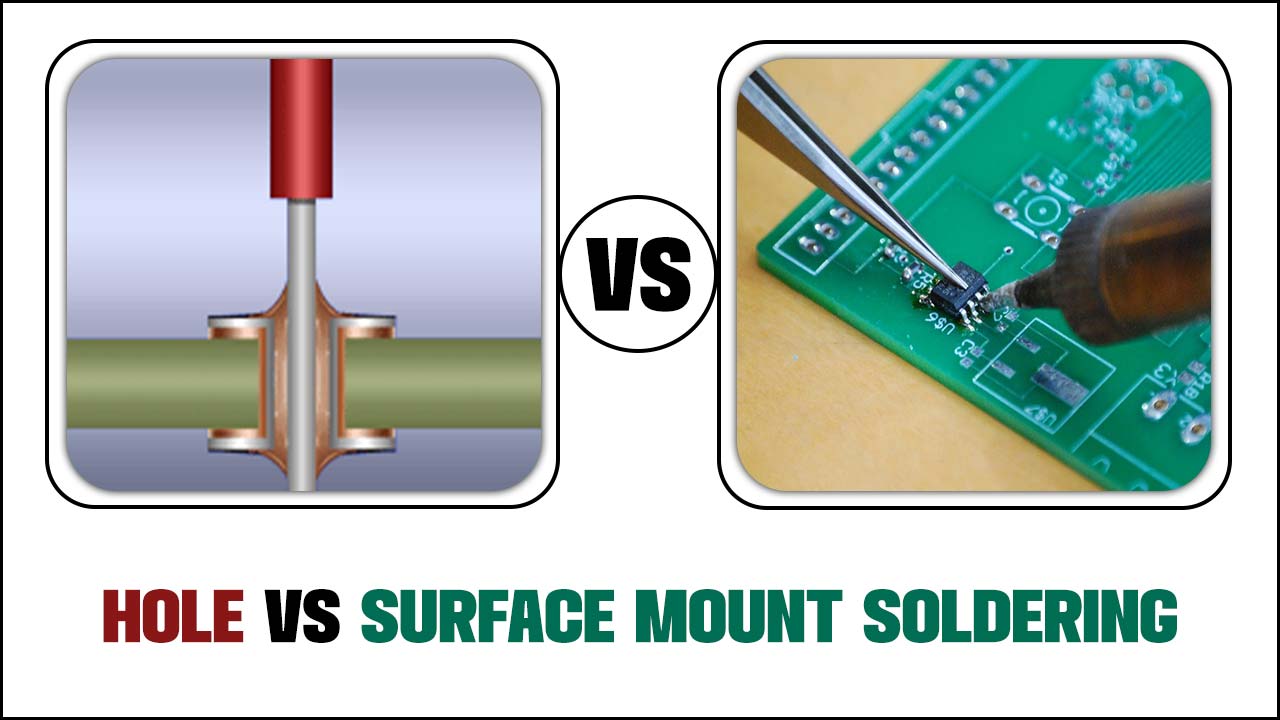

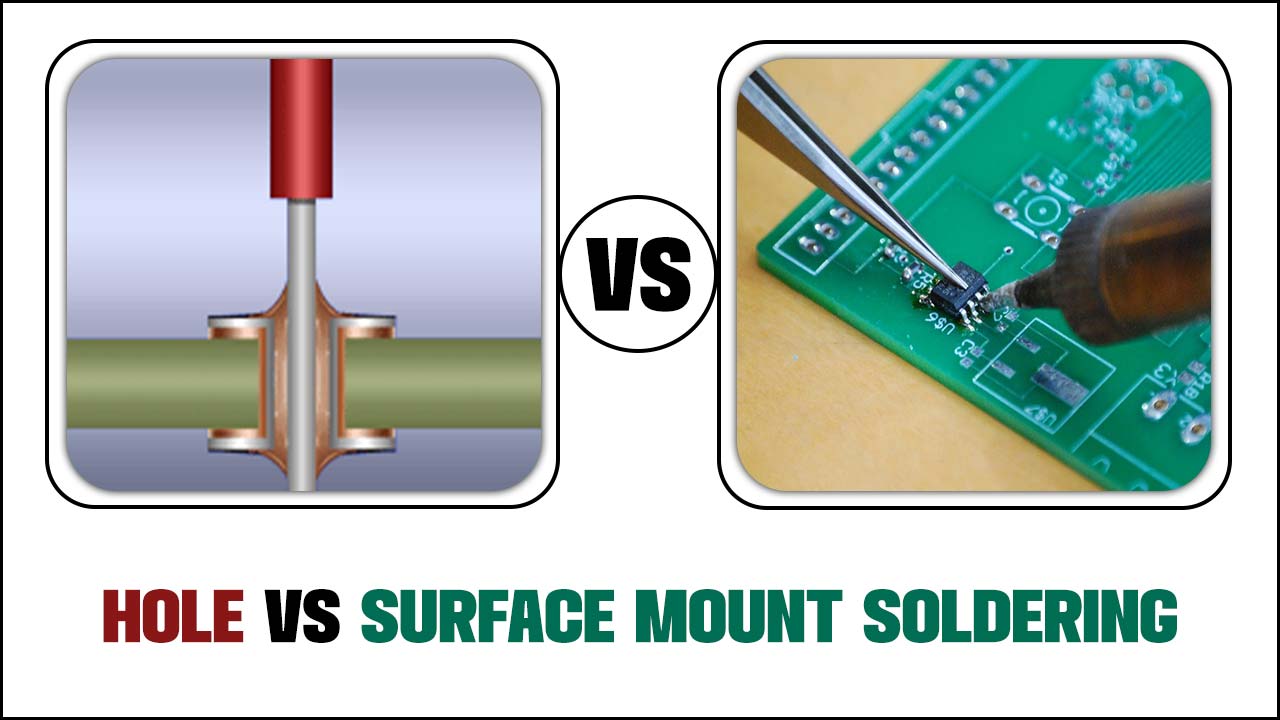

Through-Hole Soldering and Surface Mount Soldering are two of the most popular techniques used in the electronics industry. Both of these soldering processes have their own advantages and disadvantages, and choosing the right one for a particular application can be a difficult task.

This article will compare and contrast these two processes, discussing the differences in cost, time, and complexity, as well as the application areas in which each technique is most suitable. At the end, readers will have a better understanding of which soldering process is best for their needs. So, if you’re curious about Through-Hole Soldering vs. Surface Mount Soldering, read on to find out more!

Comparing Through-Hole & Surface Mount Soldering

Through-hole soldering and surface mount soldering are two distinct methods of connecting components to a printed circuit board (PCB). Through-hole soldering involves inserting components into pre-drilled holes in the PCB and then soldering them in place. Surface mount soldering, on the other hand, involves attaching components directly onto the surface of the PCB using a soldering iron.

Both methods have their own advantages and disadvantages, and the choice of which one to use depends on the specific application. In this article, we will discuss the differences between through-hole and surface mount soldering in detail, and how to decide which one is best for your project.

Types

When it comes to soldering, there are two main types: through-hole soldering and surface mount soldering. Through-hole soldering requires components to be inserted into holes in the circuit board before the solder is applied. The component leads are then bent and held in place while the solder is flowed around them.

