Air compressors and air pumps are two of the most common devices used to compress and move air for various industrial and commercial applications.

Although they are both used to move air, there are some key differences between the two. This article will explore the differences between an air compressor and an air pump, the advantages and disadvantages of each, and the best applications for each device.

It will also provide insight into which device may be the best choice for a particular application. By the end of this article, readers will have a better understanding of the differences between an air compressor and an air pump and which device is best suited for their needs.

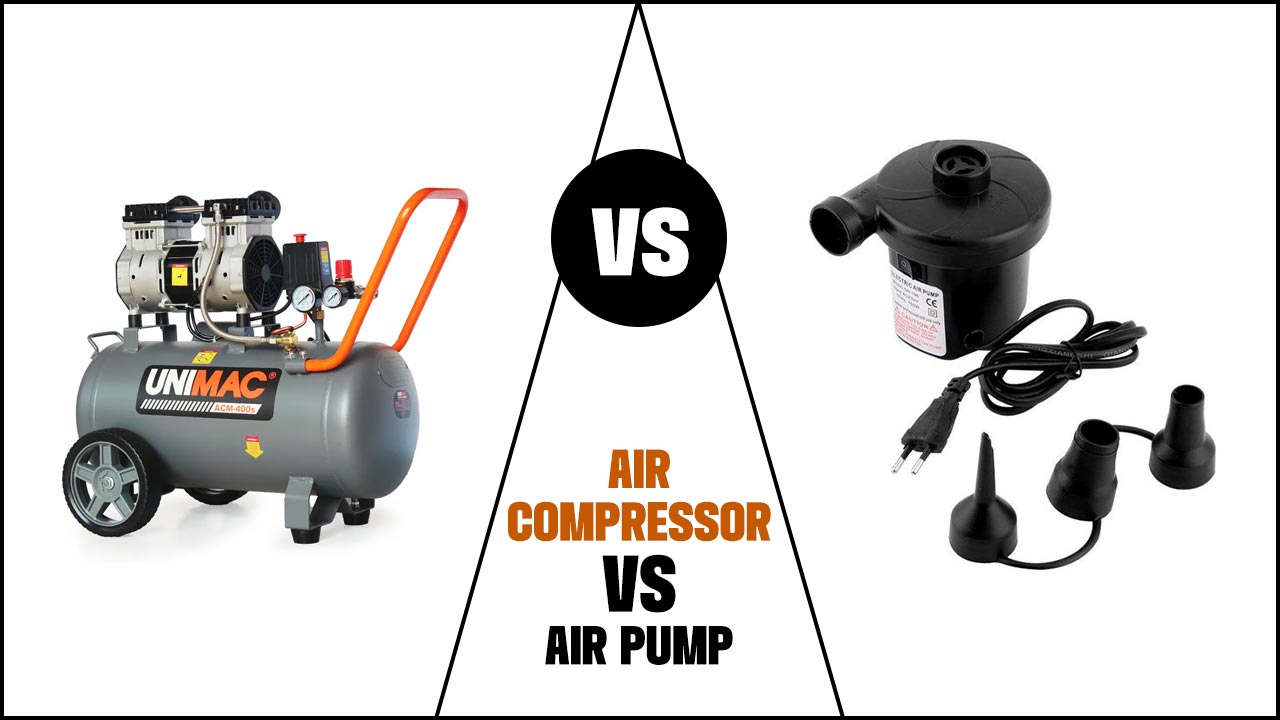

Air Compressor Vs. Air Pump: What’S The Difference?

Before diving into the main article, it is important to understand the differences between an air compressor and an air pump. An air compressor is a mechanical device that converts power into potential energy stored in pressurized air.

It is used to power pneumatic tools, inflate tires, and even power air-conditioning systems. On the other hand, an air pump is a device that uses a piston or diaphragm to move air or gas from one place to another. Air pumps are commonly used to fill inflatable objects such as air mattresses, pool toys, and even car tires.

Both air compressors and air pumps are essential tools for a variety of applications, but they serve different purposes. In this article, we will explore the differences between air compressors and air pumps and discuss which one is best for your needs.

Overview

An air compressor and an air pump are two devices that are used to generate and push air. Air compressors use electric or gas power to compress air and push it into a storage tank or other device, while air pumps use a manual or electric motor to generate and push air. Both devices can be used for a variety of applications, such as inflating tires, powering pneumatic tools, and providing air for medical and dental equipment.

However, air compressors are generally more powerful and can generate higher air pressure than air pumps. While air pumps are relatively inexpensive and can be used for a variety of tasks, air compressors are more expensive but are better suited for highly demanding applications.

