Air compressors are a vital part of many industries, from automotive repair to manufacturing. When deciding on which kind of air compressor to purchase, it is important to understand the differences between single-stage air compressors and two-stage air compressors.

This article will provide an overview of the differences between these two types of air compressors, their benefits, and their drawbacks, as well as discuss the applications for which they are best suited.

By the end of the article, readers will have a better understanding of the differences between single-stage and two-stage air compressors and be better informed when making their purchasing decisions. An interesting read awaits, so let’s dive in and explore the world of air compressors!

Comparing Single-Stage & Two-Stage Air Compressors

In this article, we will be discussing the differences between single-stage and two-stage air compressors. We will look at the advantages and disadvantages of each type, and discuss which type of compressor is best suited for various applications. By the end of the article, you will have a better understanding of the differences between single-stage and two-stage air compressors and be able to make an informed decision when selecting the right compressor for your needs.

Singlestage Air Compressor

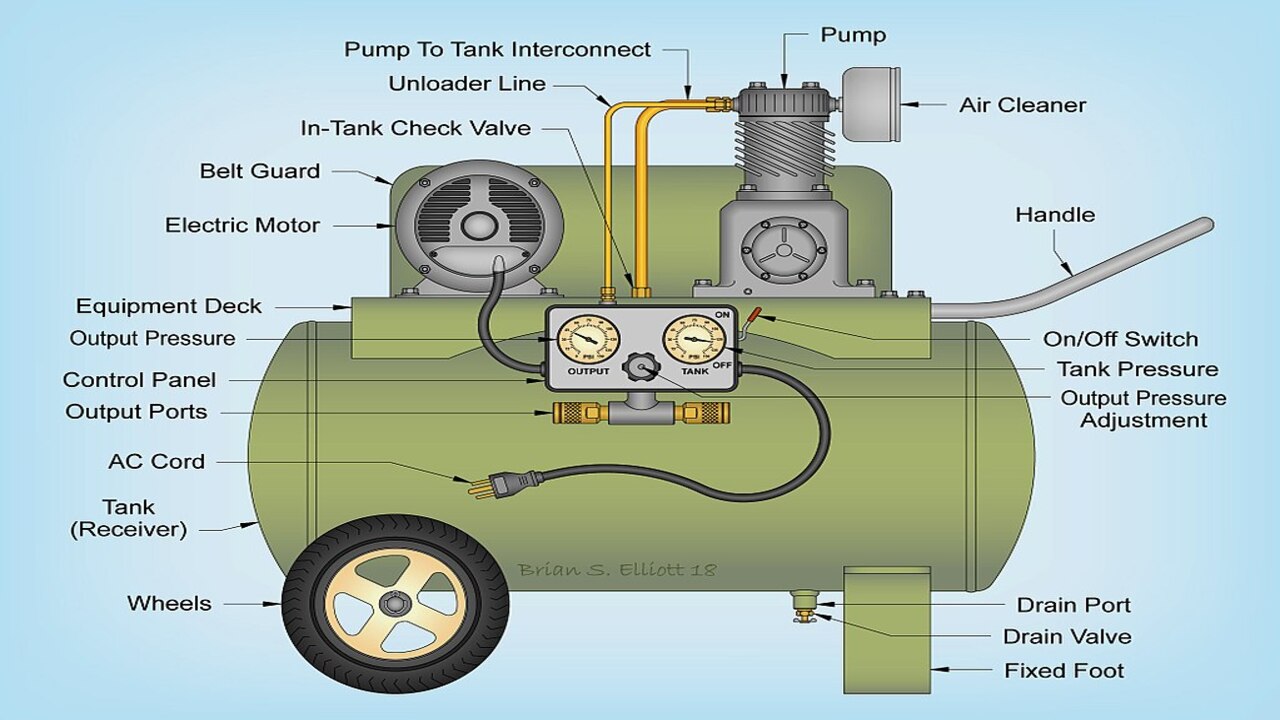

A single-stage air compressor operates using one piston to compress air. The piston compresses the air in one stroke and stores it in the receiver tank. This type of air compressor is best suited for low pressure applications such as powering tools such as nail guns, staplers, and drills.

It is also ideal for airbrushes, tire inflators, and impact wrenches. Single-stage air compressors are lightweight, easy to use, and cost-effective. However, they can only generate up to around 125 psi, which is not enough for some industrial applications. They also consume more power than two-stage air compressors.