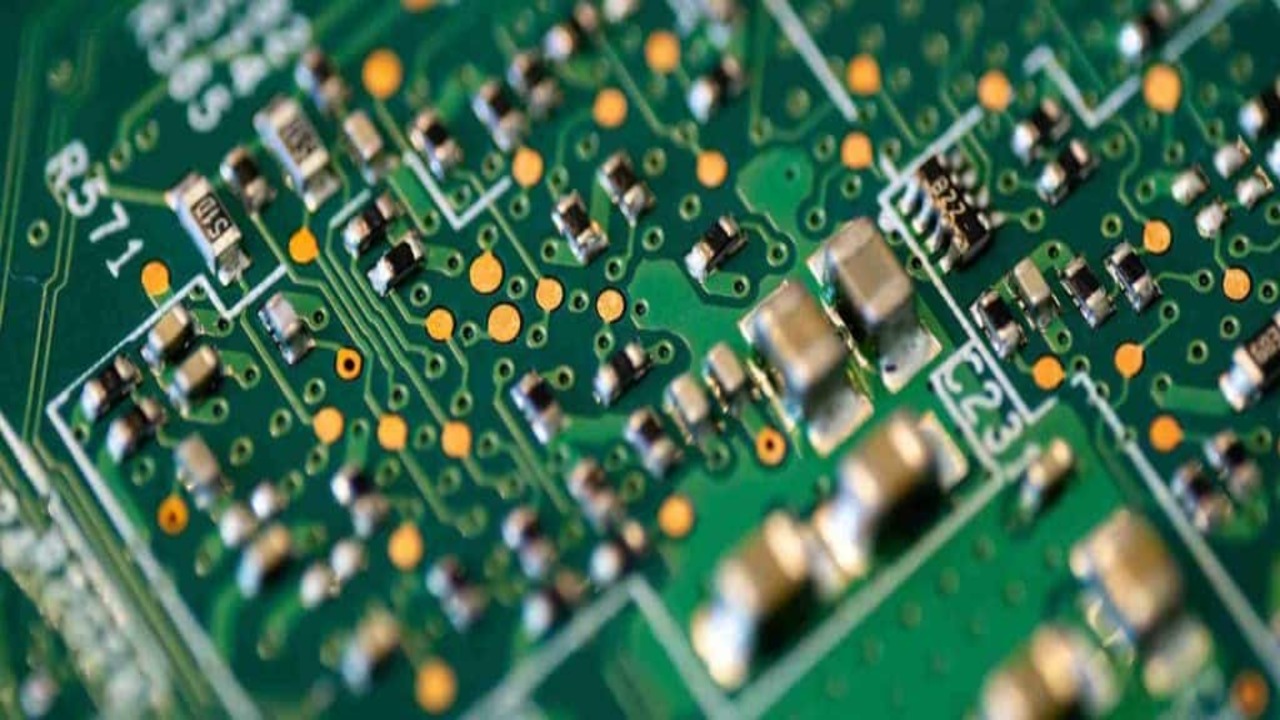

Surface mount soldering involves adhering components to the surface of the circuit board with solder paste before soldering them in place with a soldering iron. This type of soldering is more popular in the modern electronics industry as it is much faster and requires less manual labor. It is also much smaller and produces a more reliable connection.

