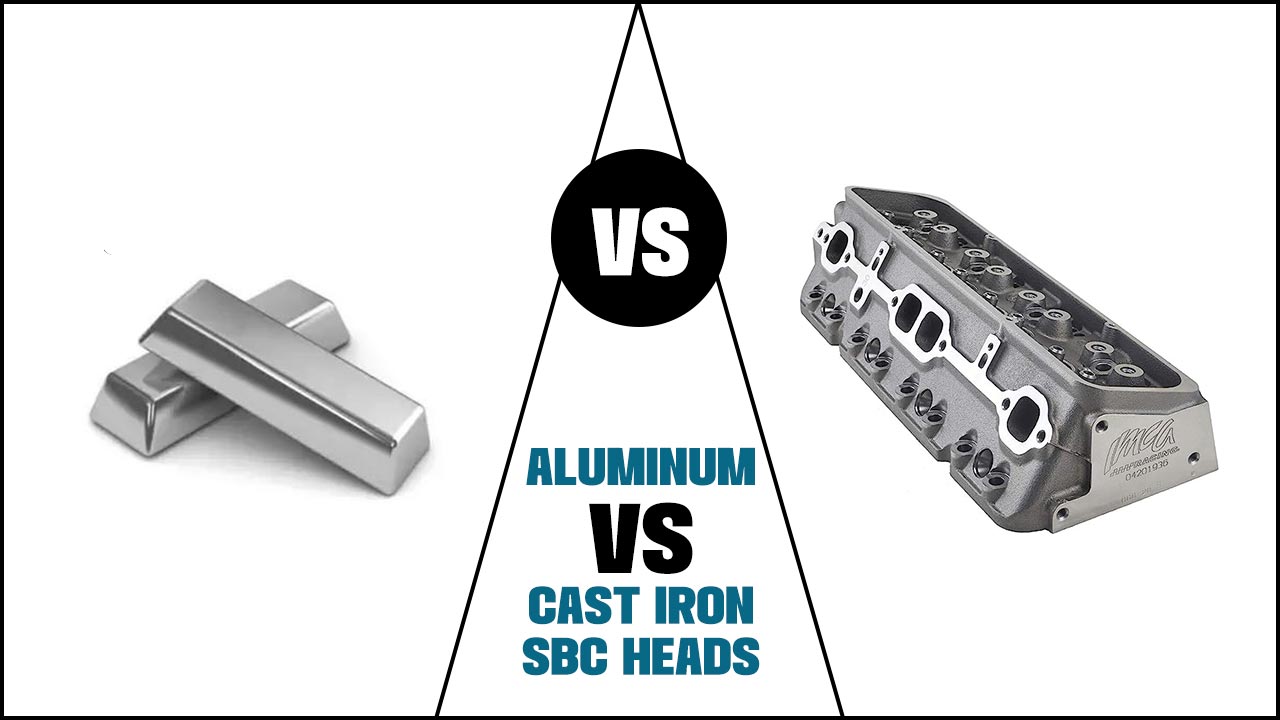

The debate between aluminum SBC heads and cast iron SBC heads has been ongoing for decades. Both types of heads offer advantages and disadvantages in terms of performance, cost, and durability.

While aluminum SBC heads are lighter and more efficient, cast iron SBC heads are more durable and often cheaper. In this article, we will explore the differences between aluminum SBC heads and cast iron SBC heads, in order to help you decide which is right for your engine.

We will also discuss the importance of proper installation and maintenance for each type of head. By the end of this article, you will have a better understanding of the pros and cons of each type of head and be able to make an informed decision about which is the best option for your engine.

Aluminum Vs. Cast Iron: Sbc Heads

Before delving into the comparison of Aluminum SBC Heads vs. Cast Iron SBC Heads, it is important to understand the basics of both types of heads. Aluminum SBC (Small Block Chevy) heads are lightweight and provide increased performance due to their lighter weight and improved airflow.

Cast iron SBC heads are heavier, but offer greater durability and strength. Both types of heads offer advantages and disadvantages, which will be discussed in this article. The focus of this article will be to compare the differences between Aluminum SBC Heads and Cast Iron SBC Heads to determine which is the better option for your specific application.

Advantages

Aluminum small-block Chevy (SBC) heads have several advantages over cast iron SBC heads. Aluminum heads are lighter in weight, which reduces the overall weight of the engine, resulting in better fuel economy.

Aluminum heads also dissipate heat faster than cast iron heads, which helps to keep the motor cool and extends its life. Additionally, aluminum heads offer higher performance than cast iron heads due to their lighter weight and better airflow.