Working Principle

A single-stage air compressor works by sucking in air and compressing it to a higher pressure in one go. This means that the air is compressed within the same cylinder, and the air is delivered at the same pressure as intake. On the other hand, a two-stage air compressor compresses the air twice.

This is done in two separate cylinders, with the intake air being compressed in the first cylinder and then again in the second cylinder to a higher pressure. The result is a much higher pressure air output than a single-stage air compressor. The higher pressure of a two-stage air compressor also makes it more efficient than a single-stage compressor.

Advantages

One of the main advantages of a single-stage air compressor is that it is generally cheaper to purchase than a two-stage air compressor. It is also simpler in design, making it easier to maintain and repair. Single-stage compressors have a shorter lifespan than two-stage compressors, but they are good for small, quick jobs since they can reach higher pressures faster. They are also portable, making them easier to transport from job to job.

Two-stage compressors are better for larger and more demanding jobs as they produce more air pressure and have a longer life span. They are more expensive and more difficult to maintain, but they are more reliable and can last for many years.

Disadvantages

A single-stage compressor is a basic, single-cylinder model that compresses air in one step. It is the most commonly found compressor and is suitable for many applications. It is less costly than the two-stage model, but it has some drawbacks.

The main disadvantage to a single-stage air compressor is its lack of power. It is not as powerful as a two-stage air compressor and is only able to produce a pressure of up to 150 psi. This is not enough for certain applications that require higher pressure, such as those with higher air flow requirements. Additionally, a single-stage air compressor is not as energy efficient as a two-stage model.

It tends to use more energy and is more likely to overheat than a two-stage compressor. Finally, single-stage air compressors tend to be noisier than two-stage compressors. The noise level of a single-stage compressor can be up to 90 dB, which is much louder than a two-stage compressor.

Applications

Air compressors are widely used in a variety of applications, such as powering tools, inflating tires, and painting. Single-stage air compressors are typically used for applications that require lower pressure, such as running air tools. On the other hand, two-stage air compressors are better suited for applications that require higher pressure, such as painting and inflating tires.

They are also more energy efficient and have a longer service life than single-stage compressors. Additionally, two-stage air compressors are usually more expensive than single-stage ones. Before purchasing an air compressor, it is important to determine the type of application it will be used for and select the right type of compressor accordingly.

Twostage Air Compressor

A two-stage air compressor works by compressing air in two separate cylinders. The first cylinder takes in air at atmospheric pressure and compresses it to a lower pressure. The second cylinder then takes in the compressed air from the first stage and further compresses it to the desired pressure. This two-stage process allows the compressor to reach higher pressures with less energy than a single-stage compressor.

The higher pressure also results in better air quality and higher efficiency. Furthermore, two-stage compressors are usually quieter than single-stage models, making them the preferred choice for homes and other quiet workplaces.

Working Principle

Single-stage air compressors use a piston to compress the air and then discharge it into the receiver. This is a much less efficient process, as the air is not cooled down before being used. Two-stage air compressors use two pistons, one to compress the air and the other to cool it down before it reaches the receiver.

This is much more efficient, as the air is cooled before it is used, resulting in a much higher quality of air. Additionally, two-stage compressors can reach higher pressures than single-stage compressors. This makes them ideal for applications that require high pressure air, such as painting, sandblasting, and air tools. Furthermore, two-stage compressors are quieter than single-stage compressors, making them better suited for indoor use.

Advantages

When it comes to air compressors, the two most common types are single-stage and two-stage. While both types offer the same basic function, there are advantages and disadvantages to each. In this article, we will explore the advantages of a single-stage air compressor versus a two-stage air compressor.

A single-stage air compressor is more affordable than a two-stage air compressor. This is due to the fact that the single-stage compressor has fewer parts, which helps to reduce the cost. Additionally, the single-stage air compressor is more compact and easier to transport, making it a great choice for people who need a compressor for DIY projects. Two-stage air compressors, on the other hand, offer more power and a higher capacity for air storage than single-stage compressors.

This makes them ideal for industrial and commercial applications where large amounts of air may be needed. Additionally, two-stage compressors are more efficient and can provide uninterrupted air flow, which is great for tools that require continuous air pressure. In conclusion, it is important to consider your specific needs when deciding between a single-stage or two-stage air compressor.

