Air compressors are a must-have tool for many businesses and DIY enthusiasts. However, transporting these heavy and bulky machines can be daunting, especially if you don’t know how to do it properly.

In this blog post, we will guide you through the steps on how to transport an air compressor safely whether you are moving it to a different job site or storing it in your garage. It’s important to take the necessary precautions to ensure your equipment remains in good condition.

Transporting an air compressor may seem simple, but it requires careful planning and preparation. This includes selecting the right vehicle and equipment for the job and securing the compressor properly. And knowing how to load and unload it safely. We will cover all the essential steps you need to take to ensure that your air compressor arrives at its destination intact and ready to use.

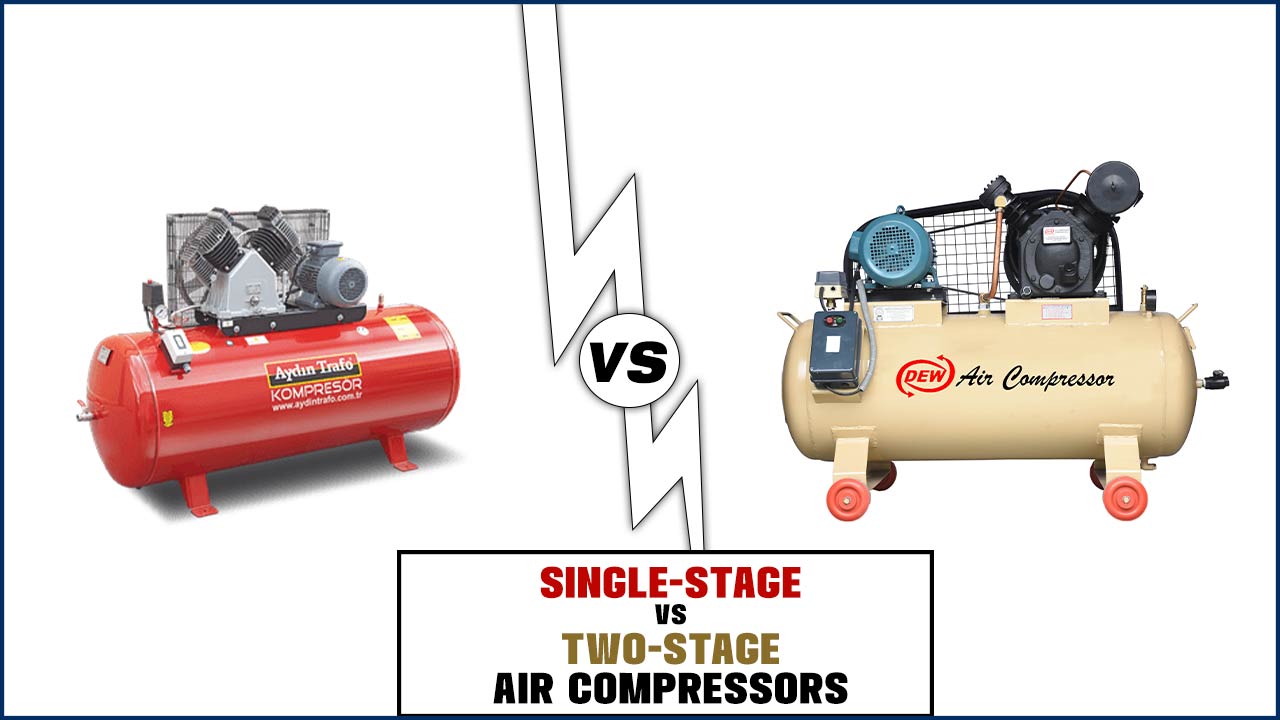

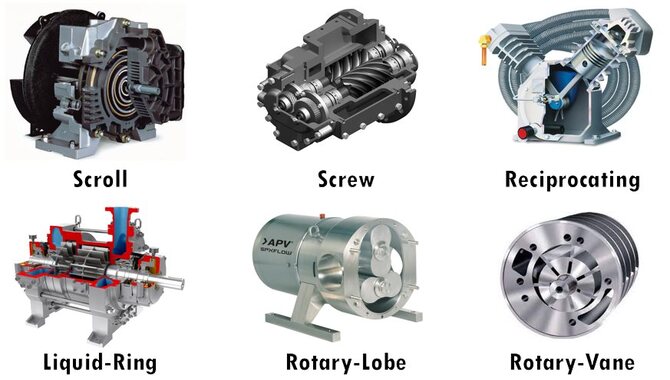

Types Of Air Compressors

Air compressors widely use in various industries and applications, from power tools and machinery to inflating tires and balloons. Different types of air compressors are available, each with unique characteristics and capabilities.

