Ensuring proper adjustment of the gaskets is one of the most crucial aspects of engine maintenance. The head gasket, in particular, plays an essential role in sealing the engine’s combustion chamber and keeping fluids from leaking into the engine’s cylinders.

This is why it is important to understand how to adjust SBC head gaskets to prevent engine damage and keep running smoothly. In the post, we will explain everything you need to know about correctly adjusting them. This post is aimed at car enthusiasts, mechanics, and anyone who wants to learn more about engine maintenance and repair.

We will cover the different types of SBC head gaskets, their installation process, and the most common problems associated with improper adjustment. We will also detail the tools and equipment you will need to adjust SBC head gaskets properly and the step-by-step process.

What Are SBC Head Gaskets?

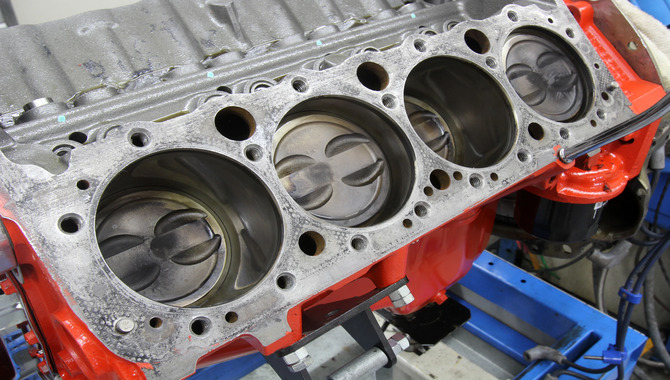

SBC head gaskets refer to head gaskets designed for small-block Chevrolet engines. These gaskets seal the cylinder head and engine block, preventing leaks and maintaining proper compression. Quality head gaskets are essential for the proper functioning of an engine, as they help prevent coolant and oil from mixing and potentially causing engine damage.

SBC head gaskets are widely available from various manufacturers and come in different materials and thicknesses depending on the specific application and performance needs.

Why Might I Need To Adjust The SBC Head Gasket?

Adjusting SBC (Small Block Chevy) head gaskets may be necessary in certain situations. For example, if the engine has been rebuilt or the cylinder head has been machined, the gasket thickness may need to be adjusted to ensure proper compression.

Additionally, adjusting the head gasket may be a solution if the engine is experiencing compression issues or leaks. Following manufacturer guidelines and using the correct gasket thickness is important to avoid engine damage.

How Much Does It Cost To Adjust SBC Head Gaskets?

The cost of tools and materials to adjust SBC head gaskets can vary depending on several factors. These factors may include the brand and quality of the tools and materials and the vehicle’s specific needs. The cost can generally range from a few hundred to over a thousand dollars. Researching and comparing prices from different suppliers is important to find the best deal for your situation.

Type Of SBC Head Gaskets

Composite Gaskets: These are made of layered materials such as graphite or fibre and are suitable for most stock or mildly modified Small Block Chevy (SBC) engines.

MLS (Multi-Layer Steel) Gaskets: These gaskets have multiple layers of steel with a sealing layer of elastomer or rubber. They provide excellent sealing and durability, ideal for high-performance or turbocharged SBC engines.

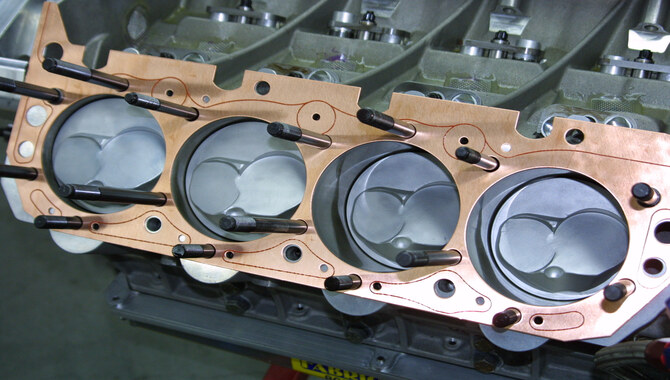

Copper Gaskets: Copper head gaskets offer superior heat conductivity and sealing properties, making them suitable for engines with extreme operating conditions or high compression ratios.

Rubber-Coated Fiber Gaskets: These gaskets have a fibre core with a rubber coating on both sides. They provide a good balance between affordability and performance for SBC engines with moderate power levels.

Solid Copper Gaskets: Solid copper head gaskets are highly resilient and withstand extreme temperatures and pressures. They are commonly used in racing applications or engines with customized specifications.

MLS-Coated Gaskets: These gaskets combine the benefits of MLS technology with a coating of rubber or elastomer on the sealing surfaces, providing enhanced sealing capabilities.

How To Adjust SBC Head Gaskets For Optimal Performance

To adjust SBC (small block Chevy) head gaskets for optimal performance, ensure your engine’s head gasket is the correct thickness. You can determine this by measuring the compressed thickness of your old head gasket and comparing it to the compressed thickness of the new one.

Torque the head bolts to the manufacturer’s specifications in the recommended sequence. Below are step-by-step instructions on how to adjust SBC head gaskets.

