Forced induction adds a significant amount of power to an engine. And if you’re planning to install it in your SBC engine, you must ensure that your engine is ready for it.

One important aspect you should look into is the cylinder heads. The SBC (Small Block Chevy) engine is widely popular among car enthusiasts. And cylinder heads play a critical role in its performance. This blog post will discuss how to set up SBC heads for forced induction.

Setting up SBC heads for forced induction is not a straightforward process. It involves considerations such as the type of heads, compression ratio, valve size, and more. The process requires a fair amount of knowledge and expertise, and it’s crucial that you get it right to ensure the best possible performance from your engine.

Choosing The Right Heads For Forced Induction

If you plan to add forced induction to your Small Block Chevy (SBC), properly setting up the heads is crucial. Forced induction puts a lot more stress on the engine, so the heads must be able to handle the increased pressure and heat.

The first step is to choose the right heads. You’ll want a set of heads with a high compression ratio and good flowing ports. It’s also essential to ensure that the heads are properly machined and installed with the right gaskets and bolts.

Once the heads are in place, you must adjust the valve lash and check the rocker arm geometry. This will help ensure the valves are opening and closing correctly and the valvetrain is properly aligned. Next, install the correct spark plugs and adjust the ignition timing to match the increased boost pressure. Finally, you’ll need to tune the fuel system to provide the right fuel for the increased airflow.

How To Set Up Sbc Heads For Forced Induction – Explained With Details

If you plan to add forced induction to your Small Block Chevy (SBC), properly setting up the heads is crucial. Forced induction puts a lot more stress on the engine. So the heads must be able to handle the increased pressure and heat. The first step is to choose the right heads.

You’ll want a set of heads with a high compression ratio and good flowing ports. It’s also important to ensure that the heads properly machine and installed with the right gaskets and bolts.

Once the heads are in place, you must adjust the valve lash and check the rocker arm geometry. This will help ensure that the valves are opening and closing correctly and the valvetrain is properly aligned. Here are some guidelines to help you learn How to set up SBC heads for forced induction.

Next, install the correct spark plugs and adjust the ignition timing to match the increased boost pressure. Finally, you’ll need to tune the fuel system to provide the right fuel for the increased airflow.

1. Preparing The Heads For Forced Induction

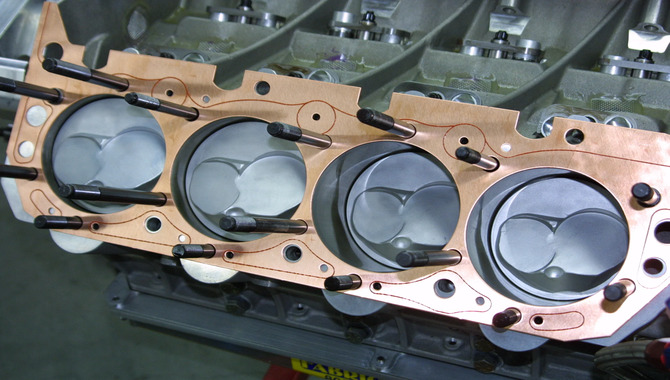

Preparing the heads for forced induction is crucial in getting your engine ready for the boost it needs. One of the most important things you can do is to ensure that the heads are properly cleaned and inspected for any signs of damage or wear.

This includes checking the valve seats, guides, and seals, as well as the overall condition of the cylinder head surface. It’s essential to have a flat and smooth surface to ensure the head gasket seals properly and doesn’t leak under pressure.

Once you’ve inspected and cleaned the heads. You’ll need to decide on the type of head gasket you want to use. Multi-layer steel (MLS) head gasket is an excellent choice for forced induction engines because it can handle high levels of boost and heat.

Choosing the right size head studs is also important to ensure that the heads tightly secure to the block and don’t lift under pressure.

