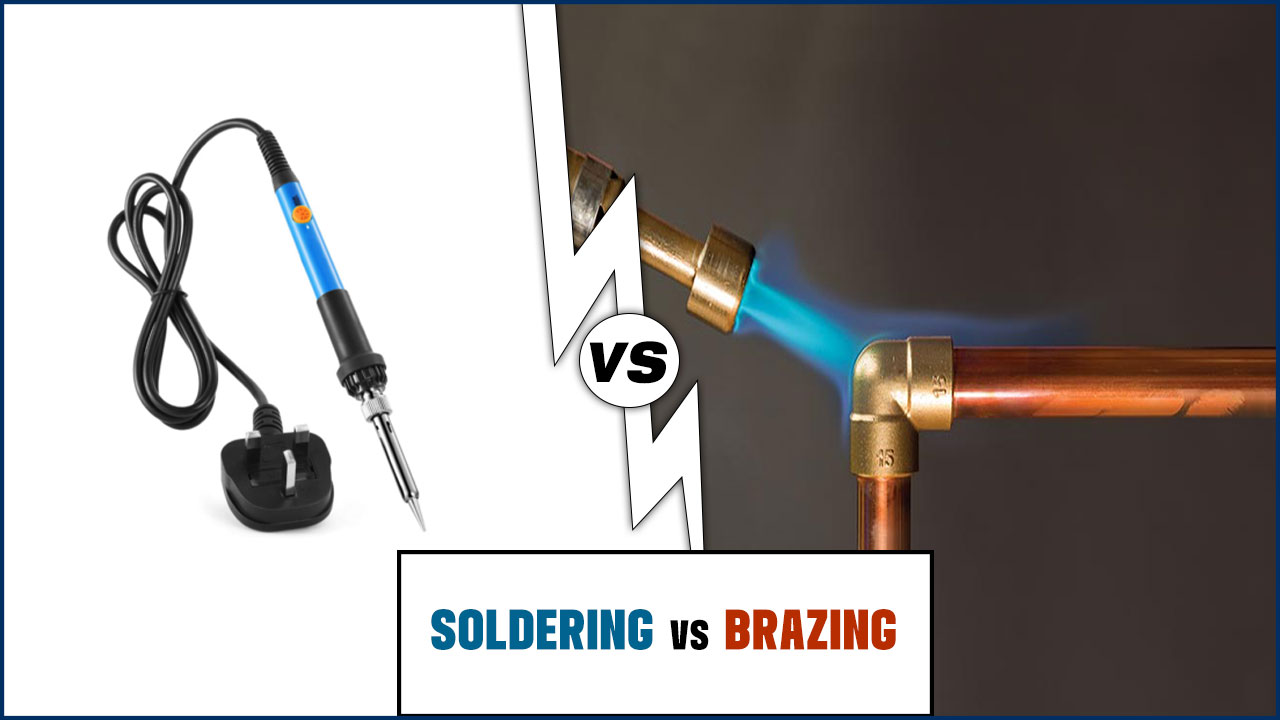

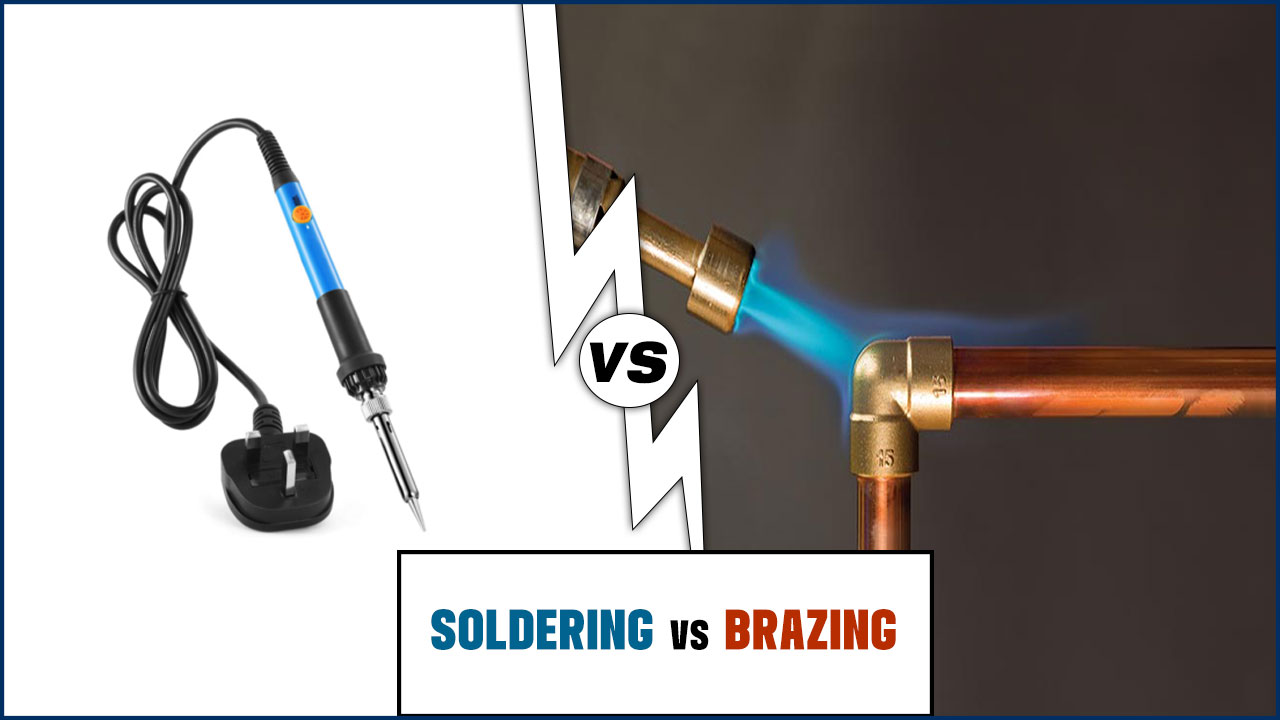

Soldering and Brazing are two common joining techniques used in metalworking. Both processes involve melting a filler material to form a bond between two or more workpieces.

While similar in many ways, soldering and brazing differ in terms of the temperature required to melt the filler material, the strength of the joint, and the types of materials that can be joined. In this article, we’ll explore the differences between soldering and brazing and discuss which method is best for different applications.

With this knowledge, you’ll be able to make an informed decision when it comes to joining metal. So, if you’re looking to learn more about soldering and brazing, read on to find out how these two processes compare.

Soldering Vs. Brazing: A Comparison

Soldering and brazing are two processes used to join metals together. Soldering involves melting a low-melting-point metal alloy, known as solder, between two metal surfaces to form a joint. Brazing, on the other hand, involves heating a filler metal, known as a braze, to a temperature above its melting point and then applying it to the two metals to form a joint.

Both processes are commonly used in various fields, such as electronics, engineering, and plumbing. Despite some similarities, there are a few key differences between soldering and brazing that should be considered when choosing which process to use. These include the types of metals used, the temperature required, and the strength of the joint.

