The Small Block Chevy (SBC) engine is a staple of the American automotive industry and has been a popular choice for enthusiasts and racers alike.

However, after years of use and abuse, the cylinder heads on an SBC engine can become worn and damaged, leading to decreased performance and reliability. Replacing the heads on an SBC engine can be costly and time-consuming, but rebuilding them can be a more affordable and practical solution.

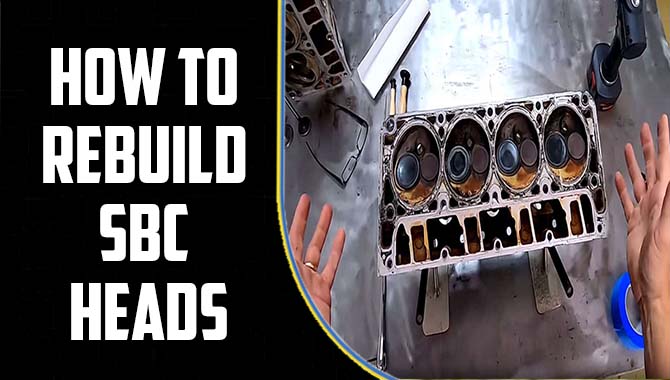

This blog post will explore the step-by-step process of how to rebuild SBC heads. With detailed instructions and expert tips, we will guide you through disassembling and cleaning the heads, inspecting for damage, and performing necessary repairs and upgrades.

From valve seat replacements to porting and polishing, we will cover all aspects of rebuilding SBC heads. Whether you are a seasoned mechanic or a novice enthusiast, this guide will provide you with the knowledge and techniques to rebuild your SBC heads confidently.

What Are SBC Heads?

SBC heads refer to cylinder heads designed for small-block Chevrolet engines. These heads can significantly affect engine performance by controlling the flow of air and fuel into the combustion chamber. They are available in various designs, such as stock, aftermarket, and performance-oriented. Choosing the right SBC heads depends on the specific application and desired performance goals.

Signs That Your SBC Heads Need Rebuilding

Several signs may indicate your Small Block Chevy (SBC) heads need rebuilding. One common sign is a loss of power or performance. You may also notice a decrease in fuel efficiency or an increase in engine noise.

If you see smoke from the exhaust or notice coolant in the oil, these can also be signs of head problems. Additionally, if you notice a rough idle or difficulty starting the engine, inspecting your SBC heads and possibly rebuilding may be time.

Tools Required For Rebuilding SBC Heads

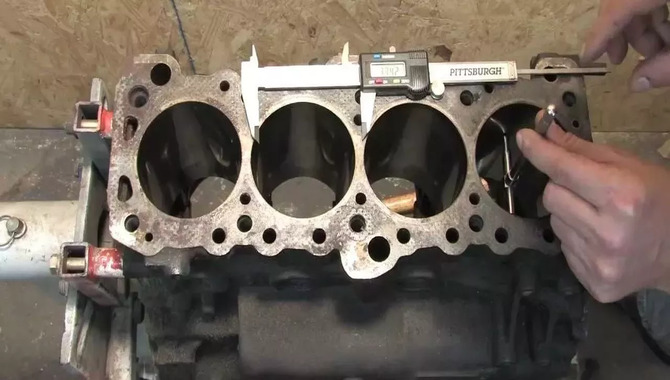

When rebuilding Small Block Chevy (SBC) heads, several tools are necessary to ensure a successful outcome. Some essential tools include a valve spring compressor, a valve guide driver, a valve seat cutter, a valve face cutter, a dial indicator, a torque wrench, and a micrometre.

It is important to have high-quality tools specifically designed for this type of work to ensure precision and accuracy during the rebuilding process. Additionally, it is important to follow proper safety precautions when using these tools to avoid injury or damage to the engine components.

Cost For Rebuilding SBC Heads

The cost of rebuilding SBC (small block Chevrolet) heads can vary depending on the extent of the damage and the quality of the parts used for the repair. A basic rebuild can cost anywhere from $300 to $500 per head.

However, the cost can increase significantly if the heads require extensive work, such as welding or replacing valves, springs, or guides. Finding a reputable mechanic or machine shop is important to ensure the job is done correctly and with high-quality parts.

