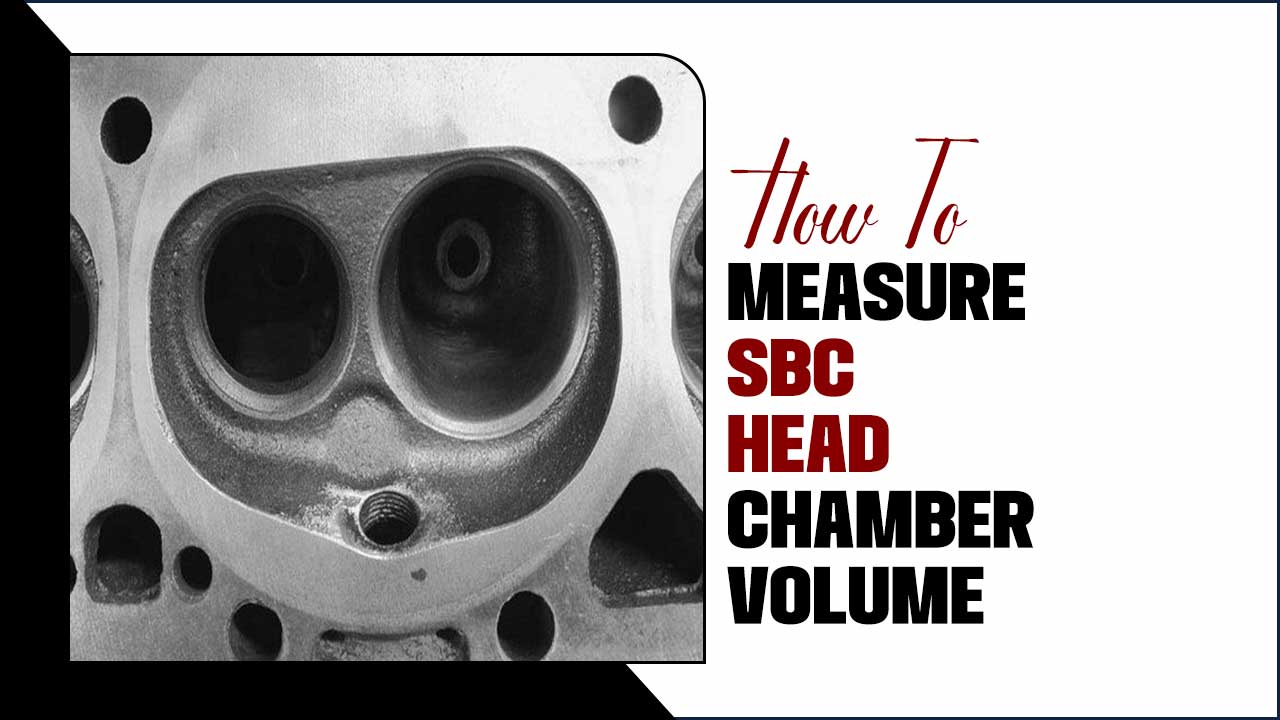

As a car enthusiast, you know that the Small Block Chevy (SBC) engine is one of the most popular and versatile. One of the critical components of the SBC engine is the head.

And understanding its chamber volume is crucial for improving performance and optimizing power. But how do you measure SBC head chamber volume? Fear not; this ultimate guide will give you all the information you need to measure SBC head chamber volume quickly and accurately.

In this comprehensive guide, we will break down the process of measuring SBC head chamber volume step-by-step, including the tools and equipment required. We will also cover the different methods of measuring head chamber volumes, such as the liquid displacement method and the CC kit method, and explain the pros and cons of each.

How To Measure SBC Head Chamber Volume – Comprehensive Guide

Measuring the head chamber volume of an SBC (Small Block Chevrolet) engine is an essential step for determining the engine’s compression ratio and optimizing performance. Here’s a comprehensive guide on how to measure SBC head chamber volume, along with some important “what not to dos” to ensure accurate measurements:

1. Gather The Necessary Tools:

- Cylinder head volume kit or a burette

- Precision measuring equipment (micrometer, caliper, etc.)

- Clean solvent and lint-free cloth for cleaning the head chambers

- Graduated cylinder for measuring liquid volume (if using a burette)

2. Clean The Head Chambers:

- Thoroughly clean the head chambers with a suitable solvent to remove any carbon deposits, dirt, or debris.

- Use a lint-free cloth to ensure the chambers are clean and dry before proceeding.

3. Seal Off Any Openings:

- Seal the intake and exhaust ports with rubber or plastic caps to prevent any liquid from entering or exiting the head chambers during measurement.

