Soldering is a reliable and common method of joining two metals together. It’s a process that has been around since the Bronze Age, and it’s used in a variety of applications today.

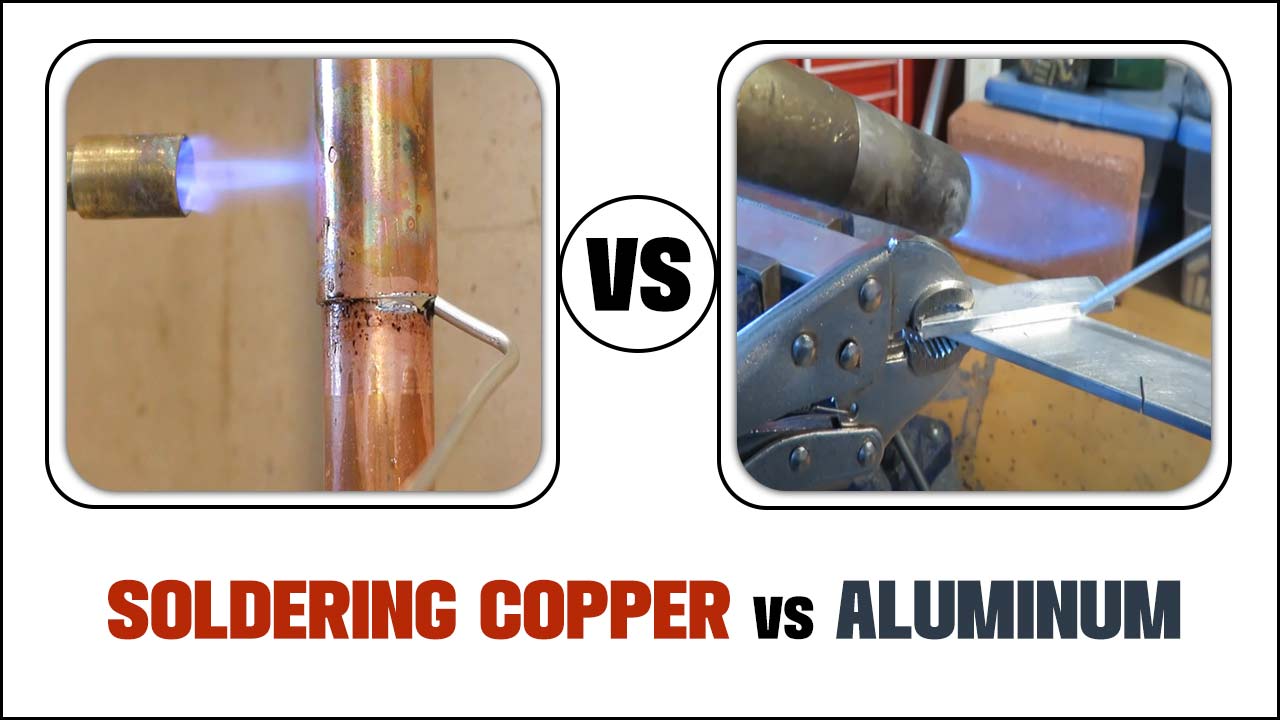

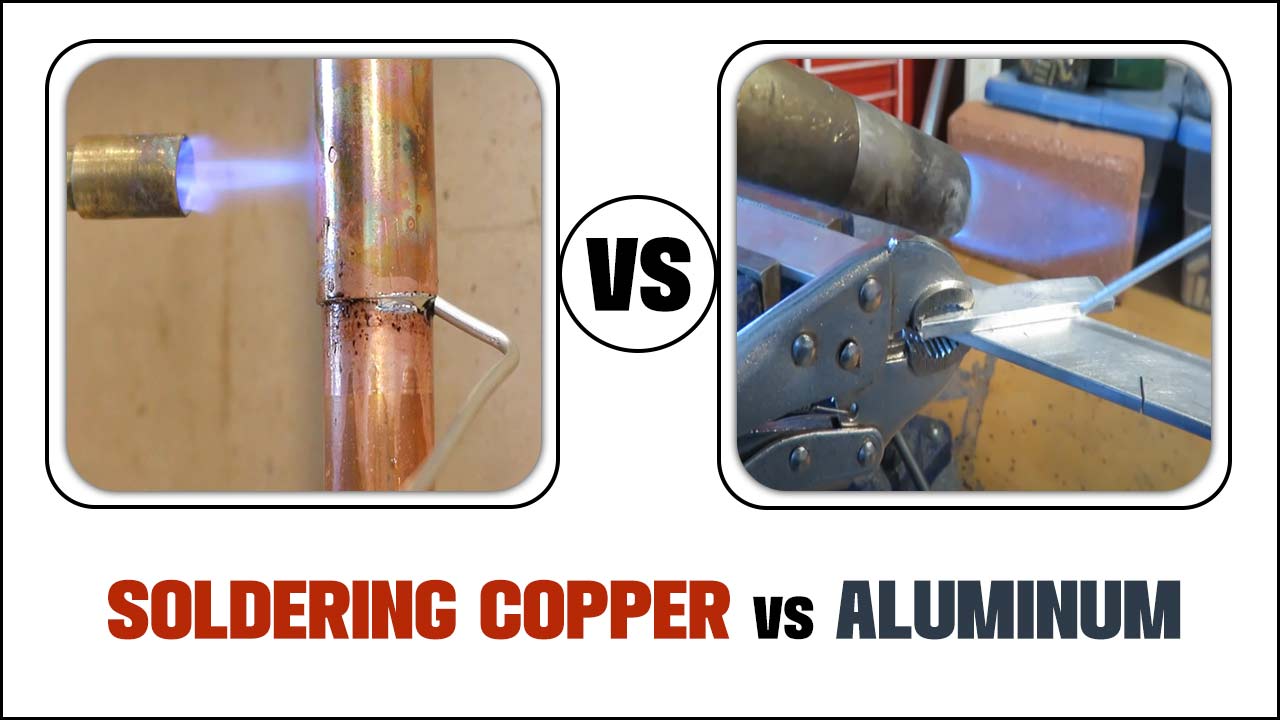

Soldering copper and aluminum are two of the most common metals used in soldering. Both metals have their unique properties that make them suitable for different applications. This article will explore the differences between soldering copper and aluminum, including the tools and techniques needed for each.

Additionally, this article will look at the best practices for soldering each metal and the potential risks associated with each. With this information, you’ll be able to make an informed decision about which metal is best for your soldering project. So, if you’re ready to learn more about soldering copper and aluminum, then read on to find out the differences between the two!

Soldering Copper Vs Aluminum: A Comparison

Soldering copper and soldering aluminum are two common methods used to join metal parts together. However, they require different techniques and materials, and the finished product will vary depending on the metal being soldered. In this article, we will compare the advantages and disadvantages of soldering copper and aluminum, as well as the best practices for each process.

We will also discuss the safety considerations for each method, and provide tips on how to get the best results. By the end of this article, you should have a better understanding of the differences between soldering copper and aluminum, and be able to confidently choose the right process for your project.

Advantages Of Soldering Copper

Soldering copper has numerous advantages over soldering aluminum. Copper is much easier to work with than aluminum due to its low melting point and malleability. Copper is also more resistant to corrosion than aluminum, meaning it can last longer with less maintenance.

When it comes to electrical conductivity, copper is also superior to aluminum. Copper has the highest electrical conductivity of all metals, making it ideal for electrical applications. Finally, copper is much less expensive than aluminum, meaning it is a more cost-effective option for many projects. Soldering copper is therefore a great choice for many projects where electrical conductivity, longevity, and cost are key considerations.

Low Melting Point