Single-stage compressors are more affordable and compact, making them a great choice for DIY projects. Two-stage air compressors offer more power and capacity, making them ideal for industrial and commercial applications.

Disadvantages

When it comes to air compressors, two-stage models offer a number of advantages over single-stage compressors. However, there are also some drawbacks that come with a two-stage air compressor. One of the main disadvantages of a two-stage air compressor is its size.

It is typically larger and heavier than a single-stage compressor, making it more difficult to move. Additionally, two-stage air compressors are often more expensive than single-stage compressors. This is because they include more features and components, such as two cylinders and two pistons. They also require more maintenance due to their complexity.

Finally, two-stage compressors tend to be louder than single-stage compressors, making them less suitable for quieter work environments.

Applications

When looking at the applications that a single-stage and two-stage air compressor can be used for, it is important to note that the two compressors are designed for different purposes. Single-stage compressors are best suited for lighter tasks such as inflating tires and powering small air tools.

On the other hand, two-stage compressors are ideal for powering larger air tools and equipment that require a greater amount of air pressure. Additionally, two-stage compressors are also more efficient at compressing air than single-stage compressors, making them better for applications that require a higher amount of air pressure. Furthermore, two-stage compressors are less likely to be overworked and break down when used for heavy-duty tasks.

Conclusion

The choice between a single-stage and two-stage air compressor depends on the user’s needs. Single-stage compressors are more efficient and require less maintenance, but can’t generate the same pressure as two-stage units. Two-stage compressors are more expensive and require more maintenance, but can generate higher pressures. Ultimately, the decision should be based on the user’s specific requirements.

FAQ’s

1.What Are The Advantages Of A Single-Stage Air Compressor Over A Two-Stage Air Compressor?

Ans: The main advantage of a single-stage air compressor is that it is simpler and cheaper than a two-stage compressor. It is also more reliable and requires less maintenance.

Additionally, a single-stage compressor can typically produce higher pressure than a two-stage compressor, allowing for more efficient operation. Finally, single-stage compressors are generally smaller and lighter than two-stage compressors, which makes them easier to transport and install.

2.What Are The Disadvantages Of A Two-Stage Air Compressor Compared To A Single-Stage Air Compressor?

Ans: The main disadvantage of a two-stage air compressor compared to a single-stage compressor is that it is more expensive and requires two motors and two cylinders. Additionally, two-stage compressors take up more space and require more maintenance.

Furthermore, two-stage compressors are not as efficient as single-stage compressors, and they produce a much higher level of noise. Finally, two-stage compressors are not suitable for applications that require high pressure.

3.What Type Of Applications Are Best Suited For A Single-Stage Air Compressor?

Ans: Single-stage air compressors are best suited for applications that require low pressure output and are not used frequently. They are ideal for powering small pneumatic tools, such as staplers, spray guns, sanders, drills, and other light-duty applications.

Single-stage air compressors are also often used for inflating tires and other inflatable items. They are generally not suitable for industrial applications that require higher pressure or more frequent use.

4.What Type Of Applications Are Best Suited For A Two-Stage Air Compressor?

Ans: Two-stage air compressors are best suited for applications that require a large volume of air at high pressures. These can include applications such as sandblasting, spray painting, and air-powered tools.

Two-stage air compressors are also ideal for industrial applications that require a continuous supply of compressed air, such as in manufacturing and packaging. Finally, they are also suitable for use in air-conditioning systems and in air-powered pumps.

5.What Factors Should Be Taken Into Consideration When Choosing Between A Single-Stage And A Two-Stage Air Compressor?

Ans: When choosing between a single-stage and a two-stage air compressor, the main factor to consider is the pressure requirements of the application. Other factors to consider include the size of the tank, the motor horsepower, the CFM output, and the cost.

Additionally, the duty cycle should be considered, as single-stage compressors can be overworked if the duty cycle is too high. Finally, the environmental conditions should be taken into consideration, as some two-stage compressors are better suited for cold climates.

![7 Best Spray Gun For Small Compressor [Reviews With Buying Guide]](https://accuratepicker.com/wp-content/uploads/2023/07/Best-Spray-Gun-For-Small-Compressors.jpg)