High-build and low-build primers are essential components of any painting project, and understanding the differences between them is critical for achieving professional results.

High-build primers are designed to provide a thicker, more substantial coat of paint, while low-build primers are designed to provide a thinner, more even coat. Both types of primers have their own unique advantages and disadvantages, making it important to choose the right one for the job.

This article will explore the differences between high-build and low-build primers, as well as provide tips for selecting the best option for your project. With the right primer, you can ensure a beautiful and lasting finish for your painting project. So, let’s take a look at the differences between high-build and low-build primers and learn how to choose the right one.

High-Build Vs Low-Build Primer: What’s The Difference?

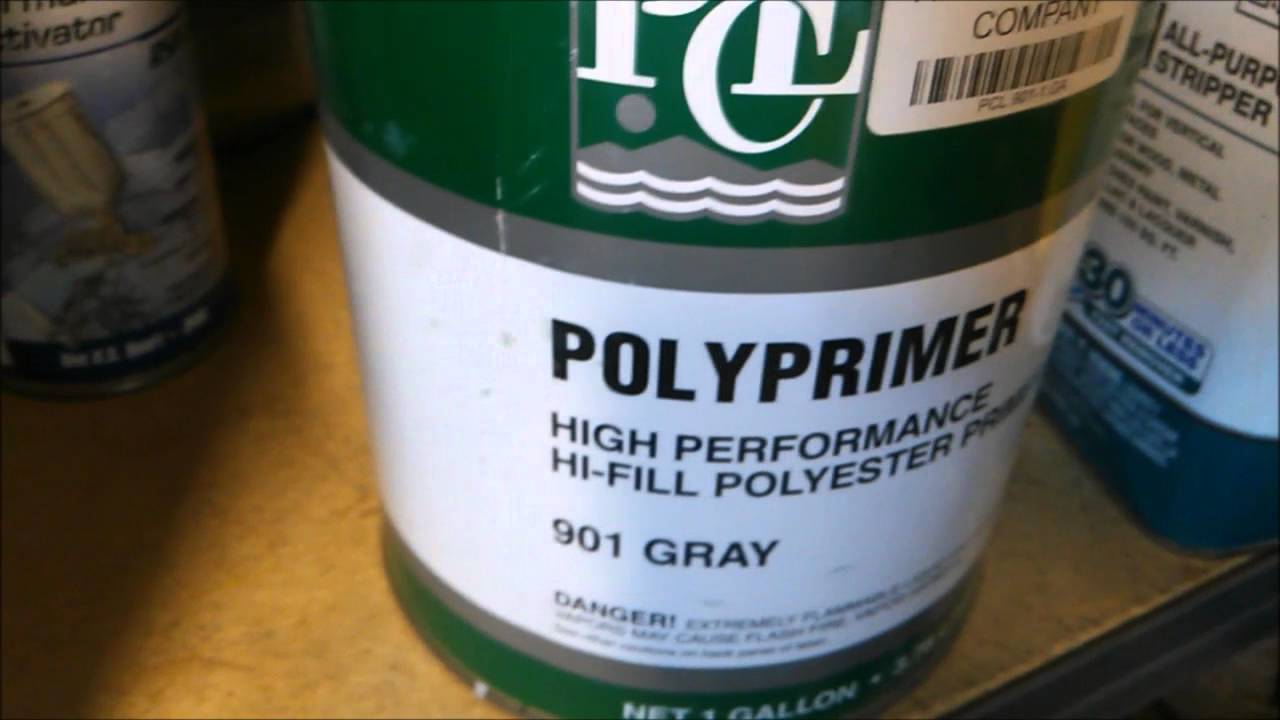

Before delving into the comparison of high-build primer vs. low-build primer, it is important to understand the basics of both. High-build primer is a thick coating applied to a surface that provides a high level of protection. It is usually applied in multiple layers and is ideal for surfaces with a large number of imperfections.

Low-build primer, on the other hand, is a thinner coating that is applied in a single layer and is designed to provide a smoother surface. It is best suited for surfaces that don’t have a lot of imperfections. Now that we have a basic understanding of the two types of primer, let’s look at how they compare in terms of performance, cost, and application.

Definition

High-build and low-build primers are the two main types of primers used in painting projects. A high-build primer is a thicker primer that is used to fill in deep surface imperfections, such as cracks, chips, and holes. Low-build primers are thinner and better suited for smoothing out light imperfections in a surface.

