Cable cutters are essential tools for any electrician or technician, allowing for the precise cutting of electrical cables and wires. As such, they must be maintained and kept in good condition in order to ensure their continued functionality.

This article will discuss the importance of maintenance for cable cutters and the best practices that should be followed in order to ensure their proper upkeep. It will also explore the potential consequences of not adhering to a regular maintenance schedule. By understanding the importance of proper maintenance, users can ensure that their cable cutters remain in optimal condition and are ready to use whenever needed.

Maintaining Cable Cutters: A Must

Regular maintenance of cable cutters is essential for ensuring their efficient and safe operation. It is important to regularly inspect and lubricate the blades, as well as check for any signs of wear or damage. This will help to reduce the risk of injury from sharp blades, as well as extend the life of the cutter.

Additionally, it is important to regularly clean and sharpen the blades to ensure they are able to cut through cables with ease. Regular maintenance of cable cutters is also important for preventing rust and corrosion, which can damage the blades and reduce their effectiveness. By taking the time to properly maintain cable cutters, users can ensure their safety and extend the life of their equipment.

Background

Cable cutters are an essential tool for electricians and other professionals dealing with wires. They are used to cut through metal and other hard materials. In order for these tools to be effective, they must be regularly maintained.This means that the blades should be kept sharp, the handles should be oiled, and any rust should be removed. Maintenance can help ensure that the tool remains functional and safe to use.

It can also help increase the tool’s lifespan, meaning that it can be used for longer without needing to be replaced. Maintenance is essential for any tool, but with cable cutters, it is especially important. Without proper maintenance, the blades can become dull and dangerous, leading to accidents or damage to the wires. Regular maintenance can help prevent this from happening.

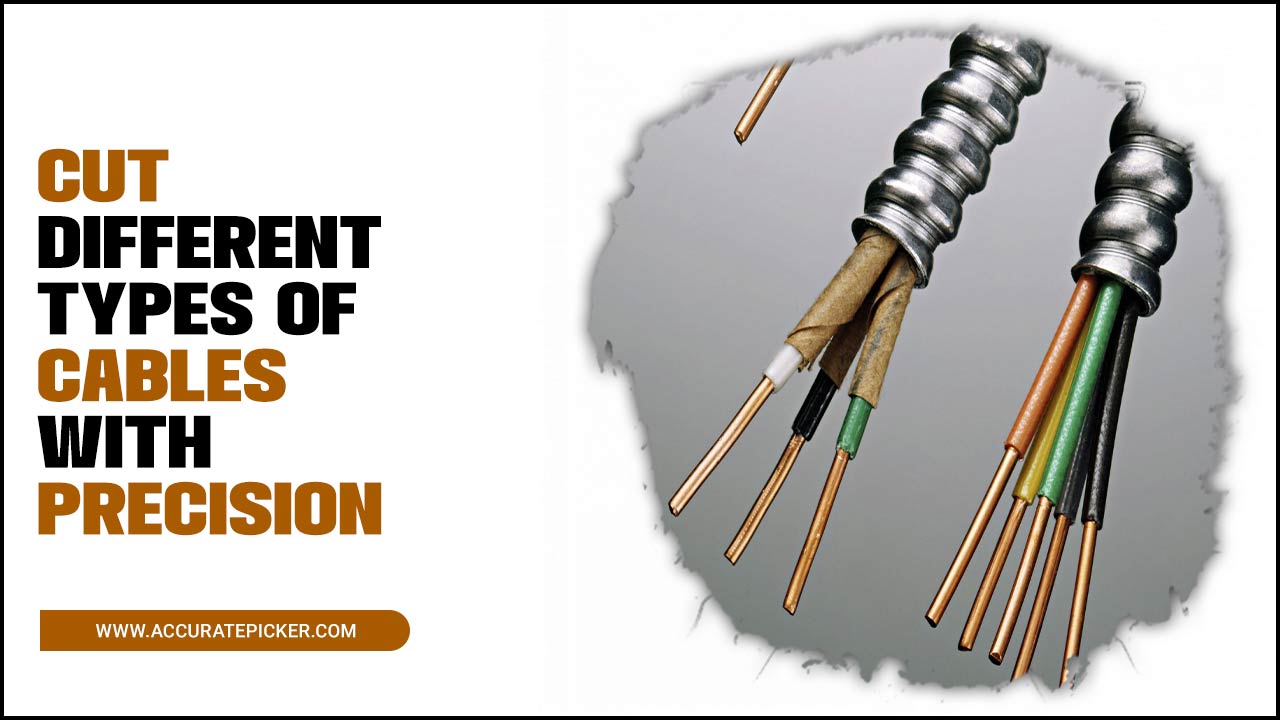

Types Of Cable Cutters

Cable cutters are essential tools for any electrician or technician. They are used to cut and shape wires in a variety of different ways. They come in a variety of sizes and styles, and it’s important to make sure you have the right type of cable cutter for the job you’re doing. Different types of cable cutters are designed for different types of wire and cable.