One of the most common types is the reciprocating air compressor, which uses a piston and cylinder to compress air. Reciprocating air compressors know for their versatility and can use for low- and high-pressure applications.

Another type of air compressor is the rotary screw compressor, which uses twin screws to compress air. Rotary screw compressors know for their efficiency. And often use in industrial applications that require a consistent and reliable air supply.

Apart from these, there are also centrifugal compressors, which use high-speed rotating impellers to compress air. These compressors commonly use in large-scale industrial applications and can produce a significant amount of compressed air.

How To Transport An Air Compressor Safely – By Following The Below Steps

Transporting an air compressor may seem like a daunting task, but with proper preparation and safety measures, it can do easily and effectively. Ensure that you properly secure the air compressor when transporting it.

This can do using straps or ropes to secure the compressor to a truck or trailer bed. Ensuring that the compressor cannot move around during transport is important as this can cause damage to the equipment or result in accidents.

In addition to securing the compressor, it is important to consider the weight of the equipment. Air compressors can be very heavy. So it is important to ensure that the vehicle used for transport can handle the weight. Using a larger vehicle or renting a truck or trailer to transport heavy equipment may be necessary. Here we give you a step-by-step guideline on How to transport an air compressor safely.

Safety Considerations For Air Compressors

When it comes to using air compressors, safety considerations should always be a top priority. One of the most important safety considerations is proper maintenance and inspection of the air compressor before use. This includes checking for leaks, ensuring that all hoses and connections are secure, and examining the tank for signs of corrosion or damage.

It is also important to follow proper operating procedures and safety instructions provided by the manufacturer. This may include wearing appropriate protective equipment, such as safety glasses. Or hearing protection and ensuring the compressor ground and all electrical connections are secure.

Another critical safety consideration for air compressors is the potential for compressed air to cause injury. Compressed air can cause serious harm if directed at the skin, eyes, or other body parts. Therefore, it is important to never point the air compressor nozzle at yourself or others and always to direct the airflow away from your body and other people.

Preparing The Air Compressor For Transport

Transporting an air compressor can be challenging, especially if you do not know how to prepare it. Proper preparation is essential to ensure the air compressor remains in good condition and functions optimally after transport. Before transporting your air compressor, it is essential to turn it off and unplug it from the power source.

Next, drain the air tank to remove any moisture or debris that may have accumulated inside it during use. This can do by opening the valve at the bottom of the tank and allowing all the air to escape. Be sure to open the tank’s drain valve slowly to avoid damaging the tank or other parts.

After draining the air tank, you should remove any attachments or accessories connected to the compressor. These may include hoses, regulators, and filters. Ensure that these items are securely packed and labelled for easy identification and reassembly when you arrive at your destination.

Choosing The Right Vehicle For Transport

Choosing the right vehicle for transport can be daunting, especially if you’re unsure what you need. There are many factors to consider, such as the type of goods or materials you need to transport, the distance you’ll be traveling, and the terrain you’ll be covering.

For shorter distances or urban areas, a smaller vehicle such as a hatchback or small van may suffice, while for longer distances or rural areas, a larger vehicle such as a truck or SUV may be more appropriate. Another important consideration is the capacity of the vehicle.

If you need to transport large or heavy items, you’ll need a vehicle with a high payload capacity. Similarly, if you need to transport many goods, you’ll need a vehicle with ample storage space. It’s also important to consider the vehicle’s fuel efficiency, which can significantly impact transport costs.

Loading And Securing The Air Compressor

When loading and securing an air compressor, there are a few key steps to ensure that it does safely and effectively. First, ensuring that the air compressor properly store and secured before loading it onto a vehicle is important.

This may involve using straps or other forms of tie-downs to prevent the compressor from shifting or moving during transport. Once the compressor properly secures, it can load onto the vehicle using a forklift, crane, or other lifting equipment. It is important to ensure that the compressor properly balances and centered during loading to prevent damage to the unit or the vehicle.

Once the compressor loads onto the vehicle, it should again secure using straps or other tie-downs to prevent movement during transport. Finally, it is important to ensure that the compressor properly labels and marked with information about its weight, size, and any other relevant details to ensure that it transport safely and legally.

Transporting The Air Compressor Safely

Transporting an air compressor safely is crucial to ensuring that it remains in good working condition and doesn’t cause any harm to individuals or property during transit. Proper preparation is key to successful transport.

First, ensure that the air compressor is fully drained of any air or gas, as this will help prevent any accidental discharge or pressure buildup during transport. Next, ensure the compressor is securely fastened or tied down to prevent it from shifting or falling over during transit.