Safety Precautions To Take Before Rebuilding SBC Heads

Before rebuilding SBC (Small Block Chevrolet) heads, it is important to take certain safety precautions. First, make sure to disconnect the battery to avoid accidental electrical shock. Wear protective gear such as gloves, safety glasses, and ear protection.

Working in a well-ventilated area is also recommended to avoid inhaling harmful fumes. Finally, ensure all tools and equipment are in good condition and used properly to prevent accidents. Following these safety precautions can reduce the risk of injury and confidently complete the rebuilding process.

How To Rebuild SBC Heads – A step-by-step guide

Rebuilding SBC (Small Block Chevy) head is a process of disassembling, cleaning, inspecting, repairing, and reassembling the cylinder heads. It is important to rebuild SBC heads to ensure optimal engine performance and longevity.

The process involves checking for cracks, warping, and wear on the head and valve seats, replacing worn-out components, such as valves, springs, and guides, and resurfacing the head to ensure a flat mating surface.

It is recommended to have the heads professionally rebuilt or to follow a detailed guide to ensure proper assembly and avoid costly mistakes. Here are the steps to how to rebuild SBC heads:

- Disassemble the heads and clean all the parts using a parts washer.

- Inspect the cylinder heads for cracks, warping, and other damage.

- Resurface the cylinder heads and valve seats if necessary.

- Replace the valve guides, valve seals, and valve springs.

- Install new valves and valve retainers.

- Reassemble the cylinder heads using new gaskets and torque the bolts to specification.

- Install the cylinder heads onto the engine block and torque the bolts to specification.

- Adjust the valve lash to the manufacturer’s specifications.

- Test the cylinder heads for leaks and proper operation.

- Install the remaining engine components and fluids.

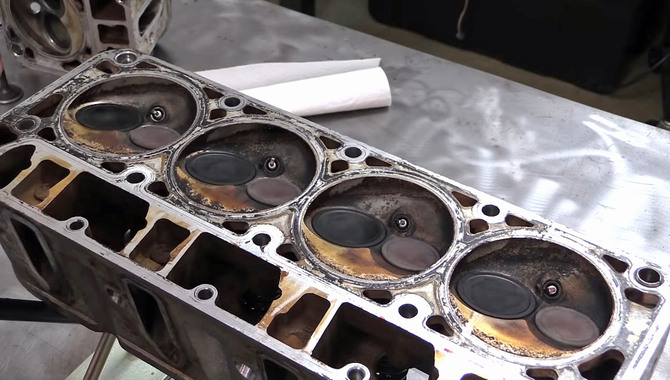

Inspect SBC Heads For Damage

Start by checking for cracks or warping on the cylinder head surface. If you find any damage, it is recommended to replace the head.

Additionally, check the valve springs for signs of wear or damage, as they are essential for the engine’s performance. Inspecting SBC (Small Block Chevy) heads for damage is an important step in maintaining the health of your engine. Here are a few steps to follow when inspecting SBC heads:

- Remove the heads from the engine and place them on a clean, flat surface.

- Inspect the combustion chamber for cracks or other signs of damage.

- Check the valve seats for wear or damage, and make sure they are properly aligned.

- Inspect the valves for wear or damage, and check that they move freely in their guides.

- Inspect the head gasket surface for signs of warping or damage.

- Check the rocker arm studs for signs of wear or damage.

- Finally, inspect the head bolts and ensure they are not stretched or damaged.

You can address any potential issues with your SBC heads before they cause bigger problems for your engine.

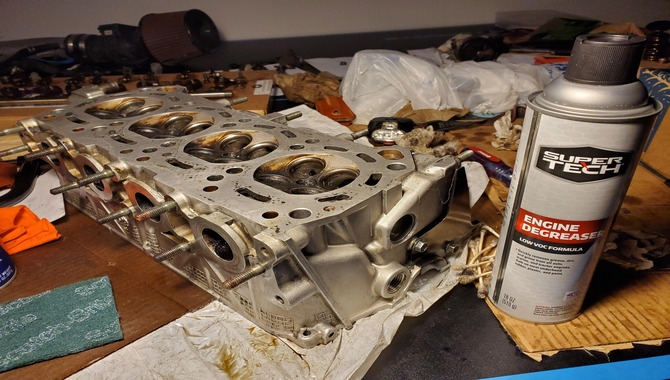

Clean SBC Heads Before Rebuilding

Remove all valves and springs to clean SBC (small block Chevy) heads before rebuilding. Use a wire brush and degreaser to clean the heads thoroughly, paying special attention to the combustion chambers and valve pockets. Clean any remaining debris with compressed air and check for cracks or other damage. Finally, apply a light coat of oil to the heads to prevent rusting.

