The small-block Chevy engine has been a favorite among car enthusiasts for decades, and with good reason. This engine’s power, reliability, and versatility are well-known.

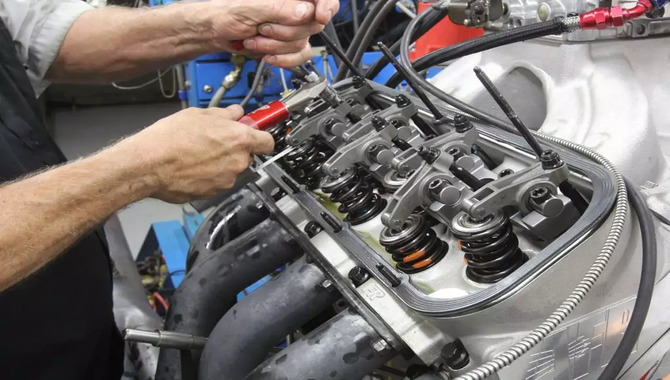

(Note: This sentence is already in the active voice.) You must know how to properly adjust the rocker’s arms to get the most out of your small block Chevy engine. This can be a daunting task for beginners, but it’s a relatively simple process with the proper guidance. In this ultimate guide, we’ll take you through the step-by-step process of How to adjust rocker arms on SBC Heads.

We’ll cover everything from the tools you need to the proper technique, so you can confidently change your engine to improve its performance. Our expert tips and tricks will help you do the job correctly and efficiently.

Whether you’re a seasoned mechanic or just starting, our guide will give you the knowledge and confidence to adjust your rocker arms like a pro. So, let’s get started and take your engine’s performance to the next.

How To Adjust Rocker Arms On SBC Heads – Comprehensive Guide

Adjusting rocker arms on Small Block Chevy (SBC) head is important to ensure proper valve operation and performance. Here is a comprehensive guide on how to adjust rocker arms on SBC heads, along with some “what not to do” tips:

Gather The Necessary Tools:

When adjusting rocker arms on SBC heads, you will need the following tools:

- Wrench or socket set: Depending on the type of rocker arm nuts used, you may need a wrench or socket set to loosen and tighten the nuts.

- Feeler gauge: A set of feeler gauges is essential for measuring the gap between the rocker arm and the valve stem. Ensure you have a feeler gauge set covering the required range of measurements.

- Torque wrench: If your engine requires a specific torque specification for the rocker arm nuts, a torque wrench will be necessary to achieve the proper tightness. Check your engine’s specifications to determine if a torque wrench is needed.

- Ratchet or breaker bar: During the adjustment process, a ratchet or breaker bar will be useful when turning the engine’s crankshaft to position it at the top dead center (TDC).

- Screwdriver or pry bar: Sometimes, you may need a screwdriver or pry bar to assist in positioning the rocker arms for adjustment or to hold them in place while tightening the nuts.

- Shop manual or repair guide: It’s always a good idea to have access to a shop manual or repair guide specific to your SBC engine. These resources will provide detailed instructions and specifications for rocker arm adjustment.

Identify The Firing Order

When adjusting the rocker arms on Small Block Chevy (SBC) heads, it’s crucial to identify the firing order. The firing order refers to the sequence in which each cylinder in the engine fires. On an SBC engine, the firing order is 1-8-4-3-6-5-7-2.

This means that cylinder number one fire first, followed by cylinder number eight, then cylinder number four, and so on. Knowing this order is essential because you must work on each cylinder in a firing order sequence when adjusting the rocker’s arms.

This ensures that the valves will be adjusted at the correct time in relation to the camshaft. To begin adjusting the rocker’s arms, you’ll want to start with cylinder number one. Rotate the engine until the number one cylinder is at the top dead center on the compression stroke. Then, loosen the rocker arm nut until the pushrod can be moved up and down slightly.

Position The Engine

When adjusting the rocker arms on SBC heads, it’s important to position the engine correctly. This task requires patience and attention to detail, but it’s necessary to ensure that your engine runs smoothly and efficiently.