Throughhole Soldering

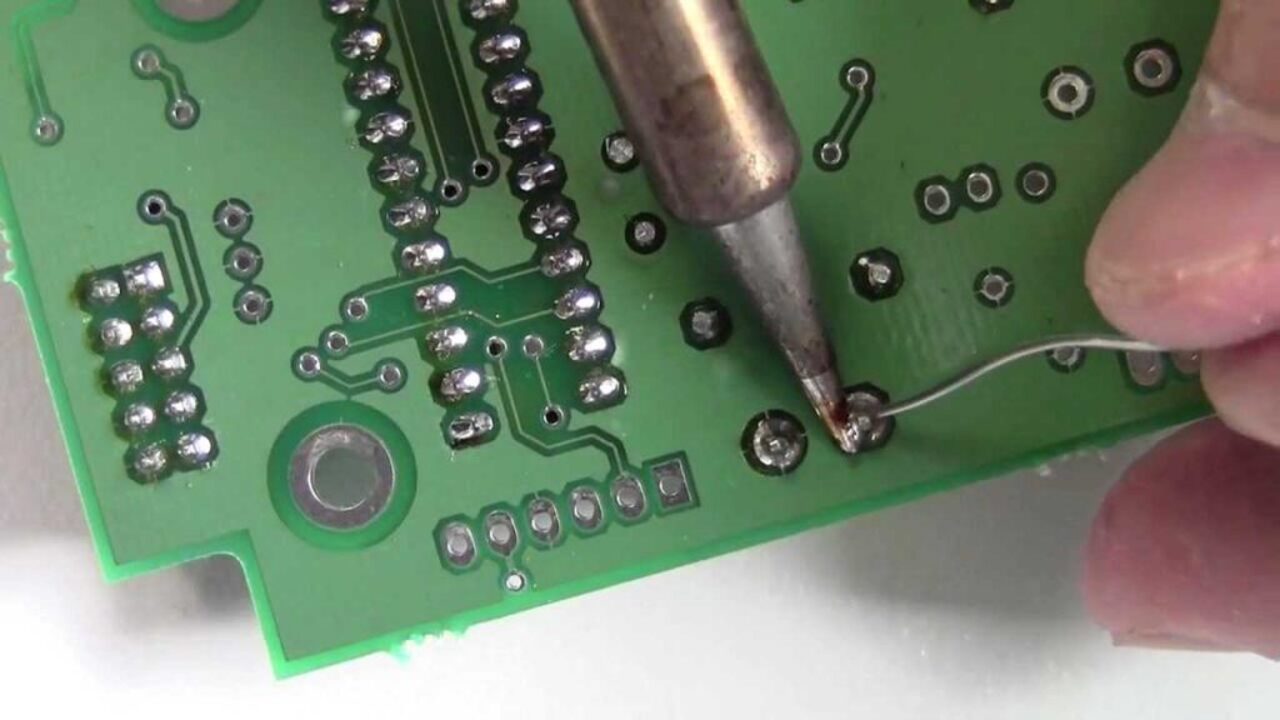

Through-hole soldering is a process in which components are connected to a printed circuit board (PCB) through metal leads, usually made of copper. It is the traditional method for connecting components to a PCB and is still widely used today. The process involves soldering the component leads to the plated through-holes in the PCB.

The component is then secured to the board with an adhesive. Through-hole soldering is a relatively easy process and does not require specialized equipment. It is very reliable and can be used for both prototyping and mass production.

The main advantages of through-hole soldering are that it can be used for a wide variety of components, it is relatively simple to perform, and it is highly reliable. On the other hand, through-hole soldering is time-consuming and can lead to excessive heat build-up which can damage components or even the PCB itself.