High-build primers are often used to provide a better base for the topcoat of paint, while low-build primers are often used to provide a smoother finish and a better bond between the primer and the topcoat. Both types of primer are available in different finishes, such as glossy, satin, and matte, to match the look of the topcoat.

High Build Primer

High-build primer is a type of primer that is used to provide a thicker coating than traditional primers. This type of primer is ideal for high-traffic areas, such as walls and floors, where a thicker coating is required for better protection. High-build primer is also a great choice for wood surfaces, as it helps to create a stronger bond between the wood and the paint.

It also provides better adhesion and protection from moisture, making it a great choice for wood surfaces. High-build primer is also more expensive than traditional primers, but it is worth the investment due to its superior protection and durability.

Lowbuild Primer

Low-build primer is a type of primer that is designed to provide a thin, uniform layer of protection on a substrate. This type of primer is often used in industrial and commercial painting projects, as it offers excellent coverage with minimal build up of material.

Low-build primer is a great choice for painting projects that require a thin layer of coverage, as it can provide an even, consistent coat without creating thicker areas of paint. Low-build primer is also often used on surfaces that are exposed to harsh environmental conditions, as it provides a layer of protection that can help prevent damage from moisture, UV rays, and other environmental factors.

Usage

When painting a wall, the type of primer used can have a big impact on the overall finish. High-build primer and low-build primer are two popular options, but they have different uses. High-build primer is used when more coverage is needed, such as on walls with multiple coats of paint or stains that are difficult to cover. It also helps to even out surface imperfections.

On the other hand, low-build primer is best for walls with minimal damage or when new paint is being applied. It’s thinner than high-build primer and is often used when painting cabinets or furniture. Both types of primer are available as oil-based or water-based, depending on the surface and desired finish. Ultimately, the best primer to use depends on the surface being painted and the desired result.

Highbuild Primer

High-build primers are a type of primer that are thicker than traditional primers. When applied to a surface, they leave a thicker coating. This thicker coating provides a better bonding surface for the paint, allowing for a more even and uniform finish.

High-build primers are typically used on surfaces that have more imperfections, such as those with cracks, dents, or rust. The thicker coat also helps to fill in any gaps, creating a smoother surface. Additionally, high-build primers provide better coverage and have more adhesive properties than low-build primers, which makes them ideal for surfaces that have been previously painted.

Low Build Primer

Low-build primer is a type of primer used to prepare a surface for painting or staining. The thickness of a low-build primer is typically less than one hundredth of an inch. It is applied in thin layers, which helps to ensure a smooth, even surface. This type of primer is usually used on interior walls and exterior siding, as well as on hardwood and metal surfaces.

Low-build primer is also often used to cover up blemishes on the surface prior to painting or staining. Since the layers of primer are thin, they do not fill in any cracks or holes in the surface. This makes it better suited for surfaces that require a more durable coating. Low-build primer also offers a good base for subsequent coats of paint or stain. When applied properly, it helps to ensure a smoother, more even finish.

Advantages

High-build primer and low-build primer each have their advantages. High-build primer is thicker than low-build primer and provides better coverage. This makes it ideal for surfaces with imperfections that require more material to properly cover.

It also has a higher solids content, which means it can be used to fill in small gaps and crevices. Low-build primer is thinner and more economical. It is also better for surfaces that are already relatively smooth and don’t require a lot of material to cover. It works well for small areas or areas with few imperfections. Both types of primers provide a good base paint, but high-build primer is better for surfaces with more imperfections.

Highbuild Primer

High-build primers are a type of primer that are designed to provide an even, thick coating that completely seals the surface. They are usually applied in multiple layers to ensure maximum coverage and protection. High-build primers are ideal for surfaces that are highly porous, such as concrete, wood, and metal.

They are also great for sealing chalky surfaces, as well as creating a uniform base for paint to adhere to. High-build primers are generally thicker than low-build primers, and provide a greater level of protection against moisture, dirt, and other contaminants. Additionally, they can help fill in small imperfections, and can be used to create a uniform texture on a variety of surfaces.

Lowbuild Primer

Low-build primer is a type of primer used in automotive refinishing. It is designed to be used in the first coats of paint and is typically sprayed on in thin layers. The primer is meant to create an even surface so that the paint can be applied evenly.