This increased performance can lead to improved acceleration and higher top-end speeds. Finally, aluminum heads are typically much less expensive than cast iron heads, making them a cost-effective upgrade for a wide variety of engines.

Weight

Weight is a major factor to consider when choosing between aluminum and cast iron SBC heads. Aluminum heads are much lighter than cast iron heads, weighing in at around 14 lbs. versus the 22 lbs.

of a cast iron head. This difference in weight can lead to improved performance. Since aluminum is a lighter material, it allows for the engine to accelerate faster and cornering to be sharper. Additionally, because aluminum is a stronger material, the heads can be more efficiently designed, leading to improved flow and combustion.

On the other hand, cast iron heads offer increased durability and are more tolerant of high temperatures and pressures. With cast iron heads, the engine can remain at higher RPMs without fear of damage. However, the increased weight of the cast iron heads can affect the performance of the engine.

Heat Dissipation

Heat dissipation is an important factor to consider when comparing aluminum SBC heads to cast iron SBC heads. Aluminum SBC heads are much better at dissipating heat due to their higher thermal conductivity and lighter weight.

Aluminum is also a much better material for dissipating heat quickly in high-performance engine builds. Cast iron SBC heads, on the other hand, are much heavier and have a far lower thermal conductivity.

This means that they don’t dissipate heat as effectively as aluminum, making them unsuitable for high-performance builds. Aluminum SBC heads also have a significantly lower thermal mass than cast iron SBC heads, which allows them to cool down more quickly and more efficiently.

This makes aluminum SBC heads the preferred choice for high-performance engine builds, as they will dissipate heat more quickly and more efficiently than cast iron SBC heads.

Performance

When it comes to performance, aluminum SBC heads have an edge over cast iron heads. Aluminum heads are lighter, which means they can rev higher and faster than their cast iron counterparts. Additionally, aluminum heads have better heat dispersion qualities, resulting in cooler operating temperatures. This helps to prevent detonation and reduces the need for large amounts of fuel.

Aluminum heads are also able to flow more air, which increases horsepower and torque. Lastly, aluminum heads offer a higher compression ratio, which also increases power. Ultimately, aluminum heads are better for performance and will give your engine the edge you need.

Cost

When it comes to cost, aluminum SBC heads may be more expensive than cast iron heads. However, this cost difference is often offset by the performance benefits of aluminum heads. Aluminum heads are lighter, which means they can be easily transported, and they can also be machined to deliver more power.

In addition, aluminum heads dissipate heat more efficiently, which can lead to improved engine performance and increased fuel economy. Cast iron heads may be cheaper, but they are usually heavier, more difficult to machine, and they don’t provide the same heat dissipation benefits. Ultimately, the cost of the project should be weighed against the performance benefits of aluminum heads.

Disadvantages

Aluminum SBC heads have some distinct disadvantages compared to cast iron. One of the biggest disadvantages is the cost. Aluminum SBC heads are much more expensive than cast iron. They are also more difficult to machine and require more specialized tools.

Additionally, aluminum SBC heads are more prone to warping when exposed to high temperatures. This requires more frequent head gasket changes which can be costly and time consuming. Lastly, aluminum SBC heads are generally not as durable as cast iron and can be easily damaged.

Material Strength

The material strength of aluminum SBC heads is significantly greater than that of cast iron SBC heads, making them a superior choice for performance applications. Aluminum is a much lighter metal than cast iron, allowing it to withstand higher cylinder pressures without the risk of cracking or warping. It also dissipates heat more efficiently, helping to keep temperatures regulated.

Additionally, aluminum heads are able to support higher compression ratios and larger valves, giving the engine more potential for power. The lighter weight of aluminum heads also reduces the strain on the engine block, allowing for a higher redline and more power.

Corrosion

Aluminum SBC heads are less prone to corrosion compared to cast iron SBC heads. This is due to the inherent resistance of aluminum alloys to oxidation. Aluminum is also much lighter than iron, which can help reduce the overall weight of the engine.

However, aluminum SBC heads require more frequent maintenance to prevent corrosion. Regular cleaning and wax coating of aluminum SBC heads will help protect them from corrosion. Additionally, using a high-quality anti-corrosion coating can also help protect the heads from oxidation. Additionally, aluminum heads are less prone to warping and cracking due to temperature changes.

This makes them a more stable and reliable option for performance engines.

