Ever wonder how much a truck can provide on being the air compressor truck owners seek? We often find truck drivers interrelating their frustrating truck driving life while lying flat on a flat tire.

But is there any efficient solution out there to put an end to such troublesome situations? Trucks themselves could provide the air compressing work a heads up as long as you carry a tank and your truck motors are working perfectly.

Simply connect the truck motor part with the tank through a pipe. The tank will pump up that tank, resulting in giving a complete air compressor job. Quite a handy and reliable process anyone can follow turning their half-broken truck into a useful semi truck air compressor.

Once you set the process up properly, it could be used as a portable air compressor. Therefore, Keep reading to find out the proper usage of Semi Truck into Air compressor!

Aspects To Consider Before Starting

In many cases, people overlook this essential and important part over here to directly on the guide. Therefore, we have to patient to view more glances at what we do before we begin.

Why?

Because before you learn the technique, you need to fully understand and buy the equipment as per your necessity. This is a “must-do” pointer that we should not ignore.

The Equipment’s:

The first and foremost thing, equipment. What essential elements will you need to possess to deliver a healthy air compressing operation to your flat wires?

The answer is as your necessity. If you have gloves already, then don’t bother buying a new one for this. However, here’s a rundown of the products you may need to fix such a situation for the first time –

- Gloves/Safety gloves

- A tank to store motor power

- An air compressor

- Motor quality of Truck

- Plastic tubes

Why These?

Because these are the most basic on-hand supplies that you will require to use and process the Semi Truck forf doing an air compressing job.

Size & Pressure Limit

This is another concern you need to keep in the head while buying tanks and pipes. The size of the tubes, tank does matter. Going for an extra expensive or costly pipe that does more than you need is simply a waste.

If you need a minimum amount of power level or pressure level, then buy a tank short in size. Big tanks can gather more energy, but that is unnecessary if you are doing this air compressor thing for home use.

Going for a big size is always good, but inside your home use type situation, the suggestion is to go for short sized ones.

In simple words, let’s just save spend our pennies wisely.

Semi Truck Air Compressor

Now that we have followed all the precautions and procedures, we are finally ready to take on the action first hand. So read this guide step by step as we give in-detailed information regarding this.

Step 1 –

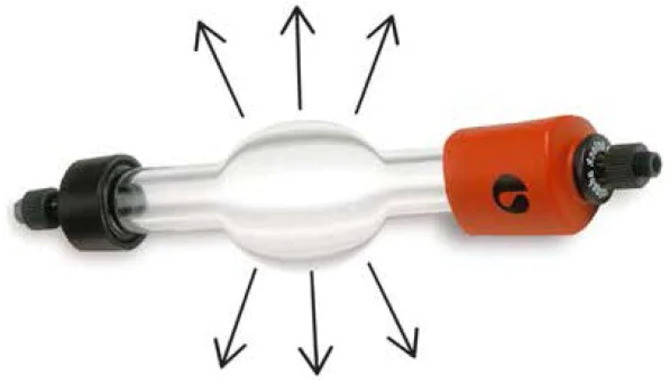

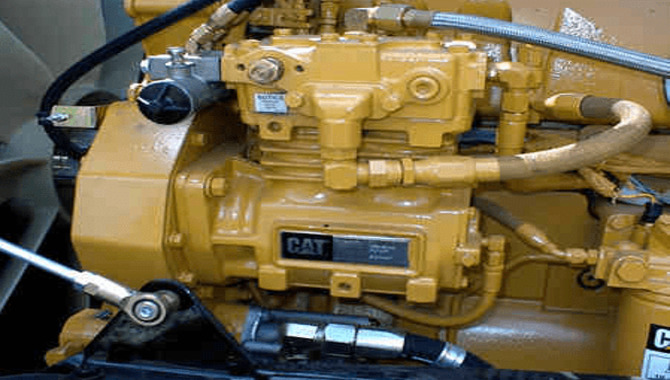

The first thing that one has to do to connect the truck is sportifying the motor’s holes that stay attached with the truck. A truck may have 4-6 holes on its motor part, and you can connect a tube or pipe there.

Step 2 –

Bring in the plastic tubes. Take one at hand and connect it with motor holes.

Step 3 –

After connecting one side with motor holes, connect the other part with the tank. That’s how the tank and truck motor gets connected.

Step 4 –

Start your truck to blow out some power through the motor part. Observe the tank if it is charging properly. The tank will automatically start charging to a minimum point before you can use it on any case.

Step 5 –

Wait until the tank charges up to a specific point. After that, connect the air compressor with the tank, and you’ll see that the air compressor is fully operational.

Step 6 –

Finally, use your truck air compressor and take out the tires with ease.

With these simple 6 steps, you can use semi-trucks to make a heaven out of it.

Challenges That You May Face

Often many people find this process challenging for some specific points. These are not ordinary cases, and these cases are not to be taken lightly.

So if any of these happen during your execution process, try to seek help from an expert.

1st Case

The motor is not working. If the motor cannot pump up the tank because of its unfunctionabilty, don’t force it. Simply seek help by phone or technicians around.

2nd case

The tank is not charged enough, but you started using it. This way, your air compressor will keep stopping on a path, making it feel like a disaster. So let your tank charge up for a bit.

3rd case

Confused about the plastic tubes. You don’t have to be confused. Just go for any cheap plastic tube too, if that gives the service you need.

These are the cases people often find challenging while doing this whole process as a beginner. So don’t despair when you face these situations. Rather just try to do as the solution is written, and you are good to go.

Conclusion

We often just keep the jammed truck lying around the garage. Sometimes we don’t need it anymore for a while or just lazy to fix it properly. But even after these, we go to the market to purchase the air compressors that costs a lot with other features.

However, buying an air compressor only and using your truck to power it up is a safe and neat method used by almost every rookie truck owner out there.

Be it any of such cases; a semi-truck air compressor stands as a great way to deal with such trucks on getting the proper output from them. So follow this guide next time you need an air compressor, and have a great day! I hope now you know about the semi truck air compressor.