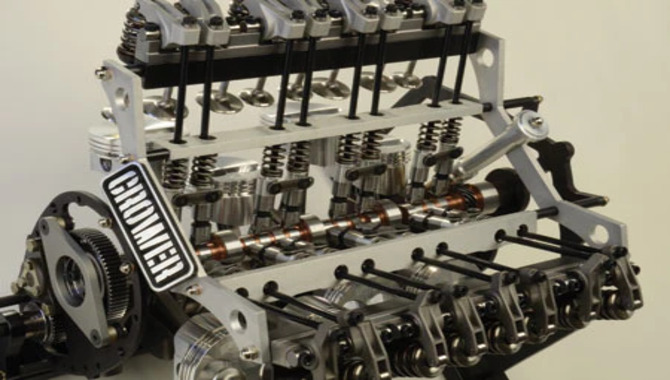

2. Choosing The Right Camshaft

When it comes to building an engine, choosing the right camshaft can make all the difference in performance. The camshaft controls the timing and duration of the engine’s valves. Which determines how much air and fuel can enter and exit the engine.

There are several factors to consider when selecting a camshaft, such as the engine’s intended use, the desired powerband, and the available supporting components. For example, a high-performance camshaft might provide more top-end power but may sacrifice low-end torque and drivability.

On the other hand, a milder camshaft may better suited for a street-driven car that needs low-end power and good drivability. Matching the camshaft to the other components in the engine is also important.

A camshaft that is too aggressive for the rest of the setup can cause poor performance or even engine damage. Selecting the right camshaft involves balancing power, drivability, and reliability.

3. Upgrading The Valvetrain For Boost

Upgrading the valvetrain for boost is a crucial step in maximizing the performance of a forced induction engine. When adding a turbocharger or supercharger to an engine, the increased air and fuel flow can put additional stress on the valvetrain components.

This can lead to valve float. Which occurs when the valve cannot close properly due to the high pressures and speeds. Valve float can cause a loss of power and, in severe cases, cause catastrophic engine failure.

To prevent valve float and ensure reliable operation, upgrading the valvetrain is necessary. This can include installing stronger valve springs, titanium retainers, and high-quality camshafts designed for boosted applications.

The increased spring pressure provided by upgraded valve springs can keep the valves in contact with the camshaft lobes, even at high engine speeds. Titanium retainers are much stronger than stock retainers and can handle the additional stress generated by a forced induction setup.

4. Selecting The Right Pistons And Connecting Rods

When building an engine, selecting the right pistons and connecting rods is crucial for achieving optimal performance. The choice of pistons and connecting rods largely depends on the engine’s intended use. And the desired power output.

For example, if you’re building a high-performance engine that will be used for racing or other demanding applications. You’ll likely want to choose forged pistons and connecting rods. Forged components are much stronger and more durable than cast components, making them better suited for high-stress applications.

When selecting pistons, it’s important to consider factors like compression ratio, bore size, and piston material. Choosing the right connecting rods is also critical, as they are responsible for transmitting the power generated by the pistons to the crankshaft. Factors like length, weight, and material should considere when selecting connecting rods.

Ultimately, the goal is to choose pistons and connecting rods that are strong enough to handle the stresses of the engine but not so heavy that they negatively impact performance.

5. Gaskets, Seals, And Fasteners For Forced Induction

Forced induction systems require precision and reliability to operate effectively, and that’s where gaskets, seals, and fasteners come into play. High-performance engines with turbochargers or superchargers must have airtight seals to prevent air leaks.

Which can cause a decrease in performance or even engine failure. Gaskets and seals are used to create a tight seal between the different components of the forced induction system. Such as the turbocharger or intercooler. These components must be sealed properly to ensure that the pressurized air is directed to where it is needed and not lost through leaks.

Fasteners are crucial for keeping the components tightly secured, as the high-pressure air flowing through the system can cause vibrations and loosening of parts. High-quality fasteners made from durable materials, such as stainless steel, are ideal for use in forced induction systems.

They can withstand the high pressures and temperatures associated with forced induction systems, ensuring the components remain securely fastened together.

6. Air And Fuel Delivery For Forced Induction

Air and fuel delivery are critical components for forced induction systems. Forced induction refers to the process of compressing the air drawn into an engine to increase its power output.

