Airbrushing is a popular technique in many applications, including automotive painting, makeup artistry, and artistic design. The air compressor is an essential tool to achieve a flawless airbrushing finish.

It is a necessary piece of equipment that helps deliver consistent and smooth airflow to the airbrush, allowing for greater control and precision. However, for those new to the world of airbrushing, it can be challenging to understand how to use an air compressor effectively.

That is why in this blog post. We will share some tips and tricks for airbrushing using an air compressor. From choosing the suitable size compressor to setting the correct air pressure, we will cover all the basics of air compressor usage for airbrushing. We will also discuss the importance of maintenance and cleaning, so you can extend the lifespan of your compressor and ensure it continues to perform at its best.

How To Use An Air Compressor For Airbrushing – Details Discussion

Air compressors are versatile tool that can be used for a wide range of applications, including airbrushing. If you’re new to airbrushing, learning how to use an air compressor can be intimidating. However, with a little practice and a comprehensive guide, you’ll be airbrushing like a pro in no time.

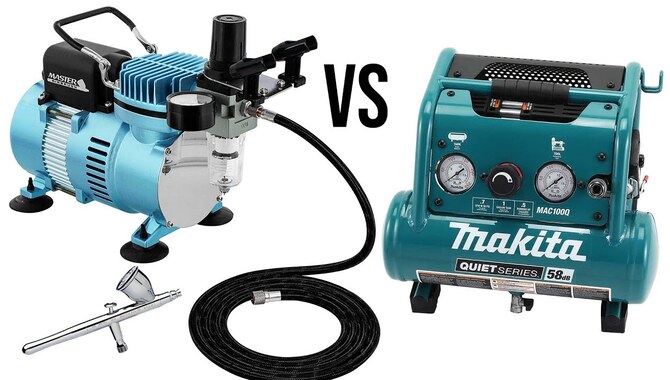

Choosing the right type of air compressor for your airbrushing needs is important. Look for a compressor with a tank that is at least 1 gallon in size, as this will provide a steady flow of air and prevent pulsation in your airbrush.

You should also consider the horsepower of the compressor, as well as its CFM rating, which stands for cubic feet per minute and indicates the amount of air the compressor can deliver. Once your compressor is set up, it’s time to connect your airbrush. You’ll need an airbrush hose that fits securely onto the airbrush and the compressor.

Types Of Air Compressors For Airbrushing

Several types of air compressors are available in the market that caters to different needs and budgets. The most commonly used air compressors for airbrushing are the piston, diaphragm, and screw compressors. Piston compressors are the most affordable option and suitable for beginners.

They are relatively loud but provide a consistent airflow perfect for most airbrushing projects. Diaphragm compressors are quieter than piston compressors and offer a smoother airflow, making them ideal for detailed work. They are also more durable and require less maintenance.

Screw compressors are the most expensive option but offer the best performance and durability. They are designed for heavy-duty use and provide continuous airflow without fluctuations. However, they are not recommended for small projects as they are more suited for commercial or industrial use.

Choosing The Right Airbrush

When it comes to airbrushing, choosing the proper airbrush is crucial. Various types of airbrushes are available, from gravity-fed to siphon-fed airbrushes. Gravity-fed airbrushes are popular among beginners as they require less air pressure and are easy to clean. However, they are not suitable for large-scale projects.

On the other hand, siphon-fed airbrushes are ideal for larger projects as they can handle a higher volume of paint. They are also easier to refill and can handle thicker paints. The shape of the airbrush nozzle also plays a vital role in the quality of the airbrushed artwork.

A conical nozzle is ideal for fine details and small areas, while a fan-shaped nozzle is perfect for larger areas. The needle size also affects the spray pattern, with a smaller needle producing finer lines and a larger hand making a broader spray pattern.

Setting Up Your Air Compressor For Airbrushing

Setting up your air compressor for airbrushing is an essential step to ensure the success of your project.

- The first thing you need to do is ensure your air compressor has a tank. A tank will help regulate the air pressure and prevent the compressor from constantly cycling. Once you have a compressor with a tank, you need to attach an airbrush hose to the compressor. Use a hose designed for airbrushing to prevent moisture or oil from getting into your airbrush.

- Next, attach a moisture trap to the hose. The moisture trap will remove any water from the air before it reaches your airbrush, preventing any potential damage to your equipment.

- Finally, you need to adjust the pressure on your compressor. Most airbrushing requires a pressure between 15 and 30 PSI, but always check your airbrush manufacturer’s recommendations.

Adjusting Air Pressure

Adjusting air pressure is essential to maintaining the performance and safety of various devices and equipment. For example, in the automotive industry, tires must inflate to a specific pressure level to ensure optimal handling, fuel efficiency, and tire lifespan.

Similarly, air pressure must adjust in HVAC systems to balance airflow, prevent duct leaks, and maintain indoor air quality. Changing air pressure can also be critical in medical settings, such as respiratory therapy, where patients require precise oxygen and airflow levels to support their breathing.

In manufacturing and industrial processes, air pressure adjustments are often necessary to control the speed and accuracy of machinery and regulate the temperature and humidity levels in production environments. However, adjusting air pressure can also be hazardous if not done correctly. Following safety protocols and using appropriate equipment, such as pressure gauges, is important to ensure accurate readings.