Definition

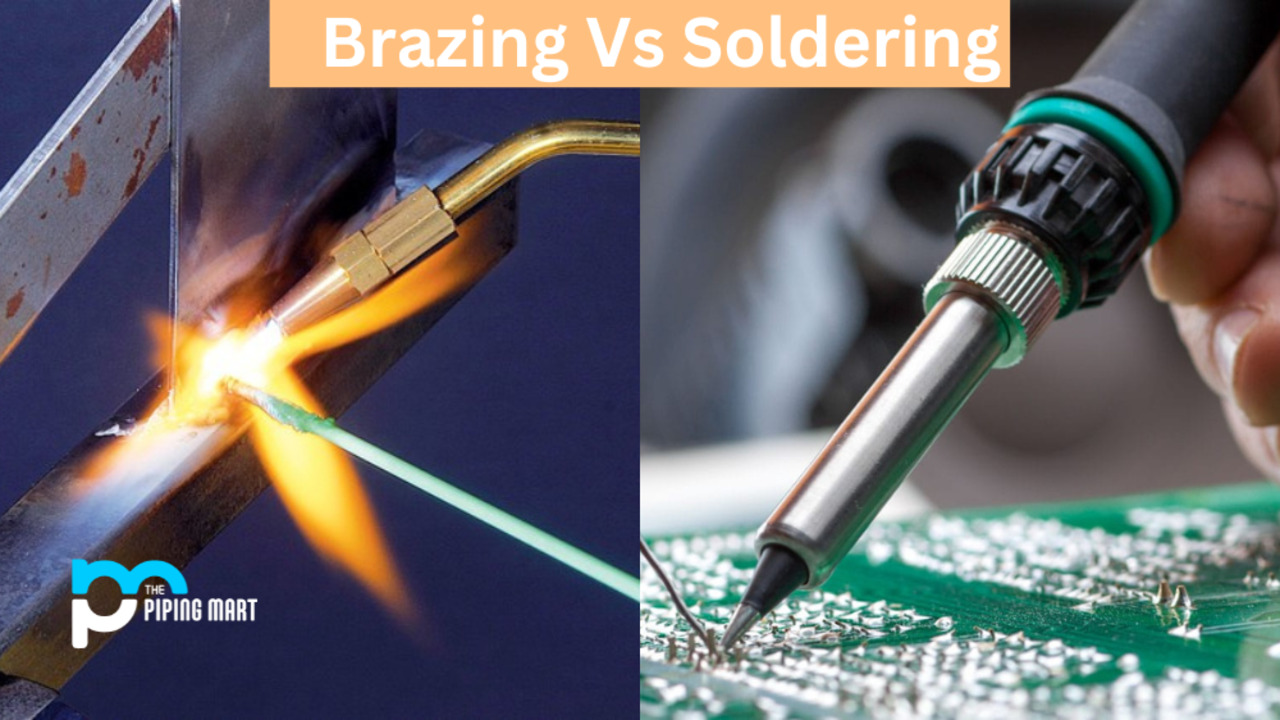

Soldering and brazing are two metal joining processes that are used to connect two metal components. Soldering is typically used for smaller components, as it involves the use of a low-temperature, lead-based alloy. This alloy is heated to a temperature of around 450 degrees Celsius and is then used to join two metals together.

Brazing, on the other hand, is a higher temperature process that utilizes a brass or bronze alloy to join two metals together. This alloy is heated to around 900 degrees Celsius before being applied to the two metals. Both processes are used to join metals, but their differences in temperature, alloy composition, and application make them suitable for different types of metal joining.