4. Prepare The Burette Or Cylinder Head Volume Kit:

- If using a burette, mount it securely and fill it with a known volume of liquid, preferably alcohol or oil, that won’t damage the components.

- If using a cylinder head volume kit, follow the manufacturer’s instructions for setup.

5. Position The Cylinder Head:

- Carefully position the cylinder head with the head chamber facing upwards, ensuring it’s stable and level.

6. Install The Piston And Cylinder Head Gasket:

- Install a correct-size piston and the corresponding head gasket into the cylinder.

7. Place The Burette Or Volume Kit:

- If using a burette, connect it to the head chamber and allow the liquid to flow until it fills the chamber without air bubbles.

- If using a volume kit, follow the manufacturer’s instructions for attaching it to the head chamber.

8. Measure The Liquid Volume:

- Record the liquid volume indicated on the burette or volume kit. This represents the head chamber volume.

Camshaft Selection

Camshaft selection is a crucial step in engine building. The camshaft is responsible for opening and closing the engine’s valves, which allows fuel and air to enter the combustion chamber and exhaust gases to exit. The right camshaft can significantly affect an engine’s performance, including horsepower, torque, and overall drivability.

There are many factors to consider when selecting a camshaft, such as the engine’s displacement, compression ratio, and intended use. A high-performance camshaft designed for racing may not be suitable for a street-driven car, as it may sacrifice low-end torque and drivability for top-end power.

On the other hand, a mild camshaft designed for a street car may not provide the power gains desired for a race car. Researching and consulting with experts when selecting a camshaft is essential to ensure it meets the engine’s needs and performance goals. Additionally, proper installation and tuning are essential to achieving the full potential of the selected camshaft.

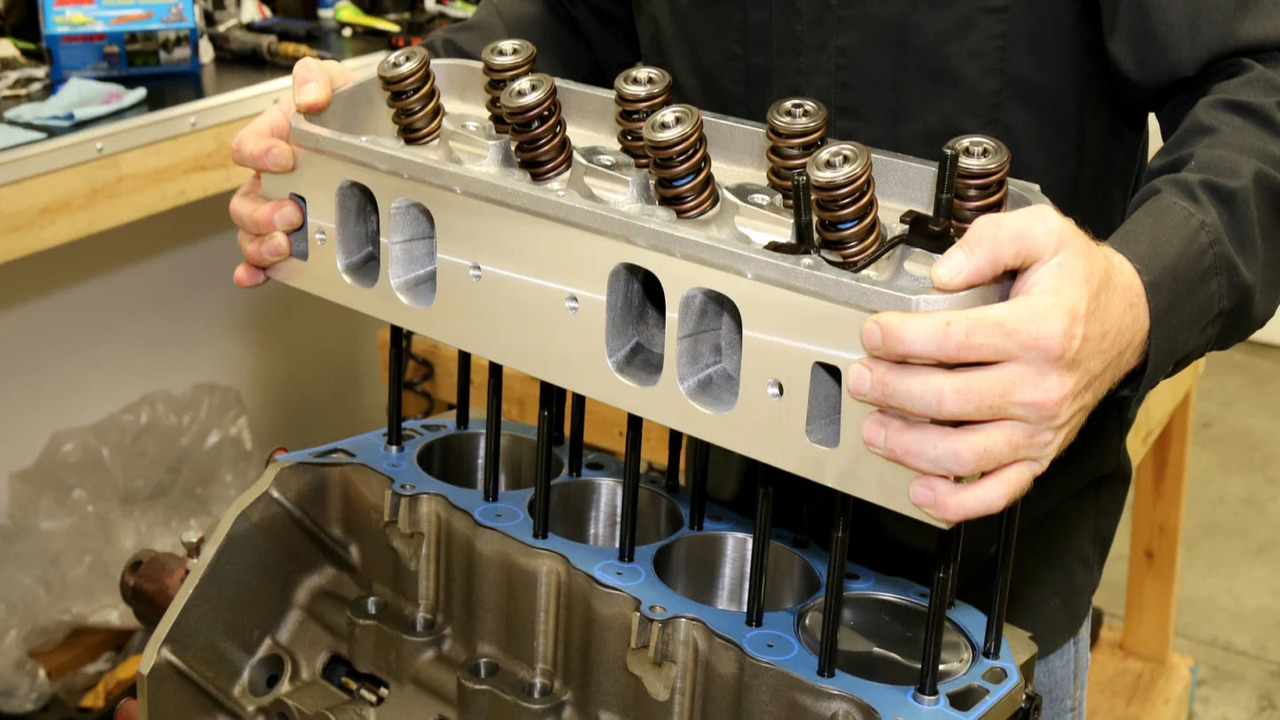

Combustion Chamber Modifications

Combustion chamber modifications are an excellent way to improve engine performance. These modifications enhance the fuel-air mixture in the combustion chamber, resulting in more complete combustion and increased power output. One of the most common modifications is the installation of high-performance cylinder heads, which feature larger intake and exhaust valves, reshaped combustion chambers, and improved port design.

