Automotive repairs can be a daunting task, especially when it comes to fixing worn-out parts and pieces. However, using an air compressor allows the process to be streamlined and accomplished more easily and efficiently.

If you are an automotive enthusiast or a DIY mechanic. Mastering the use of an air compressor can be a valuable tool in your arsenal. An air compressor can be an invaluable asset in your garage, from inflating tires to powering air tools.

But, if you are new to the world of air compressors, it can be challenging to know where to start. This blog post will explore how to use an air compressor for automotive repairs. We will cover the basics of air compressors, their types, and their applications. We will also look at the necessary safety precautions and maintenance tips to ensure you get the most from your air compressor and avoid costly mistakes.

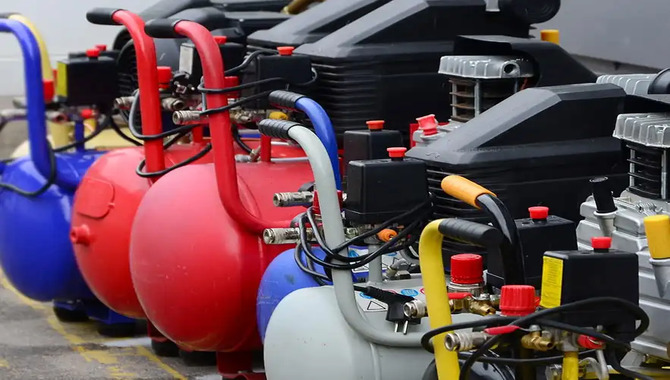

Types Of Air Compressors And Their Uses

Air compressors are essential in various industries, including automotive, construction, and manufacturing. Several air compressors are available, each with unique features and use. The most common types of air compressors are reciprocating rotary screws and centrifugal. Reciprocating air compressors typically use in small-scale applications, such as powering air tools and inflating tires.

Rotary screw air compressors commonly use in larger industrial settings, such as powering pneumatic machinery or air conditioning systems. Centrifugal air compressors are the most powerful type of air compressors. And primarily used in large-scale industrial applications that require high volumes of compressed air, such as in oil refineries or power plants.

How To Use An Air Compressor For Automotive Repairs – Follow The Guideline

If you’re looking to perform some automotive repairs at home. One tool you should consider investing in is an air compressor. An air compressor can use for various tasks, including powering air tools like impact wrenches, spray guns, and ratchets. Here’s how to use an air compressor for automotive repairs:

First, ensure you have a good quality air compressor capable of delivering enough air pressure for your intended use. Check the specifications of your air tools to determine the minimum air pressure and volume required. Once you have a suitable air compressor, connect it to your air tools using the appropriate fittings and hoses.

Always wear eye and ear protection when using an air compressor for automotive repairs. Start by testing the air compressor and air tools to ensure they work properly before using them on your vehicle. Adjust the air pressure as needed for each task, and be sure to follow the manufacturer’s instructions carefully.

Choosing The Right Air Compressor For Your Needs

Choosing the right air compressor for your needs requires careful consideration of several factors. First and foremost, you need to determine the specific application or task for which you intend to use the air compressor. This will help narrow your options to the most suitable compressor types based on capacity, pressure output, and air delivery rate.

For instance, if you need an air compressor for light-duty tasks such as inflating tires or powering small pneumatic tools. A portable electric compressor with a tank capacity of 1 to 6 gallons and a pressure output of 90 to 150 psi would suffice.

On the other hand, if you need a compressor for heavy-duty industrial applications such as sandblasting, painting, or drilling, a stationary compressor with a larger tank capacity, higher pressure output, and greater CFM (cubic feet per minute) is necessary.

Other factors to consider when choosing an air compressor include the power source, mobility, noise level, and maintenance requirements.

Essential Tools And Accessories For Air Compressor Use In Automotive Repairs

Regarding automotive repairs, having an air compressor is a must-have tool. However, having the essential tools and accessories to use the air compressor effectively is equally important. An air hose is necessary to connect the compressor to the desired tool or accessory. A good quality hose will help prevent leaks and kinks, ensuring proper airflow.

Additionally, air tools such as impact wrenches, sanders, and spray guns are essential to have on hand, as the air compressor powers them. Good air tools will help you work faster and more efficiently. Another important accessory is an air filter and regulator.

These tools help regulate air pressure and remove moisture. And filter out impurities to prevent damage to the tools and ensure a clean and efficient work environment. Finally, safety equipment such as safety goggles, earplugs, and gloves should also be considered essential when working with an air compressor.

Safety Measures And Precautions When Using An Air Compressor

Air compressors are powerful tools essential in many industries, such as construction, manufacturing, and automotive repair. However, they can also pose serious safety hazards if not used properly. To ensure the safety of the users, it is important to follow some safety measures and precautions when using an air compressor.

First and foremost, it is crucial to read the user manual and know the proper operating procedures of the air compressor. This includes knowing the compressor’s maximum pressure and capacity and the tools and accessories that can be used with it. It is also important to inspect the equipment before use, checking for any damage or leaks in the hoses, fittings, and other components.

Another important safety measure is to wear appropriate personal protective equipment, such as eye protection, ear protection, and gloves. This will prevent injuries from flying debris, loud noises, and hot or sharp materials.