A supercharger or turbocharger is used to force more air into the engine. which requires a corresponding increase in fuel to maintain the proper air-fuel ratio. The air and fuel delivery system must be carefully engineered to ensure that the engine receives the necessary amount of both in a timely and efficient manner.

Inadequate fuel delivery can lead to engine knock, which can cause serious damage to the engine. Similarly, insufficient air delivery can cause the turbocharger or supercharger to fail, leading to costly repairs.

Proper air and fuel delivery is essential for the longevity of the engine and the performance of the forced induction system. Tuners must take into account factors such as the engine’s size, airflow capacity, and fuel delivery system when designing a forced induction system.

7. Tuning Your Engine For Optimal Performance

Tuning your engine for optimal performance is vital to maintaining your vehicle’s longevity and efficiency. Whether you’re a seasoned mechanic or a casual driver, understanding the basics of engine tuning is crucial for keeping your car running smoothly.

The first step in tuning your engine is to ensure all the components are functioning properly, from the air filter to the fuel injectors. Regular maintenance, such as oil changes and spark plug replacements, can also go a long way in improving engine performance.

Once the basics covere, it’s time to fine-tune your engine to your specific driving needs. This can include adjusting the fuel-to-air ratio, adjusting the timing, and upgrading certain components like the exhaust system or intake manifold.

However, it’s important to remember that tuning your engine too aggressively can lead to increased wear and tear, decreased fuel efficiency, and even engine damage.

8. Maintenance And Upkeep For Forced Induction SBC Heads

Maintaining and keeping up with the upkeep of forced induction SBC heads is crucial for ensuring optimal engine performance and longevity. Regular maintenance includes inspecting and cleaning the heads, replacing worn-out components, and checking the boost levels to ensure they are within the safe range.

Additionally, monitoring the oil pressure and temperature is crucial, as high boost levels can strain the oil system. Upgrades such as high-performance valve springs, head gaskets. And head studs can also improve the reliability and performance of the heads.

Proper upkeep will prevent issues that can arise from neglecting the heads and increase the engine’s power output. It is recommended to consult with a professional mechanic or engine builder to determine. The best maintenance schedule and upgrade options for your specific application.

Conclusion

Setting up SBC heads for forced induction requires careful attention to detail and a thorough understanding of the process. Choosing the right components, such as the right camshaft, lifters, and valve springs, is important to ensure optimal performance and reliability.

Following the steps outlined in this guide, along with seeking the guidance of a professional, will help to ensure a successful installation and an engine that is capable of handling the demands of forced induction.

With the right preparation and installation, SBC heads can provide excellent performance gains for those looking to increase the power of their engines. We hope you understand How to set up SBC heads for forced induction.

Frequently Asked Questions

1.What Are The Key Considerations When Selecting SBC Heads For Forced Induction?

Ans: Setting up SBC (small block Chevy) heads for forced induction requires several steps: Choose the right heads, Install stronger valve springs, Check the head gasket, and Install a thicker head stud.

2.How Do You Properly Size The Intake And Exhaust Ports For Optimal Airflow In Forced Induction Applications?

Ans: Sizing the intake and exhaust ports for optimal airflow in forced induction applications requires careful consideration of several factors, including the engine size and configuration, the type and size of the turbocharger or supercharger, and the desired power output.

3.What Is The Recommended Compression Ratio For SBC Heads In Forced Induction Setups?

Ans: The recommended compression ratio for SBC (Small Block Chevy) heads in forced induction setups is typically around 8:1 to 9:1.

4.What Modifications Are Typically Needed To SBC Heads For Use In Forced Induction Applications?

Ans: Modifications needed for SBC (Small Block Chevy) heads for use in forced induction applications include upgrading the valve springs, installing hardened exhaust seats, installing stronger pushrods, and sometimes replacing the stock head gaskets with a more robust alternative.

5.How Do You Properly Tune The Fuel And Ignition Systems When Running SBC Heads With Forced Induction?

Ans: Properly tuning the fuel requires adjusting the air-to-fuel ratio to ensure optimal combustion and engine performance. This can be done by adjusting the fuel injectors, carburetor, or electronic fuel injection system.