Air compressors and air tanks have been used for decades to store and provide pressurized air for a variety of applications. As technology has advanced, the two have become more efficient and reliable.

In this article, we will compare air compressor vs. air tank, discussing their key differences, advantages, and disadvantages. We will also look at the various applications they are used for and how they can help improve efficiency in a variety of industries.

By the end of this article, you will have a better understanding of which option is best for your needs and how to make the most of it. So, let’s get started and explore the comparison of air compressor vs. air tank.

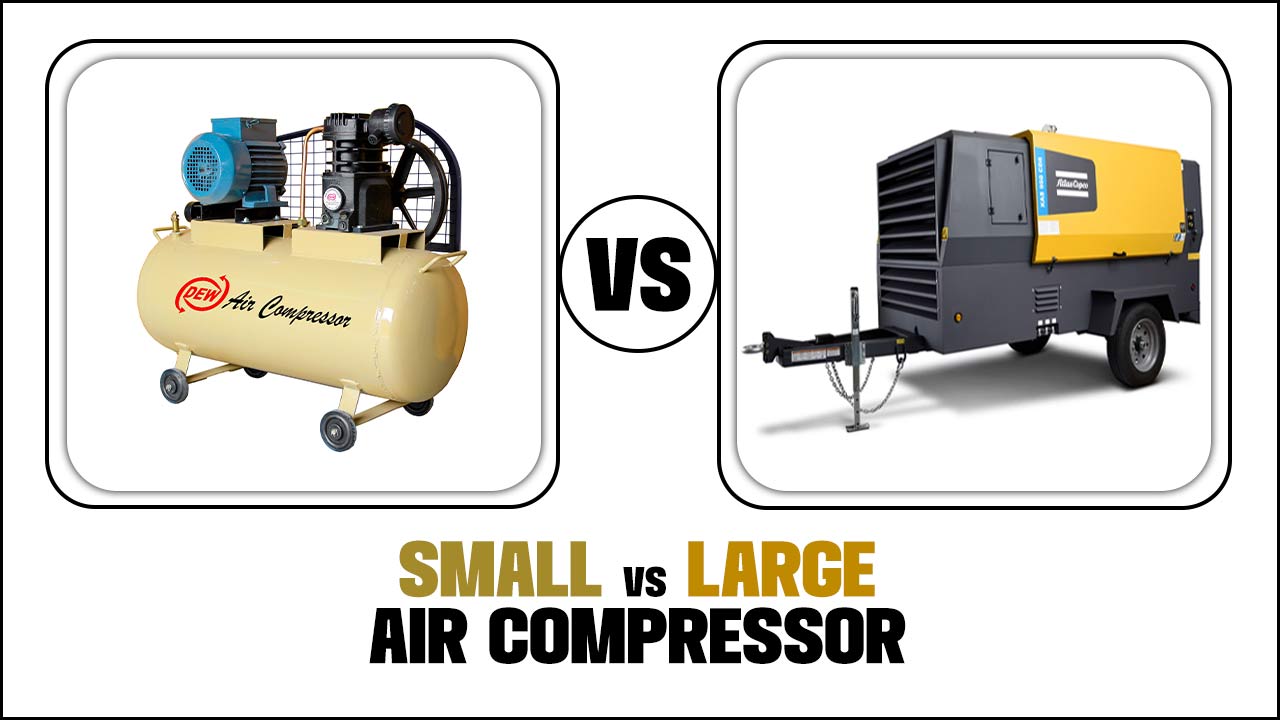

Air Compressor Vs. Air Tank: What’S The Difference?

Before we dive into the details of the comparison between an air compressor and an air tank, it is important to understand the basics of both. An air compressor is a machine that converts power into potential energy stored in pressurized air.

It is used to power pneumatic tools and other equipment. An air tank, on the other hand, is a metal container that holds compressed air and helps to regulate air pressure for pneumatic tools. In this article, we will discuss the differences between an air compressor and an air tank, and which one is best for your needs.

Benefits Of Air Compressor

Air compressors offer a plethora of benefits that are not found in traditional air tanks. Air compressors are a more efficient way to store air and offer several advantages. One of the biggest advantages of an air compressor is that it takes up less space than an air tank. An air compressor requires no special installation and can be easily transported from one location to another.