The first step is to locate the timing marks on the crankshaft and camshaft gears, which will help you determine the proper position for the engine. Once you’ve found these marks, rotate the engine until the number one cylinder is at the top dead center (TDC) on the compression stroke.

This will allow you to adjust the rocker arms on that cylinder. When adjusting the rocker’s arms, following the manufacturer’s specifications for torque and clearances is important.

You’ll need a feeler gauge to measure the gap between the rocker arm and valve stem and adjust as needed. Remember to adjust one cylinder at a time, and always double-check your work before moving on to the next one.

Adjusting Valve Lash

Begin with cylinder number one (following the firing order). Loosen the rocker arm nut until you feel some resistance.

a.Use a feeler gauge to measure the gap between the rocker arm and the valve stem. Refer to the engine specifications for the recommended valve lash range. Adjust the nut to achieve the desired clearance. Tighten the nut until you feel slight resistance on the feeler gauge, and then lock it in place.

b.Proceed to the next cylinder in the firing order and repeat the same process until all rocker’s arms have been adjusted.

- Check for proper adjustment: After adjusting all the rocker arms, double-check the valve lash using the feeler gauge again. Make sure the clearance is within the recommended range for each valve.

Additional Considerations:

- Use the correct torque specifications: If your engine requires a specific torque for the rocker arm nut, use a torque wrench to achieve the proper tightness.

- Follow the recommended valve lash: Adhere to the engine manufacturer’s recommended valve lash specifications. Setting the valve lash too tight or loose can result in poor performance, excessive valve train wear, or damage.

- Be patient and precise: Take your time to ensure accurate adjustments. Rushing or being imprecise can lead to improper valve lash settings.

Introduction To Rocker’s Arms On SBC Heads

Rocker’s arms are an essential component of any internal combustion engine. As their name suggests, rocker’s arms are responsible for “rocking” back and forth to open and close the engine’s valves.

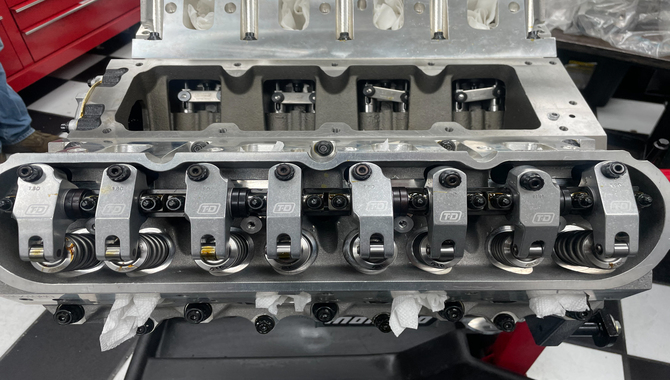

On Small Block Chevy (SBC) heads, rocker’s arms come in various sizes and configurations, depending on the application of the engine. The stamped steel rocker arm is the most common type used on SBC heads. These are typically used in stock or mildly modified engines and are known for their reliability and affordability.

However, roller rocker arms are preferred for their superior strength and durability for high-performance applications. Roller rocker arms feature a roller at the tip of the arm, which reduces friction and wear between the rocker arm and the valve stem.

This reduces the load on the camshaft and valve springs, allowing for higher lift and duration camshafts to use. Also, roller rocker arms can withstand higher spring pressures, making them ideal for high-performance engines requiring high-lift camshafts.

Understanding Valve Lash And How It Affects Rocker Arm Adjustment

Valve lash is an important aspect of engine maintenance that directly affects the rocker arm adjustment. It refers to the clearance between the rocker’s arm and the valve stems when closed. Understanding valve lash is crucial because it can affect the engine’s performance and lifespan.

If the valve lash is too tight, the valve might not fully close, causing a loss of power and increased engine wear. On the other hand, if the valve lash is too loose, the valve might not open fully, leading to poor combustion and reduced engine power.