Low-build primer is lightweight and provides a smooth finish with a thin coat. This makes it easier to sand down and less likely to crack or bubble. Low-build primer is also more flexible than high-build primer and can be used on a variety of surfaces, including aluminum, steel, and fiberglass. It is also less likely to cause overspray and is easier to clean up. Low-build primer can be used in a variety of applications, such as base coats for large-scale vehicle repair and restoration projects.

Disadvantages

High-build primers have several disadvantages compared to low-build primers. Firstly, they tend to be more expensive than their low-build counterparts, making them impractical for large-scale projects. Secondly, they are more difficult to work with. These primers require a skilled applicator, making them difficult to use on DIY projects.

Furthermore, the higher build of the primer can make it difficult to sand and work with after application. High-build primers also tend to take longer to dry, and can run or sag in areas if not applied correctly. These primers can also be susceptible to cracking and peeling over time, depending on the surface they are applied to. Finally, some high-build primers require more than one coat to achieve the desired finish, resulting in additional labour and materials.

Highbuild Primer

High-build primers are a type of primer used in a variety of industrial and commercial applications. They are designed to be thicker and more resilient than low-build primers, allowing them to be used in applications that require more protection and durability. High-build primers are typically applied in multiple coats, and can be used to reduce the number of top coats needed to achieve a desired finish. They can also be used to protect surfaces from corrosion and other damage.

High-build primers come in a variety of types, including epoxy-based, acrylic, and polyurethane options. Each type offers its own set of advantages and disadvantages, so you should carefully consider which type is best for your particular project.

Low Build Primer

Low-build primers are the perfect starting point for any painting project. They are designed to provide a thin, even layer of paint that can be easily sanded and filled with a thicker coat of paint. This helps to create a smooth, uniform base for a more detailed finish. Low-build primers are also preferred for outdoor surfaces because they are less likely to crack or flake when exposed to weather conditions.

As a result, they are often used for aluminum, steel, and other metal surfaces. Low-build primers also provide a great base coat for wood, masonry, and other porous surfaces. They are easy to apply, dry quickly, and provide an even coat that is ideal for creating a smooth surface.

Conclusion

High-build primers are ideal for providing a thicker, more protective coating than a low-build primer. They are perfect for filling in minor imperfections, and can be used on a variety of surfaces, from wood to metal. Low-build primers, on the other hand, are thinner and less protective, but they are easier to apply and dry faster.

Both types of primers are useful for preparing surfaces for painting, but the choice of which to use depends on the desired outcome and the surface being painted.

FAQ’s

1.What Are The Differences Between A High-Build Primer And A Low-Build Primer?

Ans: A high-build primer is thicker and provides a greater degree of protection than a low-build primer. High-build primers are typically used to fill gaps, cover imperfections, and provide a more uniform surface for a top coat. Low-build primers are thinner and are used to seal surfaces and provide a better foundation for a top coat. Low-build primers are also cheaper to use than high-build primers.

2.When Should A High-Build Primer Be Used, And When Should A Low-Build Primer Be Used?

Ans: A high-build primer should be used when you need to fill in deep scratches or cracks as it is thicker and provides a thicker layer of protection. A low-build primer should be used when you don’t need to fill in deep scratches or cracks, as it provides a thin layer of protection and can be applied more quickly. Both primers should be used in conjunction with a topcoat of paint to properly protect the surface.

3.What Are The Advantages And Disadvantages Of Using A High-Build Primer?

Ans: The advantages of using a high-build primer include its ability to fill in minor surface imperfections, its ability to provide a good base for the topcoat, and its ability to seal the surface from moisture and contaminants. The disadvantages include that it is more expensive than standard primer, it is slower to dry, and it can be difficult to sand.

4.What Are The Advantages And Disadvantages Of Using A Low-Build Primer?

Ans: The advantages of using a low-build primer include faster drying times and less thickness needed for an even coat. This makes it ideal for projects that require multiple coats of primer. The main disadvantage of using a low-build primer is that it is not as durable as a high-build primer and may require more coats to achieve the desired finish. Additionally, it may not provide the same level of protection as a high-build primer.

5.How Many Coats Of A High-Build Primer Should Be Applied, And How Many Coats Of A Low-Build Primer Should Be Applied?

Ans: Generally, two coats of a high-build primer should be applied to ensure adequate coverage and protection. One coat of a low-build primer should be adequate for most surfaces. However, if the surface is especially rough, then additional coats may be needed. It’s always best to follow manufacturer’s instructions for best results.