Use appropriate strapping, ties, or chains to secure the compressor to the transport vehicle or container. Protecting the compressor from any external elements such as dust, moisture, or extreme temperatures is also important.

Cover the compressor with a protective material such as tarpaulin, bubble wrap, or plastic sheeting to minimize the risk of damage. Lastly, it’s important to have clear communication with the transport team regarding the air compressor’s specific requirements and any potential hazards that may arise during transport.

Unloading The Air Compressor

Unloading the air compressor is an important step in the maintenance and operation of the equipment. The process involves releasing the pressure that has built up inside the compressor tank after use. This does prevent any potential hazards while performing any maintenance or repairs on the equipment.

The first step in unloading the air compressor is to turn off the power supply to the machine. This is important to ensure no accidental start-up occurs during the unloading process. Next, the pressure switch on the compressor should turn off, and the air valve opened to release any remaining compressed air.

Air release should be done slowly to prevent any sudden and dangerous release of pressure. Once all the air has been released, the drain valve should be opened to remove any accumulated moisture or condensation in the tank. This helps to prevent corrosion and other damage to the compressor tank. Finally, the compressor should be thoroughly cleaned and inspected for any signs of wear or damage.

Maintenance And Inspection After Transport

Maintenance and inspection after transport are crucial to ensure the safety and efficient operation of any machinery or equipment. After being transported, machines may have undergone various stressors such as vibrations, temperature fluctuations, and even mishandling.

As such, it is essential to conduct a thorough inspection to identify any potential damage that may have occurred during transportation. The inspection should begin with an examination of the exterior of the equipment to check for any visible damages, such as scratches or dents.

Moving on to the interior, all critical components, such as the engine, transmission, and hydraulic systems, should be inspected for any leaks, cracks, or signs of wear and tear. Once the inspection is complete, any repairs or maintenance should correct any identified defects.

This may include replacing damaged parts, adjusting belts and hoses, and checking fluid levels. Additionally, it is important to carry out routine maintenance such as changing the oil and filters, lubricating moving parts, and checking tire pressure.

Troubleshooting Transport Issues

Troubleshooting transport issues can be a daunting task, especially when it comes to logistics and transportation. Various factors, such as unexpected delays, traffic congestion, and mechanical problems, can affect the smooth transport flow.

To minimize these issues, it is important to identify the root cause of the problem and take appropriate measures to prevent it from happening again. A good starting point is to establish clear communication channels with all stakeholders involved in the transportation process, including drivers, dispatchers, and customers.

This can help ensure everyone is on the same page and aware of potential issues. A reliable tracking system can provide real-time updates and quick response times to unexpected incidents. Regular maintenance and inspections of transport vehicles and equipment can also go a long way in preventing mechanical issues.

Overall, troubleshooting transport issues requires a proactive approach and a willingness to adapt and improve processes to ensure the transport system runs as smoothly and efficiently as possible.

Conclusion

Transporting an air compressor safely requires careful planning and adherence to safety protocols. Ensuring the compressor is properly secured and all components, including the hose and electrical cords, properly stowed away is important.

Additionally, following the manufacturer’s instructions regarding the weight limit and proper compressor handling is crucial. Individuals can transport their air compressors safely and with minimal risk of damage or injury by taking these steps.

It is imperative that individuals prioritize safety when handling heavy equipment, such as air compressors, to prevent accidents and ensure a successful and efficient transportation process. We’ve discussed How to transport an air compressor safely.

Frequently Asked Questions

1.What Safety Measures Should Take While Transporting An Air Compressor?

Ans: Some safety measures that should take while transporting an air compressor are:

- Switch off and unplug the air compressor before transporting it.

- Secure the air compressor using straps or chains to prevent it from moving during transportation.

- Use appropriate lifting equipment, such as a forklift or crane, to lift and move the air compressor.

2.What Is The Ideal Way To Secure An Air Compressor During Transportation?

Ans: The ideal way to secure an air compressor during transportation is to use straps or chains to anchor it to the vehicle floor or wall and to use padding or cushioning to prevent damage from vibration or impact.

3.What Are Some Important Safety Precautions To Take When Transporting An Air Compressor?

Ans: Some important safety precautions to take when transporting an air compressor include.

- Secure the compressor

- Disconnect the power source

- Drain the tank

- Check the oil level

- Use proper lifting techniques

4.Is It Necessary To Drain The Air Compressor Before Transporting It?

Ans: Draining the air compressor before transporting it is necessary to prevent any damage or accidents during the transportation process.

5.What Kind Of Vehicle Is Best Suited For Transporting An Air Compressor?

Ans: A pickup truck or a cargo van with a large, open cargo area would be the best vehicle for transporting an air compressor.