Surface Mount Soldering

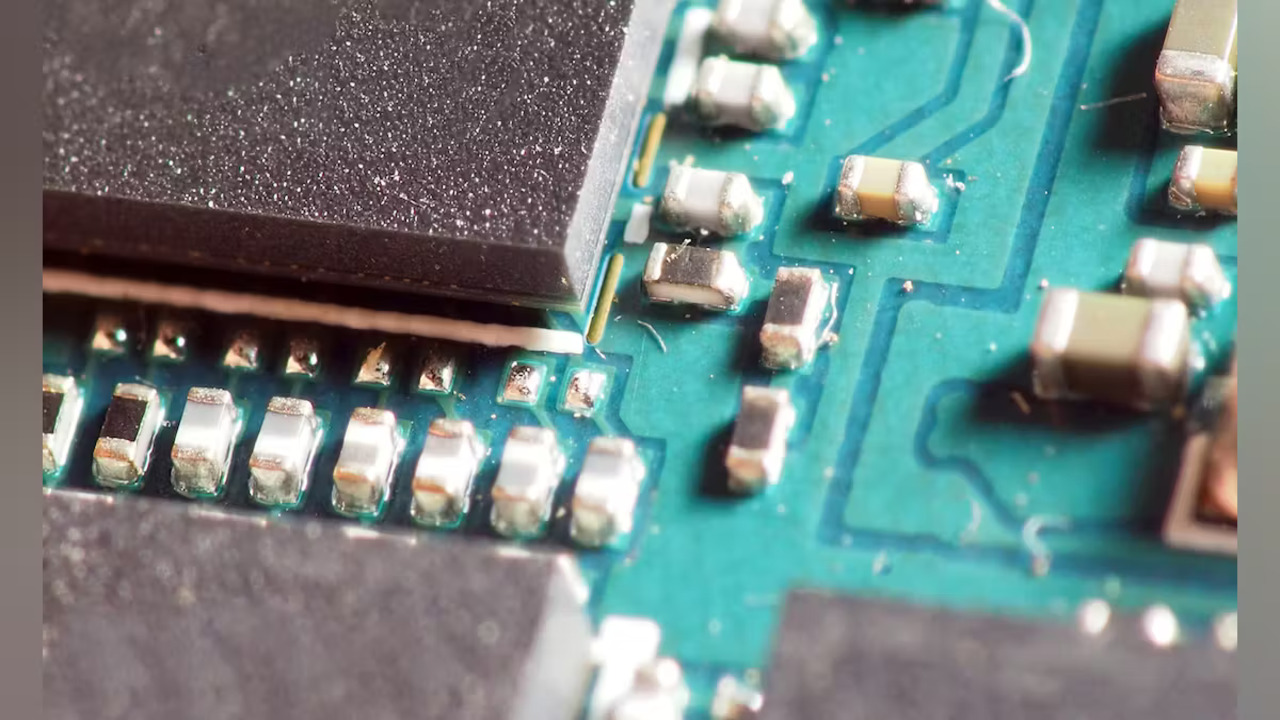

Surface mount soldering is a process of connecting small electronic components to a printed circuit board (PCB). This type of soldering is done by placing the component onto the surface of the PCB and then using a soldering iron to attach the component to the board.

Unlike traditional through-hole soldering, surface mount soldering does not require the component to be placed through a hole in the PCB. This makes the process faster and easier, as well as more cost-effective.

Surface mount soldering also allows for the use of smaller components, which helps to reduce the overall size and weight of the PCB. Additionally, surface mount components are more resistant to damage from heat or vibration, making them more reliable.

Benefits

The two soldering processes, through-hole soldering and surface mount soldering, provide different benefits to engineers and manufacturers. Through-hole soldering is beneficial due to its reliability in making strong and durable electrical connections. It is also relatively easy to assemble components using through-hole soldering.

On the other hand, surface mount soldering is beneficial in that it allows for greater miniaturization, as components can be made smaller than with through-hole soldering. Additionally, surface mount soldering is faster and less labor-intensive, reducing production costs.

It is also more consistent in producing high-quality results, which helps to reduce the chances of product failure. Finally, surface mount soldering produces less waste than through-hole soldering, making it more environmentally friendly.