Also, the air pressure generated by an air compressor is higher than that of an air tank, allowing you to power more tools with a single unit. Furthermore, air compressors are more energy-efficient than air tanks, as they require less energy to maintain the right pressure. Lastly, air compressors are much quieter than air tanks, making them ideal for use in a variety of settings.

Compact

Air compressors and air tanks are both used to store compressed air. However, their sizes and capabilities vary significantly. Air compressors are typically more compact than air tanks as they are designed to be portable. This makes them ideal for those who need to store compressed air but lack the space for a large air tank.

Furthermore, air compressors are easier to transport and can be taken with you wherever you need to go. On the other hand, air tanks are larger and typically more permanent. They are great for those who need to store large amounts of compressed air or require a stationary storage solution.

Portable

Portability is a key factor when considering an air compressor vs. an air tank. Air compressors are typically smaller and lighter than air tanks, making them a great option if you need to transport your device from one place to another. Additionally, air compressors usually come with a carrying handle, allowing you to easily move them around.

Air tanks, on the other hand, are much heavier and less mobile. They require a lot of effort to be transported and are not ideal for frequent relocations. If portability is a priority, an air compressor is the better choice.

Versatile

Air compressors and air tanks are both versatile pieces of equipment. An air compressor can be used for a variety of applications, such as inflating tires and powering air tools. An air tank, on the other hand, is primarily used for storing compressed air. It can also be used for applications like operating pneumatic tools and powering air-powered vehicles.

A compressor and tank can be used in tandem to provide a reliable source of pressurized air. The compressor is used to fill the tank with air, and the tank is then used to power the tools or other applications. This combination allows for a reliable source of pressurized air and can be used for a variety of applications.

Affordable

When it comes to affordability, an air compressor and an air tank are two different things. An air compressor is generally the more affordable option, as it typically costs less than an air tank. They are also easier to maintain and install, meaning that they don’t require a lot of upfront costs.

An air tank, on the other hand, can be more expensive, since they tend to require greater upfront costs for installation and maintenance. Additionally, air tanks may require more frequent upkeep and replacement, resulting in additional costs. Ultimately, both an air compressor and an air tank can be a great option for those looking for an affordable way to add air to their home or business.

Benefits Of Air Tank

Air tanks are a great way to store compressed air for a variety of applications. They provide many benefits that air compressors alone do not, such as increased portability, a greater capacity for storage, and improved efficiency. Air tanks are often used alongside air compressors to improve the overall performance of a system. Air tanks provide an efficient way to store compressed air for use when it is needed.

By having an air tank, the air can be stored and used when needed, instead of having to keep the air compressor running continuously. This can help reduce energy costs, as the compressor does not have to be running all the time. Air tanks also help to increase portability, as they can be moved around more easily than air compressors.

This makes them useful for applications where the compressor needs to be moved from one place to another, such as in an automotive workshop. Air tanks can also help reduce the noise coming from air compressors, as the tank helps to muffle the sound.

Air tanks can also help improve the overall efficiency of a system. By having a larger capacity for storing compressed air, the compressor does not have to work as hard to create the same amount of compressed air.

This can help reduce the strain on the motor and increase the life of the compressor. Overall, air tanks provide many benefits that air compressors alone cannot. They are an efficient way to store compressed air and make it more portable and quieter. They also can increase the efficiency of a system by providing more capacity for storing compressed air.

Large Capacity

When it comes to large capacity air storage, air compressors and air tanks both have their own strengths and weaknesses. Air compressors are able to provide a continuous supply of air, but are limited by their storage capacity. An air tank, on the other hand, is able to store a lot of compressed air, but it can only provide a limited amount of air at a time. Air tanks are also often much larger and heavier than air compressors, making them difficult to move around.

Air compressors are often the best choice when it comes to large capacity air storage, as they can provide a continuous and unlimited supply of air. They are usually smaller and more lightweight than air tanks, making them easier to move and store. Air compressors are also much less expensive than air tanks, so they are often the more cost-effective option.

Overall, air compressors are usually the best choice for large capacity air storage when compared to air tanks. They can provide a continuous supply of air, are usually smaller and lighter, and are more cost-effective than air tanks. However, air tanks are still a viable option for those who need a lot of air storage, but they may be more expensive and difficult to move around.

