Do you know that you can’t choose the size of the wire gauge by yourself for a 220v air compressor? Not only for 220v, but different amperages also require different sized wires.

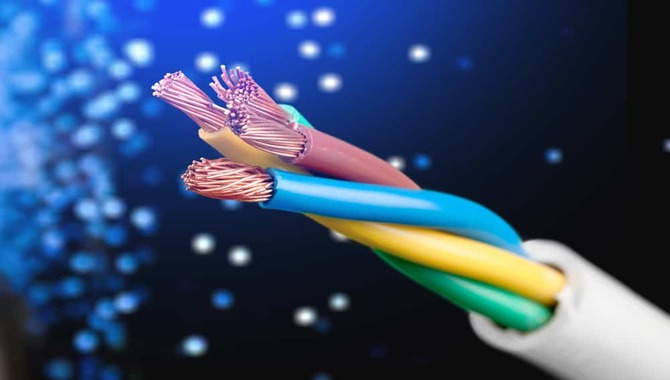

It’s because “the electricity movement depends on space inside of the wire. More space in a wire means more space for electrons to move. Thin wires have less resistance than thick wires. The relationship between the space inside of the wire and resistance is inversely proportional”.

The thinner the wire, the hotter its inside gets. You may have got a little idea of why it’s important to know which size wire for which voltage; there are other important factors you must know about for keeping you and your family safe from sudden accidents electricity might cause. So, what size wire for 220v air compressor?

Let us inform you everything regarding the importance of wire size, along with which size wire you need for your 220v air compressor. Therefore let’s jump right onto the facts wasting no more of your valuable time.

Does Diameter Of The Wire Affect Electricity Flow?

Sad but true, the diameter of electric wires does have impacts on the movements of the electrons. That’s why a 15 amperage current requires the smallest wire size.

And a 95 amperage current requires the largest-sized common wire. The fact here is the movements of electrons. Through a small size, wire electrons take a longer time to move.

However, inside the larger diameter, electrons can move freely and fast. The right flow of electrons ensures safe electricity. Let us make you understand this more easily.

It’s like you want to make a road for ten cars to go easily side by side, but you have sized the road in a way that only four cars can pass freely.

As thousands of electrons flow together, they need a lot of space to go with the same flow and want to reach destiny together at the same time.

What If You Want To Use A Small Size Wire For 220V Air Compressor?

If your home has an outlet that is wired with 15 amp wire, and you want to plug in an appliance of 20 amp, you are putting pressure on your wiring for delivering more current than it can supply.

If this happens, your electrical wire will get too hot and affected. To stop the cause of further danger, the circuit breaker will trip and knock off the electricity flow through the circuit.

This way, the breaker protects affected electrical wires. Even if you add a new circuit breaker with higher capacity, the small size wire will raise the risk of setting fire in your home.

Because no matter how high capacity circuit breaker you use, it can control the overloaded electrical power the wire will produce.

Do Larger Diameter Wires Cause Any Electrical Issue?

Here is a fun fact, you may get the exact rated wire for your demanded amperage, yet if you decide to use larger than the required one, you help lessen energy loss.

The same current load can make a small wire get too hot and relieve much energy. But the same current load in a larger wire produces less heat and thus relief less energy.

Let us give you an example. When a 100 feet and 12 gauge wire deliver 15 amps of current, it loses energy around 77 watts.

With the same length, a ten gauge wire loses energy around 48 watts while delivering 15 amps. Take one tip from us if you want to lower the overall energy cost.

“Always use a little larger size wire from the recommended one and save more energy.” There is never any danger using large-sized electrical wires, and rather it will provide you some additional benefits.

What Benefits Do Bigger Wires Provide?

AWG wire with a larger gauge ensures the flexibility of electrons flows no matter the electric system. Larger wires can increase the current potential, which allows you to add more outlets.

In risky areas, electricians Install larger wires because small-sized wires increase the chance of accidental risks.

If you first use large wiring, you don’t have to install more wire when you want to upgrade the home’s wiring.

Save yourself from the future headache of wall ripping out for wiring upgrades, and Install the large upgrade now. Large wires also work as insurance for the electrical devices when the voltage drops.

It will save your devices from the hampers caused by voltage drops and highs. There’s a way you can understand if your wiring is inadequate for the electricity flow.

Check if your fuses blow often or your toaster becomes slow. It means the wiring you already have is not delivering the right amount of current and is inadequate.

Therefore, now is the time to hire an electrician and Install the larger diameter wires for energy efficiency, further electrical expandability, and home safety.

