Air compressors are powerful tools that have the ability to drive a variety of pneumatic tools, including impact wrenches. These wrenches are used in a wide range of applications, from automotive repair to construction and manufacturing.

Impact wrenches are designed to deliver high torque, making them an essential tool for professionals and DIY enthusiasts. We’ll learn How to use an air compressor for powering impact wrenches. However, many people are unsure how to use an air compressor to power their impact wrench.

In this blog post, we will explore the key steps of using an air compressor to power an impact wrench effectively. We will cover the basics of air compressor operation, including understanding pressure and volume requirements for different impact wrenches.

We will also look at the different types of air compressors available and the features to consider when choosing the right one for your needs. Additionally, we will provide tips on maintaining your air compressor and impact wrench. Ensuring they remain in excellent condition for years to come.

Understanding Air Compressor Output And Impact Wrench Requirements

Understanding air compressor output and impact wrench requirements is essential for anyone working with power tools, especially mechanics and DIY enthusiasts. The output of an air compressor is measured in cubic feet per minute (CFM), which represents the amount of air it can deliver at a given pressure.

This is important because different tools require different levels of CFM to operate effectively. For example, an impact wrench typically requires 5-7 CFM to work properly. If your compressor can’t deliver the necessary CFM, the impact wrench won’t be able to produce the torque you need to loosen or tighten bolts.

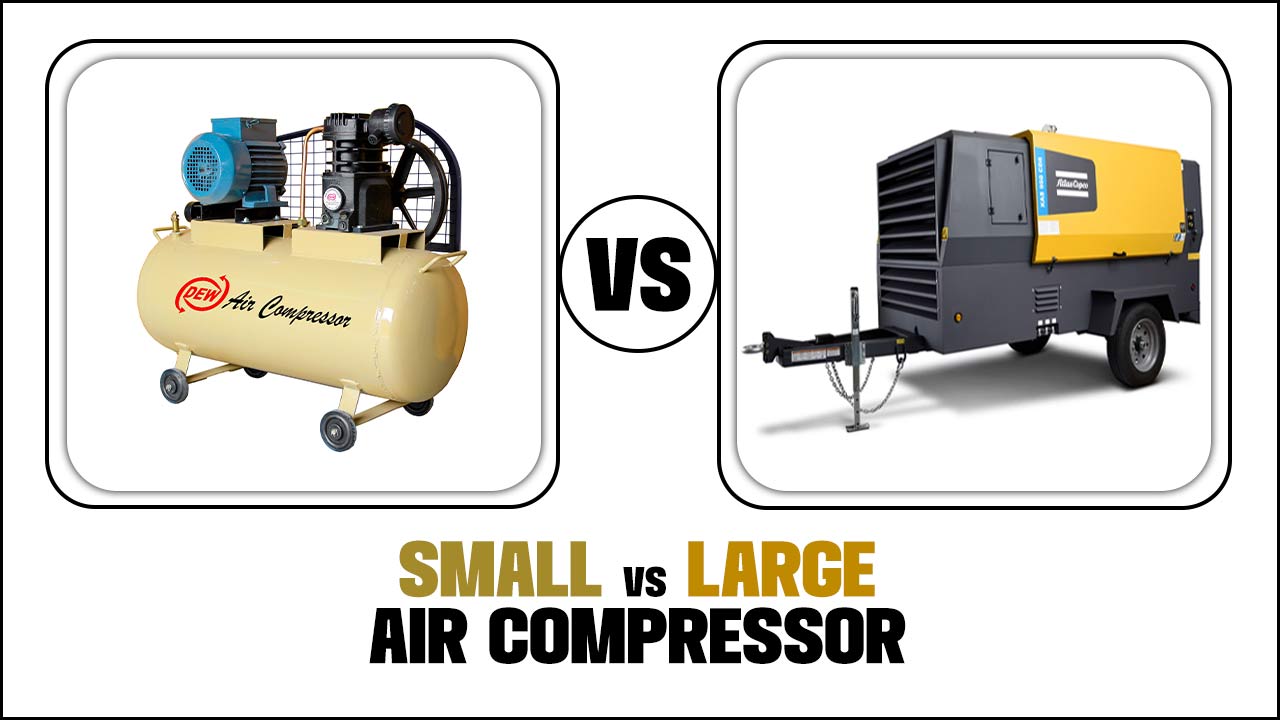

To ensure the right level of CFM, you need to consider the size of your compressor’s tank and horsepower. Generally, the larger the tank and higher the horsepower, the greater the CFM output. However, it’s important to strike a balance between power and portability based on your needs.