Some are designed for thicker cables, while others are designed for thinner wires. Some are also made to cut specific types of metals, such as aluminum or steel. It’s important to choose the right type of cable cutter for the job so that you don’t damage the wire or cable. With proper maintenance and storage, cable cutters can last for many years.

Common Maintenance Issues

Regular maintenance is essential for any cable cutter to ensure it remains in optimal working condition. Common maintenance issues include checking for wear and tear on the cable, inspecting the blade for any damage, and ensuring that all connections are tightened and secure. Additionally, it is important to periodically lubricate the internal components of the cutter to reduce friction and prevent wear.

A yearly maintenance check is recommended to ensure the cable cutter is operating at peak efficiency. It is important to clean the cable cutter regularly to ensure it is free from dirt and debris. This will help to reduce the risk of rust and corrosion, and will also help to maintain the blades for a longer period of time.

When cleaning the cutter, ensure that all components are properly dried to avoid any moisture from affecting the performance of the cutter. Finally, it is important to store the cable cutter properly. This means keeping the blades sharp and free from rust and corrosion. It is also important to keep the cutter away from direct sunlight and moisture, as this can lead to further damage. With proper maintenance, the cable cutter should last for many years with minimal issues.

Benefits Of Maintenance

Maintenance is an important part of any cable cutting job. Without proper maintenance, tools and equipment can quickly become ineffective and create hazardous working conditions. The benefits of maintenance include improved efficiency, safety, and reliability. Regular maintenance can help extend the life of a tool and reduce the risk of accidents due to defective or malfunctioning equipment.

It can also reduce the amount of time spent on maintenance and repair, as well as the cost of replacement parts and labor. Additionally, regular maintenance can help ensure that a tool is functioning properly and safely, which can lead to improved performance and enhanced customer satisfaction. Ultimately, maintenance is essential for reducing downtime and ensuring the success of any cable cutting job.

Maintenance Tips

Maintaining your cable cutter is an important part of ensuring it lasts for years to come. Regularly inspecting your cutter and cleaning it after each use will help maintain its performance. Here are some maintenance tips you should consider when using a cable cutter:First, always inspect the cutting blades before use.

Make sure they are sharp and free of any rust or corrosion. If the blades are dull or damaged, replace them immediately. Second, use a lubricant on the cutting blades after each use. This will help to reduce wear and tear, as well as prevent corrosion. Third, keep the cutting blades clean and free of dirt and debris.

This will help them stay sharper and last longer. Finally, store your cable cutter in a safe and dry place when not in use. This will help prevent rust and corrosion. By following these simple maintenance tips, you can ensure your cable cutter will continue to perform well for years to come. Regular inspections, cleaning, and proper storage will help keep your cable cutter in top condition.

Conclusion

Cable cutters are essential tools for many industries, and proper maintenance is key to ensuring they remain in good condition and perform their job correctly. Regular maintenance should include cleaning, lubrication, and adjustments to keep the blades sharp and in optimal condition. Additionally, replacing worn or damaged parts should be done as soon as possible to ensure the tool is safe to use. With proper maintenance, cable cutters can be a reliable and effective tool for years to come.

FAQ’s

1.What Are The Most Important Maintenance Tasks To Perform On A Cable Cutter?

Ans: The most important maintenance tasks to perform on a cable cutter are to check for proper lubrication, inspect the blades for wear, sharpen the blades if necessary, and clean the tool after each use. Additionally, it is important to check the tension of the cutting arm and ensure that all fasteners are tightened to the manufacturer’s specifications.

2.How Often Should Cable Cutters Be Serviced?

Ans: Cable cutters should be serviced on a regular basis, depending on the frequency of use. Generally, it is recommended that they be serviced every 3-6 months if they are used on a regular basis. However, if the cable cutters are used infrequently, then they should be serviced at least once a year. It is important to take proper care of the cable cutters in order to ensure they are functioning properly.

3.What Are The Potential Consequences Of Not Servicing A Cable Cutter Regularly?

Ans: If a cable cutter is not serviced regularly, it can cause a number of problems. The tool may become blunt and not cut as efficiently, leading to poor workmanship. It may also suffer from wear and tear which can lead to breakages and malfunction. In addition, dirt and debris can affect its performance, leading to the tool becoming less reliable. Finally, it can become a safety hazard if it is not maintained properly.

4.What Safety Checks Are Necessary Before Using A Cable Cutter?

Ans: Before using a cable cutter, it is important to check that it is in good condition, that the blade is sharp and undamaged, that the handles are undamaged and secure, and that the cable being cut is the correct size for the cutter. Additionally, protective gloves and safety glasses should be worn to guard against any potential injury.

5.What Are The Best Techniques To Ensure Proper Maintenance Of A Cable Cutter?

Ans:

- The blades of the cable cutter should be sharpened regularly to ensure clean, precise cuts.

- It is also important to keep the cable cutter lubricated to reduce wear and tear on the blades and handles.

- It is essential to regularly inspect the cable cutter for signs of wear or damage.

- It is also important to store the cable cutter in a clean, dry place to prevent rust.