1. Remove The Old Head Gaskets

Before removing any engine components, ensuring the engine has thoroughly cooled down is essential. Once the engine is cool, disconnect the battery and drain the coolant. Next, remove the air intake system and any components blocking access to the valve covers.

Remove the valve covers and disconnect the spark plugs. Loosen and remove the head bolts carefully not to damage the cylinder head. Finally, remove the old gaskets and thoroughly clean the surfaces before replacing any components.

2. Inspect The Head And Block

Before reassembling an engine, inspecting and preparing the cylinder head and block surfaces thoroughly is essential. Check for warping or cracks in the cylinder head and measure its height to ensure proper compression.

Inspect the head gasket surface for any damage or wear. Similarly, check the block surface for warping, cracks, or damage. Finally, thoroughly clean both surfaces to remove debris or old gasket material before reassembling. These steps will help ensure a proper seal and prevent future engine issues.

3. Install The New Head Gaskets

When replacing a head gasket, choosing the correct gasket for your engine is essential. Before torquing the head bolts to specification, align the gasket properly. Applying sealant may be necessary, but be cautious not to overuse it. Finally, check for proper compression before starting the engine. Proper head gasket installation will prevent leaks and ensure your engine runs smoothly.

4. Reinstall The Cylinder Heads

Proper installation of the head gasket and head is crucial. To align them correctly, ensure the mating surfaces are clean and debris-free. Tighten the head bolts using a torque wrench according to the manufacturer’s specifications.

After torquing, install the pushrods and rocker arms in their proper locations. Reinstall the valve covers and check for any oil leaks. For optimal performance, check and set the engine timing correctly. Following these steps will help ensure a successful engine rebuild.

5. Refill The Coolant And Oil

Regular maintenance on your vehicle is crucial for its longevity and optimal performance. One important task is changing the engine oil, which you should do according to your manufacturer’s recommendations. Another task is refilling the cooling system with new coolant and following the proper procedure to avoid air pockets.

After refilling, it’s necessary to bleed the system of any air that may have gotten trapped. Always check for leaks before starting the engine and ensure it operates smoothly. These simple steps can save you from costly repairs and keep your vehicle running smoothly for years.

Use Quality Parts

It’s important to select a reputable brand. Cheaper options may seem appealing, but they often have lower quality and less reliability. OEM or equivalent gaskets can also ensure a proper fit and prevent leaks.

Skimping on quality may save money in the short term, but it can lead to costly repairs down the line. Always ensure parts are compatible with your make and model, and use the parts the manufacturer recommends for optimal performance and longevity.

Use Proper Tools

A torque wrench is a tool that allows the user to tighten bolts to a specific torque value. Ensuring that the bolt is tightened correctly prevents damage or failure. A gasket scraper removes old gasket material from surfaces and prepares them for a new gasket.

You can use a feeler gauge, a thin metal strip, to measure the gap between two surfaces. You can use a dial indicator to measure small distances or changes in surface height.

What Can Happen If The SBC Head Gaskets Are Not Properly Adjusted?

Improperly adjusted SBC (Small Block Chevy) head gaskets can lead to several issues. The most common problem is coolant leaking into the combustion chamber, which can cause engine overheating, loss of power, and potentially catastrophic engine failure.

Additionally, oil leaks can occur, leading to decreased lubrication and potential engine damage. To avoid these issues, it is important to ensure that head gaskets are properly adjusted during engine assembly.

Conclusion

Adjusting SBC head gaskets requires attention to detail and precision. By following the steps outlined in this guide, you can ensure proper seating of the gasket and smooth operation of the engine. While the process may seem daunting, it’s important to remember that adjusting your head gaskets properly can prevent costly engine damage down the road.

It is crucial to use the correct torque specifications and to evenly tighten the bolts in a specific sequence to avoid warping, leaks, or other damage. By adjusting SBC head gaskets properly, you can prevent costly repairs down the line and ensure your engine is running at its best.

As always, consult with a professional mechanic if you are unsure or have any questions regarding the process. This guide explains how to adjust SBC head gaskets by following the steps outlined and consulting a professional mechanic if necessary to ensure that your SBC head gaskets are properly adjusted and your engine is running optimally.

FAQ’s:

1.What Is An SBC Head Gasket?

Ans: An SBC head gasket is a seal between the engine block and the cylinder head of a small-block Chevrolet engine.

2.How Do I Know If The SBC Head Gasket Is Leaking?

Ans: You may notice coolant leaking from the engine, white smoke from the exhaust, or a loss of engine power.

3.Do I Need To Use A Sealant With The SBC Head Gasket?

Ans: In most cases, using a sealant with a Small Block Chevy (SBC) head gasket is unnecessary. Modern head gaskets typically create a reliable seal without the need for additional sealants.

4.What Is A Torque Angle Gauge?

Ans: You use a torque angle gauge to measure the rotation required to achieve the proper torque value.

5.Should I Replace Both SBC Head Gaskets At The Same Time?

Ans: It is recommended to replace both head gaskets simultaneously to ensure even compression in all cylinders.

![383 Stroker Torque Monster [Easy Steps & Tips]](https://accuratepicker.com/wp-content/uploads/2022/03/383-Stroker-Torque-Monster.jpg)