How To Use An Air Compressor For Powering Impact Wrenches – Explained With Details

If you’re looking to use an air compressor for powering impact wrenches, there are a few things you need to know. First, you must ensure you have the appropriate size air compressor for the task. The larger the impact wrench, the larger the compressor you will need. Additionally, you’ll want to ensure you have the right fittings and hoses to connect the compressor to the impact wrench.

Once you have everything set up, it’s important to properly adjust the air pressure and flow rate to ensure optimal performance of the impact wrench. Too little pressure and the wrench won’t have enough power, while too much pressure can cause damage to both the wrench and the compressor.

When using the impact wrench, keeping safety in mind is important. Always wear eye and ear protection, as the noise and debris from the wrench can be hazardous. Additionally, ensure the work area is clear of any obstructions or hazards.

1. Selecting The Right Air Compressor For Your Impact Wrench

When it comes to using an impact wrench, selecting the right air compressor is essential to ensure optimal performance. The air compressor is responsible for providing the power to operate the impact wrench, so choosing a powerful compressor to meet your needs is important.

Firstly, consider the size of your impact wrench. Smaller impact wrenches typically require lower CFM (cubic feet per minute) and PSI (pounds per square inch) ratings, while larger wrenches require higher ratings. Additionally, consider the frequency of use and the air tank size.

