Thinking of installing ARP head bolts for your SBC? If this is the case, then we would say you have made a great choice because these head bolts do their job great.

Generally, ARP stands for Automotive Racing Products, handling the business of creating ultra-strong fasteners for your car engine. The ARP head bolts are one of the fasteners.

It plays a very vital role in increasing the speed of your car. Just having a basic concept on this will not help you enough with it. You need to understand it properly by knowing each information regarding it. So, what are the SBC ARP head bolt torque specs?

That is why we are here, and we are going to explain to you in detail about the SBC ARP head bolt specs such as, what it is, what it’s made of, its overall performance.

What Is SBC ARP Head Bolts?

Well, as mentioned before, ARP including products that are used as fasteners. SBC stands for Small Block Chevy, it is an engine, and we should remember that different engines require different cylinder head bolts.

For example, you can also use aluminum cylinder heads for the SBC engine or ARP head bolts. Both are good, but you have to choose in between them anyway.

The basic job of ARP heads to make your engine faster by producing a great amount of power. Also, it can make a good torque (this time, by the torque, we mean the power produced in the engine for twisting.

It gives you a perfect experience of driving a racing car. Moreover, the ARP fasteners are bulletproof, and you can use them for high-performance machines.

Why Are ARP Head Bolts Better?

The reason behind them being considered as better head bolts is the ‘quality. Both of the used materials for the production of different fasteners by ARP are of high quality.

They are produced in the U.S. Besides, and ARP always chooses top-shelf materials. For example, one of the most ever-popular is 8740 chrome-moly steel used to make ARP fastener products.

The product still is made in four varieties of grades. The lower two grades are called aircraft and commercial, while the top two graded stills are CHQ and SDF, which the ARP uses.

The grades are expensive enough, and that’s why they cost almost two times the usual price. No doubt is left about why the ARP has the reputation of providing products that are of zero defect.

There is a difference in the quality of 8740 stills, and as ARP guarantees you high quality, its fasteners will cost you more than other brands such as Brand X fasteners.

What Are ARP Bolts Made Of?

The ARP fasteners are generally made in ten different grades, from the famous 8740 chrome moly to ultra-high-strength chromium-cobalt-nickel grades, like Custom Age 625+.

Also, stainless steel and titanium are used. Though depending on your spending and application, they choose the quality. But commonly used stills are ARP2000 and 8740 chrome-moly.

ARP2000 is a temper still also graded as a heavy martensitic quench. It stays stable at a very high temperature, and its properties let it get tempered to a higher Rockwell.

Besides, like the 4340 and 8740, it does not become brittle. The strength of APR200 is between 200,000 and 220,000 psi, and it’s from the 8740 upgrades.

Moreover, the ARP has stopped using 4340 because 8740 is superior to it. Another commonly used material by ARP is stainless steel.

It is also considered perfect for automotive applications as well as marine. It looks nice and will not get affected by corroding or rust.

ARP uses “Stainless 300,” which is used especially for its durability, and its tensile strength is rated between 170,000 to 190,000 psi. The “Custom 450” has the exact tensile strength, but this has a higher yield strength.

Are SBC ARP Head Bolts Torque To Yield?

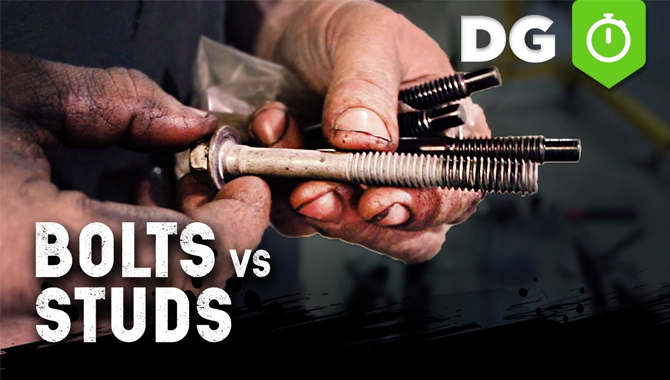

Well, torque to yield (TTY) fasteners usually strength when they are being torqued, which happens for the material’s elastic properties.

It gives them the required clamping force, but the sad part You cannot reuse them. But the ARP fasteners are different, and they are made in a way that you can reuse them as many times as possible.

The Installation Process Of ARP Head Bolts For SBC

Follow the instructions mentioned below to install the ARP head bolts for your SBC engine with ease;

- Dissemble the rods to clean them properly and separate rust preventative.

- Under each of the head bolts and threads, apply ARP moly lube.

- Set up the rods to the piston. You must show the notches of the rods to the engine intake due to the crankshaft rotation direction.

- Bring the beam and cap into alignment for installing the rods. Before you Install, the bolts don’t forget to tap into place (note that you should not use the bolts for pulling caps into position).

Ensure you have numbered each rod and assembled them with the exact number on the beam and cap.

SBC ARP Head Bolt Torque Specs

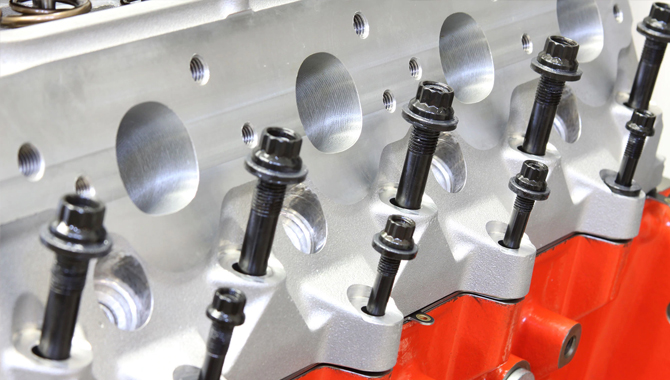

There is a good reason why the ARP hardware is Installed in high-end rods because of the high quality.

Now you may spend 1,500 dollars in purchasing a new forged crank, 700 dollars for forged aluminum slugs, and 800 dollars to purchase some sweet H-beam rods.

All these together can make one fastener that will fail anyway, and the purchased part might end up as metal leftovers.

But if you go for the ARP, $400 head bolts set, it will surely protect all the other parts you spend money on and thus serve you as insurance.

Other common brands ARP, is more expensive, but that’s because their used materials are also expensive, and you don’t have to change the head bolts often either. Hence, we can say for sure that SBC ARP head torque is worth it.

Conclusion

Hopefully, we have delivered the proper answers to you. You can now compare the ARP head bolt torque for SBC to other head bolt torques.

If this will be your first-time head bolt shopping, you should not be confused and try to buy from a brand.

Before leaving, we would feel happy to share one little good advice; it’s better to purchase from a well-known brand ignoring the expensiveness because quality matters. I hope now you know about SBC ARP head bolt torque specs.