If you are in the market for SBC (small block Chevy) head gaskets, you have likely realized the importance of choosing the right one for your engine.

Head gaskets are crucial in ensuring your engine runs smoothly and efficiently. However, choosing the right head gasket can be daunting with so many options available. That is why we have created this comprehensive guide to help you make an informed decision when purchasing How to choose SBC head gaskets.

In this guide, we will take you through everything you need to know about Choosing SBC head gaskets, from understanding the different types available to factors you should consider when selecting the best head gasket for your engine.

We will also explore the key features that make a suitable head gasket and the common mistakes to avoid when selecting the right one. Choosing the right SBC head gasket is essential to maintaining the integrity of your engine.

How To Choose SBC Head Gaskets – Some Quick Tips

Several important factors must consider when choosing SBC (Small Block Chevy) head gaskets. Here are some quick tips to help you make an informed decision:

Dos:

- Consider the engine’s specifications: Consider the engine displacement, compression ratio, and intended use (street, performance, or racing) when selecting a head gasket. Different gaskets are designed to handle varying levels of power and heat.

- Choose the right material: Head gaskets are typically made from composite, MLS (Multi-Layer Steel), or copper. Each material has its own strengths and weaknesses, so select one that suits your engine’s needs. MLS gaskets are commonly used for high-performance applications due to their durability and sealing capabilities.

- Check for compatibility: Ensure that the head gasket you choose is compatible with your specific engine model and cylinder head design. SBC engines have gone through various iterations, so it’s crucial to match the gasket to your engine’s specifications.

- Consider aftermarket options: Depending on your performance goals, you may want to explore aftermarket head gaskets that offer improved sealing, better thermal conductivity, or additional features like fire rings for extreme applications. Research reputable brands and read reviews to find a reliable option.

- Pay attention to installation instructions: Follow the manufacturer’s recommendations for installation procedures, torque specifications, and any additional steps or precautions to ensure proper sealing. Proper installation is crucial for achieving a reliable and leak-free seal.

Types Of SBC Head Gaskets

When it comes to Small Block Chevy engines, different types of head gaskets can use. The first type is the composite head gasket, made of multiple layers of materials such as graphite, steel, and rubber. This type of gasket is cost-effective and can use for engines with low to moderate horsepower.

The second type is the MLS (Multilayer Steel) gasket, made of multiple steel layers and coated with a rubber layer. These gaskets are more durable and can handle higher horsepower levels. The third type is the Copper head gasket, made of a single layer of copper and commonly used in high-performance engines due to its excellent heat conductivity.

Copper gaskets are also reusable and can anneal to maintain their seal. A combination of steel and rubber makes the fourth type, the Elastomeric gasket.

Factors To Consider When Choosing SBC Head Gaskets

When choosing SBC head gaskets, several factors must consider.

- ensuring the gasket is compatible with your engine model is essential. This is because different engine models have different specifications, and using the wrong gasket could result in poor engine performance or even damage.

- the material of the gasket is important. Composite gaskets are the most common, but some engines may require a metal or rubber gasket. The environment in which the engine will operate also affects the choice of gasket material. A metal gasket may be more suitable if the engine operates in extreme temperatures. If you are using the engine for racing, you should use a high-performance gasket.

Another factor to consider is the thickness of the gasket. Thicker gaskets are more durable and can withstand higher compression ratios, but they may also negatively affect the engine’s performance.

Material Of SBC Head Gaskets

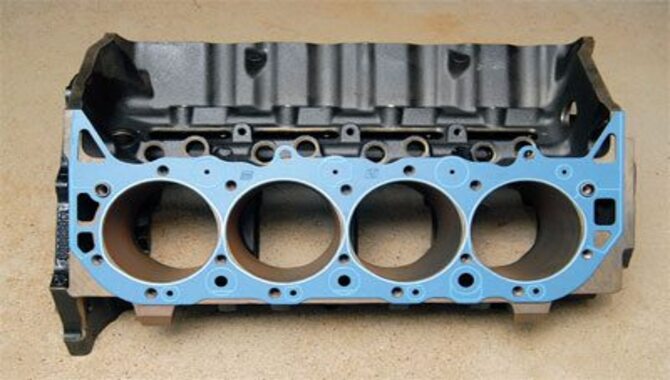

SBC head gaskets are one of the most critical components in an engine’s combustion chamber. They serve as a seal between the engine block and cylinder head, preventing oil and coolant leaks and keeping the combustion gases contained.

The material of SBC head gaskets is crucial to their durability and performance. Some common materials used in SBC head gaskets include composite, graphite, and multilayer steel. Manufacturers make composite gaskets combining graphite and aramid fibres to withstand high heat and pressure.

Graphite gaskets are made from pure graphite to provide excellent sealing properties. Similarly, manufacturers make multilayer steel gaskets from several layers of steel to enhance their durability and resistance to blowouts. Each material has advantages and disadvantages, and choosing the right one depends on the specific application and requirements of the engine.