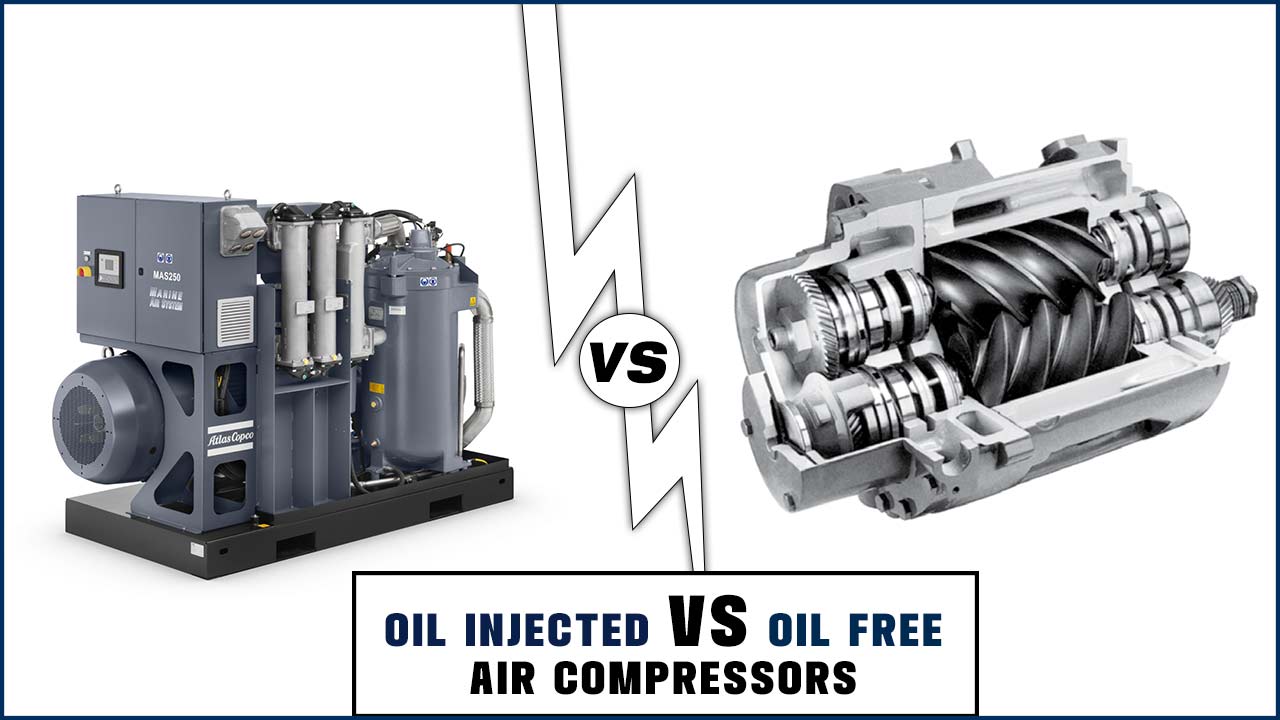

If you use the impact wrench frequently and for prolonged periods, you’ll need a larger air tank to provide a continuous air supply. A compressor with a higher CFM rating will also help to maintain the air pressure and prevent the tank from emptying too quickly. It’s also important to consider the noise level of the compressor. Especially if you plan on using it in a residential area. Choosing an oil-free compressor can help.

2. Setting Up Your Air Compressor And Impact Wrench

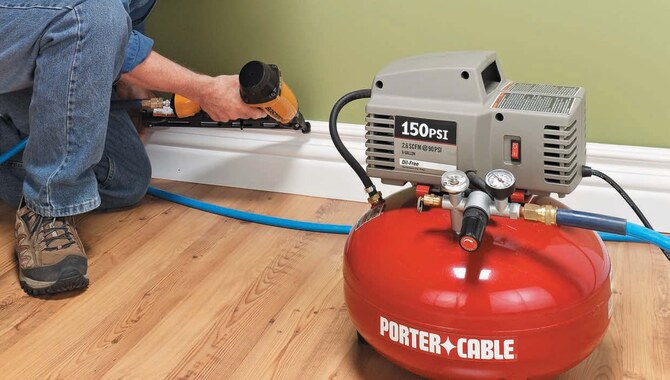

Setting up your air compressor and impact wrench can seem overwhelming, but with a few simple steps, you’ll be ready to tackle any job. First, ensure your air compressor is in a well-ventilated area, away from flammable materials. Next, ensure all hoses and connections are secure and free of leaks.

Once your compressor is set up and running, it’s time to connect your impact wrench. Look for the air inlet on the bottom of the wrench and attach the air hose to it. Make sure the connection is tight and secure. Now, you’ll need to adjust the air pressure to the appropriate level for your specific wrench.

Check the manufacturer’s instructions for the correct pressure range. Once you’ve set the pressure, turn on your compressor and let it build up to the desired level. With your impact wrench connected and the air pressure set, you’re ready to start using it. Remember always to wear proper safety gear, including eye protection and gloves.

3. Maintaining Your Air Compressor And Impact Wrench

Maintaining your air compressor and impact wrench is crucial to ensure they work efficiently and effectively. Regular maintenance and cleaning can help prolong your equipment’s life and prevent breakdowns. One important step in maintaining your air compressor is to check the oil level and change it regularly.

Dirty or low oil levels can cause damage to the compressor’s internal components and reduce its overall performance. Additionally, it is important to clean or replace the air filter to prevent dust and debris from entering the air compressor and causing damage.

When it comes to your impact wrench, keeping it clean and lubricated is essential. This involves wiping down the tool after each use and applying a few drops of oil to the air inlet before each use. It is also important to regularly check the impact wrench’s torque and adjust it as needed. Failure to maintain your air compressor and impact wrench can lead to costly repairs and replacements in the long run.

4. Troubleshooting Common Problems With Air Compressors And Impact Wrenches

Air compressors and impact wrenches are essential for many professionals, from mechanics to construction workers. However, as with any piece of equipment, they can experience common problems that require troubleshooting.

One of the most common issues with air compressors is leaking air. Which a damaged or worn-out valve or gasket can cause. Another issue that can arise is low air pressure, which may be due to a clogged air filter or a malfunctioning pressure switch.

