It’s essential to know how to check the oil in an air compressor maintenance task that should be done regularly to ensure optimal performance. Make sure the compressor is turned off and unplugged before proceeding.

After that, locate the oil dipstick, which is usually located on the side of the compressor, and remove it by twisting it counterclockwise. Then, wipe the dipstick clean with a cloth and reinsert it back into the dipstick hole, making sure to push it all the way down. Finally, remove the dipstick again and check the oil level.

The oil on the dipstick should be between the minimum and maximum marks. If the oil level is low, add the appropriate type of oil to the compressor until it reaches the recommended level.

Introduction To Air Compressors

An air compressor is a mechanical device that converts power (usually from an electric motor, diesel engine, or gasoline engine) into potential energy stored in compressed air.

It uses this compressed air to perform various tasks such as powering pneumatic tools, inflating tires, operating machinery, and supplying clean air for breathing or industrial processes. Various industries and applications widely use air compressors due to their versatility and efficiency in generating compressed air.

Understanding The Importance Of Checking The Oil In An Air Compressor

Understanding the importance of checking the oil in an air compressor is crucial for ensuring the longevity and efficient functioning of the equipment. Neglecting this simple task can lead to expensive repairs or even replacement of the entire compressor.

The oil in an air compressor serves as a lubricant for the moving parts and also helps to dissipate heat from the compressor. Without proper oil levels, the compressor can overheat and cause damage to its internal components. Check the oil levels in an air compressor at least once a month or more frequently if the compressor is used frequently or in harsh conditions, I recommend.

You can complete checking the oil in an air compressor in just a few minutes. It is a straightforward task. First, turn off the compressor and let it cool down. Then locate the oil level indicator and remove the dipstick. Wipe it clean and reinsert it fully into the oil tank. Finally, remove the dipstick and check the oil level against the markings on the dipstick.

Safety Precautions While Checking The Oil

Safety should always be a top priority when it comes to checking the oil in your car. There are a few precautions you can take to ensure that you stay safe while performing this routine maintenance task. First, ensure the car is parked on a level surface, and the engine is turned off. This will prevent the car from rolling or shifting while you are working under the hood.

Next, allow the engine to cool down for a few minutes before checking the oil. This will prevent you from accidentally burning yourself on hot engine parts. When it’s safe to do so, open the hood of the car and locate the dipstick. Pull the dipstick out and wipe it clean with a cloth or paper towel.

Reinsert the dipstick and pull it out to check the oil level. If the oil level is low, add more oil as needed. As you work, be sure to keep your hands and clothing away from moving parts, such as the fan or belts.

Tools And Materials Required For Checking The Oil

Engine oil dipstick: This is a long, slender metal rod with markings on one end that indicate the oil level. You can usually get it with the engine or buy it separately.

Clean cloth or paper towel: You will need this to wipe the dipstick clean before and after checking the oil.

Adequate lighting: Sufficient lighting is necessary to read the oil level on the dipstick accurately. Make sure you have a well-lit area to perform the check.

Safety gloves (optional): While not strictly necessary, gloves can protect your hands from dirt or hot engine parts.

Engine oil: If the oil level is low, you may need to add oil to bring it up to the recommended level. Refer to the vehicle’s owner’s manual to determine the appropriate type and amount of oil.

Before checking the oil, ensure that the engine is turned off and has cooled down for a few minutes to allow the oil to settle. Then follow the specific instructions provided in the vehicle’s owner’s manual on locating and using the dipstick.

A Step-By-Step Guide On How To Check The Oil In An Air Compressor

- Safety first: Before beginning any maintenance task, ensure that the air compressor is turned off and unplugged from the power source. This will prevent any accidental startup or electrical hazards.

- Locate the oil fill cap: The oil fill cap is typically located on the top or side of the compressor pump. It is usually marked with an oil symbol or labeled “Oil Fill.”

- Clean the area around the oil fill cap: Use a clean cloth or rag to wipe away any dirt or debris around the oil fill cap. This will prevent contaminants from entering the oil reservoir when the cap is removed.