Maintenance And Cleaning Of Air Compressor

Maintenance and cleaning of air compressors are crucial factors in ensuring the longevity and efficiency of the equipment. Regular maintenance involves checking the oil levels, replacing filters, and inspecting the valves, hoses, and belts for signs of wear and tear.

It is recommended to schedule maintenance at least once every six months or per the manufacturer’s guidelines. Cleaning the air compressor is also essential to prevent the buildup of dirt, debris, and moisture that can cause corrosion and damage to the equipment.

The cleaning process involves draining the water from the tank, wiping the surfaces with a cloth, and using a compressor cleaner to remove any oil or dirt buildup. It is essential to follow safety procedures when cleaning the air compressor, such as wearing protective gear and disconnecting the power supply. Neglecting air compressor maintenance and cleaning can decrease efficiency, increase energy consumption, and cause equipment failure.

Troubleshooting Common Problems

Troubleshooting common problems is essential to any technical support team’s daily routine. It involves identifying issues that customers may encounter when using a product or service and finding solutions to resolve them. Customers’ most common problems are connectivity, performance, and software compatibility.

For instance, users may experience slow internet speeds due to network congestion, or their devices may not connect to a Wi-Fi network. In such cases, troubleshooting steps may include resetting network hardware, updating drivers, or changing network settings. Similarly, software compatibility issues can cause programs to crash or fail to open altogether.

A standard solution here is to update the software or reinstall it. Troubleshooting also involves addressing user errors, such as forgetting login credentials or accidentally deleting files. In such cases, resetting passwords or restoring deleted files may be the remedy. Troubleshooting common problems requires a systematic approach, patience, and good communication skills.

Best Practices For Air Compressor And Airbrushing

Following the best practices to achieve optimal results is essential regarding air compressors and airbrushing. One of the first things to consider is the type of compressor used. A compressor with a tank is recommended, as it allows for a steady airflow and reduces the risk of pulsation.

In addition, the compressor should have a moisture trap and regulator to ensure that the air is dry and at the correct pressure. When it comes to airbrushing, it is essential to use the correct type of paint and thin it to the appropriate consistency.

Using the wrong paint can cause clogging, splattering, and other issues. It is also essential to keep the airbrush clean and in good condition. Regular cleaning and maintenance will help prevent clogging and ensure the airbrush continues functioning correctly.

Advanced Techniques For Airbrushing With An Air Compressor

Airbrushing has been a popular art form for many years. With technological advancements, advanced techniques for airbrushing with an air compressor have become more accessible than ever before. Air compressors provide a steady stream of compressed air that allows artists to create intricate designs, smooth color transitions, and detailed textures.

With an airbrush and an air compressor, artists can achieve a wide range of effects, from fine misting to thick lines, as well as control the pressure and flow of the air to suit their needs. These advanced techniques for airbrushing with an air compressor have revolutionized the art form and opened up new possibilities for artists to express their creativity.

From creating realistic portraits to abstract designs, airbrushing with an air compressor allows artists to experiment with different styles and techniques and achieve professional-grade results.

Conclusion

mastering an air compressor for airbrushing takes time and patience, but anyone can achieve professional-looking results with the right tools and techniques. By following the tips and tricks outlined in this blog post, individuals can improve their airbrushing skills and create stunning artwork.

It is important to remember to use the correct air pressure, maintain proper ventilation, and clean the airbrush and compressor after every use to ensure longevity and the best performance. With practice and dedication, utilizing an air compressor for airbrushing can be a valuable skill in art and design.

FAQs

1.What Common Mistakes To Avoid When Using An Air Compressor For Airbrushing, And How Can You Troubleshoot Issues?

Ans: Not properly adjusting the air pressure: Changing the air pressure to the appropriate level for the type of paint being used is essential. Using too high of a force can result in overspray and paint splattering, while too low power can cause the paint to spatter or not apply evenly.

2.What Are Some Advanced Tips And Techniques For Using An Air Compressor For Airbrushing, Such As Using Different Nozzle Sizes Or Adjusting The Airflow For Specific Effects?

Ans: Adjusting the airflow: The air pressure you use can affect the outcome of your airbrushing. Lower air pressure suits fine detail work, while higher pressure covers large areas or creates texture.

3.What Airbrush Should You Use With An Air Compressor, And What Are The Differences Between Single And Dual-Action Airbrushes?

Ans: When using an air compressor, it is recommended to use an airbrush designed for use. This typically means using a gravity feed or a bottom feed airbrush with a small nozzle that can handle higher air pressure levels.

4.What Are Some Common Mistakes To Avoid When Using An Air Compressor For Airbrushing, And How Can You Correct Them?

Ans: Not adjusting the pressure: Changing the air pressure to suit the task is essential. Too much stress can cause splattering and overspray, while too little pressure can result in uneven or incomplete coverage.

5.Can You Use An Air Compressor For Other Painting Or DIY Projects, And What Accessories Or Attachments Would You Need?

Ans: An air compressor can use for other painting or DIY projects. You would need a spray gun attachment and an air hose for painting. You may need other extensions for DIY projects, such as an air nailer, air sander, or air drill. The specific attachments or accessories required would depend on the project being undertaken.