These heads can increase engine power by up to 20% by improving airflow and fuel distribution. Another popular modification is using a high-performance camshaft, which alters the valve timing to optimize power output at different engine speeds. This modification can also improve idle quality and fuel economy.

Other modifications include increasing the compression ratio, installing a larger carburetor or fuel injection system, and using high-performance ignition components. These modifications create a more efficient combustion process, increasing horsepower, torque, and overall engine performance.

Intake And Exhaust Manifold Upgrades

When upgrading your car’s performance, the intake and exhaust manifold upgrades are crucial components that shouldn’t be overlooked. Upgrading these parts can improve your car’s horsepower, torque, and efficiency. The intake manifold delivers air to the engine, while the exhaust manifold removes exhaust gases.

Upgrading these parts can increase airflow, improving combustion and boosting your car’s performance. Several intake and exhaust manifold upgrades are available, such as porting and polishing or replacing the entire manifold with an aftermarket option. Porting and polishing involve smoothing out the rough edges of the manifold to reduce turbulence and increase airflow.

On the other hand, replacing the manifold with an aftermarket option can provide a larger diameter, better materials, and a more optimized design. These upgrades can be done individually or together for maximum performance gains.

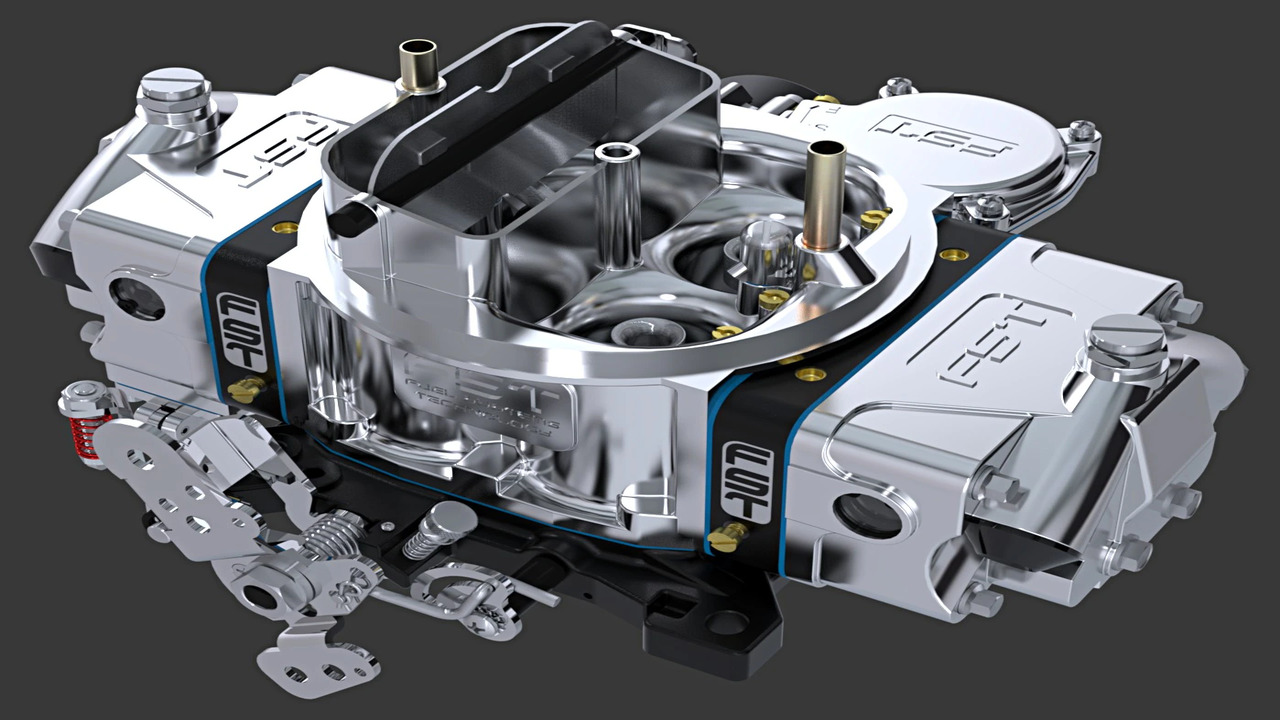

Carburetor And Fuel System Considerations

Carburetor and fuel system considerations are crucial when maintaining and upgrading your vehicle’s performance. The carburetor is essential for mixing air and fuel in the combustion chamber. It’s a mechanical device that requires regular maintenance to ensure optimal performance.

