An air compressor is an essential tool in a workshop or garage. It is used for powering air tools and inflating tires, among other things.

However, proper storage is crucial to ensure that the compressor works efficiently and lasts long. When storing an air compressor, certain precautions must take to prevent damage and ensure that it is ready for use whenever needed. In this blog post, we will discuss how to properly store an air compressor.

Firstly, we will discuss the importance of cleaning the compressor before storage. We will then guide the best location for storage. And the measures that need to take to protect the compressor from dust, moisture, and other potential hazards.

We will also discuss tips on maintaining the compressor during storage, including lubrication and draining of the tank. Finally, we will offer some advice on preparing the compressor for use after storage, ensuring it is in good working condition.

Importance Of Proper Storage

Proper storage is of utmost importance when preserving the quality and safety of various products. It is crucial to consider the type of product being stored. The appropriate storage conditions are required to maintain its integrity.

For instance, food products should be stored in cool, dry places to prevent spoilage and reduce the growth of harmful bacteria. Medications, on the other hand, require specific storage conditions to maintain their potency and effectiveness. Failure to store medications properly can lead to their degradation, rendering them ineffective and potentially harmful.

Moreover, proper storage can also help to extend the lifespan of certain products, such as electronics and clothing. Exposure to moisture, heat, and other environmental factors can cause these items to deteriorate over time, resulting in reduced functionality and durability. Storing these items in a dry, cool environment can extend their lifespan, making them last longer and reducing the need for frequent replacements.

How To Properly Store An Air Compressor – A Step-By-Step Guide

Air compressors are essential tools for various industrial and home applications. Knowing how to store an air compressor properly is important to ensure its longevity and efficiency. The first step in storing an air compressor is disconnecting it from the power source and releasing all the air pressure. This can do by turning off the compressor and opening the drain valve.

Remove any hoses or attachments once the air pressure is released, and clean the compressor with a dry cloth. It is important to store the compressor in a dry and cool place, away from direct sunlight or heat sources. If possible, cover the compressor with a dust cover or tarp to prevent dust and debris from accumulating on the unit.

It is also recommended to store the compressor in an upright position to prevent any oil leaks. Additionally, it is important to check the oil level before storing the compressor and change the oil if needed. Properly storing an air compressor will help extend its lifespan and ensure it is ready for use. By following the below steps, How to properly store an air compressor.

Selecting The Right Storage Location

Selecting the right storage location is crucial for any business that wants to ensure the safety and security of its inventory. When it comes to choosing a storage location, several factors must consider. The first thing to consider is the type of goods that will store.

Different types of goods require different storage conditions. For example, perishable goods like food require a cool, dry environment. While electronic equipment should store in an area with low humidity and stable temperatures.

The second factor to consider is the size of the storage location. The storage location should be large enough to accommodate all the goods needed. Overcrowding can lead to damage and loss of inventory. The third factor to consider is the location of the storage facility.

The facility should be easy to access, preferably located near major transportation routes. This makes it easier to move goods in and out of the facility. Finally, security is a top priority.

Cleaning And Maintenance Before Storage

Cleaning and maintenance before storage is essential to ensure that your belongings are well-preserved and ready for use when needed. Whether it’s seasonal clothes, sports equipment, or household items, proper cleaning and maintenance are crucial to prevent mold, mildew, and other forms of damage.

Before storing your items, it is important to clean and dry them thoroughly, remove any dirt, dust, or stains, and pack them in airtight containers or bags. For clothes, use a gentle detergent and avoid using bleach or fabric softeners that can damage the fibers.

For sports equipment, such as skis or bikes. Wipe them down with a damp cloth and lubricate moving parts to prevent rusting. Remove any food or debris from household items, such as appliances or furniture, clean the surfaces with a mild detergent, and wipe them down with a dry cloth.

Draining The Air Tank

Draining the air tank is crucial in maintaining a compressor and ensuring longevity. Over time, the air tank can accumulate moisture, which can lead to rust and corrosion.

This can compromise the tank’s structural integrity and lead to leaks or catastrophic failure. To prevent this from happening, it is important to drain the air tank regularly. The process is relatively simple and can do in a few easy steps. First, ensure that the compressor turned off and unplugged.