Wire Size For 220v Air Compressor

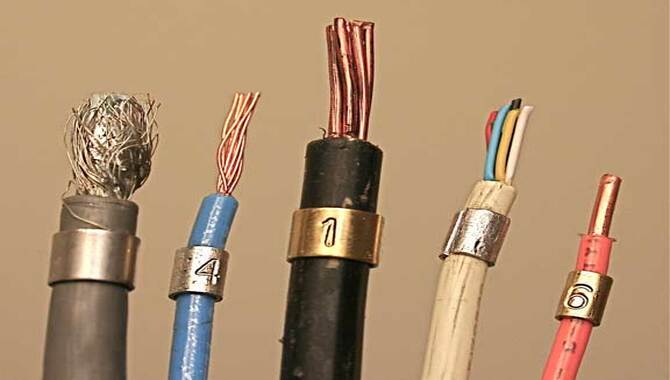

Well, it depends on the amperage. Usually, people use a six gauge wire for a 220v air compressor, but it actually will put you at risk. Because the wire size is not big enough, and it can cause the electrons to move slow.

Moreover, it will create a lot more hits and will often blow a fuse. That’s why keeping the wire cool and getting the right electron flow inside the wire use a 12 gauge wire instead.

This way you can save a lot of energy too which will reduce the energy costs. If you have decided to use a 220v air compressor, get a 12 gauge wire for its good performance and safety.

What Size Wire For 220v Air Compressor?

If you are thinking of saving more money by not hiring an electrician and want to wire a 220v air compressor by yourself, you can do it by following the steps we mentioned below.

First Step – Placing The Compressor

Place your compressor in a way that the compressor and circuit breaker are close to each other so that accessing them at any time is easy. With the help of lag bolts and anchors, bolt it to the floor.

Second Step – Shutting Off The Main Circuit Breaker

Remove the fuse box’s cover to install a circuit breaker of 220 volts and 30 amp for the compressor. Run three conductor wires of 12 gauge in the box.

Make a connection between circuit breaker terminals and the black and red wires. Connect white wire and bare copper wire to the ground bus if there are two ground busses.

Third Step – Securing The 12 Gauge Wire To The Wall

Run the wire to a junction box placed near the compressor according to the local codes. The wire connection from the box to the air compressor should be made with a 12/3 adjustable power cord.

Connect a wire length from the junction box to the air compressor switch box. Then again, connect the circuit breaker box wire. Now connect the two types of wire with the help of big wire nuts.

Fourth Step – Removing The Compressor Cover

Switch box and then make the 12/3 power cord connected to the terminals marked. Connect them using solderless ring connectors.

FAQs

1.Does Wire Size Affect Amperage?

Ans: The wire size affects amperage because of the electron movement. Electrons require a huge space for moving fast and free.

That’s why small size wires are rated for low amperage limits, and large-sized wires are rated for high amperage limits.

2.What Happens If Wire Gauge Is Too Big?

Ans: Using a big size gauge will not create any dangerous situation. Rather using too big wire will bring benefits like energy efficiency, the house’s safety, and ease to upgrade home wiring.

3.How Does Diameter Of The Wire Affect The Amount Of Current?

Ans: The wires of large size have lower resistance. And lower resistance wire means less heat produced. The less heat means it can carry more current.

Hence, larger diameter wires produce the right amount of current while keeping the wire hot and reliving less energy. On the other hand, small diameter wires do the opposite of the large size wires.

4.What Size Wire Do I Need For A 220 Air Compressor?

Ans: The minimum requirement for wire size for a 220 air compressor is 6/2 or 8/2. But using a little larger size wire than the suggested one will rather be beneficial for you.

5.How Do I Calculate What Wire Size Do I Need?

Ans: You can calculate and find out the size of wire you need using the law below;

VDI = Amps × Feet ÷ (%volt drop × voltage)

Here,

Amps stand for watts that are divided by voltage

Feet means the wire distance of one-way

%volt drop means the voltage drop percentage acceptable for the circuit.

Conclusion

We hope now you can have the correct size wire for your 220v air compressor. If you are going to have wire for the first time, it will be best to hire an electrician.

Before we close the guide, keep another little yet useful tip from us; your safety matters first; therefore, always use larger wires and ensure your welfare. I hope now you know about what size wire for 220v air compressor.

![7 Best 110V Air Compressor 2022 [Reviews With Buying Guide]](https://accuratepicker.com/wp-content/uploads/2023/05/Best-110V-Air-Compressor.jpg)