Soldering copper and soldering aluminum both require low melting points. Copper has a melting point of 1,984°F (1,085°C) while aluminum has a melting point of 1,221°F (660°C), making aluminum a better choice when it comes to soldering. When soldering aluminum, the lower melting point allows for a faster process and less heat is needed to achieve a good connection.

This is beneficial when working with delicate components that could otherwise be damaged by too much heat. Additionally, aluminum is a better choice for soldering in tight or hard-to-reach areas due to its lower melting point. This makes it easier to achieve a good bond in areas where copper may be difficult to access.

Versatility

When it comes to soldering, copper and aluminum are two of the most common materials used. However, aside from the different properties of the two metals, there are other factors that come into play when choosing between copper and aluminum soldering.

One of the most important of these is versatility. Copper soldering is highly versatile and can be used for a wide variety of applications, including electrical work and plumbing.

It is also relatively easy to use, making it an ideal choice for DIYers and hobbyists. Aluminum soldering, on the other hand, is more specialized and is best suited for precision engineering work. It requires greater skill and attention to detail, but can produce higher-quality results.

Both materials also require the use of special soldering tools and techniques to ensure a successful outcome. Ultimately, the choice between copper and aluminum soldering depends on the application and the skill level of the user.

Low Cost

When it comes to soldering, cost is an important factor. Soldering copper and aluminum are both relatively inexpensive, but aluminum tends to be the more cost-effective option for many applications.

Aluminum is a much lighter metal than copper, so it is easier to work with and can be soldered at a lower temperature, which can help to keep costs down. Additionally, aluminum is typically less expensive than copper, so it can be a great way to keep costs low while still achieving a quality result.

Easy To Use

Soldering copper and soldering aluminum are two very different processes. Copper is a soft metal and is much easier to solder than aluminum, which is much harder to work with. Copper also has a lower melting point than aluminum, which makes it easier to heat and solder. Copper is much less likely to suffer from thermal shock due to its low melting point.

Copper is also less likely to chip or crack when heated due to its malleability. Aluminum on the other hand, has a much higher melting point. This makes it much more difficult to heat and solder.