It would be best to regularly inspect the carburetor for any signs of wear, corrosion, or clogs that could affect its operation and cause engine problems. Fuel system considerations are equally important. Without proper fuel delivery, the engine won’t function correctly. You are regularly checking the fuel filter and pump. And fuel lines for any damage or clogs are necessary to prevent fuel flow issues.

Upgrading your carburetor and fuel system can also boost your vehicle’s performance. Installing a high-performance carburetor can improve throttle response and increase horsepower. Upgrading a performance fuel pump or injector system can also increase fuel efficiency and power output.

Tuning And Dyno Testing For Maximum Performance

When maximizing your vehicle’s performance, tuning and dyno testing are essential steps that should not be overlooked. Tuning involves adjusting the engine’s computer settings to optimize its performance, while dyno testing is a process that measures the horsepower and torque output of the engine.

Tuning helps to ensure that your vehicle is running at its best, with optimal fuel efficiency and power output. By adjusting the fuel and ignition settings, the engine can be tuned to deliver the best possible performance. This is particularly important for performance vehicles, where every bit of extra power counts.

Dyno testing measures the horsepower and torque output of the engine, providing valuable information on its performance. This can help identify areas where improvements can be made, such as adjusting the air/fuel ratios or upgrading specific components.

Maintenance And Care For Your Upgraded Sbc Heads

Maintaining and caring for your upgraded SBC heads is crucial in ensuring optimal performance and longevity for your engine. One of the key maintenance practices is regular cleaning. Clean the heads thoroughly after every use, especially if exposed to dirt, debris, or moisture.

Use a soft-bristled brush and mild detergent to remove any buildup or deposits. Another critical aspect of maintenance is checking the head bolts and fasteners. Ensure they are tight and secure, and torque them properly to prevent leaks or damage.

Inspect the heads for wear or damage, such as cracks, erosion, or warping. If you notice any abnormalities, it’s best to have them checked by a professional mechanic. Additionally, ensure that your engine oil and coolant levels are adequate and that you’re using the recommended grade of oil and coolant. Regular oil changes are also essential to keep your engine running smoothly.

Conclusion

How to Measure SBC head chamber volume is a crucial step in engine building. It helps to determine the compression ratio, a significant factor in the engine’s performance. The head chamber volume can be measured accurately and efficiently with the right tools and techniques.

It is important to note that this procedure should be carried out by a professional engine builder or machinist with the necessary experience and expertise to avoid costly errors. Following the guidelines and tips in this guide, engine builders can achieve the desired compression ratio and optimal engine performance.

FAQ

1.What Are The Benefits Of Knowing The Head Chamber Volume Of An SBC Engine?

Ans: Improved engine performance: By knowing the head chamber volume, you can calculate the engine’s compression ratio, which is critical in determining its power output. You can achieve optimal engine performance and efficiency with the right compression ratio.

2.Can The Head Chamber Volume Measurement Diagnose Engine Problems Or Identify Performance Issues In An SBC Engine?

Ans: No, the head chamber volume measurement alone cannot diagnose engine problems or identify performance issues in an SBC (Small Block Chevrolet) engine alone. It is just one of the many factors that can affect engine performance and should be considered in conjunction with other factors such as engine compression, valve timing, fuel delivery, and ignition timing.

3.Are There Any Common Mistakes To Avoid When Measuring SBC Head Chamber Volume?

Ans: Not cleaning the combustion chamber properly before measuring: Any debris or residue left in the chamber can affect the accuracy of the measurement.

4.How Does SBC Head Chamber Volume Affect Engine Performance And Efficiency?

Ans: The SBC head chamber volume affects engine performance and efficiency by altering the engine’s compression ratio. A smaller head chamber volume increases the compression ratio, which can improve engine performance and efficiency by providing more power and better fuel economy.

5.What Are Some Tips For Interpreting SBC Head Chamber Volume Measurements And Adjusting The Engine?

Ans: Understand the purpose of head chamber volume measurements: Head chamber volume measurements determine the engine’s compression ratio. By measuring the volume of the combustion chamber, you can calculate the compression ratio and make adjustments to improve performance.

![SBC Main Cap Torque Sequence [Effective Ways]](https://accuratepicker.com/wp-content/uploads/2022/03/SBC-Main-Cap-Torque-Tester.jpg)