Basic Maintenance And Troubleshooting For Air Compressors

Air compressors are essential in various industries, including automotive, construction, and manufacturing. Basic maintenance and troubleshooting are necessary to ensure they work efficiently and effectively. One of the critical tasks in maintaining an air compressor is checking the oil levels and changing the oil regularly.

This helps prevent overheating, reduce wear and tear of the components, and prolong the compressor’s life. Additionally, inspecting the air filter and cleaning or replacing it when necessary can improve airflow. And prevent dust and debris from entering the system.

Another crucial maintenance aspect is checking for leaks in the hoses and fittings and tightening them as needed. Identifying and repairing leaks can prevent energy waste and improve the compressor’s performance.

Using An Air Compressor For Sandblasting And Painting

Using an air compressor for sandblasting and painting can be a game-changer for any DIY or professional project. Sandblasting is a process that uses high-pressure air and abrasive material to remove rust, paint, and other unwanted substances from surfaces.

An air compressor can provide the pressure and volume of air needed to power the sandblasting process. Additionally, painting with an air compressor can provide a smooth and even coat of paint.

The compressed air atomizes the paint particles into a fine mist that can be easily sprayed onto surfaces. This method of painting also allows for less overspray. And can save time and money compared to traditional brushes or rollers.

Air Compressor Applications For Brake And Suspension Repairs

Air compressors are versatile equipment for various applications, including brake and suspension repairs. Regarding automotive repairs, air compressors are an essential tool for mechanics and technicians who need to remove and replace brake and suspension components quickly and efficiently.

For example, air compressors can use to power impact wrenches, which are necessary to remove lug nuts and bolts that hold brake and suspension parts in place. Air compressors can also power air hammers, which are useful for removing stubborn parts that may be rusted or corroded.

In addition to these tools, air compressors can use in various other ways during brake and suspension repairs. For example, they can inflate tires, test brake lines for leaks, and power pneumatic pumps for hydraulic fluid changes. With their versatility and power, air compressors are an indispensable tool for any mechanic or technician who wants to do the job quickly and efficiently.

Air Compressor Used For Engine Repair And Maintenance

Air compressors are a critical tool for engine repair and maintenance. They provide a steady and reliable compressed air source for various tasks, including removing debris and dirt from engine components, powering pneumatic tools, and blowing out clogged lines and hoses. Whether you’re a professional mechanic or a DIY enthusiast, an air compressor is an essential piece of equipment in your garage or workshop.

One of the key benefits of using an air compressor for engine repair and maintenance is its versatility. With the right attachments and accessories, you can use your air compressor to tackle various tasks, from inflating tires and powering impact wrenches to sanding, painting, and cleaning. Additionally, air compressors are highly efficient, allowing you to complete tasks faster and with less effort than traditional hand tools.

Advanced Air Compressor Techniques For Custom Auto Work

Advanced air compressor techniques are essential for custom auto work, especially when achieving the perfect finish on a vehicle. These techniques involve using various advanced tools and equipment, including high-quality air compressors, spray guns, and paint booths.

Air compressors are the backbone of any custom auto workshop, providing the necessary air pressure to power the various tools used in the painting and finishing process. With advanced air compressors, technicians can achieve greater control over the amount of air pressure used, leading to more precise and consistent results.

These techniques are especially critical for custom auto work, where every detail counts. Whether applying for a custom paint job or detailing intricate parts, the right air compressor can make all the difference.

By investing in advanced air compressor techniques, custom auto shops can elevate their craft to new heights, delivering unparalleled results to their clients. And with the latest technological advancements in air compressor technology. Custom auto work has never been more accessible or more rewarding.

Conclusion

An air compressor can be an incredibly useful tool for automotive repairs. It provides a steady supply of compressed air that can be used for various tasks, from inflating tires to powering pneumatic tools. However, it is important to use an air compressor correctly and safely.

By following the steps outlined in this guide, users can ensure they are using their air compressor effectively and minimizing the risk of injury or damage to their vehicle. With the right knowledge and precautions, an air compressor can be an indispensable tool for any automotive repair enthusiast. We hope you understand How to use an air compressor for automotive repairs.

FAQs

1.What Type Of Air Compressor Is Best For Automotive Repairs?

Ans: A reciprocating air compressor with at least 5-6 gallons capacity is best for automotive repairs. It should have a minimum CFM (cubic feet per minute) rating of 2.5-3.5 to power air tools such as impact wrenches and air ratchets.

2.What Type Of Air Compressor Is Best Suited For Automotive Repairs?

Ans: A portable or stationary rotary screw air compressor is best suited for automotive repairs. It provides consistent and efficient airflow for powering air tools such as impact wrenches, ratchets, and sanders.

3.What Are Some Common Automotive Repairs That Require An Air Compressor?

Ans: Some common automotive repairs that require an air compressor include inflating tires, using pneumatic tools such as impact wrenches and sanders, painting and spraying, and cleaning and degreasing engine parts.

4.What Are Some Important Safety Precautions To Remember When Using An Air Compressor For Automotive Repairs?

Ans: Some important safety precautions to remember when using an air compressor for automotive repairs include wearing eye and ear protection, using the correct air pressure and size of the hose for the tools used, properly grounding the compressor, and avoiding kinking or twisting the hoses.

5.What Maintenance Is Required For An Air Compressor For Automotive Repairs?

Ans: Regular maintenance, such as checking and changing the oil, cleaning or replacing air filters, and inspecting and tightening belts and hoses, is required for an air compressor for automotive repairs.