High Pressure

High pressure can be a major factor for many air compressor applications. Air tanks can store a much higher pressure than what an air compressor can generate. It is not uncommon for an air tank to be pressurized up to 200 psi while an air compressor can only generate up to 150 psi.

This means that if you need a higher pressure, an air tank is necessary. With a tank, you can store the air pressure and use it when needed. An air compressor requires continuous running to maintain the pressure, making the tank a more efficient and cost-effective option. Additionally, air tanks can be used in applications where a machine needs to be powered for a long period of time. They are a great way to store air pressure for later use.

Longer Runtime

When it comes to air compressors versus air tanks, the most important factor to consider is the longer runtime that a tank provides. An air compressor is only able to provide power for a short duration, and then it will need to be allowed to cool down before it can be used again. An air tank, however, is able to store power and provide continual use.

This is because the air is stored in the tank and is able to be released slowly over time. Air tanks also provide more power than air compressors, making them ideal for larger tasks. In addition, air tanks are able to provide a steady and consistent pressure that is essential for certain applications.

Durable

Air compressors and air tanks are both durable pieces of equipment, however, their durability differs in a few key ways. Air compressors are designed for regular use and are typically made from heavy-duty materials. Air tanks, on the other hand, are made from lighter but still durable materials and are designed to store compressed air for future use.

This means that air tanks are typically more durable than air compressors as they are not subject to the same wear and tear. Additionally, air tanks are designed to be corrosion resistant, meaning they can last for a longer period of time. Both pieces of equipment are reliable and when properly maintained, can last for years.

Conclusion

An air compressor and an air tank are two different tools used in a variety of applications, such as powering pneumatic tools or inflating tires. An air compressor takes in air and compresses it into a smaller volume, while an air tank stores compressed air for use when needed.

Air compressors are more efficient and cost-effective than air tanks, but air tanks can be used to store compressed air for longer periods of time. Ultimately, the choice between an air compressor and an air tank depends on the needs of the user.

FAQ’s

1.What Are The Differences Between An Air Compressor And An Air Tank?

Ans: An air compressor takes in air at atmospheric pressure and compresses it to a higher pressure, while an air tank is simply a container that is designed to hold compressed air. The air compressor is the device that creates the compressed air, and the air tank is used to store it until it is ready to be used.

An air compressor typically has a motor that powers the compressor, while an air tank does not. An air compressor is used to create the compressed air, while an air tank is used to store the compressed air until it is needed.

2.What Are The Advantages And Disadvantages Of An Air Compressor Versus An Air Tank?

Ans: The main advantage of an air compressor over an air tank is that it is capable of producing more air pressure in less time. An air compressor is also more portable than an air tank. However, air compressors are usually more expensive than air tanks and can be louder and require more maintenance. Additionally, air tanks are more suitable for large, long-term projects, while air compressors are better for short-term projects.

3.What Types Of Applications Require An Air Compressor Or Air Tank?

Ans: Air compressors and air tanks are used in a variety of applications, such as air tools, spray painting, air brakes, pneumatic controls, and air conditioning systems. They are also used in the automotive industry for inflating tires and for powering certain tools.

Air compressors and air tanks are also used in industrial processes, such as powering pneumatically operated valves and for cooling and heating processes. Finally, air tanks are used in medical applications such as providing compressed air for oxygen tanks.

4.What Are The Safety Concerns When Using An Air Compressor Or Air Tank?

When using an air compressor or air tank, safety concerns should be taken into consideration. These include ensuring that the air pressure is set correctly, that all safety features are in good working order, and that the air pressure is allowed to be released slowly to avoid any sudden bursts of air. Additionally, any air tank should be securely mounted and checked for leaks regularly.

5.What Type Of Maintenance Is Required For An Air Compressor Or Air Tank?

Regular maintenance on an air compressor or air tank should include checking valves, pressure gauges, and connections for any signs of wear or damage. Additionally, air filters should be cleaned and checked for blockages or dirt, and the oil level should be checked and maintained.

The air compressor/tank should also be kept clean and free of debris. Regular maintenance and routine inspections should be conducted to ensure the air compressor/tank is running properly and safely.