- Remove the oil fill cap: Unscrew the oil fill cap in a counterclockwise direction. It may require some force, so use a firm grip to avoid any spills or accidents.

- Check the oil level: Once the cap is removed, look inside the oil fill hole to check the oil level. The oil should be at the proper level, typically indicated by a dipstick or a sight glass. If the oil is below the recommended level, it needs to be topped up.

- Top up the oil (if necessary): If the oil level is low, add the appropriate type of oil recommended by the air compressor manufacturer. Pour the oil slowly and carefully to avoid overfilling. Refer to the compressor’s manual or specifications for the correct oil type and quantity.

- Reinstall the oil fill cap: After checking or topping up the oil, securely screw the oil fill cap back into place in a clockwise direction. Ensure that it is tightened properly to prevent any oil leaks.

- Clean up any spills: If any oil was spilled during the process, wipe it up using a clean cloth or rag. It is important to keep the work area clean and free from oil to avoid slips or accidents.

- Perform a visual inspection: Before turning the compressor back on, visually inspect the oil fill area and the surrounding components for any signs of damage or leaks. Address any issues before operating the compressor.

- Turn on the air compressor: Once everything is in order, plug in the compressor and turn it on. Allow the compressor to run for a few minutes to circulate the oil and ensure proper lubrication.

How Much Oil Does My Air Compressor Need?

One of the most common questions people have is how much oil their compressor needs. The answer to this question will depend on the specific model of your air compressor, as each one has different oil requirements. Some compressors may require a few ounces of oil, while others require several quarts.

To determine how much oil your air compressor needs, you should consult the owner’s manual or contact the manufacturer for guidance. Keeping your compressor properly lubricated with the right amount of oil is important to ensure optimal performance and longevity.

Neglecting to add enough oil or using the wrong type of oil can lead to damage or even complete failure of your compressor. Regularly checking and changing the oil in your air compressor is essential for keeping it in good working condition. So, if you’re unsure of how much oil your compressor needs, make sure to do your research and follow the manufacturer’s recommendations to keep your compressor running smoothly for years to come.

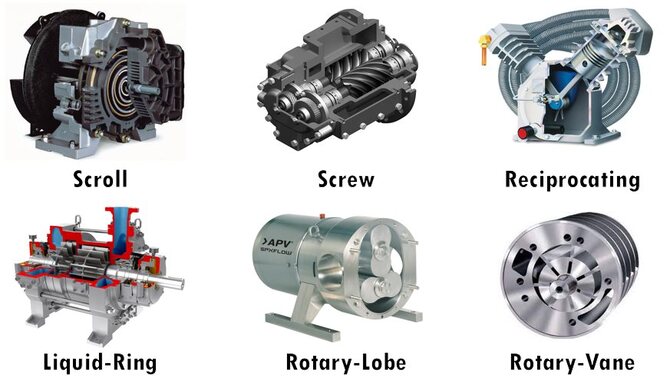

Types Of Air Compressors And Their Oil Requirements

Reciprocating Air Compressors:

- Reciprocating air compressors are also known as piston compressors.

- They typically require oil for lubrication and cooling purposes.

- The oil used in reciprocating compressors is usually a non-detergent, mineral-based oil with high lubricity and thermal stability.

- It is important to check the oil level regularly and change the oil as recommended by the manufacturer.

Rotary Screw Air Compressors:

- Rotary screw air compressors use two interlocking helical rotors to compress air.

- These compressors may require oil for lubrication and sealing purposes.

- The oil used in rotary screw compressors is typically a specially formulated synthetic oil or a high-quality mineral oil.

- Some rotary screw compressors have oil-free designs, eliminating the need for oil.

Rotary Vane Air Compressors:

- Rotary vane air compressors utilize a rotor with vanes that slide in and out of slots to compress air.

- These compressors often require oil for lubrication and sealing.

- The oil used in rotary vane compressors is usually a high-quality mineral oil with good lubricating properties.

- Some rotary vane compressors have oil-free designs, eliminating the need for oil.

Centrifugal Air Compressors:

- Centrifugal air compressors use centrifugal force to accelerate and compress air.