A common problem with impact wrenches is the lack of torque, which worn-out or damaged impact sockets may cause. Another issue can be the inability to turn on the wrench, which may be due to a malfunctioning power switch or a dead battery.

Troubleshooting these common problems with air compressors and impact wrenches is essential for maintaining efficiency and prolonging the lifespan. Regular maintenance, such as cleaning and lubricating the equipment, can also prevent these problems from occurring.

5. Using Your Air Compressor And Impact Wrench Safely

Using your air compressor and impact wrench safely is crucial for preventing accidents and injuries in the workplace. Before using these tools, it’s important to read the manufacturer’s instructions and become familiar with the machine’s specifications. Always wear proper safety gear, including eye and ear protection, gloves, and sturdy shoes.

When using an air compressor, ensure the power source is grounded and the unit is properly maintained. Check the hoses and fittings for any signs of wear or damage and replace them if necessary. When using an impact wrench, be aware of the torque and speed settings and adjust them for the task at hand.

Never exceed the recommended settings, as this can cause damage to the tool and create a safety hazard. Always use the correct socket size to avoid slippage and ensure the proper fit. Never use an impact wrench on a fastener that is already loose or overtightened. Always ensure the work area is clean and debris-free to avoid tripping hazards.

6. Tips And Tricks For Maximizing The Power Of Your Air Compressor And Impact Wrench

If you’re looking for tips and tricks to maximize the power of your air compressor and impact wrench, you can do a few things to get the most out of these powerful tools. First, make sure to properly maintain your air compressor by regularly checking the oil levels and cleaning or replacing the air filter as needed.

This will help ensure that your compressor is running efficiently and that you’re getting the maximum amount of air pressure possible. Next, when using your impact wrench, use the right size socket to prevent stripping or damaging the bolts.

Additionally, make sure to adjust the air pressure on your compressor to match the recommended pressure for your impact wrench. This will help prevent damage to the wrench and ensure it works at its maximum capacity. Finally, when using your impact wrench, try to use short bursts of power instead of continuous pressure, as this will help prevent overheating and extend the life of your tool.

Conclusion

Utilizing an air compressor to power an impact wrench is essential for any professional or DIY mechanic. Understanding the importance of the compressor’s CFM and PSI ratings and the size of the hose and fittings are crucial to achieving maximum efficiency and performance.

Proper maintenance and safety precautions should also be considered to prevent any accidents or damage to the equipment. We hope you now understand How to use an air compressor for powering impact wrenches. Overall, mastering using an air compressor for powering impact wrenches can greatly enhance the productivity and quality of any mechanical task.

Frequently Asked Questions

1.What size air compressor is needed to power an impact wrench?

Ans: The size of air compressor needed to power an impact wrench depends on the specifications of the wrench. Generally, a small to medium-sized compressor with a minimum of 4-5 CFM at 90 PSI is sufficient for most impact wrenches.

2.How do I adjust the air pressure on my compressor for use with an impact wrench?

Ans:

- Turn off the compressor and unplug it from the power source.

- Locate the pressure regulator knob on the compressor. It is usually located on the front or top of the unit.

- Turn the knob clockwise to increase the pressure or counterclockwise to decrease the pressure.

- Plug in the compressor and turn it on.

3.Can I use an extension cord with my air compressor when powering an impact wrench?

Ans: It depends on the power requirements of your air compressor and impact wrench, as well as the capacity of the extension cord. If the extension cord is of sufficient gauge and capacity to handle the power needs and is used properly and safely, then it may be possible to use it with your air compressor and impact wrench.

4.What type of oil should I use in my air compressor when using it to power an impact wrench?

Ans: When using an air compressor to power an impact wrench, it is recommended to use an air compressor oil that is specifically designed for high-pressure applications, such as a synthetic compressor oil or a non-detergent mineral oil.

5.What type of fittings do I need to connect my impact wrench to my air compressor?

Ans: You will need a male quick-connect fitting to attach to the impact wrench and a female quick-connect fitting to attach to the air compressor hose.