Next, locate the drain valve at the bottom of the tank and attach a hose to it. Open the valve and allow the air and moisture to escape through the hose. It is important to wear safety goggles and gloves when performing this task. Once all the air and moisture have been drained, close the valve and remove the hose. Draining the air tank after each use or at least once a month is recommended.

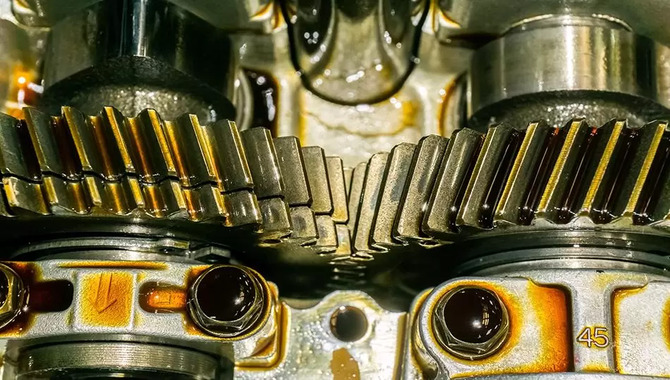

Lubrication And Protection Of Moving Parts

Lubrication and protection of moving parts are crucial in ensuring smooth operation and longevity of any mechanical system. Without proper lubrication, moving parts can become damaged due to friction and wear, leading to costly repairs and downtime.

Lubricants such as oils, greases, and lubricating fluids reduce friction between moving parts, dissipate heat, and prevent corrosion. They also act as a barrier between metal surfaces. Preventing them from coming into direct contact and causing wear and tear.

Proper lubrication and machinery maintenance can extend its lifespan and improve its efficiency. Regular inspection and lubrication of moving parts can prevent the buildup of dirt and debris that can cause malfunction. In addition, lubricant additives can enhance the lubricant’s performance by reducing friction and wear. Preventing rust and corrosion and improving thermal stability.

Choosing the right lubricant for specific applications is important, considering the operating conditions, temperature, and load requirements.

Removing And Storing Accessories

Removing and storing accessories is essential to maintaining and organizing any household or work environment. Whether it’s electronics, kitchen gadgets, or outdoor equipment, proper removal and storage can extend the life of these items and prevent clutter.

When it comes to electronics such as laptops, phones, and cameras, removing accessories, such as chargers or batteries, is important before storing them. This prevents damage to the accessories and reduces the risk of accidents such as electrical fires.

In the kitchen, removing and storing accessories such as blender blades and food processor attachments. And mixer paddles can also prevent damage and prolong the life of these appliances. Outdoor equipment, such as gardening tools or sports gear, should clean And stored properly to prevent rust or wear and tear. Proper removal and storage allow these items to easy accessed when needed. And won’t take up unnecessary space in your home or workplace.

Covering The Air Compressor

Covering the air compressor is essential in maintaining its longevity and efficiency. An air compressor is an important investment that requires proper care. And protection from weather elements that can damage its components.

When left exposed, moisture and dust can accumulate and cause corrosion, rust, and other damage, leading to costly repairs or replacements. To avoid this, it is recommended to cover the air compressor with a suitable cover that offers protection against rain, snow, sun, and other weather conditions.

A cover made of durable and waterproof material is ideal for outdoor use, while a breathable fabric is suitable for indoor storage. Additionally, the cover should fit snugly and securely to prevent any debris or pests from entering and damaging the compressor.

Regularly cleaning the air compressor before covering it can also help prevent any buildup of dirt and debris that can attract pests. Overall, investing in a quality cover and taking the time to cover and maintain the air compressor properly can extend its lifespan and ensure reliable performance for years to come.

Covering And Securing The Air Compressor

When it comes to maintaining an air compressor, covering and securing it properly is essential. A cover will protect the compressor from dust, debris, and moisture, which can cause damage to its components over time.

Additionally, a cover will prevent animals and insects from nesting inside the compressor, which can lead to clogging and other issues. Choosing a cover specifically designed for your compressor model is important, as an ill-fitting cover can cause more harm than good.