Soldering

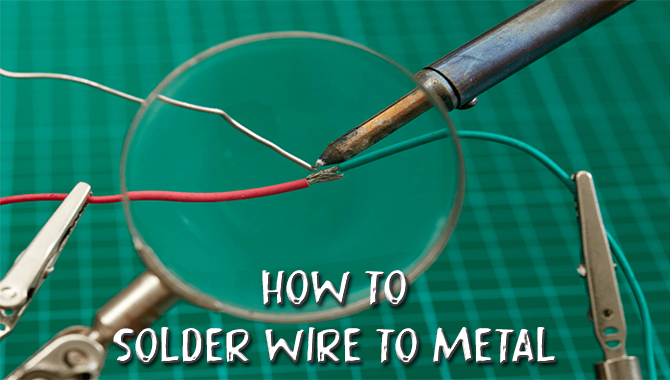

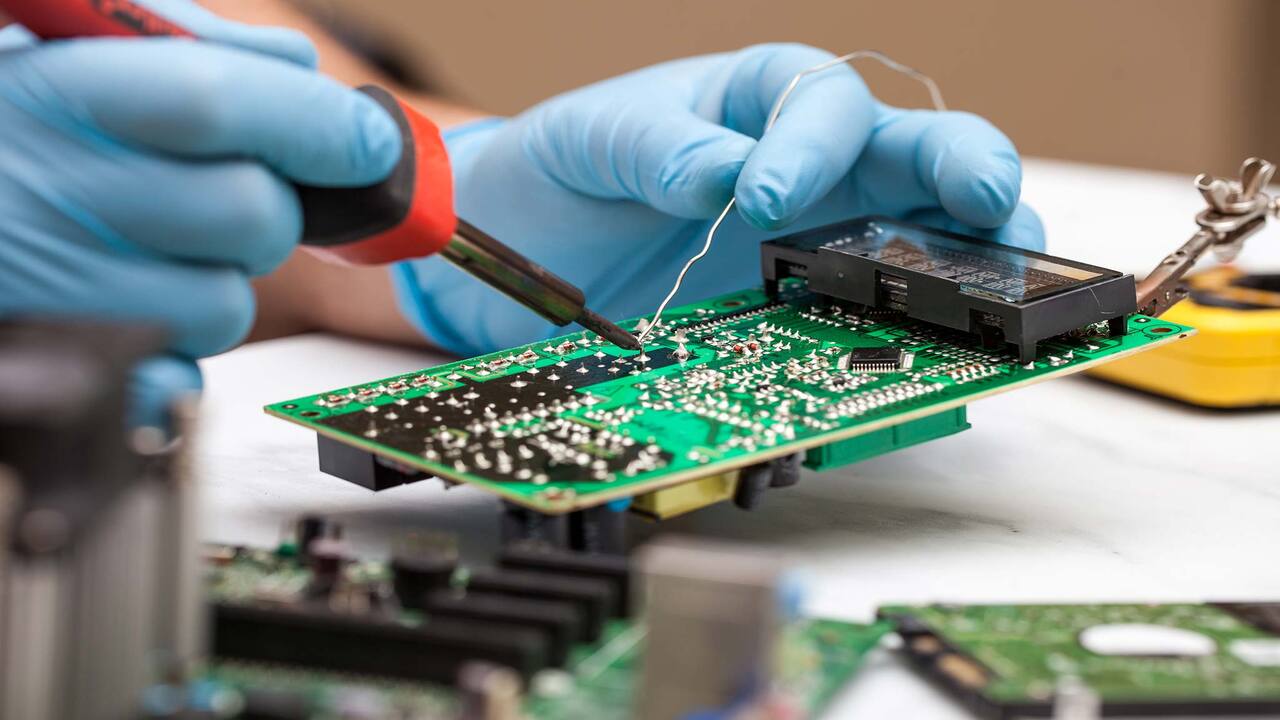

Soldering is a process that permanently joins two pieces of metal together. It is commonly used in electrical and plumbing applications, such as the joining of wires and pipes, but is also used to attach components in manufacturing.

The process involves melting a metal filler material, called a solder, between the two pieces of metal to form a bond. The solder also helps to insulate the connection and keep it from corroding.

The process requires heat, either from a soldering iron or a torch, and flux, a chemical that helps to remove impurities from the metal surfaces and ensure the solder flows properly. Soldering is a relatively simple process that does not require a great deal of skill, making it a popular choice for DIYers and hobbyists.

Brazing

Brazing is a type of joining process that is similar to soldering. It is a process that is used to join two or more metal components together by melting and flowing a filler metal into the joint, which is then cooled to create a strong bond.

Unlike soldering, which is typically used to join dissimilar metals, brazing is commonly used to join similar metals. It is also capable of creating joints that are stronger than the base metals themselves.

Brazing is usually done at temperatures higher than soldering, and requires the use of a flux to protect the metal from oxidation. The filler metal used in brazing has a lower melting point than the base metals, and is typically an alloy of copper, silver, and zinc.

Process

Soldering and brazing are two popular joining processes, each with their own unique benefits. Soldering is a process that joins two metals with a filler metal of lower melting point, while brazing uses a higher melting point filler metal.

The process of soldering requires the application of heat to melt the filler metal, which then forms an electrical and mechanical bond between the two metals. The temperature required for soldering is usually below 800 degrees Celsius.

On the other hand, the process of brazing requires the application of heat to melt the filler metal, which then forms a mechanical bond between the two metals. The temperature required for brazing is usually above 800 degrees Celsius.

Both processes have their advantages, however, soldering is typically used for electrical and electronic components, while brazing is typically used for joining two metal components that require a stronger bond.

Soldering

Soldering is a process of joining two or more metal components together using a solder alloy. It is a process that involves melting the solder alloy to create a strong bond between two or more components.

The solder alloy is applied to the metal components using a soldering iron or a soldering torch. The alloy is heated to a certain temperature and then allowed to cool, forming a strong bond between the two components.

Soldering is often used in the construction of electronic devices, and in the assembly of components in a circuit. It is also used to join metal pipes together and in the repair of jewelry and other small metal items. Soldering is an economical and relatively simple process, and it can be completed by a novice with the right tools and supplies.

Brazing

Brazing is a metal-joining process that involves heating two metals to a temperature above their melting point and then bonding them together with a filler metal. It is similar to soldering in that it uses a filler metal to join two components, but the temperatures required for brazing are much higher.

The filler metal used in brazing typically has a melting point above 450°C (842°F). This is significantly higher than the melting point of solder, which is generally between 180°C and 200°C (356°F to 392°F).

As a result, brazing is suitable for joining metals that cannot be joined using solder. It is also a good choice for joining metals with very different melting points, such as copper and steel. The increased temperature also results in a stronger joint than can be achieved with soldering.