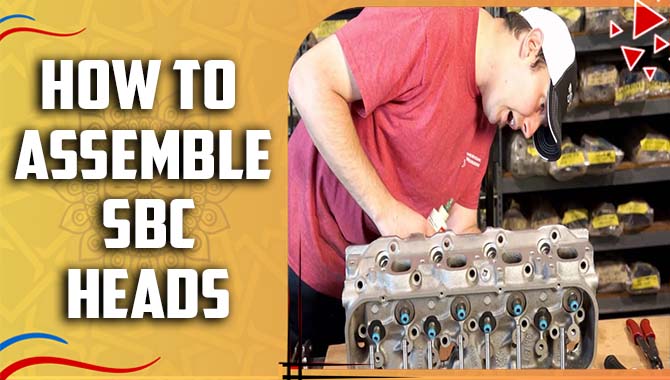

Reassemble SBC Heads

To reassemble SBC heads, thoroughly clean all components, and inspect for damage. Then, lubricate the valve stems and install new valve seals. Install the valves, springs, and retainers to specification in the correct order and torque.

Next, install the rocker arms and pushrods, ensuring they are properly aligned. Install the head gasket and carefully place the head back onto the engine block. Finally, torque the head bolts correctly and install the remaining components. Double-check all connections and fluid levels before starting the engine.

Disassemble SBC Heads

Remove the valve covers to disassemble SBC (Small Block Chevy) heads. Then, disconnect the rocker arms and pushrods. Next, remove the bolts that connect the cylinder head to the engine block.

Gently tap the head with a rubber mallet to loosen it. Lift the head off the engine, careful not to damage the gasket. Finally, remove the remaining components from the head, such as the valves, springs, and retainers. Clean all parts thoroughly before reassembly.

Reface Valves In SBC Heads

To reface valves in Small Block Chevy (SBC) heads, you will need specialized tools such as a valve grinder, a dial indicator, and a micrometre. First, remove the valves from the heads and clean them thoroughly. Then, set up the valve grinder and use it to grind the valve face to the correct angle and size.

Check the valve seat with a dial indicator and adjust it as necessary. Finally, measure the valve stem diameter with a micrometre and ensure it meets the manufacturer’s specifications. Repeat the process for all valves before reassembling the heads.

Replace Valves In SBC Heads

To replace valves in SBC (small block Chevy) heads, you must remove the heads from the engine block. Once you remove the heads, you can use a valve spring compressor tool to compress the valve spring and remove the keepers. This will allow you to replace the old valves with new ones. Replacing the valve seals while you have the heads off is also a good idea.

After installing the new valves and seals, use the valve spring compressor tool to compress the valve spring again and re-install the keepers. Finally, re-install the heads onto the engine block with new head gaskets and torque the bolts to the manufacturer’s specifications.

Recut Valve Seats In SBC Heads

Recutting valve seats in Small Block Chevy (SBC) heads can be done with a few steps. First, remove the valves and inspect the seats. Use a cutter to remove any damage or imperfections. Next, use a stone to create a smooth surface.

Check the seat width and depth and make any necessary adjustments. Finally, lap the valves to ensure a tight seal. Use proper safety equipment and follow instructions carefully for a successful outcome.

Torque SBC Head Bolts

To torque SBC (small block Chevy) head bolts, following a specific tightening sequence and using a torque wrench is recommended. First, tighten all bolts to half the recommended torque, then tighten them to the full recommended torque in three stages.

Always use a high-quality torque wrench and lubricate the threads and washers with engine oil before installation. Remember to follow the manufacturer’s specifications for the specific engine model and type. Properly torquing head bolts helps ensure a secure seal and prevents leaks or engine damage.