The Thickness Of SBC Head Gaskets

The thickness of SBC head gaskets is a crucial factor to consider when building an engine. SBC head gaskets are essential components that seal the combustion chamber and prevent oil and coolant from leaking. The gasket’s thickness affects the engine’s compression ratio and performance.

Thicker gaskets can reduce the compression ratio, which can be helpful when building an engine for forced induction or high-boost applications. Thinner gaskets increase the compression ratio, improving power output and fuel efficiency. However, thicker gaskets also increase the distance between the cylinder head and the block, affecting the engine’s valve timing and combustion efficiency.

It is essential to choose the correct thickness of the SBC head gasket based on the application, engine displacement, and intended use. High-quality SBC head gaskets are crucial because they provide excellent heat resistance and durability.

Quality Of SBC Head Gaskets

The quality of SBC head gaskets is crucial to the performance and longevity of any small-block Chevy engine. These gaskets seal the cylinder head and the engine block, preventing oil, coolant, and combustion gases from leaking.

When choosing a head gasket, it’s essential to consider factors such as material, thickness, and design. Manufacturers make many high-performance gaskets from multilayer steel (MLS) or graphite, which offer better-sealing properties than traditional composite gaskets.

Thicker gaskets can also benefit engines that experience high levels of cylinder pressure or thermal expansion. Additionally, the design of the gasket can impact its durability and resistance to blowouts. Some manufacturers offer gaskets with special coatings or reinforced areas to prevent excessive heat or cylinder pressure damage.

Ultimately, investing in a high-quality SBC head gasket can save you time and money in the long run by preventing costly engine damage and the need for frequent repairs.

Installation And Maintenance Tips For SBC Head Gaskets

When installing and maintaining SBC head gaskets, a few tips can help ensure their longevity and reliability. Firstly, it is essential to thoroughly clean and inspect the cylinder head and engine block surfaces before installation.

Any debris or damage can potentially cause leaks or failure. Additionally, using a high-quality gasket with the proper thickness and material is crucial for optimal sealing and heat resistance.

During installation, it is important to torque the bolts to the manufacturer’s specifications in the correct tightening sequence to ensure even pressure distribution. After placing the gasket, it is recommended that you perform a coolant system pressure test to check for any leaks.

In terms of maintenance, regularly checking and replacing worn or damaged gaskets can prevent costly engine repairs. Monitoring the temperature and coolant levels to prevent overheating and potential gasket failure is also important. Properly installing and maintaining SBC head gaskets can lead to a longer-lasting and more reliable engine.

Conclusion

choosing the right head gasket for your SBC engine is essential to ensure its longevity and performance. By considering factors such as the engine type, material, thickness, and brand reputation, you can make an informed decision that will serve you well in the long run.

Remember to prioritize quality over cost and consult a professional mechanic or engine builder if you have any doubts or questions. With this comprehensive guide, you are now equipped with the knowledge of How to choose SBC head gaskets for your needs and enjoy a smooth and reliable engine performance.

FAQ

1.What Are The Key Factors When Choosing An SBC Head Gasket?

Ans: Head gaskets can make of different materials, such as copper, composite, and multilayer steel. Each material has advantages and disadvantages, depending on the application and the level of Performance Desired.

2.What Are The Benefits Of Using A Multi-Layered Sbc Head Gasket?

Ans: The benefits of using a multi-layered SBC (steel shim, fibre facing, and elastomer coating) head gasket include improved sealing between the cylinder head and engine block, increased durability and reliability, better heat transfer, and reduced risk of blowouts or leaks under high pressure and temperature conditions.

3.What Materials Are Commonly Used In SBC Head Gaskets, And How Do They Differ In Performance And Durability?

Ans: SBC (Small Block Chevy) head gaskets are commonly made of composite, graphite, and multilayer steel (MLS). Manufacturers make composite head gaskets from non-metallic materials like asbestos, rubber, or fibre. They are inexpensive and easy to replace. However, they are not as durable as other materials and are prone to blowing out if the engine overheats.

4.What Factors Should Be Considered When Selecting An SBC Head Gasket, Such As Material, Thickness, And Design?

Ans: The material of the head gasket can affect its durability, sealing properties, and resistance to heat and pressure. Common materials include graphite, composite, and multilayer steel (MLS).

5.What Are Some Reputable Brands And Manufacturers Of SBC Head Gaskets, And What Should Be Considered When Evaluating Their Products?

Ans: Some reputable brands and manufacturers of SBC (Small Block Chevy) head gaskets include Fel-Pro, Cometic, and MLS (Multilayer Steel) from companies like SCE and ARP. When evaluating their products, it is essential to consider factors such as the material quality, thickness, and design of the gasket.