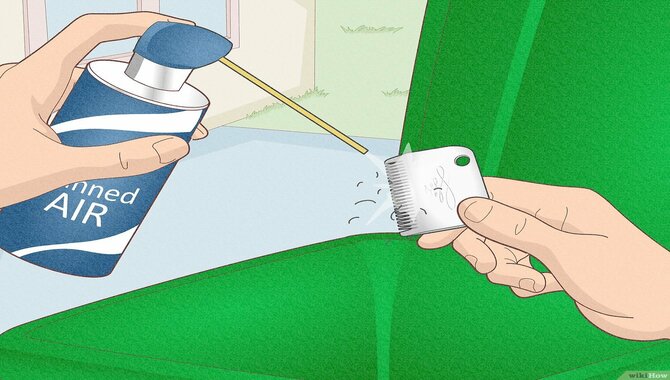

Second Step – Clean The Cutter Blades

Make sure to clean the whole blade before starting the sharpening process. Use soapy water to remove the rust on it.

Third Step – Secure Diagonal Cutter Piler is a Vice

Place your diagonal cutter pliers in a vice keeping the direction of the jaw upwards. It will ease the cleaning of the blade with a hand file protecting it from damage.

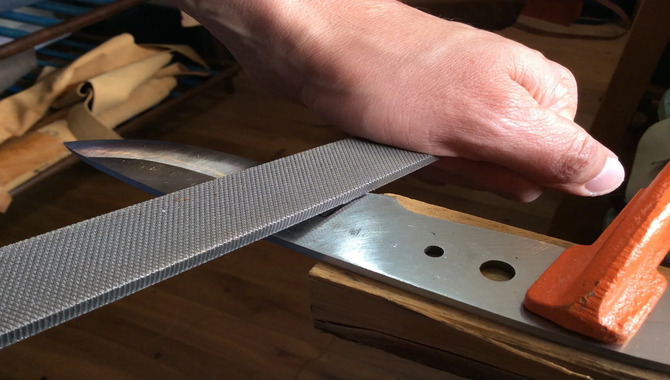

Fourth Step – Rub The Cutter Blade With The Hand File

Select one side of the diagonal cutter blade for starting the sharpening procedure. Rub that hand file keeping its angle correct, and rub fast with short movements.

Put pressure while rubbing but not too much that your cutter’s blade loses much metal. We aim to remove kinks and small metal bobbles from the diagonal cutter blade.

Fifth Step

Keep rubbing both sides of the blade. Keep doing this until it gets sharped again.

If you think the blades got sharpen, check their sharpness by cutting a wire. You will understand by yourself how much the diagonal cutter is sharped, seeing how easily it cuts the wire.

Sixth Step

Finish the cleaning by washing the blades again in soapy water to remove metal filings. Once they are fully dried, use oil and make a thin layer on pilers for coating. You can use rubbing alcohol too as an alternative to the oil.

Some Easy Steps To Clean Rust From Diagonal Cutters

The iron oxide layer we see overall kind of steel is the rust. It causes damage to the steel and makes it useless soon.

Therefore cleaning up the rust often off the diagonal cutter is a wise job to do. Some household items are everything required.

Follow these simple steps and clear every rust on your diagonal cutter –

1. Choose Chemicals

Lemon and salt two items or apple cider vinegar would do the job. Baking soda can do the cleaning too.

2. Prepare The Chemicals

If you have lemon available in your home, then use it and salt. Mix them to create a juice of thick liquid.

Or make a thick paste of baking soda using water. Or take enough amount of salt and mix that with the vinegar.

3. Apply The Mixture

Take the diagonal cutter and carefully cover every rusty part with your created mixture. Leave the tool for either a few hours or for one day, depending upon the rust’s extent.

4. Use A Toothbrush

Pick any old useless toothbrush you have at home and use that to rub the diagonal cutter. Continue rubbing gently so that only rust is removed and the tool is not damaged.

Don’t try the wire brush for cleaning because it may rather damage the diagonal cutter metal underneath.

5. Repeat The Procedure

Keep following the 2 to 4 steps until all the rust is removed. Sometimes the rust is too stubborn and doesn’t get off quick; in that situation, you have to keep the tool covered with the mixture for a longer time.

When you can see no more rust on your diagonal cutter pliers, use water and soap to wash it. If you any rust left after finished washing, dry it using your hairdryer or air dry it.

6. Make Your Diagonal Cutter Rust-Proof

Prevention is better than cure. It would be best to prevent rust so that your tool is safe from its attack and works longer. For the prevention of rust, use oil and make a thin layer on your diagonal cutter.

Tips To Maintain A Diagonal Cutter

If you take care of your diagonal cutter, you can keep that one fine forever. Believe it or not, you can take care of a diagonal cutter by following our tips below.

- Do not force your diagonal cutter to cut such thick material that it may either damage the blades or break the tool.

- Often clean your diagonal cutter, particularly its blades using soapy water. Remove any metal, sprinter, or plastic that could issue problems with the piler joints. Dry the pilers completely before storing them.

- If you find something sticky on the diagonal cutter, get a more light oil and rub it into the pilers. The sticky thing will surely get off of the cutter with a rag.

- If your diagonal cutter gets wet while working, completely dry them and then put them into the storage box to prevent rust.

- No matter how many times you clean the diagonal cutter, you should make a thick layer on it with oil each time. This way, the tool’s joint will move correctly for a longer period.

- Store your diagonal cutter in such a place that it is dry and its jaw tips are not blunted accidentally. The right place for it is into a pouch or toolbox.

Will The Sharpening of Existing Diagonal Cutter Be Helpful?

Many are confused with it, and they think the old tool will not give the exact service like the new one even if it is sharpened again.

But the truth is your old diagonal cutter tool will work and work definitely after it’s sharpened.

That’s why people who do works with diagonal cutters don’t buy new products often. They try to work with the same tool by sharpening it until it becomes useless.

Trust us and try to sharp your diagonal cutter at least once and see if it does work or not by yourself. Think about it because you can save your penny!

Conclusion

Hopefully, after knowing the easy procedure, you are ready to sharp your diagonal cutter on your own. It’s really simple to work, and you will enjoy sharpening the diagonal cutter.

If you do it for the first time, don’t get confused with the steps. Follow them one by one and keep checking the process.

Before you decide to sharpen the diagonal cutter take one tip from us; if you buy a new diagonal cutter, you have to maintain that anyway. Hence please sharp the old tool and use it as the new one. I hope now you know how to sharpen diagonal cutters.

![8 Best Safety Wire Pliers [Reviews With Buying Guide]](https://accuratepicker.com/wp-content/uploads/2022/03/Best-Safety-Wire-Pliers.jpg)

![10 Best Needle Nose Pliers [Reviews With Buying Guide]](https://accuratepicker.com/wp-content/uploads/2022/03/Best-Needle-Nose-Pliers.jpg)