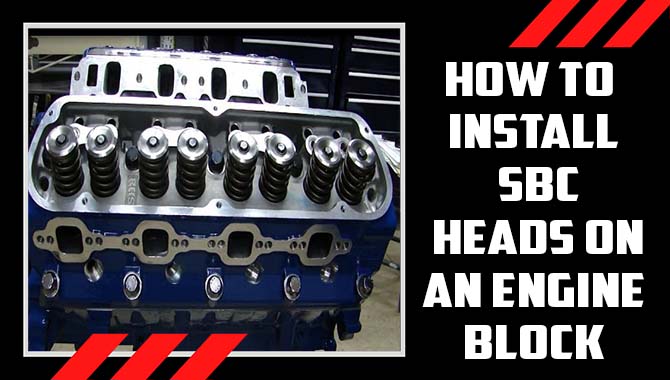

Install SBC Heads Onto The Engine Block

To install SBC (Small Block Chevy) heads onto the engine block, start by cleaning all parts thoroughly. Then, apply a sealant to the head bolts and insert them into their respective holes. Torque the bolts in the recommended sequence and to the recommended specifications.

Next, install the pushrods, rocker arms, and valve covers. Finally, adjust the valve lash and perform a leak-down test to ensure proper installation. Always refer to the manufacturer’s instructions and specifications for the specific SBC heads and engine block you are working with.

Properly Break In Rebuilt SBC Heads

To properly break in rebuilt SBC (small-block Chevy) heads, start the engine and let it run for 20 minutes at varying RPMs. Then, change the oil and filter to remove any metal shavings. Drive the car for the next 500 miles at varying speeds and RPMs, avoiding prolonged idling or high RPMs.

After 500 miles, change the oil and filter again. It’s important to gradually increase the load on the engine during this break-in period to ensure proper seating of the valves and rings.

Common Mistakes To Avoid When Rebuilding SBC Heads

When rebuilding SBC (Small Block Chevy) heads, it is important to avoid several common mistakes. First, it’s important to thoroughly clean and inspect all parts to ensure they are in good condition before proceeding with the rebuild.

Using incorrect torque specifications or improper torquing bolts can also lead to leaks or other issues. Another mistake is not properly seating the valves, which can cause poor engine performance. Finally, not following the manufacturer’s guidelines or using defective parts can also lead to problems. Avoiding these common mistakes can ensure a successful SBC head rebuild.

When To Seek Professional Help With Rebuilding SBC Heads

Professional help rebuilding SBC heads should be sought if signs of damage or wear cannot be resolved with basic maintenance. This includes cracked or warped heads, damaged valves or guides, or worn-out seats.

Additionally, if the engine is experiencing performance problems that cannot be resolved through other means, it may be necessary to seek professional help to rebuild the SBC heads.

Choosing a reputable mechanic or engine builder with experience in rebuilding SBC heads is important to ensure the job is done correctly and avoid further engine damage.

Conclusion

Rebuilding the cylinder heads involves a detailed inspection, cleaning, machining, and reassembly process to restore the heads to their optimal condition. The importance of rebuilding SBC heads lies in maximizing engine efficiency, improving power output, and ensuring long-term reliability.

By addressing issues such as worn valve seats, damaged valves, and warped surfaces, the rebuild process allows for better sealing, improved airflow, and enhanced combustion.

Specificity in rebuilding SBC heads ensures that each component is properly evaluated and restored, leading to a precision-built cylinder head assembly. With the knowledge and skills to rebuild SBC heads, individuals can take control of their engine’s performance, customize its characteristics, and enjoy the benefits of a well-tuned powerplant.

Knowing how to rebuild SBC heads empowers enthusiasts to optimize their engine’s potential and achieve the desired results on the road or track, whether for a high-performance build or a classic restoration project.

Faq’s:

1.Why Would I Need To Rebuild An SBC Head?

Ans: You may need to rebuild an SBC head if you experience low compression, oil leaks, or overheating issues.

2.Can I Rebuild An SBC Head Myself?

Ans: It is possible to rebuild a Small Block Chevy (SBC) head yourself, but it requires a certain level of knowledge, skill, and access to appropriate tools and equipment.

3.How Do I Know If My SBC Head Needs To Be Machined?

Ans: It must be machined if the head is cracked, warped, or has damaged valve seats.

4.How Long Does It Take To Rebuild An SBC Head?

Ans: The time it takes to rebuild an SBC head can vary depending on the damage’s extent and the parts’ availability, but it typically takes a few days to a week.

5.Can I Use Aftermarket Parts When Rebuilding An SBC Head?

Ans: Many aftermarket parts are available for rebuilding an SBC head, but choosing high-quality parts from reputable manufacturers is important.