Materials

Soldering and brazing are two different metal joining processes. Soldering is a process used to join two pieces of metal together by melting a filler material and allowing it to flow into the joint. The filler material must have a lower melting point than the metals being joined.

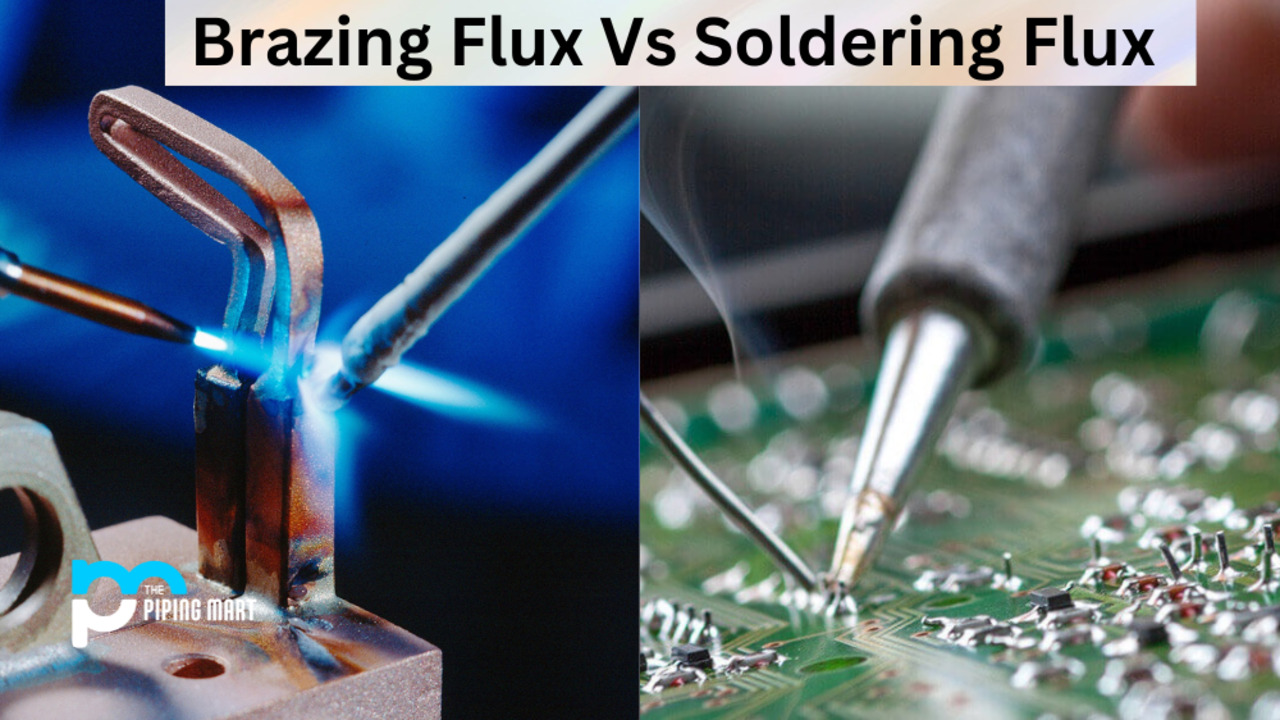

Brazing is a similar process to soldering but it uses a filler material with a higher melting point than the metals being joined. The filler material is melted and flows into the joint between the two metals. Both processes require the use of a flux, which is a cleaning agent that helps the two metals bond together.

The flux is also necessary to prevent oxidation of the metals during the process. In order to ensure a strong joint, both processes may also require additional materials such as clamps, soldering irons, and flux brushes.

Soldering

Soldering is a type of metal joining process that involves melting a filler metal, known as solder, into the joint between two or more metal surfaces. This is usually done with a soldering iron, which is a hand-held tool used to heat the metal and solder until they become liquid and can be fused together.

The goal of soldering is to create a strong and lasting bond between two metals that can stand up to wear and tear. Soldering offers a variety of advantages, including the ability to join metals of varying thicknesses, easy cleanup, and the ability to join metals without the need for pre-heating. Additionally, it is a relatively safe and simple process that can be done with minimal equipment and training.

Brazing

Brazing is a metal-joining process that involves heating two or more metal components to a temperature at which a filler metal, held between the components, is melted. The filler metal flows into the gap between the components and binds them together.

Brazing is a more complicated process than soldering, as the temperatures required are much higher, generally between 600 and 1200 degrees Fahrenheit (316 and 648 degrees Celsius). The filler metal used in brazing must have a higher melting point than the metals being joined, and it often contains an alloy of copper and zinc, or tin and copper.