Aluminum is much more likely to chip or crack when heated due to its hardness. In terms of ease of use, copper is definitely the better choice for soldering. Copper is much easier to heat and solder, and it is much less likely to suffer from thermal shock or damage due to its low melting point. Aluminum is much harder to work with and is much more prone to cracking and chipping when heated.

Advantages Of Soldering Aluminum

Soldering aluminum has distinct advantages over soldering copper. Aluminum is a much lighter material, making it easier to maneuver and work with. It is also less prone to melting or warping during the soldering process.

Additionally, aluminum is a much cheaper material to purchase, making it a great option for those on a budget. Another advantage of soldering aluminum is that it does not require a flux, which can be difficult to work with when soldering copper. Finally, aluminum is much easier to shape and mold, making it an ideal choice for intricate designs.

High Strength

Soldering copper and aluminum both have their advantages, but when it comes to strength, copper is the clear winner. Copper is a much harder metal, making it ideal for soldering projects that require a strong bond. Aluminum, on the other hand, is a softer metal which is better suited for projects that require flexibility.

Copper soldering is also more resistant to corrosion and temperature extremes than aluminum soldering. Additionally, copper’s malleability allows it to be easily manipulated into the desired shape. For projects that require a strong and durable bond, copper is the best choice.

Corrosion Resistance

When soldering copper and aluminum, corrosion resistance is an important factor to consider. Copper is more resistant to corrosion than aluminum, making it the preferred choice for soldering jobs that require a strong and long-lasting bond. Copper is also more resistant to water and chemicals, making it suitable for applications where these elements are present.

Aluminum, on the other hand, is more prone to corrosion. It is not wrong to solder aluminum, but it should not be used in applications where there is a need for a strong and long-lasting bond. Additionally, aluminum is not suitable for applications where water and chemicals are present. To ensure corrosion resistance, it is important to use flux when soldering either metal. Flux helps to prevent oxidation and create a stronger bond between metals.

Low Cost

When it comes to soldering, two of the most popular metals to work with are copper and aluminum. Both metals have their advantages and disadvantages, but when it comes to cost, copper is often the winner. Copper is generally cheaper than aluminum, and is easier to find and purchase.

Additionally, copper is often easier to work with than aluminum, making it a better choice for those on a budget. Copper is also better at conducting heat than aluminum, which makes it a better choice for soldering applications. In terms of cost, copper is a great option for those just getting started in soldering.

Easy To Use

Soldering copper and soldering aluminum both have their advantages and disadvantages when it comes to ease of use. Copper is a more malleable material than aluminum, which means it is easier to shape and mold, allowing for a more precise connection. On the other hand, aluminum is a much softer material than copper, making it easier to cut and shape.

Copper is also easier to solder than aluminum, as it requires less heat and has a lower melting point. However, aluminum is more resistant to corrosion than copper, so it requires less maintenance and upkeep. Ultimately, it is up to the user to decide which material is easier to use based on the project at hand.

FAQ’s

1.What Type Of Solder Is Best For Soldering Copper?

Ans: The best type of solder for soldering copper is lead-free, silver-bearing solder. Silver-bearing solder has a higher melting point than lead-based solder, and it also has a stronger bond. It also has a higher resistance to corrosion, which is important when soldering copper. Lead-free solder also has a much lower environmental impact than lead-based solder.

2.What Type Of Torch Or Soldering Iron Should Be Used For Soldering Aluminum?

Ans: For soldering aluminum, a torch with a high temperature flame, such as an oxy-acetylene torch, is the most suitable option. An electric soldering iron can also be used, but it needs to have a higher wattage and temperature than usual, such as one between 900 and 1100 degrees Fahrenheit. Additionally, soldering flux should be used to ensure a strong bond. Finally, lead-free solder should be used to avoid contamination.

3.What Precautions Should Be Taken When Soldering Copper?

Ans: When soldering copper, safety precautions should be taken to protect against possible injury or fire. Wear safety goggles and a face shield to protect against sparks, and use a ventilation system to remove any fumes. Ensure that the work area is free of combustible materials and that all surrounding surfaces are heat-resistant. Additionally, always use a quality soldering iron and flux that are suited for the job at hand.

4.Are There Any Special Procedures For Soldering Aluminum?

Ans: Yes, there are special procedures for soldering aluminum. The aluminum must be cleaned with an acid flux, and then the joint must be heated with a torch. The solder should be added to the joint and the joint should be heated until the solder melts and the joint is properly formed. Finally, the joint should be left to cool and then cleaned with a wire brush.

5.What Fluxes Are Best Suited For Soldering Copper And Aluminum?

Ans: The flux suitable for soldering copper and aluminum is an acid flux. An acid flux is effective in removing oxide layers from metal surfaces, allowing for a strong and durable bond. Rosin core solder is the most common flux used for soldering copper and aluminum. It is an acid-based flux that is activated by the heat of soldering and helps to ensure a strong bond between the copper and aluminum parts.