The rocker arm must adjust to the manufacturer’s specifications to adjust the valve lash. This is typically done by adjusting the valve stem with a feeler gauge while the engine runs.

It is essential to adjust the valve lash correctly to avoid damage to the engine. When the valve lash is properly set, the engine will operate smoothly, with improved performance and a longer lifespan.

Common Mistakes To Avoid During Rocker Arm Adjustment

Adjusting the rocker’s arm is essential to maintaining a healthy engine, but it’s not always easy. Many mechanics and DIY enthusiasts make common mistakes that can cost them time and money and damage their engines.

One of the most common mistakes to avoid during rocker arm adjustment is over-tightening or under-tightening the adjustment nut. Over-tightening can cause the valve to stay open, leading to damage to the engine.

On the other hand, under-tightening can cause the valve to remain closed, leading to a loss of power. Another common mistake is failing to adjust the rocker arm on a cold engine.

Adjusting the rocker arm on a warm engine can cause the metal to expand, causing the adjustment to be too tight. Failure to follow the manufacturer’s recommended torque settings can also lead to problems. Always use the correct torque wrench and follow the recommended settings to avoid problems. Lastly, failing to check the pushrod length can lead to issues.

Tips For Maintaining Proper Rocker Arm Adjustment

Maintaining proper rocker arm adjustment is crucial for the optimal performance of your engine. Fortunately, several tips can help you achieve this goal.

- following the manufacturer’s recommended torque specs when tightening the rocker arm nuts is important. This ensures the nuts are tightened to the correct amount and not too tight or loose.

- you should always use quality rocker arm studs and nuts. This ensures that the components are of the highest quality and can withstand the engine’s pressure and wear and tear. Additionally, it is important to check and adjust the rocker arm lash regularly. This is the clearance between the rocker arm and the valve stem, and it can affect the engine’s performance if not properly maintained.

- inspecting the rocker arms for wear and damage periodically is important. If any damage or wear is detected, the rocker arms should be replaced immediately to avoid further damage to the engine. By following these tips, you can ensure the proper maintenance of your engine’s rocker

Conclusion

Adjusting rocker arms on SBC Heads is essential for maintaining engine performance and longevity. This process can be straightforward and rewarding with the proper tools and knowledge. Remember to follow the manufacturer’s recommended guidelines and torque specifications to ensure optimal results.

If you feel unsure or uncomfortable performing this task, it’s always best to seek assistance from a qualified mechanic. Taking the time to adjust your rocker arms correctly will undoubtedly pay off in improved engine performance. And a longer lifespan for your engine.

FAQ

1.What Signs Indicate The Rocker’s Arms Need To Be Adjusted On SBC Heads?

Ans: The signs that indicate the rocker’s arms need to adjust on SBC (Small Block Chevy) heads include loud ticking or tapping noises from the engine, decreased engine performance or power, and poor fuel economy. Additionally, they may need to adjust if the rocker’s arms appear loose or have excessive play.

2.What Is The Correct Order For Adjusting Rocker Arms On SBC Heads?

Ans: The correct order for adjusting rocker arms on SBC (Small Block Chevy) heads is to change them in sequence according to the engine’s firing order.

3.Are There Common Mistakes To Avoid When Adjusting Rocker Arms On SBC Heads?

Ans: Ensure correct alignment of the lifter and rocker’s arm before adjusting the rocker arm to avoid failure. Failure to do so can lead to improper valve lift and timing.

4.What Is The Proper Procedure For Adjusting Rocker Arms On SBC Heads?

Ans: Start with the engine at the top dead center (TDC) on the compression stroke for the cylinder you are adjusting. You can turn the engine over with a socket and breaker bar on the crankshaft bolt.

5.What Are Some Common Mistakes To Avoid When Adjusting Rocker Arms On SBC Heads?

Ans: Some common mistakes to avoid when adjusting rocker arms on SBC (Small Block Chevy) heads include over-tightening the rocker’s components, not correctly aligning the pushrods and rocker’s parts, and not using proper lubrication and not adjusting the valves in the correct firing order.