Machining

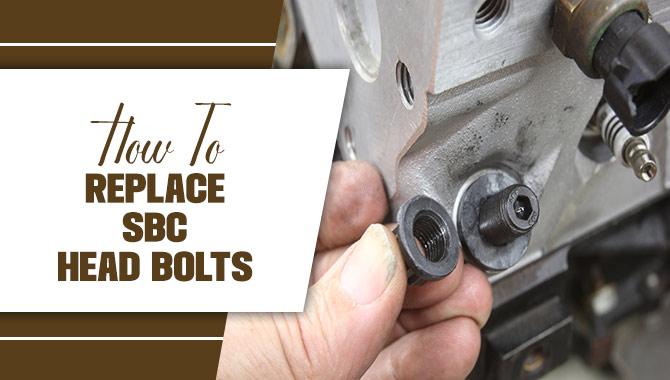

Machining is an important factor when it comes to SBC heads. Aluminum heads are more expensive to machine than cast iron heads, due to the need for specially designed tooling to properly machine aluminum. In addition, the aluminum material is less forgiving when it comes to machining than the cast iron material.

This means that any machining errors made on the aluminum heads can be much more costly to fix. As a result, machining of aluminum heads generally requires more skill and precision than machining of cast iron heads. Furthermore, aluminum heads require more frequent maintenance to prevent wear and tear on the machining tools.

Cost

When it comes to cost, aluminum SBC heads are significantly more expensive than cast iron heads. This is due to the fact that aluminum is much harder to machine than cast iron, and the cost of the raw material itself is higher. Aluminum heads also require more frequent maintenance and parts replacement than their cast iron counterparts, adding to the overall cost of ownership.

Additionally, aluminum heads are not designed to last as long as cast iron, so they may need to be replaced sooner, resulting in further costs. Ultimately, while aluminum heads may provide more power, they come with a much higher price tag and more frequent maintenance.

Conclusion

Aluminum SBC heads are a great choice for those looking for a lightweight solution for their Small Block Chevy engine. They are typically lighter than cast iron SBC heads, allowing for improved acceleration and better overall performance. However, aluminum heads require more frequent maintenance and can be more expensive than cast iron heads.

Additionally, aluminum heads may require more frequent valve adjustments and can be more prone to cracking and warping than cast iron heads. Ultimately, the decision between aluminum and cast iron heads comes down to the individual’s needs and preferences.

FAQ’s

1.What Are The Pros And Cons Of Each Type Of Head?

Ans: The pros and cons of each type of head depend on the type of head and the specific application. For example, a flat head screw has the benefit of distributing pressure over a large area, making it ideal for use in thin materials.

On the other hand, a round head screw has the benefit of being less likely to snag on materials, which is great for applications where it is important to avoid snagging. However, the round head is not as well suited to thin materials as the flat head screw.

A pan head screw is often used when a larger bearing surface is needed, but it is less suited to applications where a low profile is desired. Finally, a fillister head screw has the benefit of providing a good bearing surface, but is more difficult to install.

2.How Much More Expensive Are Aluminum Sbc Heads Compared To Cast Iron?

Ans: Aluminum SBC heads are generally more expensive than cast iron heads, typically by a factor of two to three times the cost. The cost difference is mainly due to the higher materials cost and the more involved machining process of the aluminum heads.

The aluminum heads are also lighter, which can be beneficial in some applications, and they are able to maintain their shape under higher temperatures, which can improve performance.

3.What Are The Differences In Performance Between The Two?

Ans: The differences in performance between the two depend on the specific task or activity being compared. Generally speaking, performance is typically measured in terms of speed, accuracy, reliability, and scalability.

One might be faster than the other, one might be more reliable, one might scale better, etc. Ultimately, the differences in performance will depend on the individual scenario and the specific needs of the user.

4.Which Type Is Better For High-Performance Applications?

Ans: For high-performance applications, it is generally better to use a system with a higher processor speed that can handle multiple tasks quickly. Additionally, having a larger RAM size and a better graphics card can help to ensure a faster performance.

Furthermore, having a good cooling system and the right operating system can also help to ensure optimal performance. Finally, a system with an SSD drive can provide a performance boost compared to a system with a standard hard drive.

5.Are There Any Advantages To Using Aluminum Sbc Heads Over Cast Iron In Terms Of Weight And Longevity?

Ans: Yes, there are advantages to using aluminum SBC heads over cast iron in terms of weight and longevity. Aluminum heads are significantly lighter than cast iron, which can improve handling and performance.

Aluminum also dissipates heat more efficiently, allowing the engine to run cooler and last longer. Additionally, aluminum heads are more resistant to corrosion, so they will remain functional for longer periods of time.

![How To Choose Patriot SBC Heads? [The Definitive Guide]](https://accuratepicker.com/wp-content/uploads/2022/03/Patriot-SBC-heads.jpg)