In addition to covering the compressor, securing it is equally important. This means properly anchoring it to the ground or a stable surface to prevent it from tipping over. Not properly securing a compressor can pose a safety hazard to people and property. Ensuring that all cords and hoses are neatly organized and secured is also important, as loose cords can become tangled and pose a tripping hazard.

When it comes to storing goods, it’s essential to follow recommended storage practices for both short and long-term storage. These practices ensure that your goods remain in good condition and help prolong their shelf life.

For short-term storage, it’s important to keep in mind the temperature and humidity of the storage area and the packaging of the goods. Goods that are prone to spoilage or damage should store in climate-controlled areas or refrigerators to maintain their freshness. On the other hand, goods that are not sensitive to temperature and humidity can store in dry, cool areas.

The recommended storage practices for long-term storage include proper organization and labeling of goods to make it easy to find them when needed. It’s also important to use high-quality packaging materials, such as airtight containers or vacuum-sealed bags to prevent moisture and air from getting in and damaging the goods.

Preparing The Air Compressor For Use After Storage

Before using an air compressor that has been in storage, it is important to prepare it to ensure optimal performance and longevity properly. The first step is to thoroughly inspect the compressor for any damage or signs of wear and tear that may have occurred during storage.

This includes checking the air filter, oil level, and hoses for cracks or leaks. Once the compressor has been inspected, it is important to drain any moisture or condensation that may have accumulated in the tank during storage. This can do by opening the drain valve and allowing the water to flow.

Next, the oil should check and changed if necessary, as old or dirty oil can cause the compressor to run less efficiently. It’s also important to check and adjust the pressure gauge to the recommended level before using the compressor. Additionally, it’s a good idea to run the compressor for a few minutes before actually using it to ensure that everything is working properly.

What Are The Best Practices For Storing An Air Compressor Long-Term?

The best practices for storing an air compressor long-term include the following:

- Drain all moisture from the tank and lines before storing the compressor to prevent rust and corrosion.

- Replace the oil in the compressor pump with fresh oil to prevent contamination of the pump.

- Store the compressor in a cool, dry, and well-ventilated place to prevent moisture buildup.

- Cover the compressor with a dust cover or tarp to protect it from dust and debris.

- Remove the air filter and clean it thoroughly before storing it to prevent it from becoming clogged.

- If the compressor will not use for an extended period. Removing the battery or disconnecting the power supply is recommended to prevent draining it.

Conclusion

proper storage of an air compressor is crucial to extend its lifespan and ensure it works efficiently. Following the steps outlined in this post, you can prevent rust and corrosion, protect the motor and other components from dust and debris, and maintain the compressor’s overall performance.

As a professional, it’s important to invest time and effort into proper storage methods to avoid costly repairs or replacements in the future. With these tips, you can rest assured that your air compressor will always be ready to use when needed.

FAQs

1.What Is The Best Location To Store An Air Compressor To Prevent Damage From Moisture And Temperature Changes?

Ans: The best location to store an air compressor to prevent damage from moisture and temperature changes is in a cool, dry, and well-ventilated area, preferably indoors.

2.What Is The Recommended Method For Cleaning And Maintaining An Air Compressor Before Storing It For An Extended Period Of Time?

Ans: The recommended method for cleaning and maintaining an air compressor before storing it for an extended period of time is first to drain all the moisture from the tank and then remove any remaining air from the tank.

3.What Type Of Environment Is Best For Storing An Air Compressor?

Ans: The best environment for storing an air compressor is a dry and clean area free from extreme temperatures, humidity, and dust.

4.Should I Drain The Tank Before Storing My Air Compressor, And If So, How Often?

Ans: Yes, it is recommended to drain the tank before storing your air compressor to prevent moisture buildup and rust. It is recommended to drain the tank after each use or at least once a month if the compressor is not in use.

5.Are There Any Special Considerations For Storing A Portable Air Compressor Versus A Stationary One?

Ans: Portable air compressors should proper drained of any moisture before storage to prevent rust and corrosion. They should also store in a dry and protected area to prevent damage to the compressor and its components.

![7 Best Spray Gun For Small Compressor [Reviews With Buying Guide]](https://accuratepicker.com/wp-content/uploads/2023/07/Best-Spray-Gun-For-Small-Compressors.jpg)