Definition

A compressor and a pump are two different machines that are used to move air. An air compressor is an electrically powered device that compresses air into a container, storing it for later use. An air pump, on the other hand, is a manual device that pumps air into a container or an area, such as an inflatable pool or a tire. Compressors are often used for industrial purposes, such as powering tools, while pumps are more commonly used for recreational applications.

Compressors are usually more powerful and can do more work than pumps, but they also tend to be more expensive. Both compressors and pumps can be used to move air from one place to another.

Difference

The main difference between an air compressor and an air pump is the power source they use. Air compressors use electricity to power their motors, while air pumps rely on manual labor or other non-electric sources of power. Air compressors generate higher pressure than air pumps, making them ideal for powering tools such as nail guns and spray guns. Air pumps, on the other hand, are not as powerful and are best used for inflating tires and other small pneumatic tasks.

Another difference is the amount of air output. Air compressors can rapidly fill air tanks, while air pumps are slower and provide a lower flow rate. This is why air compressors are more often used in industrial settings and air pumps are more often used in automotive and recreational settings.

Advantages

Air compressors and air pumps both have advantages when it comes to delivering compressed air. Air compressors are usually more powerful, able to generate high pressures in a short amount of time. This makes them ideal for industrial applications such as powering pneumatic tools, inflating tires, and more.

Air pumps, on the other hand, are more economical and have a lower purchase cost. They are also quieter and require less maintenance than air compressors. Air pumps are best for applications such as aquariums, home inflation, and other low-pressure applications. Both air compressors and air pumps offer their own unique benefits, so it’s important to consider the type of application before making a purchase.

Disadvantages

The primary disadvantage of air compressors and air pumps is their cost. Air compressors are typically more expensive than air pumps, as they require more powerful motors and components to generate higher pressure. Additionally, air compressors require more maintenance than air pumps, as they have more intricate parts that can break down or become worn over time.

Because air compressors and air pumps are powered by electricity, they can also be costly to operate since they must be used for extended periods of time to be effective. Finally, both air compressors and air pumps produce noise, which can be distracting and bothersome to those nearby.

Conclusion

Air compressors and air pumps are two different devices that can be used to inflate tires, balls, and other objects. Air compressors are powered by electricity and are typically more powerful than air pumps. They are also more expensive and require regular maintenance.

Air pumps are powered manually by foot or hand and are less powerful than air compressors. They are also cheaper and require less maintenance. Both air compressors and air pumps are suitable for inflating objects, but the type of device that is best for a particular situation will depend on the object being inflated, the force needed, and the user’s budget.

FAQ’s

1.What Are The Primary Differences Between An Air Compressor And An Air Pump?

Ans: An air compressor takes in air and compresses it into a small, dense space, while an air pump moves air from one space to another without compressing it. An air compressor is used to power tools like nail guns and paint guns, while an air pump is used to inflate things like tires and sports balls.

Air compressors require more maintenance and are more expensive than air pumps. Air pumps are more portable and require less maintenance.

2.What Are The Key Benefits Of Using An Air Compressor Versus An Air Pump?

Ans: The key benefits of using an air compressor versus an air pump are improved efficiency, more reliable performance, increased performance, and increased portability. An air compressor is also able to produce a higher pressure than an air pump, which can be beneficial for certain applications.

Furthermore, an air compressor is able to generate more air flow than an air pump, which can be beneficial for applications such as cooling or powering pneumatic tools. Finally, an air compressor is generally quieter than an air pump, which can be important in certain situations.

3.How Much Power Does An Air Compressor Typically Consume Compared To An Air Pump?

Ans: An air compressor typically consumes more power than an air pump. The exact amount depends on the size and efficiency of the compressor. Generally, an air compressor consumes between 2 to 5 times more power than an air pump. To get an exact number, it is best to look up the wattage for the specific compressor and pump being compared.

4.What Are The Most Common Applications For An Air Compressor And Air Pump?

Ans: The most common applications for an air compressor and air pump are inflating tires, powering pneumatic tools, powering air brakes, and providing compressed air for industrial processes.

Compressors and pumps are also used in air conditioning and refrigeration systems, as well as in medical and dental equipment, such as ventilators and suction devices. They can also be used for spray painting, running air powered hoists and winches, and for powering pneumatic valves and cylinders.

5.What Safety Precautions Should Be Taken When Using An Air Compressor Or Air Pump?

Ans: When using an air compressor or air pump, safety precautions should always be taken. Wear proper safety gear such as goggles and gloves to protect from any debris or dust that may be kicked up.

Make sure to keep any loose clothing or long hair tied back to avoid getting caught in any of the machinery. Secure all hoses and connections to ensure they don’t come apart during operation. Lastly, always read and follow the manufacturer’s instructions before operating.