Throughhole Soldering

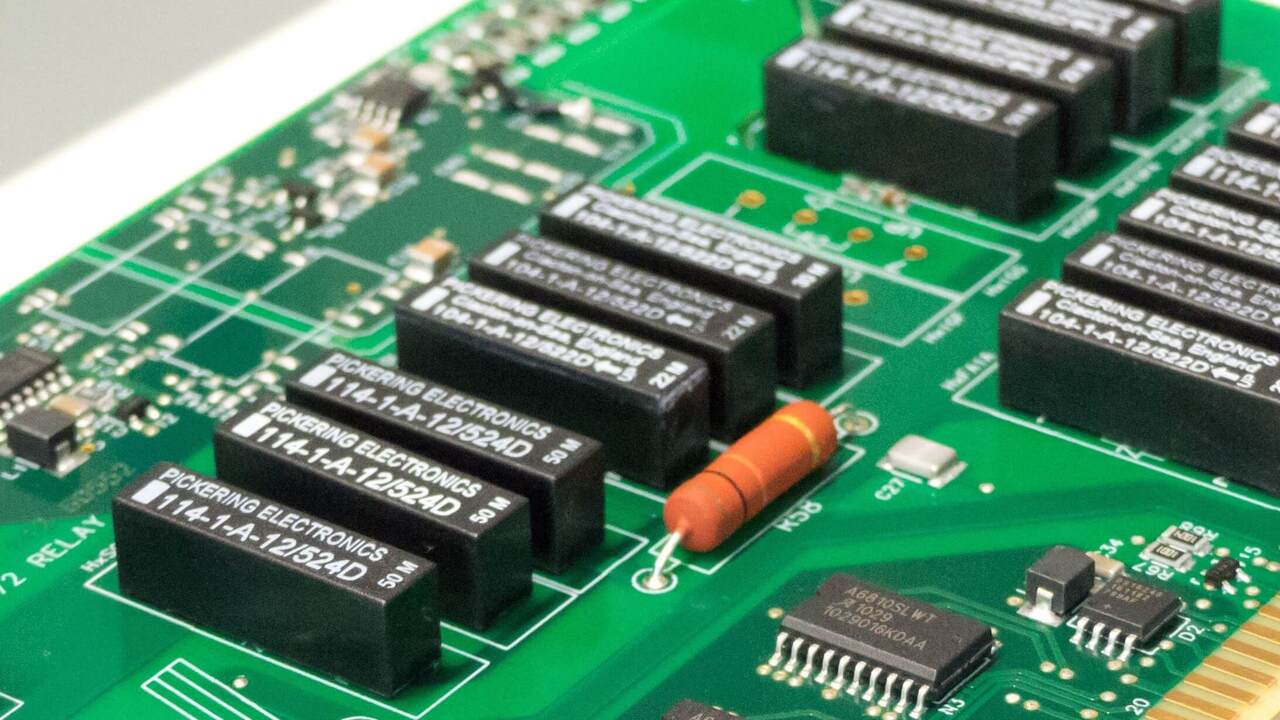

Through-hole soldering is a traditional method for connecting components to a printed circuit board (PCB). It involves inserting components such as resistors, capacitors, and integrated circuits into pre-drilled holes on the PCB and then connecting them with molten solder.

The solder forms electrical and mechanical connections that hold the components in place. This method is well-suited for prototyping, troubleshooting, and repairing existing PCBs, as it is relatively easy to inspect and repair the connections.

Additionally, through-hole soldering is ideal for larger components, as the holes provide more surface area on which the solder can adhere. The downside is that the process is slow and can be quite messy, as the molten solder can easily spread to other parts of the board.

Surface Mount Soldering

Surface mount soldering is a method of soldering that uses surface mount components (SMCs) instead of through-hole components. SMCs are smaller and more uniform than through-hole components, and they are designed to be mounted directly on the circuit board.

The process of surface mount soldering is quite different from through-hole soldering. It requires special tools and techniques in order to correctly and accurately solder the SMCs onto the circuit board.

A soldering iron, flux, solder paste, and a solder mask are all necessary tools for the job. The solder paste is applied to the pads on the circuit board, then the SMCs are placed on top. The soldering iron is then used to heat the solder paste in order to create a bond between the component and the board.

Finally, a solder mask is applied over the components to protect them from oxidation. Surface mount soldering is an important technique used in modern electronic manufacturing, and it provides a high level of accuracy and reliability when used correctly.

Drawbacks

When it comes to drawbacks, both Through-Hole Soldering and Surface Mount Soldering have their share of disadvantages. With Through-Hole Soldering, it can be difficult to manipulate components while they are in the board.

This can be tricky when components need to be adjusted or replaced. Additionally, it’s important to note that Through-Hole Soldering requires more space on a board, which makes it more difficult to design complex circuits.

On the other hand, Surface Mount Soldering requires a more precise alignment of components, which can be time consuming and difficult for inexperienced technicians. Additionally, Surface Mount Soldering requires special tools and a specialized soldering station.

This makes it more expensive than Through-Hole Soldering. Ultimately, it’s important to consider the pros and cons of each method before deciding which is best for your application.

Throughhole Soldering

Through-hole soldering is the traditional method of soldering components to a circuit board. It involves inserting the component leads through the holes in the board and then melting solder on the opposite side to create a secure electrical connection. This process is often referred to as “through-hole technology” (THT).

This method of soldering is simple to understand and execute, making it popular among hobbyists and professionals alike. The components are also easier to handle and they tend to have a longer lifespan. Also, the larger the component, the easier it is to solder it in place. However, the downside is that the use of through-hole soldering can limit the number of components that can fit on a single board, as the holes take up more space.

Surface Mount Soldering

Surface mount soldering is a relatively new technology to the world of electrical engineering and soldering. It involves soldering components to the surface of a printed circuit board or other surface instead of through holes. This method is more reliable than traditional through-hole soldering and is much faster, as components can be placed in place with automated equipment.

It is also much more precise, as the components can be placed in exact locations on the board to ensure proper connections and performance. Additionally, less space is required, making surface mount soldering ideal for use with miniaturized electronics.

Cost

When considering the cost of through-hole soldering versus surface mount soldering, it is important to take into account the cost of the components themselves. Generally, through-hole components are more expensive than surface mount components.

This means that through-hole soldering requires a larger investment upfront. However, through-hole soldering tends to have a longer lifespan, making it more cost effective in the long run.