Applications

Soldering and brazing are two metal-joining techniques used for a variety of applications. Both processes involve melting a filler material that is then used to join two pieces of metal together. The main difference between soldering and brazing is the temperature at which the process takes place.

Soldering is done at lower temperatures than brazing, and the filler materials used are different. Soldering is commonly used to join electrical components, while brazing is used to join pipes and other mechanical components.

Soldering is often used to attach components to printed circuit boards, while brazing is used to join two pieces of metal where the joint must be able to withstand higher temperatures. Brazing is also used to attach handles to cookware and to join copper plumbing pipes.

Soldering

Soldering is a process where two metal surfaces are joined together with the help of a filler metal. The filler metal melts at a lower temperature than the metals being joined and acts as a bridge between them. It is a permanent joint that is strong and can withstand temperature and vibration.

Soldering is used in a variety of applications including electrical components, plumbing, and jewelry making. It is also used to join metal objects together such as roofing and sheet metal. Some of the advantages of soldering include its low cost, ease of use, and its resistance to corrosion.

It also has a low heat input that helps to prevent damage to the components being joined. In the right hands, soldering is a reliable and effective way to permanently join two pieces of metal.

Brazing

Brazing is a type of metal joining process in which two or more metal components are joined together using a molten filler metal. It is similar to soldering, but requires a higher temperature and filler metal with a higher melting point. The filler metal is distributed between the closely fitted surfaces of the joint by capillary action.

Brazing is used to join dissimilar metals, and can be used for structural or non-structural applications. The process is also commonly used for joining copper pipes, as it provides a strong, leak-proof joint. Brazing is often seen as a more reliable joining process than soldering, as it provides a stronger bond than soldering, and is more resistant to shock and vibration.

Conclusion

Soldering and brazing are two popular methods of joining metal components. Soldering is a method of joining two metals by melting a filler metal with a low melting point, while brazing is a method of joining two metals by melting a filler metal with a higher melting point.

Soldering is typically used to join smaller parts, while brazing is used to join larger parts. Both methods are used to create a strong, permanent bond between two metals.

FAQ’s

1.What Are The Differences Between Soldering And Brazing?

Ans: Soldering is a process of joining two metals together using a low melting temperature filler material, while brazing is a process of joining two metals together using a higher melting temperature filler material.

Soldering is typically used when working with low temperature metals such as copper, brass and aluminum, while brazing is used when working with higher temperature metals such as steel and stainless steel.

Soldering is often used to join electrical components and create a watertight seal, while brazing is used to join mechanical components and strengthen a joint. Lastly, soldering usually requires flux to help the joining process, while brazing does not.

2.What Types Of Metals Can Be Soldered Or Brazed?

Ans: Common metals that can be soldered or brazed include copper, brass, and aluminum. Other metals such as steel, lead, silver, and gold can also be soldered or brazed using specific techniques. Soldering and brazing can be used to bond metals together or to attach different components to a metal. Special fluxes and solders are sometimes used to make a stronger bond with the metals being joined.

3.What Is The Melting Point Of Solder Compared To Brazing?

Ans: The melting point of solder is generally much lower than the melting point of brazing. Solder typically melts between 180°C and 190°C, while brazing can reach temperatures as high as 1100°C.

The lower melting point of solder makes it easier to use and less likely to damage the items being joined. However, the lower melting point also means that solder has a lower strength than brazing and is not suitable for all applications.

4.What Type Of Flux Is Used For Soldering Or Brazing?

Ans: The type of flux used for soldering or brazing typically depends on the type of metal being soldered or brazed. Generally, a rosin flux is used for soldering copper or brass, and an acid-based flux is used for soldering steel. Silver braze flux is used for brazing iron and steel, and copper brazing flux is used for brazing copper. Finally, an acid-based flux is used for brazing aluminum.

5.What Types Of Joints Can Be Made Using Soldering Or Brazing?

Ans: Soldering or brazing can be used to create a variety of joints, including lap joints, butt joints, and corner joints. These methods can also be used to create a fillet joint, which is a type of lap joint with a curved surface.

Additionally, soldering and brazing can be used to make T-joints, which are formed when two pieces of metal intersect at a 90-degree angle. Finally, these methods can be used to create miter joints, which are formed when two pieces of metal intersect at an angle.