- These compressors typically do not require oil for compression.

- However, they may have oil-lubricated bearings or gears that need oil for lubrication.

- The oil used in centrifugal compressors is usually a high-quality synthetic oil with excellent lubricating properties.

Tips For Maintaining And Changing The Oil In An Air Compressor

Maintaining and changing the oil in an air compressor is crucial for keeping it running smoothly and efficiently. One of the most important tips is to check the oil level regularly and replace it as needed. The frequency of oil changes will depend on the type and usage of the compressor.

It’s important to use the right type of oil recommended by the manufacturer, as using the wrong oil can cause damage to the compressor. Another tip is to change the oil when the compressor is warm, as warm oil flows more easily and removes more contaminants. Before changing the oil, it’s important to drain the old oil completely and clean any debris from the crankcase.

It’s also a good idea to replace the oil filter during the oil change. As it can become clogged with debris over time. When adding new oil, it’s important not to overfill the crankcase, as this can cause damage to the compressor. Finally, it’s important to dispose of the old oil properly and in an environmentally friendly way.

Common Problems That Can Arise If Oil Is Not Checked Regularly

Regularly checking the oil in your vehicle is crucial. Failing to do so can lead to a variety of common problems that can cause significant damage to your engine and result in expensive repairs. Not checking oil regularly can cause one of the most common issues, which is an engine seizure.

This occurs when the oil level is too low, causing the engine components to rub together and create friction, which generates heat and damages the engine. Additionally, not checking the oil can cause the engine to overheat, leading to warped or cracked cylinder heads and blown head gaskets.

Dirty or old oil can also cause problems, such as clogged oil filters, which reduce engine performance. Furthermore, lack of proper lubrication due to low or dirty oil can cause premature wear and tear on engine components such as the bearings, crankshaft, and camshaft. All these issues can result in costly engine repairs and even engine failure.

Troubleshooting Common Issues With Oil In An Air Compressor

Oil is a crucial component in an air compressor. As it lubricates the moving parts and helps to prevent wear and tear. However, some common issues can arise with the use of oil in an air compressor. One of the most common problems is oil leaks, which can occur due to worn seals or damaged gaskets.

To troubleshoot this issue, it is important to identify the source of the leak and replace the faulty component. Another common problem is oil contamination, which can occur when the oil becomes contaminated with dust, debris or moisture. This can result in decreased performance and even damage to the compressor.

To avoid this issue, changing the oil and using a high-quality oil filter regularly is important. If the oil is not properly circulated through the system, overheating can be a problem. A Malfunctioning oil pump or clogged oil passages can cause this.

Conclusion

Understanding how to check the oil in an air compressor for automotive repairs can be a valuable skill for any mechanic or DIY enthusiast to possess. It is important to follow safety protocols at all times. Including wearing appropriate personal protective equipment and ensuring that the compressor is operated in a well-ventilated area.

Also, properly maintaining the compressor and its accessories is crucial to ensure it operates at peak efficiency and prevents costly repairs. With the knowledge and skill set gained through proper usage of an air compressor. Many automotive repair jobs you can complete with greater ease and precision. Leading to increased productivity and greater success in the field.

FAQs

1.How often should I check the oil in my air compressor?

Ans: It is recommended to check the oil level in your air compressor before each use or at least once a month, depending on the frequency of usage.

2.What type of oil should I use in my air compressor?

Ans: The oil type can vary depending on the specific air compressor model. Refer to the manufacturer’s guidelines or the owner’s manual for the recommended oil type.

3.Can I check the oil level while the compressor is running?

Ans: No, it is recommended to check the oil level when the compressor is turned off and cooled down to get an accurate reading.

4.What should the oil level on the dipstick indicate?

Ans: The oil level on the dipstick should ideally fall within the recommended range indicated by the markings. It should neither be too low nor overfilled.

5.What are some signs that my air compressor may need an oil change?

Ans: Signs that your air compressor may need an oil change include excessive noise, reduced performance, and oil contamination. If the oil appears dirty or discolored during the oil check.