In contrast, surface mount soldering is a more cost-effective option for short-term projects. Additionally, because surface mount components are much smaller, they require less space, resulting in fewer materials being used and a cost savings. Ultimately, the cost of through-hole soldering or surface mount soldering will depend on the project and its long-term needs.

Throughhole Soldering

Throughhole Soldering is a process of connecting components to a printed circuit board (PCB) using a metal wire. This method of soldering requires the component to be inserted into drilled holes in the PCB and then soldered in place. It is the traditional method of soldering and is still used in many electronic components and devices today.

Throughhole soldering involves using a soldering iron to apply heat to the joint and melt the solder. The metal wire then forms a bridge between the component leads and the pads on the PCB.

This method is generally considered to be more reliable than surface mount soldering as the connection is more secure and less likely to be damaged. The downside of throughhole soldering is that it is more time consuming and requires more manual labour than surface mount soldering.

Surface Mount Soldering

Surface mount soldering is a more advanced soldering technique which involves the mounting of components on the surface of a printed circuit board (PCB). This type of soldering is used for components with very small leads or no leads at all. It requires the use of special soldering equipment, such as a hot air pencil, and specialized tools like tweezers and flux.

The component is placed on the PCB and then heated with a hot air pencil. The solder is then applied to the pads of the component, and the heat is removed. This technique is more precise and requires greater skill than through-hole soldering. It is more suitable for components that are too small to be soldered by traditional methods. It is also more reliable since it is less likely to cause damage to the PCB.

Conclusion

Through-Hole Soldering and Surface Mount Soldering are two different methods of soldering components onto a circuit board. Through-Hole Soldering requires components to be placed through holes in the board and soldered on the other side.

Surface Mount Soldering requires components to be placed directly onto the board and soldered in place. Through-Hole Soldering is more suitable for larger, heavier components, while Surface Mount Soldering is more suitable for smaller components. Both methods are essential for creating reliable and durable circuit boards.

FAQ’s

1.What Are The Key Differences Between Through-Hole Soldering And Surface Mount Soldering?

Ans: The two main differences between through-hole soldering and surface mount soldering are the size of components used and the technique used for soldering. Through-hole soldering uses larger components that are inserted into the holes of the board and then soldered.

Surface mount soldering uses much smaller components that are placed directly onto the surface of the board and soldered. The soldering technique for through-hole components is typically done by hand, whereas surface mount components are usually soldered using automated machines.

2.What Are The Advantages And Disadvantages Of Each Type Of Soldering?

Ans: The advantages of soldering include creating strong electrical connections, creating durable bonds, and providing a low-cost method for joining metal parts. The disadvantages of soldering are that it can be difficult to remove for repairs, and the heat can cause damage to nearby components.

The advantages of brazing are that it can join metals that have different melting points, and it can join thicker metals than soldering. The disadvantages of brazing are that it requires higher temperatures and specialized equipment to complete the process.

3.What Are The Most Common Types Of Components Used With Through-Hole Soldering And Surface Mount Soldering?

Ans: Through-hole soldering typically uses components such as resistors, capacitors, transistors, and diodes. Surface mount soldering typically uses components such as resistors, capacitors, diodes, transistors, integrated circuits, and connectors.

These components are much smaller than those used for through-hole soldering, and are soldered directly to the surface of the board. Both soldering methods are widely used in PCB assembly.

4.What Tools And Techniques Are Required For Successful Through-Hole And Surface Mount Soldering?

Ans: Through-hole soldering requires a soldering iron and solder wire, while surface mount soldering requires a soldering iron, solder paste, and a hot air gun. For successful soldering, the components must be correctly placed and soldering techniques such as pre-heating, heating, and cooling must be used appropriately. Through-hole soldering also requires the use of flux to help ensure a strong connection. In addition, good soldering technique requires a steady hand and patience.

5.What Safety Considerations Should Be Kept In Mind When Performing Through-Hole And Surface Mount Soldering?

Ans: When soldering, it is important to always wear safety glasses to protect the eyes from potential sparks. Additionally, a well-ventilated area should be used as fumes from soldering can be dangerous.

For through-hole soldering, it is important to ensure that the component is correctly placed and secure before soldering. For surface mount soldering, a hot air station should be used to avoid heat damage to the components.